Beruflich Dokumente

Kultur Dokumente

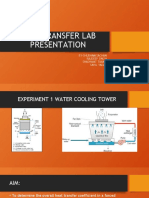

Filmwise and Dropwise Experiment

Hochgeladen von

Hafizszul FeyzulOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Filmwise and Dropwise Experiment

Hochgeladen von

Hafizszul FeyzulCopyright:

Verfügbare Formate

1

ABSTRACT

This Film and Dropwise Condensation Unit is used to observe the process of heat transfer

during condensation, as well as gather experimental data for a better theoretical understanding.

The unit itself contained bench top unit, with an integrated steam generator and air extraction

system. The main components in the unit are the specially designed condensers for the

observation of both filmwise and dropwise condensation about the differences of them. In this

experiment, we want to study the heat transfer coefficient and the heat flux. Besides that, we

were study the effect of air inside the chamber. Condensation occurs when vapour changes to

liquid state with a large heat-transfer coefficient. Filmwise condensation occurs on a vertical or

horizontal plane when a film of condensate is formed on surface and flows by action of gravity.

Dropwise condensation occurs when small drops formed on surface. The heat transfer coefficient

can be calculated using Nussselt equation. . Nusselt assumed that the heat transfer that occurs

from the vapour through the film and to the wall is conduction. Since the process is conduction is

well known, therefore calculation on the heat-transfer coefficients can be done. In this experiment,

obtained data are for T

sat

, T

surf

, T

in

and T

out

.

INTRODUCTION

Filmwise and Dropwise are two forms of condensation. In filmwise condensation a laminar film

of vapour is created upon a surface. This film can then flow downwards, increasing in thickness as

additional vapour is picked up along the way. In dropwise then flow downwards, accumulating static

droplets below them along the way.

When the rate of condensation is low (e.g., a noncondensible gas is present) or when the liquid

does not "wet" the wall, dropwise condensation occurs. In most engineering components where

condensation is a required part of an industrial process film condensation is expected, because of the

large mass flux of condensed liquid per unit length of wetted area.

Dropwise condensation was first recognized by Schmidt et al. (1930), and much interest was

stimulated by their report that heat transfer coefficient were between 5 and 7 times those found with

film condensation. Over the years there have been a few demonstrations of successful applications on

an industrial scale. This experiment would be used in by any industry which is trying to increase the

efficiency of heat transfer. An example of this is any vapour power cycle such as the rankine cycle. By

increasing the efficiency of the condenser, its operational pressure can be reduced and the overall

efficiency of the cycle can be increased. Dropwise condensation is difficult to sustain reliably; therefore,

industrial equipment is normally designed to operate in filmwise condensation mode.

2

In all application, the steam must be condensed as it transfer heat to a cooling medium which

could be cold water in a condenser of generating station, hot water in a heating calorifier, sugar solution

in a sugar refinery and etc. during condensation very high heat fluxes are possible and provided that the

heat can be quickly transferred from the condensing surface into the cooling medium, the heat

exchangers can be compact and effective.

The SOLTEQ Film & Dropwise Condensation Unit (Model: HE163) is designed to help student to

understand several key aspects in condensation topic, in particular the process of filmwise and dropwise

condensation. It allows students to visualize both phenomena and perform a few experiments to

demonstrate both concepts and how their applied and give benefit in industry.

OBJECTIVES

1. To demonstrate the filmwise and dropwise condensation.

2. To describe filmwise and dropwise condensation

3. To demonstrate the effect of air on heat transfer coefficient of condensation

4. To demonstrate the filmwise heat flux and surface heat transfer coefficient ay constant

pressure.

5. To determine the dropwise heat flux and surface heat transfer coefficient at constant pressure.

THEORY

Mechanism of Condensation

Condensation of a vapor to a liquid and vice versa, both involve a change of a fluid with large

heat-transfer coefficients. Condensation occurs when a saturated vapor such as steam makes a contact

with a solid whose surface temperature is below the saturation temperature, to form a liquid such as

water.

When a vapor condenses on a surface, for example vertical or horizontal tube or other surface, a

film of condensate is formed on the surface and flows over the surface because of gravity. It is this film

of liquid between the surface and the vapor that produce the main resistance of heat transfer. This is

called filmwise condensation.

Another type of condensation is dropwise condensation. Dropwise condensation occurs when

small drops are formed on the surface. These drops grow and mix together, and the liquid flows from

the surface. Large areas of tube are devoid of any liquid and are exposed directly to the vapor during

condensation. Very high rates of heat-transfer occur on these bare areas. The average heat transfer

coefficient for dropwise condensation is five to ten times larger than the filmwise coefficient.

3

Dropwise condensation can be promoted by making the surface non-welting by coating.

However, dropwise condensation is difficult to maintain in industrial applications because of oxidation,

fouling and degrading of coating, and finally film condensation occurs. Therefore, condenser designs are

often based on the assumption of filmwise condensation.

Film-condensation coefficients for vertical surfaces

Film type condensation on a vertical wall or tube can be find analytically by assuming laminar

flow of the condensate film down the wall. The film thickness is zero at the top of the wall or tube. It

increases in thickness as it flows downward as a result of condensation. Nusselt assumed that the heat

transfer from the condensing vapor at Tsat, through this liquid film, and at the wall at Tw, was by

conduction. Equating this heat-transfer by conduction to that from condensation of the vapor, final

expression can be obtained for the average heat-transfer coefficient over the whole surfaces.

4

APPARATUS

Equipment Prefer:

SOLTEQ MODEL: HE 163 (Film and Dropwise Condensation Unit)

PROCEDURE

General Start-up

1. The main switch is ensured in its off position.

2. The power regulator knobs are turned fully anti-clockwise to set the power to minimum.

3. Valves V1 to V6 are checked to ensure its closed.

4. The chamber is filled with distilled water until the water level stays between the hater and

baffles plates. The heater is ensured fully immersed in the water throughout the experiment.

The chamber is filled with water through the drain valve with the vent valve, V4 opened. Then

the vent valve V4 is closed.

5

5. The water flow rate to the condenser is adjusted by controlling the control valve according to

experimental procedure.

6. The main switch and the heater switch are turned on. The heater power is set by rotating the

power regulator clockwise to increase the hater power.

7. The water temperature reading is observed where the water temperature should increase when

its start heat-up.

8. The water is heated up to boiling point until the pressure reaches 1.02-1.10 bar. Immediately

valve V1 is opened and follow by valve V5 for 1 minute to vacuum out the air inside condenser.

Then both valve V1 and V5 is closed.

9. The system is let to stabilize. Then all relevant measurement is taken for experimental purposes.

Adjustment is made if required.

General shut-down

1. The voltage control knob is turned to 0 Volt position by turning the knob fully anti-clockwise.

The cooling water is kept flowing for at least 5 minutes through the condenser to cold them

down.

2. The main switch and power supply are switch off. Then, the power supply cable is unplugged.

3. The water supply is closed and the cooling water connection tubes are disconnected if

necessary. Otherwise, the connection tubes are leaved for next experiment.

4. The water inside the chamber is discharged using the discharge valve.

A) Demonstration of filmwise and dropwise condensation

1. The basic procedure is followed as written in the general set-up. The equipment by make sure

connected to the service unit.

B) The filmwise heat flux and surface heat transfer coefficient determination at constant

Pressure

1. Cooling water is circulated through the filmwise condenser starting with a minimum value of 0.1

LPM.

6

2. The heater power is adjusted to obtain the desired pressure at 1.01 bar.

3. When the condition is stabilized, the steam (

) and surface temperature (

) ,

(T1) and

(T2), and flowrate are recorded.

C) The dropwise heat flux and surface heat transfer coefficient determination at

Constant pressure

1. Cooling water is circulated through the dropwise condenser starting with a minimum value of

0.4 LPM.

2. The heater power is adjusted to obtain the desired pressure at 1.01 bar.

3. When the condition is stabilized, the steam (

) and surface temperature

(T3),

(T4) and flowrate are recorded.

RESULTS

Experiment 1: Demonstration of filmwise and dropwise condensation

Pressure is kept constant at 1.02-1.10 bar

Tin= 30.2

Tout=29.7

Tsat=61.8

7

Tsurf=31.0

Figure 2: (Left) The Filmwise Condensation and (right) The Dropwise Condensation

Experiment 2:

Table 1: The filmwise heat flux and surface heat transfer coefficient determination at constant pressure

Flowrate (LMP) Power (P)

Tin

( C)

Tout

( C)

Tsat

( C)

Tsurf

( C)

Tm

( C) q U

0.1 185 31.9 32 66.9 30.7 34.95 0.70 172.82 4.94

0.2 205 34.3 34.6 70.4 33.3 35.95 4.19 1036.91 28.84

0.3 230 34.6 34.9 70.8 34.1 36.05 6.28 1555.36 43.14

0.4 259 34.7 34.9 71.6 33.8 36.80 5.58 1382.54 37.57

0.5 269 34.6 34.8 70.8 34 36.10 6.98 1728.18 47.87

0.6 274 34.7 34.9 71.4 33.8 36.60 8.37 2073.82 56.66

8

Graph 1: Heat Flux vs. Tsat-Tsurf for filmwise without air

Graph 2: Heat coefficient against Tsat-Tsurf for filmwise without air

0.00

500.00

1000.00

1500.00

2000.00

2500.00

30 35 40

H

e

a

t

f

l

u

x

Tsat-Tsurf

0.00

10.00

20.00

30.00

40.00

50.00

60.00

30 32 34 36 38 40

H

e

a

t

C

o

e

f

f

i

c

i

e

n

t

Tsat-Tsurf

Heat coefficient against Tsat-Tsurf

9

Experiment 3:

Table 2: The dropwise heat flux and surface heat transfer coefficient determination at constant pressure

Flowrate (LMP) Power (P)

Tin

( C)

Tout

( C)

Tsat

( C)

Tsurf

( C)

Tm

( C) q U

0.4 347 34.6 35.7 68.8 41.6 33.65 30.70 7605.52 226.04

0.6 365 34.4 35.2 71.4 44.2 36.60 33.49 8296.93 226.70

0.8 487 34.9 35.9 72.2 44.6 36.80 55.82 13828.21 375.79

1 562 34.4 35.2 72 45 37.20 55.82 13828.21 371.74

1.2 588 35.1 35.9 71.8 45.2 36.30 66.99 16593.86 457.15

1.4 623 34.4 35.2 71.6 45.7 36.80 78.15 19359.50 526.09

Graph 3: Heat Flux vs. Tsat-Tsurf for dropwise without air

0.00

5000.00

10000.00

15000.00

20000.00

25000.00

25.5 26 26.5 27 27.5 28

H

e

a

t

F

l

u

x

Tsat-Tsurf

Heat Flux vs. Tsat-Tsurf

0.00

100.00

200.00

300.00

400.00

500.00

600.00

25.5 26 26.5 27 27.5 28

H

e

a

t

C

o

e

f

f

i

c

i

e

n

t

Tsat-Tsurf

Heat Coefficient vs. Tsat-Tsurf

10

Graph 4: Heat coefficient against Tsat-Tsurf for dropwise without air

Graph 5: The comparison of heat flux vs Tsat-Tsurf for dropwise and filmwise in the absence of air

Graph 6: The comparison of heat coefficient vs Tsat-Tsurf for dropwise and filmwise in the absence of air

0.00

5000.00

10000.00

15000.00

20000.00

25000.00

25 30 35 40

H

e

a

t

F

l

u

x

Tsat-Tsurf

Heat Flux vs. Tsat-Tsurf

Dropwise

Filmwise

0.00

100.00

200.00

300.00

400.00

500.00

600.00

20 25 30 35 40

H

e

a

t

C

o

e

f

f

i

c

i

e

n

t

Tsat-Tsurf

Heat coefficient vs Tsat-Tsurf

Dropwise

Filmwise

11

Experiment 4:

Filmwise

Table 3: The effect of air inside chamber for filmwise

Flowrate (LMP) Power (P)

Tin

( C)

Tout

( C)

Tsat

( C)

Tsurf

( C)

Tm

( C) q U

0.1 248 33.1 35.1 68.3 33.7 34.19 13.96 3457.05 101.112

0.2 275 33.1 33.6 69.9 32.5 36.55 6.98 1728.53 47.293

0.3 298 33.1 34.9 69.7 33.9 35.69 37.68 9334.04 261.513

0.4 308 33.3 33.4 69.8 32.1 36.45 2.79 691.41 18.969

0.5 326 33.3 33.4 69 32.1 35.65 3.49 864.26 24.243

0.6 339 33.4 33.5 70.9 32.1 37.45 4.19 1037.12 27.693

Graph 7: The heat coefficient vs Tsat-Tsurf for filmwise with 1% air

Dropwise

Table 4: The effect of air inside chamber for dropwise

Flowrate (LMP) Power (P)

Tin

( C)

Tout

( C)

Tsat

( C)

Tsurf

( C)

Tm

( C) q U

0.4 351 33.4 34.3 71.3 32.6 37.45 25.12 6222.70 166.17

0.6 499 33.4 34.4 70.5 32.4 36.60 41.87 10371.16 283.38

0.8 599 33.6 34.4 71.2 32.6 37.20 44.66 11062.57 297.39

1 383 33.6 34.5 71.4 32.7 37.35 62.80 15556.74 416.53

1.2 571 33.8 34.7 72.8 32.9 38.55 75.36 18668.09 484.28

1.4 665 34 34.9 71.7 33 37.25 87.92 21779.44 584.71

0.000

50.000

100.000

150.000

200.000

250.000

300.000

34 35 36 37 38 39 40

H

e

a

t

C

o

e

f

f

i

c

i

e

n

t

Tsat-Tsurf

Heat coefficient vs Tsat-Tsurf

Heat

coefficient

12

Graph 8: The heat coefficient vs Tsat-Tsurf for dropwise with 1% air

Graph 9: The heat coefficient vs Tsat-Tsurf for filmwise with and without 1% of air

0.00

100.00

200.00

300.00

400.00

500.00

600.00

700.00

38 38.5 39 39.5 40

H

e

a

t

C

o

e

f

f

i

c

i

e

n

t

Tsat-Tsurf

Heat coefficient vs Tsat-Tsurf

Heat

coefficient

0.00

50.00

100.00

150.00

200.00

250.00

300.00

34 35 36 37 38 39 40

H

e

a

t

c

o

e

f

f

i

c

i

e

n

t

Tsat-Tsurf

Heat coefficient vs Tsat-t surf for filmwise

without air

with air

13

Graph 10: The heat coefficient vs Tsat-Tsurf for dropwise with and without 1% of air

DISCUSSIONS

In this experiment we are mostly investigate about the film boiling condensation by

using the SOLTEQ Film and Dropwise Condensation Unit (Model: HE 163). There are 4 objectives that

must be accomplished. For the experiment 1, we have to demonstrate the filmwise and dropwise

condensation. From this experiment, we are able to describe the characteristics of filmwise and

dropwise condensation. In filmwise condensation, most materials used in the construction of heat

exchangers are wettable and during the condensation a film condensate spreads over the surface.

More vapour condenses onto the outside of this film will increases its thickness and causes the flow

downward and drip from the lowest points. The heat given up by the vapour during condensation is

conducted through the film. During filmwise condensation a layer of condensate covers the cool surface

and this will causes the resistance to the transfer of heat. However, for the dropwise condensation the

material used in the construction is non-wet table .When the steam condenses, a large number of

spherical forms on its surface. These beads become larger and then the trickle downwards. The moving

bead gathers all the static beads along its downward path, becomes larger, accelerates and leaves a

virtually bare surface in its trail.

For experiment 2 and 3, theoretically there is a big difference from the graph for the dropwise

and filmwise condensation based on its heat transfer coefficient and temperature difference. For

dropwise there is a relatively larger area heat transfer coefficient that proposes a larger value of heat

transfer during condensation. As for filmwise there is a smaller value of heat transfer and the larger area

on the graph that shows the larger margin of heat transfer value are at larger heat transfer value. But

for the errors that has ooccur, they didnt match for the desirable data.

0.00

100.00

200.00

300.00

400.00

500.00

600.00

700.00

20 25 30 35 40

H

e

a

t

c

o

e

f

f

i

c

i

e

n

t

Tsat-Tsurf

Heat coefficient vs Tsat-t surf for dropwise

without air

with air

14

For experiment 4, theoretically, the clear difference between both heat transfer coefficient and

temperature difference for filmwise and dropwise condensation is for dropwise with the present of air

there is a larger value of heat transfer coefficient at a small temperature difference rather than for

filmwise that shows a smaller value of heat transfer coefficient and at a more larger difference of

temperature. The analysis for the data collected is that heat flux shows a clear difference due to the

presence of air. With the presence of air the heat flux value is smaller. Dropwise condensation is far

more efficient for condensation process due to the specifications for each plate surface. However we

are not able to achieve the desired outcome due to some errors.

The errors involve that effect the results is due to fluid involve for the process of condensation to

occur. The impurities that contain within the fluid involve has effect the density and boiling temperature

that occur at a much lower temperature. Thus condensation occurs at a less precise order and resulting

in impairment data.

CONCLUSION

For experiment 2 and 3, we have concluded that the dropwise condensation heat flux and

surface heat transfer coefficient at constant pressure occur at a relatively larger value at smaller

temperature difference than for filmwise condensation. Thus efficient condensation

For experiment 4, we have demonstrate the effect of air on heat transfer coefficient of

condensation for dropwise and filmwise, it concluded that dropwise has a more stable and larger heat

transfer value for condensation process thus a more efficient condensation process.

RECOMMENDATIONS

1. Avoid error in taking readings and make sure eyes of observer are parallel to the meniscus

2. Make sure the valve are close tightly when the film condensation equipment is turn off.

3. Make sure all the valve close at the beginning of the experiment

4. Allow the cooling water to flow at the end of the experiment before the equipment is shut down to

avoid the cracking of cylindrical tube.

REFERENCES

1) Aksan, S. N. and Rose, J. W. (1973). Dropwise condensationthe effect of thermal properties of

the condenser material. Int. J. Heat Mass Transfer, 16, 461-467.

2) Blackman, L. C. F., Dewar, M. S. J. and Hampson, H. (1957). Compounds for promoting dropwise

condensation of steam. J. Appl. Chem., 7, 160-171.

Date of search: 27/5/2013

http://www.freepatentsonline.com/5048600.html

15

http://www.p-a-hilton.co.uk/English/Products/Heat_Transfer/heat_transfer.html

http://wins.engr.wisc.edu/teaching/mpfBook/node9.html

Date of search: 30/5/2013

http://www.focus-science.com/pahilton-heattransfer-h910.html

http://www.springerlink.com/content/46322536602154p1/

http://www.scribd.com/doc/22992765/Dropwise-and-Fimwise-Condensation-Lab-Report

http://www.husni.net/Labs/Files/HeatTransfer/Exp6.pdf

http://www.springerlink.com/content/u2882206203n3788/

16

Das könnte Ihnen auch gefallen

- Filmwise and Dropwise ExperimentDokument16 SeitenFilmwise and Dropwise ExperimentGoodMarissa100% (5)

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemVon EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNoch keine Bewertungen

- Filmwise and Dropwise ExperimentDokument33 SeitenFilmwise and Dropwise ExperimentValentinoDullSatin100% (2)

- Filmwise and Dropwise ExperimentDokument33 SeitenFilmwise and Dropwise ExperimentRizuan Hakim100% (1)

- Film Boiling Condensation ExperimentDokument17 SeitenFilm Boiling Condensation ExperimentTengku AshrafNoch keine Bewertungen

- Name Group Experimen T Date Prog/CodeDokument23 SeitenName Group Experimen T Date Prog/CodeAdnan NandaNoch keine Bewertungen

- Film Boiling CondensationDokument5 SeitenFilm Boiling CondensationMohamad Fahmi Abd Rased100% (3)

- Lab Report 5 - Group 7 - Eh2203cDokument21 SeitenLab Report 5 - Group 7 - Eh2203cAriff HaiqalNoch keine Bewertungen

- Filmdropwise LabDokument47 SeitenFilmdropwise Labaizaqsyazwan50% (2)

- Experiment Filmwise and Dropwise Condensation - Che486 - SyahrulamirulhisyamDokument14 SeitenExperiment Filmwise and Dropwise Condensation - Che486 - Syahrulamirulhisyamsyahrul myrolNoch keine Bewertungen

- Heat and Mass Transfer: Experiment No - 7Dokument9 SeitenHeat and Mass Transfer: Experiment No - 7Sakshi YadavNoch keine Bewertungen

- CHE486 - EXPERIMENT 7 (Film Boiling Condensation) UiTMDokument11 SeitenCHE486 - EXPERIMENT 7 (Film Boiling Condensation) UiTMHaikal SuhaimiNoch keine Bewertungen

- Lecture n.8 CondenserDokument33 SeitenLecture n.8 CondenserAtif MehfoozNoch keine Bewertungen

- Experiment No. 7: Objective: Apparatus: ComponentsDokument5 SeitenExperiment No. 7: Objective: Apparatus: ComponentsHannanNoch keine Bewertungen

- Lecture - 3Dokument15 SeitenLecture - 3Tadele BekeleNoch keine Bewertungen

- Dropwise and Filmwise CondensationDokument20 SeitenDropwise and Filmwise CondensationRaviyank Patel100% (1)

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDokument35 Seiten6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNoch keine Bewertungen

- Second: Heat Transfer Correlations For Flow Boiling Heat TransferDokument9 SeitenSecond: Heat Transfer Correlations For Flow Boiling Heat Transfermalek mustafaNoch keine Bewertungen

- HMT Unit 4Dokument21 SeitenHMT Unit 4Muthuvel MNoch keine Bewertungen

- Boiling and CondensationDokument5 SeitenBoiling and CondensationChaubey AjayNoch keine Bewertungen

- Condensation and BoilingDokument8 SeitenCondensation and BoilingShivananda D CNoch keine Bewertungen

- Unit ConversionDokument20 SeitenUnit ConversionHimanshu YadavNoch keine Bewertungen

- Dropwide and Film CondensationDokument10 SeitenDropwide and Film CondensationAmoluck BhatiaNoch keine Bewertungen

- Lab 03 - Film & Dropwise CondensationDokument14 SeitenLab 03 - Film & Dropwise CondensationMuhammad FarhanNoch keine Bewertungen

- Heat Transfer in Drop and Film Wise CondensationDokument4 SeitenHeat Transfer in Drop and Film Wise CondensationSasmita BalNoch keine Bewertungen

- Falling Film Evaporators WorkDokument9 SeitenFalling Film Evaporators WorkWaiz Khan Waiz KhanNoch keine Bewertungen

- 1-2 Horizental CondenserDokument23 Seiten1-2 Horizental Condenserusman0553100% (4)

- Closed Feed Water HeatersDokument56 SeitenClosed Feed Water HeatersAnudeep ChittluriNoch keine Bewertungen

- PROJECT On CondensationDokument23 SeitenPROJECT On Condensationnabajyoti19877363100% (1)

- Mass Transfer Lab Presentation: By-Shubham Sachan Rajdeep Singh Shashwat Tiwari Sahil YadavDokument21 SeitenMass Transfer Lab Presentation: By-Shubham Sachan Rajdeep Singh Shashwat Tiwari Sahil Yadavbadshah sharmaNoch keine Bewertungen

- Report On CondenserDokument5 SeitenReport On CondenserDheeraj Shukla100% (1)

- Unit Iii Phase Change Heat Transfer & Heat Exchangers: Department of Mechanical Global Institute Oe Engg&TechDokument9 SeitenUnit Iii Phase Change Heat Transfer & Heat Exchangers: Department of Mechanical Global Institute Oe Engg&TechMohanraj SubramaniNoch keine Bewertungen

- Filmwise & DropwiseDokument4 SeitenFilmwise & DropwiseAhmad IfwatNoch keine Bewertungen

- 12 Heat Transfer in Falling Film EvaporatorsDokument2 Seiten12 Heat Transfer in Falling Film EvaporatorsZahraNoch keine Bewertungen

- Boiling Heat Transfer Prac Report 21909068 K RamabulanaDokument16 SeitenBoiling Heat Transfer Prac Report 21909068 K RamabulanaAnele HadebeNoch keine Bewertungen

- Drop Wise and Film Wise CondensationDokument20 SeitenDrop Wise and Film Wise CondensationRamya MNoch keine Bewertungen

- Lab 7 Filmwise and Dropwise CondensationDokument10 SeitenLab 7 Filmwise and Dropwise Condensationathirah100% (1)

- Lab 7 ThermoDokument25 SeitenLab 7 Thermoadib assoliNoch keine Bewertungen

- Cooling Tower Lab ReportDokument20 SeitenCooling Tower Lab Reportgodfrey100% (1)

- Climbing FilmDokument34 SeitenClimbing FilmTunji Aminu100% (1)

- Investigation of The Effect of Cooling Load On Cooling Tower Performance Thermodynamic Exp 6Dokument14 SeitenInvestigation of The Effect of Cooling Load On Cooling Tower Performance Thermodynamic Exp 6hayder alaliNoch keine Bewertungen

- Comparison of Film Boiling and Nucleate BoilingDokument8 SeitenComparison of Film Boiling and Nucleate BoilingAlphy ThomasNoch keine Bewertungen

- Report Cooling TowerDokument15 SeitenReport Cooling TowerAnonymous HikwNM092% (13)

- Steam Condensation ReportDokument17 SeitenSteam Condensation ReportKingsley EdemidiongNoch keine Bewertungen

- Dropwise and Filmwise Condensation PDFDokument5 SeitenDropwise and Filmwise Condensation PDFmustafa100% (2)

- Reboilers and VaporizersDokument20 SeitenReboilers and Vaporizers58 - Darshan ShahNoch keine Bewertungen

- Reboiler and VaporiserDokument56 SeitenReboiler and Vaporiserjihad jamareiNoch keine Bewertungen

- Ngaatendwe Velah Mine Ventilation G0202267P Ass1Dokument8 SeitenNgaatendwe Velah Mine Ventilation G0202267P Ass1Tinotenda MorganNoch keine Bewertungen

- Column Pressure ControlDokument11 SeitenColumn Pressure Controlrvkumar61Noch keine Bewertungen

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Falling Film EvaporatorDokument39 SeitenFalling Film Evaporatormailnehru8955Noch keine Bewertungen

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration Systembbaytl100% (1)

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Pertemuan 7 OTK II - 21 Oktober 023Dokument69 SeitenPertemuan 7 OTK II - 21 Oktober 023latifahhanum237Noch keine Bewertungen

- Condenser DesignDokument7 SeitenCondenser Designemesam100% (2)

- Steam Jet Refrigeration SystemDokument6 SeitenSteam Jet Refrigeration SystembbaytlNoch keine Bewertungen

- Image:, Int - Entertainment, Int - Business - Finance - SMEDokument1 SeiteImage:, Int - Entertainment, Int - Business - Finance - SMEHafizszul FeyzulNoch keine Bewertungen

- The Law Not Even Leaders Says DR M/#Ta8Czjwfbep5Qmwz.99Dokument1 SeiteThe Law Not Even Leaders Says DR M/#Ta8Czjwfbep5Qmwz.99Hafizszul FeyzulNoch keine Bewertungen

- HDokument2 SeitenHHafizszul FeyzulNoch keine Bewertungen

- Then She Loses Her Hubby/#Xoxth42Jreem4Fhu.99Dokument1 SeiteThen She Loses Her Hubby/#Xoxth42Jreem4Fhu.99Hafizszul FeyzulNoch keine Bewertungen

- Then She Loses Her Hubby/#Xoxth42Jreem4Fhu.99Dokument1 SeiteThen She Loses Her Hubby/#Xoxth42Jreem4Fhu.99Hafizszul FeyzulNoch keine Bewertungen

- RDokument1 SeiteRHafizszul FeyzulNoch keine Bewertungen

- Flash Floods in Penang 46 Evacuated/#Fgqelwoajvfqyysa.99Dokument1 SeiteFlash Floods in Penang 46 Evacuated/#Fgqelwoajvfqyysa.99Hafizszul FeyzulNoch keine Bewertungen

- GDokument4 SeitenGHafizszul FeyzulNoch keine Bewertungen

- Petaling JayaDokument1 SeitePetaling JayaHafizszul FeyzulNoch keine Bewertungen

- Bab 1 Matematik Tingkatan 3 Sudut Dan Garis IIDokument1 SeiteBab 1 Matematik Tingkatan 3 Sudut Dan Garis IIHafizszul FeyzulNoch keine Bewertungen

- Kuala LumpurDokument1 SeiteKuala LumpurHafizszul FeyzulNoch keine Bewertungen

- A Big Airline Will Carry Out A Special Programme For The Constituents in Port Dickson SoonDokument1 SeiteA Big Airline Will Carry Out A Special Programme For The Constituents in Port Dickson SoonHafizszul FeyzulNoch keine Bewertungen

- Who Is The Ideal Candidate For The Badminton Association of MalaysiaDokument2 SeitenWho Is The Ideal Candidate For The Badminton Association of MalaysiaHafizszul FeyzulNoch keine Bewertungen

- Unit Map Unit 1 Things I DoDokument2 SeitenUnit Map Unit 1 Things I DoAtiqah HanifNoch keine Bewertungen

- Chapter 20 PDFDokument67 SeitenChapter 20 PDFHafizszul FeyzulNoch keine Bewertungen

- UNIT 1 Task Procedures RDokument5 SeitenUNIT 1 Task Procedures ROwlNoch keine Bewertungen

- Fakulti: Program: Ijazah Sarjana Muda Pentadbiran Korporat (Kepujian) - Am225 Mod Pengajian: Sepenuh MasaDokument2 SeitenFakulti: Program: Ijazah Sarjana Muda Pentadbiran Korporat (Kepujian) - Am225 Mod Pengajian: Sepenuh MasaHafizszul FeyzulNoch keine Bewertungen

- Chapter 20 PDFDokument67 SeitenChapter 20 PDFHafizszul FeyzulNoch keine Bewertungen

- 3pages 5Dokument3 Seiten3pages 5Paradarami SaytuNoch keine Bewertungen

- Grammar Module Year 3Dokument39 SeitenGrammar Module Year 3Janet CheeNoch keine Bewertungen

- Chapter 25Dokument17 SeitenChapter 25Hafizszul FeyzulNoch keine Bewertungen

- Chapter 23Dokument33 SeitenChapter 23hafizszul AmirushamNoch keine Bewertungen

- Quantization of Light (3 Hours)Dokument12 SeitenQuantization of Light (3 Hours)Hafizszul FeyzulNoch keine Bewertungen

- Torrent Uploaded by (Almoullim, AKA AMChanics)Dokument1 SeiteTorrent Uploaded by (Almoullim, AKA AMChanics)Hafizszul FeyzulNoch keine Bewertungen

- Resume (Epoms)Dokument6 SeitenResume (Epoms)Hafizszul FeyzulNoch keine Bewertungen

- RajeshdhannaDokument4 SeitenRajeshdhannaPrakash BabuNoch keine Bewertungen

- CV Page02Dokument1 SeiteCV Page02Hafizszul FeyzulNoch keine Bewertungen

- CV PDFDokument2 SeitenCV PDFHafizszul FeyzulNoch keine Bewertungen

- Resume AMIRUL 2014Dokument5 SeitenResume AMIRUL 2014Hafizszul FeyzulNoch keine Bewertungen

- 1page 8Dokument1 Seite1page 8vianfulloflifeNoch keine Bewertungen

- Matter and Substances.: 4.1 Changes in The States of Matter. Kinetic Theory of MatterDokument15 SeitenMatter and Substances.: 4.1 Changes in The States of Matter. Kinetic Theory of MatterElly EllynaNoch keine Bewertungen

- Liquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessDokument8 SeitenLiquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessHaru MasaNoch keine Bewertungen

- UV-VS Method For Analysis of Paracetamol PDFDokument9 SeitenUV-VS Method For Analysis of Paracetamol PDFAnonymous XFpX4E7Noch keine Bewertungen

- Determination of The Molecular Weight of Polymers From Viscosity MeasurementsDokument10 SeitenDetermination of The Molecular Weight of Polymers From Viscosity MeasurementsAbdullah MunawarNoch keine Bewertungen

- Experiment 5: Electrical Resistance and Ohm's LawDokument10 SeitenExperiment 5: Electrical Resistance and Ohm's LawsyafNoch keine Bewertungen

- Ex. 7. Winogradsky ColumnDokument6 SeitenEx. 7. Winogradsky ColumnPrecious Mae Cuerquis BarbosaNoch keine Bewertungen

- Challenges Associated With Expansive Soils and Remedial MeasuresDokument13 SeitenChallenges Associated With Expansive Soils and Remedial MeasuresSaurav BhattacharjeeNoch keine Bewertungen

- Me252 AdmcDokument262 SeitenMe252 AdmcNaniChinnuNoch keine Bewertungen

- Determination of Phytase Activity - Molybdate-Blue Method: A1. PrincipleDokument3 SeitenDetermination of Phytase Activity - Molybdate-Blue Method: A1. PrincipleyoshiNoch keine Bewertungen

- Guide On Designing A Solar Photovoltaic Powered DC Water PumpDokument6 SeitenGuide On Designing A Solar Photovoltaic Powered DC Water PumpDesmondNoch keine Bewertungen

- Quiz No. 1Dokument1 SeiteQuiz No. 1Juanito Jr OriginesNoch keine Bewertungen

- Dokumen - Pub - Rocket Propulsion 1108422276 9781108422277Dokument587 SeitenDokumen - Pub - Rocket Propulsion 1108422276 9781108422277Kyle OvertonNoch keine Bewertungen

- 3 MassSpectrometry - PPSXDokument13 Seiten3 MassSpectrometry - PPSXZebBrahviNoch keine Bewertungen

- Radicals PDFDokument34 SeitenRadicals PDFadelNoch keine Bewertungen

- Sds Zinc RevDokument11 SeitenSds Zinc RevAlfred Sandro SimanullangNoch keine Bewertungen

- Lithology and Porosity Determination: Mark of SchlumbergerDokument13 SeitenLithology and Porosity Determination: Mark of SchlumbergerSlim.B100% (1)

- (OFW) Oxy-Fuel Welding (Gas WeldingOxy-Acetylene Welding)Dokument6 Seiten(OFW) Oxy-Fuel Welding (Gas WeldingOxy-Acetylene Welding)Mohamed AtefNoch keine Bewertungen

- Col A50Dokument1 SeiteCol A50Bryn rpNoch keine Bewertungen

- Material Selection HandbookDokument127 SeitenMaterial Selection HandbookAdi SutardiNoch keine Bewertungen

- Coal Specs Sheet GAR 6400Dokument2 SeitenCoal Specs Sheet GAR 6400Adhitya AchmadNoch keine Bewertungen

- Design, Estimation and Costing of Sewage Treatment Plant A Case StudyDokument12 SeitenDesign, Estimation and Costing of Sewage Treatment Plant A Case Studyadarsh s100% (1)

- Conectores PostesDokument2 SeitenConectores PostesHabiran GonzalezNoch keine Bewertungen

- Bossard White Paper Stainless Steel and Galling ENDokument10 SeitenBossard White Paper Stainless Steel and Galling ENsklNoch keine Bewertungen

- Essay-Outline-Template For Plate TectonicsDokument2 SeitenEssay-Outline-Template For Plate TectonicsHarsha PasupulatiNoch keine Bewertungen

- Stoichiometry Basics NotesDokument5 SeitenStoichiometry Basics NoteswardaNoch keine Bewertungen

- Edexcel - Chemistry - Topics 9 & 10 - KnowIT - AS - A LevelDokument73 SeitenEdexcel - Chemistry - Topics 9 & 10 - KnowIT - AS - A LevelmariaNoch keine Bewertungen

- Exercise Problems: Palara, Arman S. (Inc) SPL Ce 5BDokument23 SeitenExercise Problems: Palara, Arman S. (Inc) SPL Ce 5BKristel LenonNoch keine Bewertungen

- 5.17 - A10706002 - Lely Ayu NingsihDokument8 Seiten5.17 - A10706002 - Lely Ayu NingsihLely Ayu NingsihNoch keine Bewertungen

- Physics For Engineers II PHYS 1220Dokument59 SeitenPhysics For Engineers II PHYS 1220Naiem IslamNoch keine Bewertungen

- Base ShearDokument3 SeitenBase ShearLaxman ShresthaNoch keine Bewertungen

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (58)

- Highest Duty: My Search for What Really MattersVon EverandHighest Duty: My Search for What Really MattersNoch keine Bewertungen

- Hero Found: The Greatest POW Escape of the Vietnam WarVon EverandHero Found: The Greatest POW Escape of the Vietnam WarBewertung: 4 von 5 Sternen4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonVon EverandSully: The Untold Story Behind the Miracle on the HudsonBewertung: 4 von 5 Sternen4/5 (103)

- The End of Craving: Recovering the Lost Wisdom of Eating WellVon EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellBewertung: 4.5 von 5 Sternen4.5/5 (81)

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Reality+: Virtual Worlds and the Problems of PhilosophyVon EverandReality+: Virtual Worlds and the Problems of PhilosophyBewertung: 4 von 5 Sternen4/5 (24)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- Pale Blue Dot: A Vision of the Human Future in SpaceVon EverandPale Blue Dot: A Vision of the Human Future in SpaceBewertung: 4.5 von 5 Sternen4.5/5 (588)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- Packing for Mars: The Curious Science of Life in the VoidVon EverandPacking for Mars: The Curious Science of Life in the VoidBewertung: 4 von 5 Sternen4/5 (1395)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaVon EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNoch keine Bewertungen

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4 von 5 Sternen4/5 (5)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (122)

- The Weather Machine: A Journey Inside the ForecastVon EverandThe Weather Machine: A Journey Inside the ForecastBewertung: 3.5 von 5 Sternen3.5/5 (31)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterVon EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterBewertung: 5 von 5 Sternen5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNoch keine Bewertungen

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureVon EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureBewertung: 5 von 5 Sternen5/5 (125)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationVon EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationBewertung: 4.5 von 5 Sternen4.5/5 (46)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseVon EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseBewertung: 3.5 von 5 Sternen3.5/5 (12)