Beruflich Dokumente

Kultur Dokumente

Drag Force Measurement

Hochgeladen von

Rezha Falaq RizkiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Drag Force Measurement

Hochgeladen von

Rezha Falaq RizkiCopyright:

Verfügbare Formate

1

3. Drag Force Measurement

OBJECTIVES:

1. Calculation of velocity profile in the wake of a two-dimensional cylinder.

2. Estimate the coefficient of drag and compare with values in the literature and

from the force balance

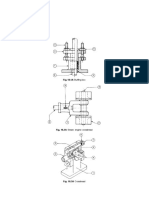

Figure 1, Armfield c2-10 subsonic wind tunnel.

THE EXPERIMENTAL UNIT:

The Armfield Wind Tunnel is simple and safe in operation. It is supplied as a complete

self-contained facility mounted on castors for ease of movement. Main equipment

comprises the tunnel with a two-component balance system and an air speed indicator.

Air enters the test section through a carefully designed contraction followed by an

aluminum honeycomb flow straightener designed to ensure that the flow is steady in both

magnitude and direction and has a flat transverse velocity profile.

A low angle diffuser at the outlet end contributes to flow stability in the test section. A

five bladed fan is located at the outlet of the diffuser section. The fan is driven by an AC

motor supplied from an inverter speed control unit, allowing smooth control of air speed.

The parallel octagonal test section is manufactured from clear acrylic and may be

retracted on rails to permit unobstructed access to the models. The two-component

balance consists of a pair of balances supported on knife edges on mutually perpendicular

axes parallel to and normal to the axial centre of the tunnel. Lift and drag components of

force exerted on the models under test are balanced by sliding weights along the arms of

the balance until a state of null deflection is reached. Graduations in units of force allow

lift and drag to be read directly. The complete assembly is linked to a simple oil filled

damping pot. Models are mounted on the balance within the working section and a

protractor with cursor allows angles of incidence to be changed quickly and accurately

while the tunnel is running.

The wind tunnel has a variable speed motor driven unit downstream of the working

section permitting stepless control of airspeed between 0 and 26ms-1. Balance: Lift and

drag Lift - 7.0N, Drag - 2.5N, Sensitivity 0.01N. Working section: 304mm wide x

304mm high x 457mm long (octagonal cross- section) . Contraction area ratio is 3:1.

Motor rating is 1.5kW.

Multi Tube Manometer

This is an inclinable manometer board equipped with 20 tubes, acrylic manifold and a

reservoir mounted on a vertical rod such that the position of the datum manometer tube

levels may be adjusted to convenient heights before commencing experiments. Scale

length is 370mm accommodating measurement of pressure up to 290mm water gauge.

This general purpose kerosene manometer is suitable for use with many Armfield model

accessories requiring pressure measurement (kerosene supplied).

PROCEDURE:

IN THE LAB:

1) Check all pressure tubes are connected to the multi-tube manometer

2) Check the model is firmly attached to the wind tunnel

3) Set the wind tunnel speed to the desired value and let it stabilize

4) Record manometer measurements for this setup as well as the rake distance from

the model

5) Use the force balance to measure the drag force on the object

6) Change the speed and repeat

The velocity profile in the wake is calculated as

(

The total pressure is measured by the pressure rake and the static pressure is measured by

the pitot-static tube mounted on the side wall.

Then the drag force is calculated as,

Where the area is the width of the rake times a unit length in the span-wise direction.

Finally the drag coefficient is given by

Table 1, Measurements Table

Run # 1 2 3 4 5

p

a

(cm Hg)

T

a

(C)

(m/s)

)

(x/D)

Re

1

R

a

k

e

T

o

t

a

l

p

r

e

s

s

u

r

e

m

e

a

s

u

r

e

m

e

n

t

s

(

m

m

H

2

O

)

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

()

()

()

()

Das könnte Ihnen auch gefallen

- 1 Mixing LectureDokument67 Seiten1 Mixing LectureMuntadher MahdiNoch keine Bewertungen

- Well blowout simulation for exploration well 5505/5-5 NewField NorthDokument34 SeitenWell blowout simulation for exploration well 5505/5-5 NewField NorthMEUBRONoch keine Bewertungen

- Fluid MachinesDokument161 SeitenFluid MachinesHaroon GhaniNoch keine Bewertungen

- Design Construction and Performance Test of A Low Cost Sub Sonic Wind TunnelDokument10 SeitenDesign Construction and Performance Test of A Low Cost Sub Sonic Wind TunnelSantosh Kumar VNoch keine Bewertungen

- Experimental Investigation of Stepped Aerofoil Using Propeller Test RigDokument4 SeitenExperimental Investigation of Stepped Aerofoil Using Propeller Test RigesatjournalsNoch keine Bewertungen

- Wind Load Calculation As Per EN1991-1!4!2005 - Rev 01 (By JR)Dokument2 SeitenWind Load Calculation As Per EN1991-1!4!2005 - Rev 01 (By JR)RigonDEC100% (2)

- Fluid Mechanics Lab Manual for Civil Engineering StudentsDokument29 SeitenFluid Mechanics Lab Manual for Civil Engineering Studentsvihangam yoga chandauli100% (1)

- AGA Report No 3 - Part 4 (Intro) PDFDokument10 SeitenAGA Report No 3 - Part 4 (Intro) PDFRidho Satya Amanda67% (3)

- Aircraft Stability and Control AssignmentDokument32 SeitenAircraft Stability and Control Assignmenttengyan100% (1)

- Fluid Mechanics-I Laboratory Manual: Prepared By: Mr. Pradeep Kuhar Approved By: Mr. Gaurav TanwarDokument30 SeitenFluid Mechanics-I Laboratory Manual: Prepared By: Mr. Pradeep Kuhar Approved By: Mr. Gaurav TanwarAeronautical Engineering HODNoch keine Bewertungen

- Specific Energy Hydraulic Jumps WeirsDokument23 SeitenSpecific Energy Hydraulic Jumps WeirsHaris jugnooNoch keine Bewertungen

- Sluice Gate ExperimentDokument1 SeiteSluice Gate Experimenttewodros getuNoch keine Bewertungen

- Missile Grid Fins Analysis Using Computational FluDokument19 SeitenMissile Grid Fins Analysis Using Computational FluÀdìtí ChoudhariNoch keine Bewertungen

- Fluid Mechanics and Hydraulic Machines Lab Manual PDFDokument55 SeitenFluid Mechanics and Hydraulic Machines Lab Manual PDFjyothiNoch keine Bewertungen

- Design of Wind TunnelDokument94 SeitenDesign of Wind TunnelVijayraj Singh Rathore0% (1)

- Drag On A Circular CylinderDokument17 SeitenDrag On A Circular CylinderBuddhima Nivantha BandaraNoch keine Bewertungen

- Revised LabDokument18 SeitenRevised LabAbu AyemanNoch keine Bewertungen

- Installation, Calibration and Testing of Low Speed Wind TunnelDokument22 SeitenInstallation, Calibration and Testing of Low Speed Wind TunnelRavi Kant100% (1)

- Airfoil DesignDokument18 SeitenAirfoil Designapi-269373691Noch keine Bewertungen

- Basic of Flow MeasurementDokument39 SeitenBasic of Flow MeasurementmrdomeniciNoch keine Bewertungen

- Measure Lift and Drag on an AirfoilDokument11 SeitenMeasure Lift and Drag on an AirfoilFanis VlazakisNoch keine Bewertungen

- Force Balance Design For Educational Wind TunnelsDokument10 SeitenForce Balance Design For Educational Wind Tunnelsnarien kondamNoch keine Bewertungen

- Permeability of Granular Soils (Constant Head) : Standard Test Method ForDokument5 SeitenPermeability of Granular Soils (Constant Head) : Standard Test Method ForEdwardNoch keine Bewertungen

- CFD Analysis of Flow Through A Conical ExhaustDokument26 SeitenCFD Analysis of Flow Through A Conical Exhaustrvnaveen26Noch keine Bewertungen

- Introduction To Wind TunnelsDokument5 SeitenIntroduction To Wind TunnelsFaiq AhmadNoch keine Bewertungen

- Smoke TunnelDokument55 SeitenSmoke TunnelABHIMANYU KHADGANoch keine Bewertungen

- ORIFICEMETER + ROTAMETERDokument19 SeitenORIFICEMETER + ROTAMETERZaidNoch keine Bewertungen

- Instruction Manual: Equipment For Engineering EducationDokument10 SeitenInstruction Manual: Equipment For Engineering Educations_nimalanNoch keine Bewertungen

- Scott Russell mechanism motion studyDokument15 SeitenScott Russell mechanism motion studyNABIL HUSSAINNoch keine Bewertungen

- Drag Reduction MethodsDokument6 SeitenDrag Reduction MethodsAngela LopezNoch keine Bewertungen

- Manual PELTON PDFDokument14 SeitenManual PELTON PDFsyahirabdullahNoch keine Bewertungen

- Design and Analysis of An Airfoil For Small Wind TurbinesDokument88 SeitenDesign and Analysis of An Airfoil For Small Wind Turbinesaravindkumar030% (1)

- CAMD ExamplesDokument30 SeitenCAMD ExamplesSameerKulkarniNoch keine Bewertungen

- Hydrostatics TrainerDokument2 SeitenHydrostatics TrainerJairo Martínez EscobarNoch keine Bewertungen

- Types of Wind TunnelDokument4 SeitenTypes of Wind TunnelKarthick Ram100% (1)

- Pelton TurbineDokument4 SeitenPelton TurbineHenDricky Magosi100% (1)

- Wind Tunnel Hand BookDokument72 SeitenWind Tunnel Hand BookAerocse EceitmechNoch keine Bewertungen

- Fluid Mechanics Chapter 6Dokument34 SeitenFluid Mechanics Chapter 6Ricky Mak100% (1)

- Thin AirfoilDokument25 SeitenThin AirfoilmgskumarNoch keine Bewertungen

- CM LC1Dokument28 SeitenCM LC1Eng W EaNoch keine Bewertungen

- Design and Fabrication of Blended Wing BodyDokument5 SeitenDesign and Fabrication of Blended Wing BodyVIVA-TECH IJRINoch keine Bewertungen

- Aerodynamic Modeling and SimulationDokument33 SeitenAerodynamic Modeling and Simulationjabach_ahrimanNoch keine Bewertungen

- Flow VisualizationDokument12 SeitenFlow VisualizationSandeep Gahlawat0% (1)

- Drag Force ReportDokument8 SeitenDrag Force ReportMateus RodriguesNoch keine Bewertungen

- Strip Theory (2 D Potential Theory)Dokument8 SeitenStrip Theory (2 D Potential Theory)Bilal MalikNoch keine Bewertungen

- Geneva MechanismDokument12 SeitenGeneva Mechanismsarodesarang4750Noch keine Bewertungen

- SA Lab ManualDokument32 SeitenSA Lab ManualAnonymous nSvmh3s67% (3)

- ME302 Assignment Test-1 2019-20Dokument2 SeitenME302 Assignment Test-1 2019-20choudary garuNoch keine Bewertungen

- Mech 448 Chapter on Normal Shock Waves in Compressible Fluid FlowDokument12 SeitenMech 448 Chapter on Normal Shock Waves in Compressible Fluid FlowaeroacademicNoch keine Bewertungen

- Laboratory ManualDokument75 SeitenLaboratory ManualĞńàŇeśhNoch keine Bewertungen

- Nose Cone Design PDFDokument8 SeitenNose Cone Design PDFsgssgs1Noch keine Bewertungen

- Cam Jump Phenomenon-1Dokument10 SeitenCam Jump Phenomenon-1Dhairyasheel Bhutkar100% (1)

- MECHANICAL IMPORTANT CONCEPTSDokument77 SeitenMECHANICAL IMPORTANT CONCEPTSVivek Mishra0% (1)

- Dynamics Lab ManualDokument51 SeitenDynamics Lab ManualRavindiran ChinnasamyNoch keine Bewertungen

- Guidelines For Preliminary Round of BAJA SAEINDIA 2022Dokument8 SeitenGuidelines For Preliminary Round of BAJA SAEINDIA 2022sonii100% (1)

- Machine DrawingDokument15 SeitenMachine Drawingganesh916Noch keine Bewertungen

- Bourdon Tube: Prepared ByDokument20 SeitenBourdon Tube: Prepared BySaptarshi Panda100% (6)

- Practical Verification of Bernoulli'S Theorem: StructureDokument3 SeitenPractical Verification of Bernoulli'S Theorem: StructureVívék SâíNoch keine Bewertungen

- Orifice Mouthpiece ManualDokument5 SeitenOrifice Mouthpiece ManualgpradiptaNoch keine Bewertungen

- Flow Over An Airfoil - Pre-Analysis & Start-UpDokument28 SeitenFlow Over An Airfoil - Pre-Analysis & Start-Uppankaj216100% (1)

- Moment of Inertia LectureDokument26 SeitenMoment of Inertia LectureMohdmuslim AbdkohaNoch keine Bewertungen

- Elbow Flow MeasurementDokument3 SeitenElbow Flow Measurementsandeep lal100% (1)

- Lab 2 ReportDokument29 SeitenLab 2 ReportBobby Golas100% (2)

- Experimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionVon EverandExperimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionBewertung: 4 von 5 Sternen4/5 (2)

- Boldyrev - Tunel de Vento HipersônicoDokument5 SeitenBoldyrev - Tunel de Vento HipersônicoalexandreburanNoch keine Bewertungen

- The Internal Flow Investigation of A Centrifugal PumpDokument8 SeitenThe Internal Flow Investigation of A Centrifugal Pumppreetham108Noch keine Bewertungen

- Theoretical and Experimental Study of Hydraulic Actuators Synchronization by Using Flow Divider ValveDokument12 SeitenTheoretical and Experimental Study of Hydraulic Actuators Synchronization by Using Flow Divider ValverezaNoch keine Bewertungen

- Python Snap7 Readthedocs Io en LatestDokument65 SeitenPython Snap7 Readthedocs Io en LatestRezha Falaq RizkiNoch keine Bewertungen

- SQL Database Using VBScriptsDokument2 SeitenSQL Database Using VBScriptsRezha Falaq RizkiNoch keine Bewertungen

- KraeplinDokument4 SeitenKraeplinRezha Falaq RizkiNoch keine Bewertungen

- ΔT Δ t S T T t t: H,in H,out C,in C,outDokument240 SeitenΔT Δ t S T T t t: H,in H,out C,in C,outRezha Falaq RizkiNoch keine Bewertungen

- Paguyuban KSE ITSDokument9 SeitenPaguyuban KSE ITSRezha Falaq RizkiNoch keine Bewertungen

- 06 Boundary ConditionsDokument31 Seiten06 Boundary Conditionstolga_enes9949Noch keine Bewertungen

- WP-2Dokument30 SeitenWP-2Rezha Falaq RizkiNoch keine Bewertungen

- 06 Boundary ConditionsDokument31 Seiten06 Boundary Conditionstolga_enes9949Noch keine Bewertungen

- Input Weight O T Weight Ke Z1 Weight Ke Z2 x1 x2 1 Z1 Z2 YDokument2 SeitenInput Weight O T Weight Ke Z1 Weight Ke Z2 x1 x2 1 Z1 Z2 YRezha Falaq RizkiNoch keine Bewertungen

- Linked inDokument1 SeiteLinked inRezha Falaq RizkiNoch keine Bewertungen

- Wind TunnelDokument1 SeiteWind TunnelAzam_Sana_Khan_1410Noch keine Bewertungen

- Ditanya: Jari-Jari Maksimal Spesimen Benda Bulat Yang Terbuat Dari Magnesium Oksida (Mgo)Dokument1 SeiteDitanya: Jari-Jari Maksimal Spesimen Benda Bulat Yang Terbuat Dari Magnesium Oksida (Mgo)Rezha Falaq RizkiNoch keine Bewertungen

- Summary of Some Useful Equations: HYPERS301.x Hypersonics - From Shock Waves To ScramjetsDokument16 SeitenSummary of Some Useful Equations: HYPERS301.x Hypersonics - From Shock Waves To ScramjetsARUL PRAKASHNoch keine Bewertungen

- Vane Pumps Lesson 2Dokument16 SeitenVane Pumps Lesson 2Admir Ramic100% (1)

- Bernoulli's Energy TheoremDokument9 SeitenBernoulli's Energy TheoremKd CaisedoNoch keine Bewertungen

- Computational Fluid Dynamics Simulation of Solar Dryers A SanghiDokument17 SeitenComputational Fluid Dynamics Simulation of Solar Dryers A SanghiQadir AbbaxeeNoch keine Bewertungen

- IADC/SPE 163545 Surge and Swab Effects Due To Vessel Heave in Deepwater Wells: Model Development and BenchmarkingDokument21 SeitenIADC/SPE 163545 Surge and Swab Effects Due To Vessel Heave in Deepwater Wells: Model Development and BenchmarkingqjbsexNoch keine Bewertungen

- Fluid Mechanics ch.1Dokument8 SeitenFluid Mechanics ch.1A ALBALOSHINoch keine Bewertungen

- Godwin UHH250Dokument1 SeiteGodwin UHH250hendrynNoch keine Bewertungen

- Heat Transfer in Double Pipe Heat Exchanger.Dokument17 SeitenHeat Transfer in Double Pipe Heat Exchanger.Vishal venkatNoch keine Bewertungen

- Transport Phenomena - MSC - Lecture 11Dokument17 SeitenTransport Phenomena - MSC - Lecture 11showravNoch keine Bewertungen

- Pipe NetworkDokument20 SeitenPipe Networkamrezzat100% (1)

- ANSYS Fluent Getting Started GuideDokument56 SeitenANSYS Fluent Getting Started GuideManoj KumarNoch keine Bewertungen

- Handout - Problems Chapter 5-Practice in ClassDokument6 SeitenHandout - Problems Chapter 5-Practice in ClassJesus Emanuel RosarioNoch keine Bewertungen

- Pressure Build Up - SteeringDokument3 SeitenPressure Build Up - Steeringwidanto0apriawanNoch keine Bewertungen

- McGraw-Hill's Fluid Mechanics Correlation GuideDokument4 SeitenMcGraw-Hill's Fluid Mechanics Correlation GuideNg Swee Loong StevenNoch keine Bewertungen

- Analyze The Effect of Variations in Shape of TubesDokument7 SeitenAnalyze The Effect of Variations in Shape of TubesSUNIL YEOLENoch keine Bewertungen

- Aircraft Design Project Designing A Competitor Fighter AircraftDokument45 SeitenAircraft Design Project Designing A Competitor Fighter AircraftKarthick. GNoch keine Bewertungen

- Chen Et Al. (1976) - Added Mass and Damping of A Vibrating Rod in Confined Viscous FluidsDokument33 SeitenChen Et Al. (1976) - Added Mass and Damping of A Vibrating Rod in Confined Viscous FluidsEmerson Borges SantanaNoch keine Bewertungen

- There Are 8 Basic Types of Fan Wheels PDFDokument3 SeitenThere Are 8 Basic Types of Fan Wheels PDFAnonymous bHh1L1Noch keine Bewertungen

- Venturi MeterDokument21 SeitenVenturi MeterMuhammad AshirNoch keine Bewertungen

- Eulerian Vs Lagrangian Description and MoreDokument10 SeitenEulerian Vs Lagrangian Description and MoreVeysel KabaNoch keine Bewertungen

- Module-1: Introduction To Fluid MechanicsDokument33 SeitenModule-1: Introduction To Fluid Mechanicsmhd slmnNoch keine Bewertungen

- Designing Airflow Systems: A Guide to BasicsDokument40 SeitenDesigning Airflow Systems: A Guide to BasicsKagitha TirumalaNoch keine Bewertungen

- 1 s2.0 S092422441730818X MainDokument18 Seiten1 s2.0 S092422441730818X MainTanakorn RachapilaNoch keine Bewertungen