Beruflich Dokumente

Kultur Dokumente

Astm C0567 - 1 (En)

Hochgeladen von

msohaibaziz0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

119 Ansichten3 SeitenConstruction learning

Originaltitel

ASTM C0567_1 (EN)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenConstruction learning

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

119 Ansichten3 SeitenAstm C0567 - 1 (En)

Hochgeladen von

msohaibazizConstruction learning

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

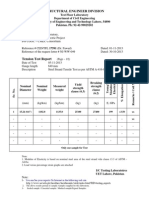

Designation: C 567 00

Standard Test Method for

Determining Density of Structural Lightweight Concrete

1

This standard is issued under the xed designation C 567; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method provides procedures to determine the

oven-dry and equilibrium densities of structural lightweight

concrete.

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 31/C 31M Practice for Making and Curing Concrete Test

Specimens in the Field

2

C 88 Test Method for Soundness of Aggregates by Use of

Sodium Sulfate or Magnesium Sulfate

2

C 125 Terminology Relating to Concrete and Concrete

Aggregates

2

C 138 Test Method for Unit Weight, Yield, and Air Content

(Gravimetric) of Concrete

2

C 172 Practice for Sampling Freshly Mixed Concrete

2

C 192/C 192M Practice for Making and Curing Concrete

Test Specimens in the Laboratory

2

C 470/C 470M Specication for Molds for Forming Con-

crete Test Cylinders Vertically

2

E 104 Practice for Maintaining Constant Relative Humidity

by Means of Aqueous Solutions

3

3. Terminology

3.1 Terminology used in this test method is dened in

Terminology C 125.

3.2 Denitions of Terms Specic to This Standard:

3.2.1 equilibrium density, nthe density as determined in

8.2 reached by structural lightweight concrete after exposure to

relative humidity of 50 6 5 % and a temperature of 23 6 2C

(73.5 6 3.5F) for a period of time sufficient to reach constant

mass.

3.2.2 oven-dry densitythe density as determined in 8.3

reached by structural lightweight concrete after being placed in

a drying oven at 110 6 5C (230 6 9F) for a period of time

sufficient to reach constant mass.

4. Summary of Test Method

4.1 This test method provides procedures for determining

the oven-dry and equilibrium densities of structural lightweight

concrete, by calculation or measurement. The calculated oven-

dry density is determined from batch quantities and volume of

a given batch of concrete. The calculated equilibrium density is

approximated by adding a xed quantity to the oven-dry

density. Measured densities are obtained from determinations

of the mass of cylindrical specimens after specied treatments.

5. Signicance and Use

5.1 The measured or calculated equilibrium density of

structural lightweight concrete determines whether specied

density requirements have been met. Unless otherwise speci-

ed, determine equilibrium density by calculation using the

procedures in 9.2.

5.2 Test Method C 138 shall be used to determine the

density of freshly mixed lightweight concrete for compliance

with concrete placement specications.

NOTE 1The fresh density of lightweight aggregate concrete is a

function of mixture proportions, air content, water demand, and the

specic density and moisture content of the lightweight aggregate.

Decrease in density of a specic lightweight concrete is due to moisture

loss that, in turn, is a function of aggregate moisture content, ambient

conditions, and the ratio of the surface area to the volume of the concrete

member. For most structural lightweight concretes, equilibrium density is

approached at about 90 days. For most high-strength lightweight con-

cretes, equilibrium density is approached at about 180 days. Extensive

tests demonstrate that despite variations in the initial moisture content of

lightweight aggregate, the equilibrium density will be approximately 50

kg/m

3

(3.0 lb/ft

3

) greater than the oven-dry density.

6. Apparatus

6.1 Tamping Rod, Mallet, Measure, Balance, and Molds

These shall conform to the requirements of Test Method C 138

1

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.21 on Lightweight Aggregates and Concrete.

Current edition approved July 10, 2000. Published September 2000. Originally

published as C 567 65 T. Last previous edition C 567 99a.

2

Annual Book of ASTM Standards, Vol 04.02.

3

Annual Book of ASTM Standards, Vol 11.03.

1

Copyright ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

and Specication C 470.

6.1.1 MeasureA 14-L (0.5-ft

3

) measure shall be the stan-

dard (see Note 3).

6.2 Controlled Humidity EnclosureA room controlled at

50 6 5 % relative humidity and 23 6 2C (73.5 6 3F) or a

small chamber meeting the requirements of Practice E 104.

6.3 Drying OvenAn oven of appropriate size capable of

maintaining a uniform temperature of 1106 5C (230 6 9F),

and an average evaporation rate of at least 25 g/h. Determine

evaporation rate in accordance with Test Method C 88.

7. Sampling, and Making, and Curing Test Specimens

7.1 SamplingSample eld-mixed concrete in accordance

with Practice C 172.

7.2 Specimens for Determining Equilibrium Density and

Oven-dry DensityDetermine the equilibrium density and

oven-dry density on 150 by 300-mm (6 by 12-in.) concrete

cylinders.

7.2.1 Make test cylinders in accordance with Practice

C 192/C 192M or C 31/C 31M, whichever is applicable. Make

three cylinders for equilibrium density measurements, and

make three cylinders for oven-dry density measurements.

7.3 Curing Specimens:

7.3.1 Unless otherwise specied, test cylinders used for the

determination of equilibrium density shall be cured in accor-

dance with Practice C 192/C 192M or the standard curing

procedure in Practice C 31/C 31M for six days.

NOTE 2Cylinders may be stripped after 24 h and wrapped securely

with a plastic sheet or bag to prevent loss of moisture, or may remain in

covered molds until the time of test.

7.3.2 Unless otherwise specied, for the rst 24 h or until

the time of test, store the test cylinders used for the determi-

nation of oven-dry density under conditions that maintain a

temperature adjacent to the cylinders in the range from 16 to

27C (60 to 80F) and that prevent loss of moisture from the

cylinders.

8. Procedure

8.1 Measurement of Freshly Mixed Concrete Density

Determine the density of the freshly mixed concrete in accor-

dance with Test Method C 138.

NOTE 3Numerous observations indicate that the same compactive

effort used on smaller concrete specimens will cause the fresh densities to

be higher. The fresh density as determined from measurements on 150 by

300-mm (6 by 12-in.) cylinders of lightweight concrete consolidated by

rodding, in accordance with Practice C 192/C 192M or Practice C 31/

C 31M will average 40 kg/m

3

(2.5 lb/ft

3

) higher than the fresh density as

measured using a 14-L (0.5-ft

3

) measure in accordance with Test Method

C 138.

8.2 Measurement of Equilibrium DensityTo measure the

equilibrium density, remove the cylinders from their curing

condition on the sixth day and immerse in water at 23 6 2C

(73.5 6 3F) for 24 h. Measure the apparent mass of the

cylinders while suspended and completely submerged in water

and record as C, the mass of the suspended-immersed

cylinder. Remove from the water and allow to drain for 1 min

by placing the cylinder on a 9.5-mm (

3

8-in.) or coarser sieve

cloth. Remove visible water with a damp cloth, determine the

mass and record as B, the mass of the saturated-surface-dry

cylinder. Dry the cylinders with all surfaces exposed, in a

controlled humidity enclosure as described in 6.2 until the

mass of the specimen changes not more than 0.5 % (gain or

loss) in successive determinations of mass 28 days apart.

Determine the mass of the dried cylinders and record as A,

the mass of the dried cylinder. Calculate the equilibrium

density of the concrete from Eq 1 and 2.

E

m

~Density, kg/m

3

! 5~A 3 997! / ~B2C! (1)

E

m

~Density, lb/ft

3

! 5~A 3 62.3! / ~B2C!! (2)

where:

E

m

= measured equilibrium density, kg/m

3

(lb/ft

3

,

A = mass of cylinder as dried, kg (lb),

B = mass of saturated surface-dry cylinder, kg (lb), and

C = apparent mass of suspended-immersed cylinder, kg

(lb).

8.3 Measurement of Oven-Dry DensityAfter 24 h but not

to exceed 32 h, remove the cylinders from the mold (see Note

4). Measure the apparent mass of the cylinders while sus-

pended and completely submerged in water and record as G

the mass of the suspended-immersed cylinders. Remove from

the water and allow to drain for 1 min by placing the cylinders

on a 9.5-mm (

3

8-in.) or coarser sieve cloth. Remove visible

water with a damp cloth, determine the mass and record as F,

the mass of the saturated surface-dry cylinders. Place the

cylinders in the drying oven for 72 h or until constant mass is

reached. Maintain oven temperature at 110 65C (230 69F).

Allow cylinders to cool to room temperature and determine the

mass and record as D, the mass of the oven-dried cylinder.

Repeat oven-drying and determination of mass at 24-h inter-

vals until the mass of the specimen changes not more than

0.5 % in successive weighings 24 h apart. Determine the

oven-dry density from Eq 3 and 4.

O

m

~Density, kg/m

3

!5~D 3 997! / ~F2G! (3)

O

m

~Density, lb/ft

3

!5~D 3 62.3! / ~F2G!! (4)

where:

O

m

= measured oven-dry density, kg/m

3

(lb/ft

3

),

D = mass of oven-dry cylinder, kg (lb),

F = mass of saturated surface-dry cylinder, kg (lb), and

G = apparent mass of suspended-immersed cylinder, kg

(lb).

NOTE 4Determination of oven-dry density may be specied to begin

at an age other than 24-h.

9. Calculation

9.1 Calculation of Oven-Dry DensityWhere mixture

quantities, aggregate moisture content, and the volume of the

concrete batch are known, calculate an oven-dry density using

Eq 5.

O

c

5~M

df

1 M

dc

1 1.2 M

ct

! / V (5)

where:

O

c

= calculated oven-dry density, kg/m

3

(lb/ft

3

),

M

df

= mass of dry ne aggregate in batch, kg(lb),

M

dc

= mass of dry coarse aggregate in batch, kg(lb),

M

ct

= mass of cement in batch, kg (lb),

C 567

2

1.2 = factor to approximate the mass of cement plus

chemically combined water, and

V = volume of concrete produced by the batch m

3

(ft

3

).

9.2 Calculation of Approximate Equilibrium Density

Using the oven-dry density determined in accordance with 8.3

or 9.1, calculate the approximate equilibrium density from Eq

6 and 7.

E

c

5 O

c

1 50 kg/m

3

~3 lb/ft

3

! (6)

or

E

c

5 O

m

1 50 kg/m

3

~3 lb/ft

3

! (7)

where:

E

c

= calculated equilibrium density (see Note 1).

10. Report

10.1 When oven-dry and equilibrium densities are deter-

mined by measurements, the report shall include following

information:

10.1.1 Fresh density, kg/m

3

(lb/ft

3

).

10.1.2 Mass of suspended-immersed cylinder, kg (lb).

10.1.3 Mass of saturated surface dry cylinder, kg (lb).

10.1.4 Mass of cylinder after reaching equilibrium, kg (lb).

10.1.5 Equilibrium density reported to nearest 10 kg/m

3

(0.5

lb/ft

3

).

10.1.6 Age at which equilibrium was reached, days.

10.1.7 Mass of oven-dry cylinder, kg (lb).

10.1.8 Oven-dry density rounded to the nearest 10 kg/m

3

(0.5 lb/ft

3

).

10.2 When oven-dry and approximate equilibrium densities

are determined by calculation, report the following informa-

tion:

10.2.1 Fresh density, kg/m

3

(lb/ft

3

).

10.2.2 Mass of cement and dry aggregates, batched, kg (lb).

10.2.3 Volume of concrete produced from the batch, m

3

(ft

3

).

10.2.4 Calculated oven-dry density, to the nearest 10 kg/m

3

(0.5 lb/ft

3

).

10.2.5 Calculated approximate equilibrium density, to the

nearest 10 kg/m

3

(0.5 lb/ft

3

).

11. Precision and Bias

11.1 PrecisionThe precision of this test method has not

yet been determined, but an industry-wide multilaboratory

testing program is being coordinated. The precision statements

will be included when the data is compiled and reviewed.

11.2 BiasBias for this test method cannot be determined

since there is no reference standard available for comparison.

12. Keywords

12.1 equilibrium density; lightweight concrete; oven-dry

density

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

C 567

3

Das könnte Ihnen auch gefallen

- LaDOTD - 2002 - Drilled Shaft Foundation Construction Inspection ManualDokument49 SeitenLaDOTD - 2002 - Drilled Shaft Foundation Construction Inspection ManualdjerollemanNoch keine Bewertungen

- DOE MethodDokument20 SeitenDOE MethodNor Khuzaimah Ab HamidNoch keine Bewertungen

- ARC (AU) - Reinforcement Handbook, Your Guide To Steel ReinformecentDokument78 SeitenARC (AU) - Reinforcement Handbook, Your Guide To Steel Reinformecentmica100% (1)

- 4 Construction Standard Cs3 2013 Aggregates For ConcreteDokument37 Seiten4 Construction Standard Cs3 2013 Aggregates For ConcretesavsengineeringNoch keine Bewertungen

- Specs For Highway and Bridge ConstructionDokument629 SeitenSpecs For Highway and Bridge ConstructionmsohaibazizNoch keine Bewertungen

- Chapter 6 Recommendations and AppendicesDokument25 SeitenChapter 6 Recommendations and AppendicesmsohaibazizNoch keine Bewertungen

- Mix Design of ConcreteDokument14 SeitenMix Design of ConcreteRaju Shetty CjNoch keine Bewertungen

- Is 2502 1963Dokument31 SeitenIs 2502 1963Lokesh SharmaNoch keine Bewertungen

- Mix Design of ConcreteDokument14 SeitenMix Design of ConcreteRaju Shetty CjNoch keine Bewertungen

- Structural Engineer Division: (Page - 1/2)Dokument6 SeitenStructural Engineer Division: (Page - 1/2)msohaibazizNoch keine Bewertungen

- Fed STD 123Dokument7 SeitenFed STD 123msohaibazizNoch keine Bewertungen

- 2014amended4 7 2014Dokument971 Seiten2014amended4 7 2014Ant TtlNoch keine Bewertungen

- A Simple Guide To Concrete Cube TestingDokument4 SeitenA Simple Guide To Concrete Cube TestingmsohaibazizNoch keine Bewertungen

- BS en 12390-6 2000 (En)Dokument14 SeitenBS en 12390-6 2000 (En)msohaibazizNoch keine Bewertungen

- Is 1343 1980 R 1990Dokument65 SeitenIs 1343 1980 R 1990Venu PrasathNoch keine Bewertungen

- Astm Standart A416.1974Dokument7 SeitenAstm Standart A416.1974SetyasasmitaNoch keine Bewertungen

- Fed STD 123Dokument7 SeitenFed STD 123msohaibazizNoch keine Bewertungen

- Cylinder Strength Versus Cube StrengthDokument26 SeitenCylinder Strength Versus Cube Strengthfsirfan100% (2)

- Mil STD 129Dokument163 SeitenMil STD 129Steele Wagemaker100% (1)

- BS en 12390-7 2000 (En) PDFDokument12 SeitenBS en 12390-7 2000 (En) PDFmsohaibaziz100% (1)

- BS en 12390-7 2000 (En) PDFDokument12 SeitenBS en 12390-7 2000 (En) PDFmsohaibaziz100% (1)

- Astm D0448 - 1 (En)Dokument3 SeitenAstm D0448 - 1 (En)msohaibazizNoch keine Bewertungen

- STD 129 RDokument165 SeitenSTD 129 RmsohaibazizNoch keine Bewertungen

- Autocad and LispDokument65 SeitenAutocad and LispmsohaibazizNoch keine Bewertungen

- AASHTO T265 Moisture of SoilsDokument2 SeitenAASHTO T265 Moisture of SoilsRuss NesterNoch keine Bewertungen

- ACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207Dokument3 SeitenACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207msohaibaziz50% (4)

- Compressive Strength OF Cylindrical Concrete Specimens Aashto T 22 ApparatusDokument2 SeitenCompressive Strength OF Cylindrical Concrete Specimens Aashto T 22 ApparatusmsohaibazizNoch keine Bewertungen

- Metric ConversionDokument1 SeiteMetric ConversionKS CheeNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lord of The FliesDokument24 SeitenLord of The Fliesmaitane7875% (4)

- Tag QuestionsDokument5 SeitenTag QuestionsIna MoroşanuNoch keine Bewertungen

- Meteorological Report of Tropical Storm Sendong Washi - Initial AssessmentDokument11 SeitenMeteorological Report of Tropical Storm Sendong Washi - Initial AssessmentMyk Twentytwenty NBeyondNoch keine Bewertungen

- Proposal CATIA Project Group A8Dokument4 SeitenProposal CATIA Project Group A8Purawin SubramaniamNoch keine Bewertungen

- Enviro SearchDokument106 SeitenEnviro SearchLorenzo C. BautistaNoch keine Bewertungen

- Aircraft Accident ReportDokument9 SeitenAircraft Accident ReportMuhammad AsyrafNoch keine Bewertungen

- Steel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionDokument7 SeitenSteel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionIrfan Prima AldiNoch keine Bewertungen

- 249 Powerful Verbs Jerry JenkinsDokument5 Seiten249 Powerful Verbs Jerry JenkinsDamla Nihan Yildiz50% (2)

- AZORES NATURE Pelagic Trip Report 2016Dokument16 SeitenAZORES NATURE Pelagic Trip Report 2016Peter AlfreyNoch keine Bewertungen

- MVTR ProcessDokument12 SeitenMVTR ProcessMaheshBendale2014Noch keine Bewertungen

- Nuclear Regulatory Commission - Columbia Generating Station Report - May 6 2019Dokument28 SeitenNuclear Regulatory Commission - Columbia Generating Station Report - May 6 2019NWPB NewsNoch keine Bewertungen

- DeVry ENGL 216 Final Exam 100% Correct AnswerDokument7 SeitenDeVry ENGL 216 Final Exam 100% Correct AnswerDeVryHelpNoch keine Bewertungen

- British Weather - ExercisesDokument2 SeitenBritish Weather - Exercisescaladelmoral1994996100% (1)

- Report On Road Assesment For Wajir South Sub County 2015 To 2016Dokument6 SeitenReport On Road Assesment For Wajir South Sub County 2015 To 2016Abdirahim MohamedNoch keine Bewertungen

- WACA Entry Quiz HIMT 271115Dokument12 SeitenWACA Entry Quiz HIMT 271115jdNoch keine Bewertungen

- Rock Slope Design GuideDokument58 SeitenRock Slope Design GuideLeonardo RojasNoch keine Bewertungen

- Public Packet - 22116939 Offense - Incident - Death Report - IncidentDokument1 SeitePublic Packet - 22116939 Offense - Incident - Death Report - IncidentThe Western JournalNoch keine Bewertungen

- Changes To BS 5950: Part 8 and Implications For The Steel Construction IndustryDokument1 SeiteChanges To BS 5950: Part 8 and Implications For The Steel Construction IndustryLim Yew KwangNoch keine Bewertungen

- 6.integral Bridges Final ReportDokument21 Seiten6.integral Bridges Final Reportmanu_696100% (1)

- Mathematical Literacy P1 Eng Nov 2008Dokument18 SeitenMathematical Literacy P1 Eng Nov 2008bellydanceafrica9540Noch keine Bewertungen

- Welding Grooving ProcedureDokument19 SeitenWelding Grooving ProcedureAzhar Ali67% (3)

- Dealing in Doubt: The Climate Denial Industry and Climate ScienceDokument25 SeitenDealing in Doubt: The Climate Denial Industry and Climate ScienceGreenpeace Germany100% (2)

- Rio Tuba FR Vol - I Main Report 090618Dokument114 SeitenRio Tuba FR Vol - I Main Report 090618Alvin Garcia PalancaNoch keine Bewertungen

- Function 1 3 Chennai MMDDokument8 SeitenFunction 1 3 Chennai MMDmhegdenNoch keine Bewertungen

- Chris - Lab Report PDFDokument4 SeitenChris - Lab Report PDFChris ZhouNoch keine Bewertungen

- T203Dokument5 SeitenT203cnhathoangNoch keine Bewertungen

- 0031 - ND Rev - 2 14-Dec-15 Guidelines For Float-Over Installations and RemovalsDokument37 Seiten0031 - ND Rev - 2 14-Dec-15 Guidelines For Float-Over Installations and RemovalsdamnagedNoch keine Bewertungen

- 15 10 13 Tn17 ElectrofusionDokument12 Seiten15 10 13 Tn17 ElectrofusionErlinawati Bintu SupiyoNoch keine Bewertungen

- Threat and Error ManagementDokument56 SeitenThreat and Error Managementcincan7Noch keine Bewertungen

- Narayana Students Like YouDokument1 SeiteNarayana Students Like Youfareed_imadiNoch keine Bewertungen