Beruflich Dokumente

Kultur Dokumente

Dupre - Travis Crane Operation and Maintenance

Hochgeladen von

mohammadazrai0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

43 Ansichten23 SeitenDupre_Travis Crane Operation and Maintenance

Originaltitel

Dupre_Travis Crane Operation and Maintenance

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDupre_Travis Crane Operation and Maintenance

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

43 Ansichten23 SeitenDupre - Travis Crane Operation and Maintenance

Hochgeladen von

mohammadazraiDupre_Travis Crane Operation and Maintenance

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 23

Crane Operation & Maintenance

Importance to Safety Performance

Travis Dupre

Thunder Oilfield Service (Thailand) Ltd

Crane Operation & Maintenance

API Specification 2C

Provides standards for offshore pedestal

mounted cranes.

API Recommended Practice 2D

Guidelines for operation, inspection and

maintenance of offshore pedestal

mounted cranes. Should be referenced in

conjunction with Spec 2C.

How to ensure the crane is 2C

Operation & Maintenance of

API Spec 2C Cranes

Operation, maintenance and inspections

must be performed by Qualified

Personnel in accordance with API RP 2D

requirements:

Qualified Rigger

Qualified Operator

Qualified Inspector

API RP 2D Qualified Rigger:

A rigger is anyone who attaches or

detaches lifting equipment to loads or

lifting devices. In order to be considered

a qualified rigger, the person shall have

successfully completed a rigger-training

program in accordance with API RP 2D.

API RP 2D Qualified Operator:

A person designated by the employer

with appropriate offshore experience and

training. Such experience and training

must comprise of classroom-type

sessions and hands-on field training on

cranes specific to the type to be

operated. These minimum requirements

are outlined in API RP 2D.

API RP 2D Qualified Inspector:

A person designated by the employer who

has appropriate experience and training, has

successfully completed classroom-type

training sessions on crane maintenance and

hoist troubleshooting and overhaul, as well

as the structural aspects of offshore cranes.

These minimum training requirements are

outlined in API RP 2D.

Inspection and Testing

Inspection & Testing must meet or

exceed API RP 2D recommendations

Cranes built to API Spec 2C are to be

repaired, inspected and tested

following API RP 2D recommendations.

Crane Usage and Categories

Infrequent Usage - 10 hours or less per

month, based on a 3 month average.

Moderate Usage - more than 10 hours

but for less than 50 hours per month,

based on a 3 month average.

Heavy Usage- cranes that are used for 50

hours or more per month.

Operator - Inspection Categories

Pre-use Inspection- prior to the first

crane use of the day, each change in

operator, and also as the qualified

operator deems necessary during the

day.

Monthly Inspection- once per month,

for all cranes assigned a heavy usage

category.

Inspector - Inspection Categories

Pre-use Inspection & Monthly

Quarterly Inspection- once every three months

all cranes are assigned a moderate or heavy

usage category.

Annual Inspection- once every twelve months.

Applies to all cranes, regardless of usage

category.

Initial Inspection cranes being placed into

service, being permanently relocated and

temporary cranes after each rig up and

relocation.

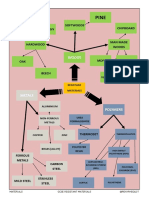

Usage/Inspection/Inspector Matrix

Usage Category

Infrequent Moderate Heavy

I

n

s

p

e

c

t

i

o

n

C

a

t

e

g

o

r

y

P

r

e

-

u

s

e

QI or QO QI or QO QI or QO

M

o

n

t

h

l

y

QI or QO

Q

u

a

r

t

e

r

l

y

QI QI

A

n

n

u

a

l

QI QI QI

Qualified Inspector

or

Qualified Operator

Qualified Inspector

Only

No Inspection

Required

Inspection & Load Test Records

A log of pre-use inspections should be

maintained.

Initial, monthly, quarterly and annual

inspection reports, as well as records of

repairs and modifications carried out on

cranes in accordance with this

Recommended Practice should be kept

readily available for a period of 4 years at

an appropriate location.

Inspection Topics to Remember

If a crane is operated more than 50 hours in one

month period, it immediately falls in to the heavy

use category.

A quarterly inspection should be performed in

the event a crane's duty cycle increases from

infrequent usage to a higher usage category.

An annual inspection should not exceed twelve

months from the last inspection.

Should the owner choose not to track usage the

crane will automatically default to heavy use

category.

Repairs and Replacements

If unsafe conditions are identified during the

inspection, the crane shall be taken out of

service or its operation restricted to

eliminate the unsafe condition.

All major replacement parts should equal or

exceed the OEMs recommendations.

Welding Repairs

No welding repairs shall be made to critical

components, such as booms and swing circle

assemblies without specific repair procedures

and recommendations from the OEM, or

other qualified source (such as an API

licensed 2C crane manufacturer, authorized

surveyor, or an engineer experienced in the

design of the crane, as determined by the

owner).

Critical Components

A critical component is any component of

the crane assembly whose failure would

result in an uncontrolled descent of the

load or uncontrolled rotation of the

upper-structure. These components are

required to have stringent design,

material, traceability and inspection

requirements.

Preventive Maintenance

A preventive maintenance program

should be established by the owner.

The referenced inspections criteria of 2D

should NOT be considered a Preventative

Maintenance program, however it is

possible to integrate the programs.

Record Retention

The manufacturer shall maintain all

inspection and testing records for 20 years.

These records shall be employed in a quality

audit program of assessing malfunctions and

failures for the purpose of correcting or

eliminating design, manufacturing or

inspection functions which may have

contributed to the malfunction or failure.

Without Spec 2C & RP 2D =

Bathtub Curve

API Spec 2C & RP 2D = Reliability

Importance to Safety

Performance

Consequently, understanding how the

documents relate to one another directly

impacts safety performance in concerns

to offshore pedestal mounted crane

operations and maintenance.

Thank you!

Das könnte Ihnen auch gefallen

- EMMARDokument5 SeitenEMMARNisar DeenNoch keine Bewertungen

- Project Technical Plan For Heavy Lifts and PipelinesDokument14 SeitenProject Technical Plan For Heavy Lifts and PipelinesMitchellgrany100% (1)

- Guide To Inspecting and Maintaining CranesDokument8 SeitenGuide To Inspecting and Maintaining CranesMohammed MujahidNoch keine Bewertungen

- Guide To Inspecting and Maintaining CranesDokument7 SeitenGuide To Inspecting and Maintaining CranesBerk TekinNoch keine Bewertungen

- SFI Coding And Classification System A Complete Guide - 2021 EditionVon EverandSFI Coding And Classification System A Complete Guide - 2021 EditionNoch keine Bewertungen

- OGUK - Helideck Perimeter Safety Net GuidanceDokument6 SeitenOGUK - Helideck Perimeter Safety Net GuidancerozitaNoch keine Bewertungen

- ANSI-AGMA 2004-B89-1995 Gear Materials and Heat Treatment ManualDokument79 SeitenANSI-AGMA 2004-B89-1995 Gear Materials and Heat Treatment ManualSantosh Shankarappa100% (4)

- TUV Nord TrainingDokument39 SeitenTUV Nord TrainingmohammadazraiNoch keine Bewertungen

- Crane Hoist and Rigging SafetyDokument36 SeitenCrane Hoist and Rigging SafetySalim Mohd RazNoch keine Bewertungen

- Cranes Rigging Your Organization Iti - Com r031512Dokument33 SeitenCranes Rigging Your Organization Iti - Com r031512Mohsin Majeed0% (1)

- BPcraneLifting North Sea Rules OffshoreDokument56 SeitenBPcraneLifting North Sea Rules Offshorebwadsager75% (4)

- IFR Flight PlanningDokument34 SeitenIFR Flight PlanningcarlosvistaNoch keine Bewertungen

- ASSAI Booklet Ver2Dokument2 SeitenASSAI Booklet Ver2mohammadazraiNoch keine Bewertungen

- CLASS SURVEY CHECKLIST FOR BULK CARRIERDokument12 SeitenCLASS SURVEY CHECKLIST FOR BULK CARRIERalex bencyNoch keine Bewertungen

- Boeing 757 Type Certificate Data SheetDokument10 SeitenBoeing 757 Type Certificate Data SheetRwilcoNoch keine Bewertungen

- Pipe SupportsDokument234 SeitenPipe SupportsSam Weber100% (1)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityVon EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNoch keine Bewertungen

- 3D & 5D Pipe Bend For PipelineDokument6 Seiten3D & 5D Pipe Bend For PipelinemohammadazraiNoch keine Bewertungen

- 3D & 5D Pipe Bend For PipelineDokument6 Seiten3D & 5D Pipe Bend For PipelinemohammadazraiNoch keine Bewertungen

- 1.4 CompositesDokument3 Seiten1.4 CompositesFuzail NaseerNoch keine Bewertungen

- Crane & Sling 1Dokument80 SeitenCrane & Sling 1pramodtryNoch keine Bewertungen

- Factors, Multiples, Primes, Prime Factors, LCM and HCFDokument2 SeitenFactors, Multiples, Primes, Prime Factors, LCM and HCFKatrice LiNoch keine Bewertungen

- 4818 DB1 OpsMan R0Dokument661 Seiten4818 DB1 OpsMan R0sep650cengrNoch keine Bewertungen

- Outreach P2 Math PDFDokument131 SeitenOutreach P2 Math PDFmohammadazraiNoch keine Bewertungen

- Outreach P2 Math PDFDokument131 SeitenOutreach P2 Math PDFmohammadazraiNoch keine Bewertungen

- 561 NR - 2022 11Dokument72 Seiten561 NR - 2022 11ENG PTBBSNoch keine Bewertungen

- 350PCDokument1.244 Seiten350PCBlueSkyMasterNoch keine Bewertungen

- Guided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilDokument30 SeitenGuided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilAr Aayush GoelNoch keine Bewertungen

- Asigmnet 1 - ShipyardDokument28 SeitenAsigmnet 1 - Shipyardulzzang looNoch keine Bewertungen

- A2A Piper J3 Pilots ManualDokument126 SeitenA2A Piper J3 Pilots Manualskeleton1Noch keine Bewertungen

- LIT2739 R9 PB308 Instruction ManualDokument16 SeitenLIT2739 R9 PB308 Instruction Manualshirley bustos14Noch keine Bewertungen

- Recommendations For Ships Lifting EquipmentDokument12 SeitenRecommendations For Ships Lifting EquipmentWirote ArcheepkosolNoch keine Bewertungen

- DS68 9-597 PDFDokument9 SeitenDS68 9-597 PDFRamon FragaNoch keine Bewertungen

- 4x 65 Ton AHTS Specification Rev 0Dokument85 Seiten4x 65 Ton AHTS Specification Rev 0pal_malay100% (1)

- LIFTING AND MOBILE EQUIPMENT AWARENESSDokument100 SeitenLIFTING AND MOBILE EQUIPMENT AWARENESSPhilip AdewunmiNoch keine Bewertungen

- Offshore Latticed Structures - Analysis of The Lattice Crane BoomDokument1 SeiteOffshore Latticed Structures - Analysis of The Lattice Crane BoomGogyNoch keine Bewertungen

- UK HSE rr444 PDFDokument313 SeitenUK HSE rr444 PDFBernardo DrehenfussNoch keine Bewertungen

- PPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaDokument80 SeitenPPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaThanh Anh MaiNoch keine Bewertungen

- Cranes Hoists Truck CranesDokument26 SeitenCranes Hoists Truck Cranesrajesh_jeev100% (1)

- Nitrogen Generation by PSADokument12 SeitenNitrogen Generation by PSALakshmi Pathi Bojja100% (1)

- DOOWIN Load Test Water Bags & Underwater Air Lifting BagsDokument10 SeitenDOOWIN Load Test Water Bags & Underwater Air Lifting BagsDavidNoch keine Bewertungen

- GL Marine Operations IV-6-10Dokument14 SeitenGL Marine Operations IV-6-10ruovNoch keine Bewertungen

- Lift Inspection Services BrochureDokument4 SeitenLift Inspection Services BrochurebugseNoch keine Bewertungen

- Offshore Structures Installation MethodsDokument23 SeitenOffshore Structures Installation Methods66apenlullenNoch keine Bewertungen

- BP 42 Guidance On The Safe Use of Container Lifting LugsDokument7 SeitenBP 42 Guidance On The Safe Use of Container Lifting LugsGaniyuNoch keine Bewertungen

- SHELL - Provision of FPSO Integrity and Specialized Pipeline Inspection and Maintenance Services On Bonga - 20221002Dokument4 SeitenSHELL - Provision of FPSO Integrity and Specialized Pipeline Inspection and Maintenance Services On Bonga - 20221002Wale OyeludeNoch keine Bewertungen

- Underwater Inspection in Lieu of Drydocking (UWILD) ExplainedDokument15 SeitenUnderwater Inspection in Lieu of Drydocking (UWILD) ExplainedRubyNoch keine Bewertungen

- ABS Construction SurveyDokument15 SeitenABS Construction SurveyMilandro Lou AcuzarNoch keine Bewertungen

- Flare Tip FailureDokument4 SeitenFlare Tip FailuremohammadazraiNoch keine Bewertungen

- Cranes & Lifting Appliances: Guidance On TheDokument41 SeitenCranes & Lifting Appliances: Guidance On Thethongchai_007Noch keine Bewertungen

- STS Transfer Operations Plan: Ship Name: Imo NumberDokument183 SeitenSTS Transfer Operations Plan: Ship Name: Imo NumbernasiramzanNoch keine Bewertungen

- HSM OffshoreDokument2 SeitenHSM OffshorePrabhakar TiwariNoch keine Bewertungen

- Gryphon FPSO vessel details and February storm damage less than 40 charsDokument3 SeitenGryphon FPSO vessel details and February storm damage less than 40 charsyalçın_dalgıçNoch keine Bewertungen

- Jiangyinshi BeihaiDokument1 SeiteJiangyinshi BeihaiNazhani Rohaidin100% (1)

- ANSI/ALI ALOIM-2000 Standard For Automotive Lifts: Safety Requirements For Operation, Inspection and MaintenanceDokument2 SeitenANSI/ALI ALOIM-2000 Standard For Automotive Lifts: Safety Requirements For Operation, Inspection and MaintenanceAlfredo VSNoch keine Bewertungen

- Thy Ahm560 A320 200 LoadtrimsheetDokument5 SeitenThy Ahm560 A320 200 LoadtrimsheetAntonio Del-Clos0% (1)

- Mini Bladeless Fan GuideDokument17 SeitenMini Bladeless Fan GuideYogesh Kumar Gaur50% (2)

- GoodrichDokument22 SeitenGoodrichRichard TehNoch keine Bewertungen

- 22.wire RopeSelection enDokument6 Seiten22.wire RopeSelection enT ThirumuruganNoch keine Bewertungen

- Mooring Systems For Floaters - FPSO Mooring System 1Dokument24 SeitenMooring Systems For Floaters - FPSO Mooring System 1apis14Noch keine Bewertungen

- Fleeting Chain Blocks-Mod 5Dokument5 SeitenFleeting Chain Blocks-Mod 5Vitor OlivettiNoch keine Bewertungen

- DNV Publication ListDokument14 SeitenDNV Publication ListmohammadazraiNoch keine Bewertungen

- LIQUITOTE IBC Tanks PDFDokument2 SeitenLIQUITOTE IBC Tanks PDFpramodtryNoch keine Bewertungen

- Offshore construction Complete Self-Assessment GuideVon EverandOffshore construction Complete Self-Assessment GuideNoch keine Bewertungen

- 64-Crane Operator Program NcmscurrentDokument5 Seiten64-Crane Operator Program NcmscurrentJojo Betanio AkajoknoNoch keine Bewertungen

- Scope:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokument10 SeitenScope:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualakbarNoch keine Bewertungen

- PROMECH Company ProfileDokument38 SeitenPROMECH Company ProfileAbu UmarNoch keine Bewertungen

- ABS Jacking Survey Guide 2016 11Dokument9 SeitenABS Jacking Survey Guide 2016 11Foad MirzaieNoch keine Bewertungen

- API RP 2D Rigger Safety (2 Day) (API-U Approved)Dokument1 SeiteAPI RP 2D Rigger Safety (2 Day) (API-U Approved)idris100% (1)

- Shipyard Report PDFDokument10 SeitenShipyard Report PDFvarsha raichalNoch keine Bewertungen

- Technical Investigation Accident Twin Crane LiftDokument6 SeitenTechnical Investigation Accident Twin Crane LiftBinh PhamNoch keine Bewertungen

- X 904 ManualDokument19 SeitenX 904 Manualuser123Noch keine Bewertungen

- No. 47 Shipbuilding and Repair Quality Standard Rev. 7-2013Dokument24 SeitenNo. 47 Shipbuilding and Repair Quality Standard Rev. 7-2013JRodNoch keine Bewertungen

- Hindustan Shipyard-10Dokument75 SeitenHindustan Shipyard-10anshul21Noch keine Bewertungen

- OJT CorrigidoDokument77 SeitenOJT CorrigidoDiomacio Apolinario da SilvaNoch keine Bewertungen

- Offshore Crane OperationsDokument1 SeiteOffshore Crane OperationsAnonymous cekPJylABoNoch keine Bewertungen

- McDermott Batam Engineering Recruitment 3 PositionsDokument3 SeitenMcDermott Batam Engineering Recruitment 3 PositionsClariossa Daora ForthortheNoch keine Bewertungen

- Efogen Rigging SlingingDokument52 SeitenEfogen Rigging SlingingBalasuperamaniam RamanNoch keine Bewertungen

- Offshore Rope TestingDokument4 SeitenOffshore Rope TestingYulkyung SungNoch keine Bewertungen

- UPF Pre-Lift Safety ChecklistDokument2 SeitenUPF Pre-Lift Safety ChecklistBhaiJan59Noch keine Bewertungen

- Crane Rule PresentationDokument44 SeitenCrane Rule PresentationbangladragosNoch keine Bewertungen

- Schools Must Ensure Student FitnessDokument83 SeitenSchools Must Ensure Student FitnessIshtiaque AhmedNoch keine Bewertungen

- Painting & Coating SpecDokument19 SeitenPainting & Coating SpecmohammadazraiNoch keine Bewertungen

- Supports 20FREDokument6 SeitenSupports 20FREmohammadazraiNoch keine Bewertungen

- Expansion Loop Guideline ExtractDokument8 SeitenExpansion Loop Guideline ExtractmohammadazraiNoch keine Bewertungen

- Ptsme 2015 Abu Dhabi - TrainingDokument6 SeitenPtsme 2015 Abu Dhabi - TrainingmohammadazraiNoch keine Bewertungen

- Momentum 2 2012.ashxDokument52 SeitenMomentum 2 2012.ashxmohammadazraiNoch keine Bewertungen

- Calcium CarbonateDokument2 SeitenCalcium CarbonatemohammadazraiNoch keine Bewertungen

- Soda AshDokument2 SeitenSoda AshmohammadazraiNoch keine Bewertungen

- Momentum 2 2012.ashxDokument52 SeitenMomentum 2 2012.ashxmohammadazraiNoch keine Bewertungen

- Pbe 20050301 31Dokument3 SeitenPbe 20050301 31mohammadazraiNoch keine Bewertungen

- Document review and approval workflow guideDokument2 SeitenDocument review and approval workflow guidemohammadazraiNoch keine Bewertungen

- CPD 002 RevisedDokument7 SeitenCPD 002 Revisedanlekgen99Noch keine Bewertungen

- Class Notations TableDokument247 SeitenClass Notations TableRobert DelafosseNoch keine Bewertungen

- CPD 002 RevisedDokument7 SeitenCPD 002 Revisedanlekgen99Noch keine Bewertungen

- Notaries Public KL & SelangorDokument3 SeitenNotaries Public KL & SelangormohammadazraiNoch keine Bewertungen

- Sn60pb40 enDokument4 SeitenSn60pb40 enEngineersSrbNoch keine Bewertungen

- EADS Case StudyDokument2 SeitenEADS Case StudyAltairKoreaNoch keine Bewertungen

- Assignments Abroad Times Today 5 April 2023 - 230405 - 102202Dokument7 SeitenAssignments Abroad Times Today 5 April 2023 - 230405 - 102202Blacking MagnonNoch keine Bewertungen

- Material Selection For A Pressure VesselDokument9 SeitenMaterial Selection For A Pressure VesselArunkumar0% (1)

- Easa Ad F-1998-537-124R1 1Dokument1 SeiteEasa Ad F-1998-537-124R1 1lakshmimurugesanNoch keine Bewertungen

- Oil Whirl Whip PDFDokument9 SeitenOil Whirl Whip PDFbwelz100% (2)

- Boeing Flight Deck Entry Video Surveillance SystemDokument4 SeitenBoeing Flight Deck Entry Video Surveillance SystemWinaldo Satryadi ManurungNoch keine Bewertungen

- F2000 - AFM SUP24E Original - 20100712Dokument10 SeitenF2000 - AFM SUP24E Original - 20100712rjohnson3773Noch keine Bewertungen

- 4E Questionnaire PDFDokument8 Seiten4E Questionnaire PDFAkash AggarwalNoch keine Bewertungen

- Oxygen System Summary B737 PDFDokument1 SeiteOxygen System Summary B737 PDFMich LMNoch keine Bewertungen

- Ceasiom TutorialDokument23 SeitenCeasiom TutorialsovsepNoch keine Bewertungen

- Power Point Presentation (PPT/PDF) Extra Terrestrial IntelligenceDokument32 SeitenPower Point Presentation (PPT/PDF) Extra Terrestrial IntelligenceDr. Tapan Kr. Dutta100% (1)

- E IM 126 - PW210 TCDS Issue 03 - 0-1 PDFDokument8 SeitenE IM 126 - PW210 TCDS Issue 03 - 0-1 PDFValBMSNoch keine Bewertungen

- 02.10b Ch10 PPT SlidesDokument58 Seiten02.10b Ch10 PPT SlidesAbu GuevaraNoch keine Bewertungen

- TECA Mechanical Ventilation Checklist 4 2014Dokument2 SeitenTECA Mechanical Ventilation Checklist 4 2014ridNoch keine Bewertungen

- Livro de Instrumentação em Túnel de VentoDokument599 SeitenLivro de Instrumentação em Túnel de VentoRonaldo Menezes100% (1)

- Click Here To Visit NAASCO's Starter Generator Web PageDokument22 SeitenClick Here To Visit NAASCO's Starter Generator Web PageHuda LestraNoch keine Bewertungen

- AE1102 Structures Slides 2Dokument20 SeitenAE1102 Structures Slides 2SaraNoch keine Bewertungen

- Baw106 Omdb-Egll (20 Jul 2155 Utc)Dokument30 SeitenBaw106 Omdb-Egll (20 Jul 2155 Utc)cpa744Noch keine Bewertungen

- Virac Airport ProfileDokument19 SeitenVirac Airport ProfileTim FloresNoch keine Bewertungen

- FAA 2015-16 HoldoverTablesDokument94 SeitenFAA 2015-16 HoldoverTablesTàn Dạ100% (1)