Beruflich Dokumente

Kultur Dokumente

Two Bed Adsorption Chiller With Regeneration

Hochgeladen von

Parimal BhambareOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Two Bed Adsorption Chiller With Regeneration

Hochgeladen von

Parimal BhambareCopyright:

Verfügbare Formate

www.ccsenet.org/mas Modern Applied Science Vol. 5, No.

4; August 2011

Published by Canadian Center of Science and Education 43

Experimental Study on Two Beds Adsorption Chiller with

Regeneration

Abdual Hadi N. Khalifa

Technical College,Baghdad ,Iraq

Tel: 964-790-185-8234 E-mail:ahaddi58@yahoo.com

Fawziea M. Hussein

Technical College,Baghdad ,Iraq

Tel: 964-790-115-3916

E-mail:Fawizea_Material@yahoo.com

Faeza M. Hadi

Foundation of Techinal Education Iraq

Tel: 964-790-492-5826 E-mail:faizam2001@yahoo.com

Received: April 25, 2011 Accepted: June 20, 2011 doi:10.5539/mas.v5n4p43

Abstract

This work is devoted to investigate the setup, charging, and the influence of the key variables on the

performance of a 1.5 tons capacity two bed adsorption chiller. The beds (66.7 c m x 52.4 cm x 23.5 cm each)

functions as methanol generators. The using of two generators is to build a nearly continuous

adsorption-desorption cycle, by allowing the generators to work alternatively either adsorbing or desorbing the

medium. The switching between desorption and adsorption phases was achieved by a simple manual electric

control system. The adsorption chiller was driven by hot water, with a temperature range of 70 to 100

o

C. Active

carbon-methanol adsorption pair was used in this study. The chiller was charged by 11 kg of active carbon and

2.2 kg of methanol, giving an initial concentration of (0.1966 kg CH

3

OH/kg AC). It was found that using the

mass recovery process increases the initial concentration of methanol in the desorption generator; hence,

improving the COP and SCP of the cycle. The COP of this adsorption chiller was about 0.301, while the SCP

was about 0.3532 kW/kg

AC

, at an outdoor temperature of 25

o

C. Eventually a mass of 200 kg of water could be

chilled from 10

o

C to about 7

o

C in about 14 min.

Keywords: Solar, Adsorption, Refrigeration, Thermally driven cycle, Cooling

1. Introduction

The use of absorption refrigeration cycle commenced efficient solar energy and waste heat utilization. Many

innovative adsorption cycles have been designed and tested in the last twenty years. The merits of such cycles

are its simplicity in design and manufacturing. Although various adsorption systems have been developed and

tested. Since adsorption systems can be operated with no moving parts and without the need for rectifier or

solution pump, the cost of adsorption systems is relatively lower than the absorption systems. Also, adsorption

system works at relatively low temperatures, namely, in the range of 70

o

C to 100

o

C. Solar energy utilization in

solar cooling faces some difficulties including its low energetic conversion efficiency and the strong impact of

the environmental factors on its performance. The ambient temperature, solar radiation and wind speed are

among these environmental variations. Since the COP of the conventional system (about 2.5-3) is much greater

than that of the adsorption cycle (about 0.1-0.3), E. E. Anyanwu and N.V.Oguke, (2005). Hildbr and C. Dind

(2004) developed an adsorption icemaker in which water was used as refrigerant and ice was produced within

the evaporator. In early 1980s Tchernev (1982) carried out an investigation of adsorption refrigeration with

zeolite-water pair. Grenier and Pons (1988) presented a solar adsorption air conditioning system with 20 solar

panels and zeolitewater working pair. Since early 1980s, the work on silica gel-water systems gained popularity

and lot of work was carried out mainly in Japan. In an effort to utilize solar energy, Critoph (1986) have studied

the performance limitations of adsorption cycles for solar cooling. They concluded that, in general, activated

carbonmethanol combination was preferable for solar cooling, giving the best performance achievable in a

single stage cycle. Pons (1986) concluded that solid sorption systems could be the basis for efficient

solar-powered refrigerators. They developed a prototype with activated carbonmethanol pair. Ortel (1997) used

methanol with silica gel instead of water, so that the system could operate at an evaporating temperature below

0

o

C. Li and Sumathy (1999) have presented the description and operation of a solar-powered ice-maker with the

solid adsorption pair of activated carbon and methanol using basic adsorption cycle. Amar (2006) presented a

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

ISSN 1913-1844 E-ISSN 1913-1852 44

solar adsorption icemaker by using flat plate collector, where the same collector, beside its functionality as a

generator it also collects the solar radiation; it was of rectangular parallel shape. A new hybrid system of solar

powered water heater and adsorption ice-maker using ACmethanol pair, has been studied by Wang (2000). The

working principle is a combination of a solar water heater and an adsorption refrigerator. Headley (1994)

constructed a charcoal methanol adsorption refrigerator powered by concentrating solar collectors, but the solar

COP was very low (about 0.02). In the University of Technology in Iraq, Hassan (2008) presented a theoretical

and experimental steady of a hybrid adsorption refrigeration system. Ali (2010) studied experimentally and

theoretically the performance of an adsorption air conditioner, the unit consists of two beds, each bed is built

from two concentrating copper tube.

This paper concern with the design and performance study of a two bed adsorption chiller, a Methanol- active

carbon is used as a working pair. An electrical boiler was used as a heat source to the generator to simulate solar

heating. A continuous operation refrigeration cycle is achieved by six steps; each step is controlled by a simple

electrical circuit.

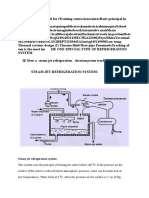

2. Apparatus description

An adsorption chiller unit was built to study the effect of its performance key variables. The chiller consists of

two generators, a condenser and an evaporator. An electrical boiler was used as a heat source to the generator to

simulate solar heating. Each generator was constructed from three heat exchangers, with 36 copper tubes, (16mm

diameters). The three heat exchangers were connected together by U tube connections to each single generator.

Activated carbon type (NORIT PK 1-3) has build particle size of 3.15mm, of apparent density of 290 kg/m

3

,

Iodine number 800 and Ash content 3%. The activated carbon was heated in the furnace with a temperature of

250

o

C for one day, before it was inserted between the heat exchangers fins. A screen of mesh was used to hold

the active carbon in place. A metal box made of mild steel which can hold a maximum pressure of 3.5 bar

maximum, is used to hold the generator.

The two generators were connected by a 25.6mm diameter copper tube and two way solenoid valve S

2

. This

connection is used during the regeneration phase in which heat and mass exchange takes place between the

generators, resulting in pressure equalization. Each generator is connected to the condenser through a 16mm

diameter copper tube and two solenoid valves S

3

and S

4

. The low pressure side of each generator is connected to

the evaporator through two solenoid valves S

5

and S

6

. Figure 1 shows the adsorption chiller with its accessories.

A tube in tube heat exchanger is used as the unit evaporator through which the refrigerant (methanol) is passes in

the inner tube while the water flows the outer tube.

2.1 Adsorption chiller cycles:

The continuous operation refrigeration cycle is achieved by six steps; each step is controlled by a simple

electrical circuit.

The first process: As generator (G

1

) receives hot water, its pressure increases, desorbing the methanol. Vapour

methanol leaving generator (G

1

) condenses in the condenser. The solenoid valves S

2

, S

4

and S

6

are closed while

S

3

and S

5

are opened. The condensate passes through an expansion valve and its pressure falls from G

1

generator

pressure, at (35-40) kPa, to the G

2

generator pressure, at about 5 kPa. The saturation temperature is about 0

o

C.

As the methanol extracts heat from cold water, it evaporates and flows to generator G

2

where it is adsorbed. In

this process the desorption process is conducted in generator G

1

, while the adsorption process is conducted in

generator G

2

, as shown in figure 2 the time required for this cycle is about (5) min.

The second process: Solenoid valve S

2

is opened (shown in figure 3) to extract the remaining vapor of methanol

from the generator G

1

at 25 kPa to generator G2 at 5 kPa the cycle stops when both generators G

1

and G

2

are at

about the same pressure, namely 19 kPa. The time required for this process is about (1) min.

The third process: In the process (shown in Figure 4), all solenoid valves are closed. The cooling water flows in

generator G

1

preparing it to the adsorption process, while the hot water flows in generator G

2

. As a result of

heating, the pressure of generator G

2

increases to about (35-40) kPa causing the methanol to desorb. The

adsorption process in the generator G

2

occurs at constant mass. At the end of this process the vapor methanol is

accumulated in generator G

2

. The time required to complete this step is about (1) min.

The fourth process (shown in Figure 5), this process is just like the first process but the active generator is G

2

,

while generator G

1

preparing to adsorption process. Methanol vapor flows through valve S

4

to condenser, then

condensates at constant pressure of about (35-40) kPa. The pressure of methanol condensate falls rapidly to

evaporator pressure of 5 kPa as it passes through the expansion valve. The cooling effect is achieved in the

evaporator. Methanol vapor flows to generator G

1

through valve S

6

, and adsorbed there. The time required to

complete this step is about (5) min

The fifth process: In this cycle (shown in Figure 6), the remaining vapor methanol is withdrawn from G

2

to G

1

as

in the second cycle. In this cycle both hot water and cooled water pumps are OFF.

The sixth process: during this process (shown in Figure 7), as in third process. , all solenoid valves are closed.

The hot water flows in generator G

1

, while the cold water flows to generator G

2

. This process rises the pressure

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

Published by Canadian Center of Science and Education 45

in generator G

1

inhibiting vapor desorption. The time of this process is 1 min. The total time required to achieve a

complete cycle, including the sixth cycle is about (14) min. The cycle continues back to process (1).

2.2 Key variables:

The key parameters studied in this work are the mass of active carbon, the temperatures of hot and cooling water

that used to heat and cool the generator, evaporating and condensing temperatures and finally the time required

to achieve each cycle.

3. Results and discussions:

Figure 8 shows the cycling time for the two generators G

1

and G

2

, with regeneration. It can be seen from the

figure that, there are two cycles, cycle (A-B-C-D-1-2-3-4), which is referred to cycle one, and cycle

(4-5-6-7-D-E-F-H), which referred to cycle two. As it can be seen, from the figure, that generator G

1

is at higher

pressure and temperature, and it is susceptible to desorption process. While generator G

2

is at low pressure, and

it is susceptible to adsorption process.

As generator G

1

is heated, the methanol desorbs (process A-B-C) and its vapour flows to the condenser,

expansion valve and evaporator, through valves S

5

, S

3

, S

1

and E

V

. These valves are opened during this process as

shown in figure 2. The generator G

1

are kept at constant pressure Pc throughout desorption phase. Meanwhile

generator G

2

possesses an adsorption process. As more and more methanol is adsorbed in G

2

its pressure

increases (points 1, 2 and 3). When G

1

reaches point C and G

2

reaches point 3, a mass recovery process started

by opening valvesS

2

bringing the two generates to the same pressure (P4 and P

D

). At points (4, D), the functions

of the two generators are switched, G

2

is now possess at desorption process, while G

1

possess adsorption process.

As G

2

receives hot water, the methanol desorbs and its pressure rises from P

4

to P

5

at point 5 then, the valves

opened to allow methanol vapor to condensate. Meanwhile, generator G

1

pressure falls, as a result of receiving

cold water, from P

D

to P

E

, commencing the adsorption process. Again at points 6 of G

2

and F of G

1

the mass

recovery process started and the pressure of the two generators are equalized at P

7

and P

E

.

Figure 9 shows the cycling time for the two generators G

1

and

G

2

, without mass recovery process. The sequence

of this cycle is the same as that of the cycle with the mass recovery process; the only difference is that valve S

2

is

kept closed during this cycle, and the function of the two generators are switched when they are at same pressure,

namely at point A. The time required to achieve such cycle is greater than that with mass recovery.

Figure 10 shows the effect of condensed methanol on the generator pressure. It can be seen from the Figure that,

the reduction in generator pressure (about 42 kPa) to the evaporator pressure (10 kPa), is not a continuous

process. This is because; the amount of desorbed methanol depends on the unit pressure and generator

temperature. Thus, it can be seen from the Figure that, the condensation process is achieved in four periods; two

of them are achieved at nearly constant pressure. The first period that extended from about 0.26 to 0.28 kg, is

achieved at constant pressure, as an amount of 0.02 kg of methanol is condensed, the unit pressure tends to

decrease afterword. The amount of condensed methanol during the reduction in pressure period is about, 0.03 kg.

The third period is like the first one, extends from about 0.33 kg to 0.38 kg, at a pressure of 35 kPa. The amount

of condensed methanol during this period is about 0.03 kg. The last period, in which the generator pressure falls

from about 35 to 10 kPa, the amount of condensate methanol is about 0.1 kg. The total amount of methanol that

condenses is about 0.48 to 0.5 kg.

Figure 11 shows the adsorption cycle for the two beds adsorption chiller without mass recovery. The ambient

temperature is 27

o

C, while the generator temperature is 87

o

C. It can be seen from the Figure that, there are four

processes. Namely; A-B: isosteric sensible heating, B-D: isobaric desorption, D-F: isosteric sensible cooling, and

F-A: isobaric adsorption.

Figure 12 shows a comparison between the theoretical and experimental analysis of an adsorption chiller with

two beds (Faeza 2008). It can be seen from the Figure that theoretical cycle is represented by the solid line cycle,

and the mass recovery process represented by line 3-5. While the dotted cycle represented the real adsorption

cycle. It can be seen from the figure that, there is a little discrepancy between the real and theoretical cycle,

especially in the sensible heating line and sensible cooling line. At the beginning of the cycle, the sensible

heating line departs from the isosteric line. The remaining three real processes are very close to that of the

theoretical process. Generally it can be said that, the theoretical results are consistent with the experimental

results.

4. Conclusions

1-Two beds adsorption unit can give continue cooling effect, contrary to single bed adsorption unit.

2- Using the mass recovery process increases the pre desorption concentration, of methanol, in the desorption

generator, and hence, improving the cycle COP and SCP.

3-The optimum COP and SCP obtained in this work is 0.403 and 0.5238 respectively, when the evaporator

temperature is 0

o

C , condensing temperature is 40

o

C, cold water temperature of 25

o

C and hot water is 80

o

C.

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

ISSN 1913-1844 E-ISSN 1913-1852 46

References

Ali H. Jabar. (2010). Experimental study of waste heat adsorption air conditioning cycle. M.Sc. thesis Submitted

to Council of Technical College/Baghdad .

Amar S. A, (2006). Design, construction and performance of solar powered ice maker. M.Sc. thesis, Submitted

to the Department of Machines and Equipment of the University Of Technology.

Critoph, R. E.; Vogel, R.; Oct 1986, Possible adsorption pairs for use in solar cooling. Int. J. Ambient Energy

(United Kingdom), Vol. 7, No. 4; pp. 183-190.

E. E. Anyanwu, and N. V. Oguke. (2005). Thermodynamic design procedure for solid adsorption solar

refrigerator. Mechanical engineering department, Federal university of technology, Renewable Energy 30, 81-96.

doi:10.1016/j.renene.2004.05.005

Faeza M. Hadia. (2008). Theoretical and experimental study of two bed solar adsorption chiller with

regeneration. M.Sc. thesis Submitted to Council of Technical College/Baghdad.

Grenier P, Guilleminot J.J, Meunier F, and Pons M. (1988). Solar powered solid adsorption cold store.

Transaction of ASME, Journal of Sol Energy engineering, 110:192197. doi:10.1115/1.3268256

Hassan J. Fadiel, (2008). Theoretical and experimental study of a hybrid adsorption system. M.Sc. thesis,

Submitted to the Department of Machines and Equipment of the University Of Technology.

Headley AF, Mcdoom IA. (1994). Charcoalmethanol adsorption refrigerator powered by a compound parabolic

concentrating solar collector. Solar Energy 53:1917. doi:10.1016/0038-092X(94)90481-2.

Hildbrand C, Dind P, Pons M, and Buchter F. (2004). A new solar powered adsorption refrigerator with high

performance. Solar Energy 77(3):3118. doi:10.1016/j.solener.2004.05.007.

Li, Z. F. and Sumathy, K. (1999). A solar powered ice maker with the solid adsorption pair of activated carbon

and methanol. International Journal of Energy Research, 23: 517- 527.

doi:10.1002/(SICI)1099-114X(199905)23:6,517::AID-ER495,3.0.CO;2-B.

Ortel, K. and Fischer, M. (1997). Adsorption cooling system for cold storage using methanol and silica gel.

Proceeding of international heat powered cycle conference, university of Nottingham, UK. 15,17.

Pons M, Guilleminot J.J. (1986). Design of an experimental solar powered, solid-adsorption ice maker.

Transaction of ASME, Journal of Sol Energy engineering, 988;110 :192197. 108(4):3327.

Tchernev, D.I, (1982). Solar air conditioning and refrigeration system utilizing zeolites. Proceeding meeting of

IIR commissions, EI-E2, Jerusalem, 209-215.

Wang, R. Z. (2000). An energy efficient hybrid system of solar powered water heater and adsorption ice maker.

Solar energy, 68(2); 189-195. doi:10.1016/S0038-092X(99)00062-6

Figure 1. The adsorption chiller

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

Published by Canadian Center of Science and Education 47

Hot water tank

S1

Generator1

High pressure

Low pressure

Cold water tank

Flowmeter

T

I-2 P

T

I-6 P

T

I-9 P

T

I-11 P

T

I-13 P

T

T

T

T

T

Generator 2

condensor

evaporator

P-147

Chilled water tank

S2

s3 s4

s6

s5

3w1

3w2

E.V

STEP 1

Time=5 min

Cold water supply & return ON

Hot water supply or return ON

Cold & Hot water supply & return OFF

Gas flow ON

solenoid valve OFF

Three way valves

solenoid valve ON

Expansion valve

Figure 2. Refrigeration cycle operation step 1

S1

Generator1

High pressure

Cold water tank

T

P

T

P

T

P

T

P

T

P

T

T

T

T

T

condensor

Hot water tank

Chilled water tank

S3

S4

S2

3W1

3W2

S5 S6

STEP( 2)

Time=1 min

E.V

evaporator

Generator 2

Cold water supply & return ON

Hot water supply or return ON

Cold & Hot water supply & return OFF

Gas flow ON

solenoid valve OFF

Three way valves

solenoid valve ON

Expansion valve

Figure 3. Refrigeration cycle operation step 2

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

ISSN 1913-1844 E-ISSN 1913-1852 48

S1

Generator1

Low pressure

Cold water tank

Cold water return

T

P

T

P

T

P

T

P

T

P

T

T

T

T

T

Generator 2

condensor

evaporator

Hot water tank

Chilled water tank

S3

S4

S2

S6 S5

3W1

3W2

STEP 3

Time=1 min.

E.V

Cold water supply & return ON

Hot water supply or return ON

Cold & Hot water supply & return OFF

Gas flow ON

solenoid valve OFF

Three way valves

solenoid valve ON

Expansion valve

Figure 4. Refrigeration cycle operation step 3

S1

Generator1

High pressure

Cold water tank

T

P

T

P

T

P

T

P

T

P

T

T

T

T

T

Generator 2

condensor

evaporator

Hot water tank

Chilled water tank

S3

S4

S2

S6 S5

3W1

3W2

E.V

STEP 4

Time=5 min.

Cold water supply & return ON

Hot water supply or return ON

Gas flow ON

solenoid valve OFF

Three way valves

solenoid valve ON

Expansion valve

Figure 5. Refrigeration cycle operation step 4

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

Published by Canadian Center of Science and Education 49

S1

Generator1

High pressure

Low pressure

Cold water tank

T

P

T

P

T

P

T

P

T

P

T

T

T

T

T

Generator 2

condensor

evaporator

Hot water tank

Chilled water tank

E.V

STEP 5

Time=1 min.

S3

S2

S4

S6

S5

3W2

3W1

Cold water supply & return ON

Hot water supply or return ON

Cold & Hot water supply & return OFF

Gas flow ON

solenoid valve OFF

Three way valves

solenoid valve ON

Expansion valve

Figure 6. Refrigeration cycle operation step.5

S1

Generator1

High pressure

Low pressure

Cold water tank

T

P

T

P

T

P

T

P

T

P

T

T

T

T

T

Generator 2

condensor

evaporator

Hot water tank

Chilled water tank

S3

S4

S2

S6 S5

3W1

3W2

STEP 6

Time=1 min.

E.V

Cold water supply & return ON

Hot water supply or return ON

Cold & Hot water supply & return OFF

Gas flow ON

solenoid valve OFF

Three way valves

solenoid valve ON

Expansion valve

Figure 7. Refrigeration cycle operation step 6

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

ISSN 1913-1844 E-ISSN 1913-1852 50

0

0.1

0.2

0.3

0.4

0.5

0.6

0 100 200 300 400 500 600 700 800 900

Time (S)

PG1

PG2

S2 ON S2 ON

A

B

c

3

1

2 4

D

5

6

E

F

7

H

S

3

,S

1

, EV and S

5

ON

S

4

,S

1

, EV and S

6

ON

P

r

e

s

s

u

r

e

b

a

r

Figure 8. cycling time for adsorption chiller with mass recovery

P

r

e

s

s

u

r

e

(

b

a

r

)

Figure 9. cycling time for adsorption chiller without mass recovery

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

Published by Canadian Center of Science and Education 51

Figure 10. Relation between mass of condensed methanol and generator pressure

Clyaperon diagram (-1/ T & Ln P)

1.25

1.75

2.25

2.75

3.25

3.75

- 0.0034 - 0.0033 - 0.0032 - 0.0031 - 0.003 - 0.0029 - 0.0028 - 0.0027

(-

1

/

T

) (

K

)

X1

X2

A

B

D

F

Figure 11. P-T-x or Clapeyron diagram for two beds adsorption chiller Cycle without mass recovery

corresponding to the experiment data

5

10

15

20

25

30

35

40

45

0.25 0.3 0.35 0.4 0.45 0.5

Mass of condensing methanol (kg)

P

r

e

s

s

e

r

(

K

p

a

)

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 4; August 2011

ISSN 1913-1844 E-ISSN 1913-1852 52

1.25

1.75

2.25

2.75

3.25

3.75

4.205

- 0.0035 -0. 0034 - 0.0033 - 0.0032 - 0.0031 - 0.003 - 0.0029 - 0.0028 - 0.0027 - 0.0026 - 0.0025

1/T K

4

1

8

5

6

2

3

Theoretical cycle

Experimental cycle

L

n

p

Figure 12. Comparison between the theoretical[13] and experimental P-T-X or Clapeyron diagram cycle

Das könnte Ihnen auch gefallen

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningVon EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningBewertung: 5 von 5 Sternen5/5 (2)

- Modeling and Simulation of A Solar Powered Two Bed Adsorption Air Conditioning SystemDokument15 SeitenModeling and Simulation of A Solar Powered Two Bed Adsorption Air Conditioning SystemsisayNoch keine Bewertungen

- Absorption Cooling System by Using Solar EnergyDokument16 SeitenAbsorption Cooling System by Using Solar Energyعراقي iraqiNoch keine Bewertungen

- Adsortion RefrigerationDokument0 SeitenAdsortion RefrigerationJonás DalladorNoch keine Bewertungen

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsVon EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNoch keine Bewertungen

- Carbon AmmoniaDokument9 SeitenCarbon AmmoniaFeyi AsgillNoch keine Bewertungen

- 2.1 Demands For CoolingDokument25 Seiten2.1 Demands For CoolingVivek LokhandeNoch keine Bewertungen

- Flat Plate Heat Pipe 2Dokument5 SeitenFlat Plate Heat Pipe 2सचिन उरुणकरNoch keine Bewertungen

- An Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice MakerDokument7 SeitenAn Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice MakerAjith KrishnanNoch keine Bewertungen

- Solar RefrigerationDokument5 SeitenSolar RefrigerationspectabearNoch keine Bewertungen

- Performance Analysis of Evacuated Tube Collector in Hot ClimateDokument13 SeitenPerformance Analysis of Evacuated Tube Collector in Hot ClimateSujit MishraNoch keine Bewertungen

- 68-Solar Waste Heat Driven Two-Stage AdsorptionDokument9 Seiten68-Solar Waste Heat Driven Two-Stage Adsorptionali105Noch keine Bewertungen

- Review of Solid Adsorption Refrigerator I An Overview of The Refrigeration CycleDokument12 SeitenReview of Solid Adsorption Refrigerator I An Overview of The Refrigeration CycleHamza MoussaNoch keine Bewertungen

- Adsorption Refrigeration System New SlideDokument23 SeitenAdsorption Refrigeration System New SlideSoujanya PuhanNoch keine Bewertungen

- Energies: Thermal Analysis of A Solar Powered Absorption Cooling System With Fully Mixed Thermal Storage at StartupDokument19 SeitenEnergies: Thermal Analysis of A Solar Powered Absorption Cooling System With Fully Mixed Thermal Storage at StartupPedro HenriqueNoch keine Bewertungen

- Unit 4 Solar CoolingDokument12 SeitenUnit 4 Solar CoolingSubhaNoch keine Bewertungen

- Design Optimization and Simulation of An Ice Plant Working by Solar Adsorption TechnologyDokument10 SeitenDesign Optimization and Simulation of An Ice Plant Working by Solar Adsorption TechnologySellihca EcleoNoch keine Bewertungen

- Moreno Quintanar2012Dokument7 SeitenMoreno Quintanar2012KArenNoch keine Bewertungen

- Solar EnergyDokument4 SeitenSolar EnergyAmanuel WorkuNoch keine Bewertungen

- Termosifón Tubo de CalorDokument6 SeitenTermosifón Tubo de CalorLuis Enrique GonzálezNoch keine Bewertungen

- Study of The Performance of A Solar Adsorption Cooling SystemDokument15 SeitenStudy of The Performance of A Solar Adsorption Cooling SystemwidhisaputrawijayaNoch keine Bewertungen

- Solar Water HeaterDokument58 SeitenSolar Water HeaterRishav DevkotaNoch keine Bewertungen

- Design and Performance Prediction of A Novel Zeolite-Water Adsorption Air ConditionerDokument21 SeitenDesign and Performance Prediction of A Novel Zeolite-Water Adsorption Air ConditionerGokul PrasathNoch keine Bewertungen

- Per ETCDokument14 SeitenPer ETCRendy YuliantoNoch keine Bewertungen

- Adsorption RefrigerationDokument22 SeitenAdsorption RefrigerationVijay Krishnan100% (1)

- Review of PST WorkDokument6 SeitenReview of PST WorkSwaksharJyoti HazarikaNoch keine Bewertungen

- Solar Gas Solid Sorption Heat Pump: L.L. Vasiliev, D.A. Mishkinis, A.A. Antukh, L.L. Vasiliev JRDokument11 SeitenSolar Gas Solid Sorption Heat Pump: L.L. Vasiliev, D.A. Mishkinis, A.A. Antukh, L.L. Vasiliev JRحسن عرقسوسيNoch keine Bewertungen

- Paper 17 DesignDokument7 SeitenPaper 17 DesignJohannes Angga PanjaitanNoch keine Bewertungen

- The Study of Solar Absorption Air-Conditioning SystemsDokument8 SeitenThe Study of Solar Absorption Air-Conditioning SystemsJaime Haro EstropNoch keine Bewertungen

- Effects of CuOwater Nanofluid On The Efficiency of A Flat-Plate SolarDokument6 SeitenEffects of CuOwater Nanofluid On The Efficiency of A Flat-Plate SolarDaniel AraújoNoch keine Bewertungen

- Nagaraj 123Dokument14 SeitenNagaraj 123Ganesh harikantraNoch keine Bewertungen

- Performance Analysis of Parabolic Trough Collector in Hot ClimateDokument21 SeitenPerformance Analysis of Parabolic Trough Collector in Hot ClimateirfanajaiNoch keine Bewertungen

- Refrigeration & Air-Conditioning: Presented by Group - IIDokument53 SeitenRefrigeration & Air-Conditioning: Presented by Group - IIAnonymous 1HlNy6nNoch keine Bewertungen

- Adsorptive Solar Powered Ice Maker Experiments PDFDokument15 SeitenAdsorptive Solar Powered Ice Maker Experiments PDFali105Noch keine Bewertungen

- Steam Jet Refrigeration SystemDokument7 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- 10 1016@j Renene 2020 10 114Dokument41 Seiten10 1016@j Renene 2020 10 114Ryuzaki GamingNoch keine Bewertungen

- Effect of Packing Factor On The Performance of PVT Water HeaterDokument6 SeitenEffect of Packing Factor On The Performance of PVT Water HeaterUmer AbbasNoch keine Bewertungen

- Shopmillingmsme: Steam Jet Refrigeration SystemDokument7 SeitenShopmillingmsme: Steam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- 1 s2.0 S0960148104001703 Main PDFDokument10 Seiten1 s2.0 S0960148104001703 Main PDFlunetaecha18Noch keine Bewertungen

- Development of Two Adsorption Heat Pump / Air Conditioning Systems Dr. Robert E. Critoph, M.Inst.E University of Warwick, Coventry CV4 7AL, UKDokument6 SeitenDevelopment of Two Adsorption Heat Pump / Air Conditioning Systems Dr. Robert E. Critoph, M.Inst.E University of Warwick, Coventry CV4 7AL, UKBalaji RajNoch keine Bewertungen

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- 48 Ragab 1-s2.0-S2352152X23004528-main - CompressedDokument14 Seiten48 Ragab 1-s2.0-S2352152X23004528-main - CompressedAbo AmroNoch keine Bewertungen

- Solar Energy For Cooling and RefrigeratiDokument10 SeitenSolar Energy For Cooling and RefrigeratiAli hegaigNoch keine Bewertungen

- Steam Jet Refrigeration SystemDokument7 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Steam Jet Refrigeration SystemDokument7 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Solar Desalination With A Humidification - Dehumidification Cycle: Performance of The UnitDokument8 SeitenSolar Desalination With A Humidification - Dehumidification Cycle: Performance of The UnitsasikalasivakumarNoch keine Bewertungen

- Steam Jet Refrigeration SystemDokument7 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Heat Loses From Parabolic Trough Solar CollectorsDokument9 SeitenHeat Loses From Parabolic Trough Solar CollectorsSaúl García HernándezNoch keine Bewertungen

- Shopmillingmsme: Steam Jet Refrigeration SystemDokument7 SeitenShopmillingmsme: Steam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Closed Cycle Solar RefrigerationDokument13 SeitenClosed Cycle Solar RefrigerationLaura FrancoNoch keine Bewertungen

- Yacoob Ijrct - Org Dec 15Dokument5 SeitenYacoob Ijrct - Org Dec 15navneetkpatil8409Noch keine Bewertungen

- Renewable Energy: Mustafa Ali Ers OzDokument13 SeitenRenewable Energy: Mustafa Ali Ers OzJasmin AhmedNoch keine Bewertungen

- New Solar Powered Adsorption Refrigerator With High PerformanceDokument9 SeitenNew Solar Powered Adsorption Refrigerator With High PerformanceBudiman Immanuel NainggolanNoch keine Bewertungen

- In Memoriam Ivo KolinDokument5 SeitenIn Memoriam Ivo KolinTimuçin KarabulutlarNoch keine Bewertungen

- Shopmillingmsme: Steam Jet Refrigeration SystemDokument7 SeitenShopmillingmsme: Steam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Solar Desiccant CoolingDokument12 SeitenSolar Desiccant Coolingdanijelkr88Noch keine Bewertungen

- Steam Jet RefrigerationDokument6 SeitenSteam Jet RefrigerationbbaytlNoch keine Bewertungen

- Collector With LinsDokument10 SeitenCollector With Linsaoauaz2000Noch keine Bewertungen

- WEResources Solar 2016Dokument80 SeitenWEResources Solar 2016Parimal BhambareNoch keine Bewertungen

- Parabola DimensionsDokument3 SeitenParabola DimensionsParimal BhambareNoch keine Bewertungen

- GRE 2018 BrochureDokument2 SeitenGRE 2018 BrochureParimal BhambareNoch keine Bewertungen

- General Overview Boilers and FlowDokument22 SeitenGeneral Overview Boilers and FlowLiam MoylanNoch keine Bewertungen

- 2 Level FactorialDokument58 Seiten2 Level FactorialParimal Bhambare100% (1)

- Physics 304 Thermodynamics Notes: An Introduction To Thermal Physics, D. V. Schroeder, Addison Wesley Longman, 2000Dokument57 SeitenPhysics 304 Thermodynamics Notes: An Introduction To Thermal Physics, D. V. Schroeder, Addison Wesley Longman, 2000AdarshNoch keine Bewertungen

- Solar GeometryDokument13 SeitenSolar GeometryParimal BhambareNoch keine Bewertungen

- Heat Transfer BasicsDokument44 SeitenHeat Transfer BasicsParimal BhambareNoch keine Bewertungen

- SME Sector in Oman - PaperDokument73 SeitenSME Sector in Oman - Paperakmohideen100% (1)

- Fundamentals of Reverse Osmosis DesignDokument16 SeitenFundamentals of Reverse Osmosis DesignJayfeson Gotuanco100% (2)

- HTchap 9Dokument18 SeitenHTchap 9Parimal BhambareNoch keine Bewertungen

- Chilling Adsorption Refrigeration Technologies Research TopicsDokument27 SeitenChilling Adsorption Refrigeration Technologies Research TopicsParimal BhambareNoch keine Bewertungen

- Echangeur SpiraleDokument5 SeitenEchangeur SpiraleMehdi HababaNoch keine Bewertungen

- Steady-State Analysis of The Multiple Effect Evaporation Desalination ProcessDokument15 SeitenSteady-State Analysis of The Multiple Effect Evaporation Desalination ProcessRitheesh KakitaNoch keine Bewertungen

- Cooling Effect by Adsorption DesorptionDokument5 SeitenCooling Effect by Adsorption DesorptionParimal BhambareNoch keine Bewertungen

- 26 Siegfried Kreussler Experiments On Solar Adsorption RefrigDokument8 Seiten26 Siegfried Kreussler Experiments On Solar Adsorption RefrigParimal BhambareNoch keine Bewertungen

- Zeolite Water RefrigeratorDokument4 SeitenZeolite Water RefrigeratorParimal BhambareNoch keine Bewertungen

- An Adsorption Chiller Driven by ThermoelectricityDokument9 SeitenAn Adsorption Chiller Driven by ThermoelectricityParimal BhambareNoch keine Bewertungen

- ISES2003 (Solar Refrigeration)Dokument5 SeitenISES2003 (Solar Refrigeration)Rahul TripathiNoch keine Bewertungen

- Life04 Env Lu 000829 LaymanDokument10 SeitenLife04 Env Lu 000829 LaymanPrabhat KumarNoch keine Bewertungen

- 26 Siegfried Kreussler Experiments On Solar Adsorption RefrigDokument8 Seiten26 Siegfried Kreussler Experiments On Solar Adsorption RefrigParimal BhambareNoch keine Bewertungen

- Adsorption Refri As An Effective Method of Utilizing Waste HeatDokument10 SeitenAdsorption Refri As An Effective Method of Utilizing Waste HeatParimal BhambareNoch keine Bewertungen

- Cooling Effect by Adsorption DesorptionDokument5 SeitenCooling Effect by Adsorption DesorptionParimal BhambareNoch keine Bewertungen

- Performance of A Zeolite Water Adsorption Refrigeration SystemDokument9 SeitenPerformance of A Zeolite Water Adsorption Refrigeration SystemParimal BhambareNoch keine Bewertungen

- Alternative and Emerging Refrigeration Technologies For Food Refrigeration ApplicationsDokument15 SeitenAlternative and Emerging Refrigeration Technologies For Food Refrigeration ApplicationsParimal BhambareNoch keine Bewertungen

- ISES2003 (Solar Refrigeration)Dokument5 SeitenISES2003 (Solar Refrigeration)Rahul TripathiNoch keine Bewertungen

- KaizenDokument21 SeitenKaizenRyan Llaneta100% (1)

- KaizenDokument21 SeitenKaizenRyan Llaneta100% (1)

- KaizenDokument21 SeitenKaizenRyan Llaneta100% (1)

- Brock Planetary Declination SDokument6 SeitenBrock Planetary Declination SDositheus Seth100% (2)

- Food Poisoning: VocabularyDokument9 SeitenFood Poisoning: VocabularyHANG WEI MENG MoeNoch keine Bewertungen

- Wic ReflectionDokument3 SeitenWic Reflectionapi-307029735Noch keine Bewertungen

- Schneider Modicon M580 CatalogueDokument268 SeitenSchneider Modicon M580 CatalogueKhaerul Imam HermanNoch keine Bewertungen

- AdPoe The Hunting of The HareDokument2 SeitenAdPoe The Hunting of The HarePI CubingNoch keine Bewertungen

- AC350 Specs UsDokument18 SeitenAC350 Specs Uskloic1980100% (1)

- Julie RiesenweberDokument14 SeitenJulie RiesenweberisidorabilbaoNoch keine Bewertungen

- Pi 0614 Hiblack f890b en WebDokument2 SeitenPi 0614 Hiblack f890b en Web王偉仲Noch keine Bewertungen

- Avionic ArchitectureDokument127 SeitenAvionic ArchitectureRohithsai PasupuletiNoch keine Bewertungen

- Sindarin-English Dictionary - 2nd EditionDokument192 SeitenSindarin-English Dictionary - 2nd EditionNea Tan100% (1)

- FENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BDokument388 SeitenFENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BQUOC LENoch keine Bewertungen

- Complicaciones Postoperatorias en Esofagectomía Por Cáncer. Evaluación de 215 Casos Según Definiciones Del Grupo de Consenso InternacionalDokument7 SeitenComplicaciones Postoperatorias en Esofagectomía Por Cáncer. Evaluación de 215 Casos Según Definiciones Del Grupo de Consenso InternacionalPaulo RoseroNoch keine Bewertungen

- COUNTERS IN PLC - Portal PDFDokument88 SeitenCOUNTERS IN PLC - Portal PDFAhwangg xGAMINGNoch keine Bewertungen

- Tank Gauging TankvisionDokument31 SeitenTank Gauging Tankvisionkhangduongda3Noch keine Bewertungen

- Notice: Environmental Statements Notice of Intent: Eldorado National Forest, CADokument2 SeitenNotice: Environmental Statements Notice of Intent: Eldorado National Forest, CAJustia.comNoch keine Bewertungen

- Iloilo City Regulation Ordinance 2006-010Dokument4 SeitenIloilo City Regulation Ordinance 2006-010Iloilo City CouncilNoch keine Bewertungen

- Fluid Solids Operations: High HighDokument20 SeitenFluid Solids Operations: High HighPriscilaPrzNoch keine Bewertungen

- Varaah KavachDokument7 SeitenVaraah KavachBalagei Nagarajan100% (1)

- The Failed Rotator CuffDokument307 SeitenThe Failed Rotator Cufforthofitness2017Noch keine Bewertungen

- Offsetting Macro-Shrinkage in Ductile IronDokument13 SeitenOffsetting Macro-Shrinkage in Ductile IronmetkarthikNoch keine Bewertungen

- University of Engineering and Technology TaxilaDokument5 SeitenUniversity of Engineering and Technology TaxilagndfgNoch keine Bewertungen

- Mathematics For Engineers and Scientists 3 PDFDokument89 SeitenMathematics For Engineers and Scientists 3 PDFShailin SequeiraNoch keine Bewertungen

- Phytoremediation Acuatic PlantsDokument120 SeitenPhytoremediation Acuatic PlantsFranco Portocarrero Estrada100% (1)

- Gcat Threathorizons Full Jan2023Dokument26 SeitenGcat Threathorizons Full Jan2023josbjsNoch keine Bewertungen

- 2UEB000487 v1 Drive On GeneratorDokument19 Seiten2UEB000487 v1 Drive On GeneratorSherifNoch keine Bewertungen

- High Performance Dialysis GuideDokument28 SeitenHigh Performance Dialysis GuideRoxana ElenaNoch keine Bewertungen

- Komatsu Technical BrochurDokument7 SeitenKomatsu Technical BrochurBenjamin MossoNoch keine Bewertungen

- Diesel Rotary UPS Configurations V1 - 00 - Jan2008Dokument10 SeitenDiesel Rotary UPS Configurations V1 - 00 - Jan2008Karim SenhajiNoch keine Bewertungen

- The Influence of School Architecture and Design On The Outdoor Play Experience Within The Primary SchoolDokument20 SeitenThe Influence of School Architecture and Design On The Outdoor Play Experience Within The Primary SchoolAnca BalotaNoch keine Bewertungen

- 10 Q - Switching & Mode LockingDokument21 Seiten10 Q - Switching & Mode Lockingkaushik42080% (1)