Beruflich Dokumente

Kultur Dokumente

11 Ijaers

Hochgeladen von

Jasmine Rai0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten4 Seitengdsgsdg

Originaltitel

11 IJAERS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldengdsgsdg

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten4 Seiten11 Ijaers

Hochgeladen von

Jasmine Raigdsgsdg

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

International Journal of Advanced Engineering Research and Studies E-ISSN2249 8974

IJAERS/Vol. I/ Issue I/October-December, 2011/51-52

Research Article

MODELING AND FINITE ELEMENT ANALYSIS OF CRANE

BOOM

Bhupender Singh

1

, Bhaskar Nagar

2

, B.S. Kadam

3

, Anuj kumar

4

Address for Correspondence

1,2

Department of Mechanical Engineering, YMCAUST, Faridabad-121006

3,4

Department of Mechanical Engineering, AITM Palwal-121102

ABSTRACT

In todays world of growing competition, all industries are trying their best to give the components of high quality with

minimum expenditure. So in present work the solid modeling and finite element analysis of crane boom has been done using

PRO/E WILDFIRE 2.0 and ALTAIR HYPER MESH with OPTISTRUCT 8.0 SOLVER Software to get the variation of

stress and displacement in the various parts of the crane boom and possible actions are taken to avoid the high stress level

and displacement. There are lot of applications of crane in industries and our daily life also. As it is a material handling

machine, it is used for lifting loads and moves it from one place to another. In case of telescopic crane the whole weight/load

is carried by its boom. Now a days, these types of cranes are commonly used due to less manufacturing cost, less space

required and load can be lifted up to a maximum height very easily.

INTRODUCTION

It is desirable for every material handling

manufacturing industry to provide the economy as

in fuel consumption as well as maximum life of

various parts of the equipment. So it is high

necessary to predict the loading capacity for which

the crane boom life is maximum. So in present work

this has been successfully done and also path is

provided for analyzing other crane parts in similar

manner. Crane boom has been analyzed for different

load application at three different points and the

loading capacity for which the value of stress is

acceptable has been predicted. the objective of the

present work may include modeling of crane parts

and other mechanical components with the help of

PRO/E software and analyzing the parts using

ALTAIR HYPER MESH software. Beside the work

also includes:

1. Testing whether boom is safe for the

various loading conditions or not.

2. Exploring ways to reduce the stress level in

various parts of the boom.

3. Finding out various techniques of modeling

such objects and finding out most

appropriate method for modeling them.

4. Declaring the safest load carrying capacity

for the maximum boom life and minimum

stress level and displacement in lifting

condition.

5. To provide the path for analyzing the other

crane parts in similar manner to get

maximum life and also saving the huge

money required for prototype or physical

model generation and testing.

Material of the crane boom

The crane boom is manufactured by mild steel

material having Indian standard 2062 with grade A.

Mild steel is an alloy of iron and carbon with carbon

contents from 0.15% to 0.45%. The carbon occurs in

form of iron carbide, because of its ability to

increase the hardness and strength of steel. Other

elements like silicon, sulphur, phosphorus and

manganese are also present to greater or less amount

to impart certain desired properties to it.

Table 1.1 Mechanical Properties of MS-IS2062 A

Grade

The Mechanical Properties of Mild Steel-IS 2062 A

Grade are as follows:-

Ultimate tensile strength (min.) 410 Mpa

Yield Strength (min.) 230-250 Mpa

Percentage Elongation min.5.65 sqrt(so) 23

Bend Test 25 mm

Mass Density 7.85 kg/m3

Poissons Ratio 0.29

There are so many softwares now a day available in

industries for standard modeling. CATIA, UG, I-

Deas, Solidworks and Pro/E. Out of these Pro/E

generates the best models in case of solids, i.e. the

reason we use this for modeling of crane boom part.

The figure 2.8 shows a set of modeling commands

and how they are engaged with one another.

Earlier views of Crane boom

Figure 1.1 Left front view of crane boom

Figure 1.2 Right front view of crane boom

Figure 1.1& 1.2 shows the three dimensional view

of crane boom used earlier in the crane by the

industry. The boom position is left front view in the

figure 1.1 and right front view in the figure 1.2.

International Journal of Advanced Engineering Research and Studies E-ISSN2249 8974

IJAERS/Vol. I/ Issue I/October-December, 2011/51-52

The thickness of the boom was 28 mm at that time

and is made of MS-IS-1092 material. The boom was

fixed at two points in the crane assembly. Figure

1.3, 1.4, 1.5 & 1.6shows the three-dimensional view

of crane boom prepared after certain modifications

or we can say modified views of crane boom in

different position. The thickness of the boom is now

reduced to 25 mm at all position and is made of MS-

IS-2062 material. The boom is fixed at three points

in the crane assembly.

Fig. 1.3 Modified Left front view of crane boom

Fig. 1.4 Modified right front view of crane

boom

Figure 1.5 & 1.6 Modified right front view of

crane boom at different position

FINITE ELEMENT ANALYSIS OF CRANE

BOOM

1. Finite element analysis is a mathematical

method that can be used to solve various

problems such as stress analysis, heat

conduction, electrical fields, magnetic

fields, ideal fluid flow, etc.

2. In structural analysis, FEA can be use to

solve for the displacement and stress for a

complicated structure, under a given

loading and boundary condition.

SOLLUTION PROCEEDURE

After the solid model generation using Pro-E wild

fire 2.0 software the solid model is imported to

analysis 8.1 software for finite element analysis

purpose. In this the stress distributions over the

boom have been studied under the applied load. In

the present section the brief description of the

method used for this work ALTAIR Hyper Mesh

was developed in head quarter in Canonsburg, USA.

The present work falls under the static structural

field. ALTAIR HYPERMESH follows following

path for performing the analysis:

Preliminary Decisions, Preprocessors,

Solution, Post processor

Preliminary decisions: At this level first the

mode of the software is selected that is best

suited for the component. We can also say

an oral report is prepared according to

component shape, size and material etc.

then final data is entered in further steps.

Preprocessor: In this stage we provide the input

data to the system. This is highly important stage in

analysis:

Modeling of the Crane Boom, Mesh generation of

the Crane Boom, Modeling of loads

Modeling of Crane Boom: The Crane Boom is a

three dimension structure. The element type used is

SOLID tetrahedral. The element is defined by 4

nodes having three degree of freedom at each node

translation in the nodal x, y, and z directions.

Command: preprocessor>> element type>

add/edit/delete

Mesh generation of the Crane Boom: During this

step mesh of regular shape is generated on the

surface of the component. More the irregularity of

mesh shape more the chances of error occurrence.

Material properties: As far as material of the Crane

Boom is concerned the material is MS-Grade IS-

2062.

Modeling of loads: For analyzing here the analysis

is done for three different conditions: Load carrying

capacity. In this level the software interprets the data

and finds actual results. These results are in form of

displacement at which point is minimum and at

which point is maximum and send the information

regarding the failure of the component.

Post processor: This level of software sends results

to the display menu and the methods to avoid the

failure to increase the life of the component. This

plays an important role in the modification of design

of the component.

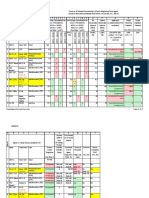

Finite Element Model in Altair Hyper Mesh

The crane boom modeled in Pro-engg imported in

the Altair Hyper Mesh software and the module

Optistruct solver 8.0 is used. The figure 3.6 shows

the values of nodes elements, surfaces of booms and

the modeled view in software.

International Journal of Advanced Engineering Research and Studies E-ISSN2249 8974

IJAERS/Vol. I/ Issue I/October-December, 2011/51-52

Figure 1.7 Crane Boom imported in Altair Hyper mesh software

Analysis Procedure of Altair Hyper Mesh for Crane Boom

Case 1: For 6 Tone Weight/load

Figure 1.8 &1.9 Left and Right Side and Front view of crane boom under the application of 6 Tonne Load

Figure 2.0Von mises stress distribution for 6 ton loading condition

Finite element model information:

1. Number of nodes: 63970,

2. Number of elements: 235794,

3. Number of rigid elements: 5,

4. Number of rigid element constraints: 2469

5. Number of degrees of freedom: 194376

6. Number of non-zero stiffness terms:

3624351

Elements:

1. Number of TETRA elements: 235794

Loads and boundaries:

1. Number of FORCE sets: 1Number of SPC

sets: 1

Materials and properties:

1. Number of PSOLID cards: 1

2. Number of MAT1 cards: 1

Static Sub cases information:

Subcase ID SPC ID Force ID Weight

2 1 2 1.00

1. Maximum displacement is 1.91mm at grid

152789.

2. Maximum 3-D element stress is 238MPa in

element 638087

Finite element model information:

1. Number of nodes: 63970

2. Number of elements: 235794

3. Number of rigid elements: 5

4. Number of rigid element constraints: 2469

5. Number of degrees of freedom: 194376

6. Number of non-zero stiffness terms:

3624351

Elements:

1. Number of TETRA elements: 235794

Loads and boundaries:

1. Number of FORCE sets: 1

2. Number of SPC sets: 1

Materials and properties:

1. Number of PSOLID cards: 1

2. Number of MAT1 cards: 1

Static Subcases information:

1. Subcase ID SPC ID Force ID Weight

2 1 2 1.00

RESULTS & DISCUSSIONS

At first point of crane boom the load applied is 6000kg.

At this point load is carried with the help of a hook.

The maximum displacement is 1.91mm and maximum

3-D element stress is 238 MPa near the upper portion

where the wire assembly is done. In the figure it is

shown by red colour.During the analysis, the Sparse-

Matrix Solver is used and the size of maximum

memory used is129 MB and maximum disk space used

is 647 MB. The analysis is carried out in three load

steps. The total analysis time is approximately four

hours taken by the software.

Table 1.2 Nodal information

Entity Number defined Description

Solid 2, 35,794 4 Nodded Tetrahedron

Nodes 63,970 Critical points

Table 1.3 Displacements (mm)

Minimum 0.0063

Maximum 1.91

Table 1.4 Shear Stresses

Minimum 171 MPa

Maximum 238 MPa

International Journal of Advanced Engineering Research and Studies E-ISSN2249 8974

IJAERS/Vol. I/ Issue I/October-December, 2011/51-52

From the result obtained from the analysis this is

concluded that the values of the stresses are maximum

for case 1(6 Tonne load). The life of the boom will be

minimum if it is working at that point. So try to lift the

load slightly less than its capacity at this point to get

the maximum life of the crane boom.

Conclusions and Scope for Future Work

The thesis starts with geometric and solid modeling,

which is important and essential aspect for the design

and manufacturing engineers from the viewpoint of

shape realization. The thesis present unified solid

model of Crane Boom, which is equivalent to actual

physical model of the crane boom. The geometry of the

boom surface patch is influenced by the topology of the

boom and is specified by the establishing proper

bounds to the parameters defining the unbounded

surfaces along with ensuring continuity condition. The

solid model is created using Pro/E Wildfire 2.0 using

given dimensions. Then the solid model is imported to

ALTAIR HYPER MESH and analysis of the model is

carried out in OPTISTRUCT SOLVER 8.0 under given

constraints. Present dissertation calculates the stress

and deformation at different nodes of the discretized

model of using ALTAIR HYPER MESH 8.1 software.

The stress values calculated for three load points were

found to be under the limits of ultimate tensile strength

and yield strength of boom material. So it can be said

that under the given conditions of boom material and

load carrying capacity, crane boom is safe to lift the

load up to 12 Tonne.

By using Finite Element Analysis the following

objectives have been achieved

1. Weight Reduction (4.86 kg, approx.5kg).

2. Stresses are within limits (at higher load

points).

3. Cost cutting (Rs-180/- for a single

component).

The analysis also concluded that maximum stress is

coming near the fixing position.

REFERENCE

1. Anup Kumar Dube, V.B.Kunturkar, B.M.Dabade and

V.M.Nandedkar, Finite element analysis of a tractor

steering lever link (2 tier)

2. Bhaskar Nagar, 2005, Modeling and Finite element

Analysis of Car Wheel, M.Tech Dissertation,

MDniversity Rohtak, India, Page 1-67

3. Floriani, L.D. and Hui., A., A scalable data structure for

three dimensional objects

4. Gueorguieva, S and Marcheix, D., Boundary

Representation for Solid Modeling

5. Imani B. M. and Elbestawi M., 2001, Geometric

Simulation of Ball-End Milling Operations, Jounral of

Manufacturing Science and Engineering, pg. l77 -184

6. Krishanamurthy C.K, Finite Element Analysis, Tata

Mcgraw Hill, Publishing Company Limited.

7. Luo,Y.. and Luhacs. G., 2001, A Boundary

Representation for Form Features and Non-Manifold Solid

Objects, First ACM Symposium on Solid Modeling, pg.

45-60

8. Mantyla, M., 1988, An Introduction to Solid Modeling,

Computer Science Press

9. Pro-engineering wildfire reference guide by CADD

CENTRE, 2005

Das könnte Ihnen auch gefallen

- Role of Stress Triaxiality in Elastoplastic Characterization and Ductile Failure PredictionDokument19 SeitenRole of Stress Triaxiality in Elastoplastic Characterization and Ductile Failure PredictionJasmine RaiNoch keine Bewertungen

- ME 631-Lectures ContentDokument1 SeiteME 631-Lectures ContentJasmine RaiNoch keine Bewertungen

- Elastic Solids Vol.1 MathDokument214 SeitenElastic Solids Vol.1 MathMohamed FaragNoch keine Bewertungen

- SpringDokument2 SeitenSpringJasmine RaiNoch keine Bewertungen

- Taylor Bar TestDokument20 SeitenTaylor Bar TestJasmine RaiNoch keine Bewertungen

- Fundametals of University Teaching Spring 2015 Workshop ScheduleDokument3 SeitenFundametals of University Teaching Spring 2015 Workshop ScheduleJasmine RaiNoch keine Bewertungen

- QuizDokument2 SeitenQuizJasmine RaiNoch keine Bewertungen

- 08 FluidStructureInteraction 113Dokument12 Seiten08 FluidStructureInteraction 113Jasmine RaiNoch keine Bewertungen

- QuizDokument2 SeitenQuizJasmine RaiNoch keine Bewertungen

- Large Density RatioDokument11 SeitenLarge Density RatioJasmine RaiNoch keine Bewertungen

- 5 3 4Dokument10 Seiten5 3 4Jasmine RaiNoch keine Bewertungen

- 08 FluidStructureInteraction 113Dokument12 Seiten08 FluidStructureInteraction 113Jasmine RaiNoch keine Bewertungen

- ReadmeDokument1 SeiteReadmeOsman OmerovićNoch keine Bewertungen

- P 339Dokument4 SeitenP 339Jasmine RaiNoch keine Bewertungen

- Maindemo KDokument4 SeitenMaindemo KJasmine RaiNoch keine Bewertungen

- CH 12 Homework SolutionsDokument16 SeitenCH 12 Homework SolutionsJasmine RaiNoch keine Bewertungen

- Maindemo KDokument4 SeitenMaindemo KJasmine RaiNoch keine Bewertungen

- 06 2Dokument14 Seiten06 2Jasmine RaiNoch keine Bewertungen

- FEM Conststrain HoleplateDokument9 SeitenFEM Conststrain HoleplateBac Nam VuNoch keine Bewertungen

- FVMDokument4 SeitenFVMJasmine RaiNoch keine Bewertungen

- Hyper Mesh 11 Install InstructionsDokument1 SeiteHyper Mesh 11 Install InstructionsJasmine RaiNoch keine Bewertungen

- Lattice Theory of Threedimensional Cracks: 129.97.21.43 On: Tue, 03 Feb 2015 18:48:53Dokument9 SeitenLattice Theory of Threedimensional Cracks: 129.97.21.43 On: Tue, 03 Feb 2015 18:48:53Jasmine RaiNoch keine Bewertungen

- Vectors AlgebraDokument19 SeitenVectors AlgebraJose Maria Hazel TadlasNoch keine Bewertungen

- Scan of Aside For Rate of Volume ElementDokument4 SeitenScan of Aside For Rate of Volume ElementJasmine RaiNoch keine Bewertungen

- AFEM 03 Rep BaoDokument48 SeitenAFEM 03 Rep BaoJasmine RaiNoch keine Bewertungen

- Formulae Involving Vector Identities With Proofs: Nabla Formulae For Vector AnalysisDokument8 SeitenFormulae Involving Vector Identities With Proofs: Nabla Formulae For Vector AnalysisMarcho HbrNoch keine Bewertungen

- FEA of Nonlinear Problems 2011 IvancoDokument62 SeitenFEA of Nonlinear Problems 2011 IvancohazemismaeelradhiNoch keine Bewertungen

- Worksheet Fluxdiv SolnDokument3 SeitenWorksheet Fluxdiv SolnJasmine RaiNoch keine Bewertungen

- All Checks PointsDokument1 SeiteAll Checks PointsJasmine RaiNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Furnace ITV Color Camera: Series FK-CF-3712Dokument2 SeitenFurnace ITV Color Camera: Series FK-CF-3712Italo Rodrigues100% (1)

- Standard Deviation IntroductionDokument3 SeitenStandard Deviation IntroductionShyam ShresthaNoch keine Bewertungen

- SQL Server 2008 Failover ClusteringDokument176 SeitenSQL Server 2008 Failover ClusteringbiplobusaNoch keine Bewertungen

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Dokument19 SeitenHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedeNoch keine Bewertungen

- 2016 Mustang WiringDokument9 Seiten2016 Mustang WiringRuben TeixeiraNoch keine Bewertungen

- Module 2Dokument42 SeitenModule 2DhananjayaNoch keine Bewertungen

- Mechanics of Deformable BodiesDokument21 SeitenMechanics of Deformable BodiesVarun. hrNoch keine Bewertungen

- Reinvestment Allowance (RA) : SCH 7ADokument39 SeitenReinvestment Allowance (RA) : SCH 7AchukanchukanchukanNoch keine Bewertungen

- Living Nonliving DeadDokument11 SeitenLiving Nonliving DeadArun AcharyaNoch keine Bewertungen

- Device Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayDokument2 SeitenDevice Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayRohit Chouhan0% (1)

- Florence Walking Tour MapDokument14 SeitenFlorence Walking Tour MapNguyễn Tấn QuangNoch keine Bewertungen

- Basic Five Creative ArtsDokument4 SeitenBasic Five Creative Artsprincedonkor177Noch keine Bewertungen

- Fiera Foods - Production SupervisorDokument1 SeiteFiera Foods - Production SupervisorRutul PatelNoch keine Bewertungen

- The Changing Face of War - Into The Fourth GenerationDokument5 SeitenThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozNoch keine Bewertungen

- TransistorDokument1 SeiteTransistorXhaNoch keine Bewertungen

- Land Measurement in PunjabDokument3 SeitenLand Measurement in PunjabJunaid Iqbal33% (3)

- Rheology of Polymer BlendsDokument10 SeitenRheology of Polymer Blendsalireza198Noch keine Bewertungen

- Tender34 MSSDSDokument76 SeitenTender34 MSSDSAjay SinghNoch keine Bewertungen

- JD - Software Developer - Thesqua - Re GroupDokument2 SeitenJD - Software Developer - Thesqua - Re GroupPrateek GahlanNoch keine Bewertungen

- Key formulas for introductory statisticsDokument8 SeitenKey formulas for introductory statisticsimam awaluddinNoch keine Bewertungen

- Practice Like-Love - Hate and PronounsDokument3 SeitenPractice Like-Love - Hate and PronounsangelinarojascnNoch keine Bewertungen

- Impolitic Art Sparks Debate Over Societal ValuesDokument10 SeitenImpolitic Art Sparks Debate Over Societal ValuesCarine KmrNoch keine Bewertungen

- Benjie Reyes SbarDokument6 SeitenBenjie Reyes Sbarnoronisa talusobNoch keine Bewertungen

- General Separator 1636422026Dokument55 SeitenGeneral Separator 1636422026mohamed abdelazizNoch keine Bewertungen

- Jazan Refinery and Terminal ProjectDokument3 SeitenJazan Refinery and Terminal ProjectkhsaeedNoch keine Bewertungen

- Clean Agent ComparisonDokument9 SeitenClean Agent ComparisonJohn ANoch keine Bewertungen

- EnerSys Global Leader in Industrial BatteriesDokument32 SeitenEnerSys Global Leader in Industrial BatteriesAshredNoch keine Bewertungen

- Impact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisDokument5 SeitenImpact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Practical Research 2: Self-Learning PackageDokument3 SeitenPractical Research 2: Self-Learning PackagePrinces BaccayNoch keine Bewertungen

- Put The Items From Exercise 1 in The Correct ColumnDokument8 SeitenPut The Items From Exercise 1 in The Correct ColumnDylan Alejandro Guzman Gomez100% (1)