Beruflich Dokumente

Kultur Dokumente

Oth-CISTEM

Hochgeladen von

Othman NasriOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Oth-CISTEM

Hochgeladen von

Othman NasriCopyright:

Verfügbare Formate

Spacecraft Thrusters Diagnosis with Vertices

Principal Component Analysis: Application to the

Rendez-vous Phase of the Mars Sample Return

Mission

Imen GUEDDI

LARATSI Lab

National Engineering School of Monastir

University of Monastir

Monastir Ibn El Jazzar 5019, Tunisia

Email: imen.gueddi@gmail.com

Othman NASRI

SAGE Lab

National Engineering School of Sousse

University of Sousse

BP 264 Sousse Erriadh 4023, Tunisia

Email: othman.nasri@eniso.rnu.tn

Kamel BENOTHMAN

LARATSI Lab

National Engineering School of Monastir

University of Monastir

Monastir Ibn El Jazzar 5019, Tunisia

kamelbenothman@yahoo.fr

Philippe DAGUE

LRI Lab

University of Paris-Sud 11

CNRS & INRIA Saclay

Ile de France

Bt 650, 91405 Orsay Cedex, France

philippe.dague@lri.fr

AbstractThis paper presents a fault diagnosis system of

the chaser thrusters used during the rendez-vous phase of the

Mars Sample Return (MSR) mission. The Vertices Principal

Component Analysis (VPCA) has been adopted as an extension

method of the classical principal component analysis for interval

valued data. The VPCA has been used to estimate the relation-

ships between the various variables of the process. To ensure

the feasibility of the proposed FDI approach, a set of interval

valued data provided by the industrial high-delity simulator

of the MSR and representing the opening rates of the spacecraft

thrusters has been considered. The test results demonstrate that

the fault detection and isolation are successfully accomplished.

I. INTRODUCTION

In many industries, the good supervision and the au-

tonomous control are required for increasing their performance

specially toward increasing complexity and automation.

Accordingly, achieving safe and reliable operation for many

complex systems now requires fast and accurate methods for

detecting and diagnosing faults on the basis of process mea-

surements. This is particularly desired for aerospace systems.

Actually, aerospace is considered as the most critical area

of applications. Thus, autonomous spacecrafts have become a

key technology for increasing their survival capability. Various

researchers have developed diagnosis systems to detect and

isolate faults that can appear in a spacecraft [1], [2], [3], [4].

In fact, these diagnosis systems are mostly based on the

redundancy concept; hardware and analytical redundancy. The

rst one can be seen as a very expensive and a complex

approach. while the second one can be based, either, on a

mathematical model or on a model-free method that usually

does not require a detailed knowledge of the system. [5], [6],

[7]. Since nding the appropriate mathematical model for some

real complex system can be difcult or sometimes impossible.

The solution is, then, to use the analytical redundancy based

on a model-free method like the Principal Component Analysis

(PCA).

The (PCA) approach has been, recently, applied success-

fully in the monitoring and the diagnosis of many complex

systems [8], [9], [10], [11]. In fact, this approach includes a

nominal PCA model for normal operation conditions and a

PCA model for each faulty situation. A simple comparison

between the two models allows the generation of the residual

signals. The signal that does not exceed its threshold can

identify faults and the actual system situation.

The only remaining problem is that the standard diagnosis

methods have been mainly developed for the analysis of single

valued variables. However, in real life this type of data is the

result of a simplication that may, in many situations, cause

severe loss of information.

Vertices Principal Component Analysis (V PCA), and

Centers Principal Component Analysis (CPCA) are consid-

ered as the most common approaches that generalize Principal

Component Analysis (PCA) to interval valued data [12], [13],

[14].

In this paper, we will present a diagnosis approach for

spacecrafts thrusters based on the VPCA technique. In fact,

this same problem has been treated using the classical principal

component analysis method [4]. Since this approach is based

on single valued data witch eliminate to take into consideration

any possible uncertainty, as a solution, we have chosen to apply

the VPCA method as an extension of the classical PCA to

intervals valued data.

The paper is organized as follows. In section II, the VPCA

technique is presented. In section III, the fault detection and

isolation method based on the VPCA approach is introduced.

The Mars Sample Return (MSR) mission is described in

section IV, with the results of thrusters fault detection and

isolation with the V PCA method. Conclusions and future

developments are presented in the last section.

II. VERTICES PRINCIPAL COMPONENTS ANALYSIS:

VPCA

The Vertices Principal Component Analysis (V PCA) was

rst proposed by Chouakria. [14]. This approach consists in

performing a classical PCA on the vertices matrix.

Considering the interval data matrix X

I

,

X

I

= [X

1

, X

2

, . . . , X

N

]

T

R

(Nm)

with N observation

units characterized by m interval valued variables recorded on

the system under normal operation.

At an instant time k,

X

k

= ([x

1

(k), x

1

(k)], . . . , [x

m

(k), x

m

(k)])

T

(1)

with k = 1, . . . , N.

Each given observation, described with m interval valued

variables, can be represented as a hyperrectangle in R

m

with

2

m

vertices. For N observation the total number of vertices is

then N 2

m

.

The rst step of this method is to replace the interval valued

matrix X

I

(represented by eqution 2) by a single valued one

X

H

(represented by equation 3) with N 2

m

rows and m

columns.

X

I

=

_

_

_

_

_

_

x

1

(1), x

1

(1)

_

_

x

m

(1), x

m

(1)

_

.

.

.

.

.

.

.

.

.

_

x

1

(N), x

1

(N)

_

_

x

m

(N), x

m

(N)

_

_

_

_

_

_

(2)

X

H

=

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

x

1

(1) x

m

(1)

.

.

.

.

.

.

.

.

.

x

1

(1) x

m

(1)

_

_

.

.

.

_

_

x

1

(N) x

m

(N)

.

.

.

.

.

.

.

.

.

x

1

(N) x

m

(N)

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

(3)

Considering an example with 2 interval valued variables

and N observations. The interval data is given by:

X

I

=

_

_

_

_

_

_

x

1

(1), x

1

(k)

_ _

x

2

(1), x

2

(1)

_

.

.

.

.

.

.

_

x

1

(N), x

1

(N)

_ _

x

2

(N), x

2

(N)

_

_

_

_

_

_

:

:

N

N

N N

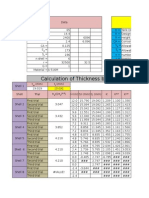

Fig. 1. Hypercube representation in a 2-dimensional space

Considering one observation, the corresponding space rep-

resentation is given by the rectangle in gure 1.

In an n-dimensional space, an hypercube can be described

with a matrix of 2

n

rows and n columns where the i

th

row

corresponds to the coordinates of the i

th

vertex.

According to this example, the interval data can be de-

scribed as:

X

H

=

_

_

_

_

_

x

1

x

2

x

1

x

2

x

1

x

2

x

1

x

2

_

_

_

_

_

Once the interval valued data matrix is transformed into a

single valued one, it is possible to apply the standard PCA.

A. The standard PCA

The PCA is considered as a very effective statistical

method in extracting information from the measured data [15],

[16]. Considering the data matrix X,

X = [x(1), x(2), . . . , x(N)]

T

R

(Nm)

gathering N sam-

ples of m observed variables recorded on the system under

normal operation.

At an instant time k,

x(k) = [x

1

(k), x

2

(k), . . . , x

m

(k)]

T

(4)

with k = 1, . . . , N.

The linear transformation of the data matrix X into a new

set of variables T is then given by:

T = XP and X = PT

T

(5)

where: T = [t

1

, t

2

, . . . , t

m

] R

(Nm)

and P =

[p

1

, p

1

, . . . , p

m

] R

(mm)

is the matrix of the eigenvectors

(called also principal vectors) associated with the eigenvalues

of the covariance matrix :

=

1

N

X

T

X (6)

The right choice of the number of principal components to

retain is a very important step in the process of developing a

PCA model. Several methods are to be adopted to determine

the required number (l) of principal components [17].

In this paper, two methods were exploited. The rst one

is based on minimizing the Variance of the Reconstruction

Error (V RE) [18]. The second one is based on maximizing

the Cumulative Percent of Variance (CPV ) [17]. In fact the

CPV method measures the percent variance captured by the

rst l principal components. A balance between retaining as

few principal components as possible and providing as much

of variance as possible is the key to an appropriate choice of

l.

Once l is xed, the number of used data is then reduced

to the rst l (l < m) variables which are the most signicant

components. The data and the two matrices T and P can be

partitioned into a principal part and a residual one:

T = [

T

[Nl]

T

[N(ml)]

] (7)

P = [

P

[ml]

P

[m(ml)]

] (8)

The data matrix can be partitioned as follows:

X =

P

T

T

+

P

T

T

=

X +

X (9)

where

X is the principal part of the data composed of the

rst l eigenvectors, while

X is the residual part of the data

composed of the remaining components.

X =

CX ;

X =

CX (10)

with

C =

P

P

T

and

C =

P

P

T

= (I

m

C), which are the

two vectors that form the PCA model.

B. The VPCA algorithm

Considering X

I

(see equation 2) the interval valued data

matrix.

1. For each sample k, describe for each X

k

the corresponding

single valued matrix X

H

k

composed of 2

m

rows and

m columns which elements are the coordinates of the

associated hypercubes vertices.

2. Construct the single valued matrix X

H

(see equation 3)

composed of N 2

m

rows and m columns and gathering

the N X

H

k

matrices.

3. Apply the standard PCA on X

H

(see equation 3). Let

T

1

, , T

l

(l m) be the l rst single valued principal

components (PC

S

).

4. Calculate the interval valued principal components (PC

I

)

T

I

1

, , T

I

l

. Let R

X

k

be the number of rows in X

H

associated with the k

th

observation X

k

and t

ij

, i R

X

k

be

the j

th

PC

S

associated with X

k

corresponding to the j

th

row of X

H

. The PC

I

j

corresponding to the k

th

observation

can be then represented by equation 11:

t

I

X

kj

=

_

t

kj

, t

kj

(11)

where:

t

kj

= min

iR

X

k

(t

ij

)

t

kj

= max

iR

X

k

(t

ij

)

Algorithm 1 summarizes the different steps of the VPCA

method. X

I

denotes the interval valued data matrix, m the

number of variables, N the number of observations, l the

retained number of principal components, PCs

S

and PCs

I

represent, respectively, the single and the interval valued

principal components.

Algorithm 1: VPCA generalized algorithm

Inputs : X

I

, m, N.

Outputs: l, PCs

S

, PCs

I

.

1 for (k = 1 to N) do

2 Calculate X

H

k

.

3 end

4 Reconstruct X

H

.

5 Apply PCA(X

H

).

6 Determine l.

7 Calculate PCs

S

.

8 Calculate PCs

I

.

III. FAULT DIAGNOSIS USING VPCA

A. Fault detection

Once the principal components are calculated, it is possible

to proceed to the fault detection step. Several indexes are used

to represent any variations in the data and thereby to detect

faults [9], [19]. We will then explain the process of fault

detection using the Squared Prediction Error (SPE) index that

operates in the residual subspace.

Since the SPE index operates in the residual subspace, then,

rst, it is necessary to determine PCs number for a system with

m variables and N 2

m

observations. Once the number of

required PCs l is chosen, the principal component matrix can

be then partitioned into the principal and the residual parts as

shown in equation 7:

At an instant time k

= k 2

m

, k

= 1, . . . , N 2

m

, the

SPE is given by equation 12:

SPE(k

) =

m

j=l+1

t

I

2

j

(k

) (12)

The system is declared in failure at an instant k

if;

SPE(k

)

2

(13)

where

2

is the threshold proper to the SPE index calculated

according to [20].

B. Fault isolation

After achieving the fault detection step, it is necessary

to identify and isolate the faulty variables. Among various

strategies of fault localization we have chosen the variable re-

construction approach. This method assumes that each variable

is faulty and suggests to reconstruct it using the VPCA model

from the remaining variables [19], [21].

Let

R

be the matrix indicating the reconstruction di-

rection. It is built with 1 and 0 indicating respectively the

reconstructed variables from the non reconstructed ones.

At an instant k

, a reconstructed variable is given by

equation 14:

X

R

(k

) = G

R

x(k

) (14)

with:

G

R

= I

m

R

(

T

R

R

)

1

T

R

(15)

Fig. 2. The MSR mission

(a) (b)

Fig. 3. (a): The MSR spacecraft, (b): The spacecrafts thrusters

R

= (I

m

C)

R

(16)

The residual vector can be dened by equation 17:

X

R

(k) = (I

m

C)

X

R

(k) = P

R

x(k) (17)

with:

P

R

= (I

m

C)

R

(

T

R

R

)

1

T

R

(18)

In order to isolate the faulty variable, the SPE index may be

computed by equation 19:

spe

R

(k

) = x

R

(k

)

T

P

P

T

x

R

(k

) (19)

The isolation index is then dened, by equation 20:

A

spe

R

(k

) =

spe

R

(k

)

(

2

(k

))

(20)

where R = 1, . . . , m corresponding to the reconstructed

variable and

2

is the spe

R

threshold. The variable for which

the isolation index is lower than one is declared faulty.

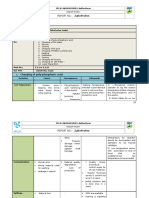

IV. APPLICATION

A. Mars Sample Return Mission

The MSR mission, as represented in gure 2, plans col-

lecting samples from Mars and then returning to earth. The

diagnosis process concerns only the 5

th

step of this mission.

This step is called the rendez-vous. Only the last 100 meters

of the rendez-vous/capture phase are considered the most

critical for the occurrence of failures.

In this phase, in order to control the orientation of the

chaser spacecraft (see gure 3.a), a Laser Image Detection

And Ranging (LIDAR) and a Radio Frequency Sensor (RFS)

are used. As the Orbiter Sample (OS) must remain in the eld

of vision of the Orbiter Module (OM) sensors, the difculty

will be in controlling the attitude, the movement and the two

axes describing the motion relative to the orbital plane.

Thrusters (gure 3.b) are considered as the most important

features of the propulsion system assuring the attitude control

of the spacecraft. These propulsive devices are capable of

generating a thrust (force) to control the attitude and a torque

to control the rotation (about the three axes of the spacecraft:

roll, pitch and yaw). To provide the system stabilization, the

thrusters must be placed about all three axes with at least two

thrusters in each one.

Therefore, the failure of one or more thrusters can cause

a spacecraft to lose its ability to maintain position and hence

potentially causing a mission failure. So, the objective of this

application is to detect and isolate the thrusters faults of the

MSR chaser spacecraft, considering that the propulsion system

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

1

]

X

1,2

1

X

1,1

1

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

2

]

X

1,1

2

X

1,2

2

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

3

]

X

1,2

3

X

1,1

3

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

4

]

X

1,2

4

X

1,1

4

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

5

]

X

1,1

5

X

1,2

5

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

6

]

X

1,1

6

X

1,2

6

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

7

]

X

1,2

7

X

1,1

7

0 2000 4000 6000 8000 10000 12000

0

0.2

0.4

0.6

0.8

1

(time)

[

X

8

]

X

1,2

8

X

1,1

8

Fig. 4. Thrusters measurment evolution, [X

1,1

] (blue) and [X

2,1

] (red)

is composed of 8 thrusters.

The fault diagnosis process of the spacecrafts thrusters

requires two sets of data, one to build the PCA model and

another to test the inuence of a fault in the residual and/or

the principal space.

B. VPCA Model

To build the VPCA model, two data matrices X

min

R

(Nm)

and X

max

R

(Nm)

, in the absence of faults in the

system, has been generated. These two matrices are the two

bounds of the general interval data matrix X

I

= [X].To test

the effectiveness of the fault detection and isolation method,

described previously, two types of faults have been considered.

1) fault1 in the rst thruster between 200s and 210s,

2) fault2 in the second thruster between 400s and 410s.

In this case study we consider [X

1,1

] and [X

2,1

], denoting

the interval valued data matrix in the presence of fault1 and

fault2 respectively, where N = 13514 is the number of

observations of the m = 8 chasers thrusters. The measurement

vectors represent the opening rate at a k time of the 8 thrusters.

Figure 4 represents the evolution of the measurement

vectors during an abnormal operating mode of the 8 nominal

thrusters. The simulation results conrm the presence of faults

in the spacecrafts thrusters.

Once the data matrix in the absence of faults is scaled

(using mean and standard deviations of the variables), the

VPCA model can be then built.

According to the V RE method the appropriate number of

PCs is l = 5 while with the CPV approach with l = 4 it

is possible to account for 99.99% of variance. Since the rst

aim of the principal component analysis is to reduce the data

representation space, we have adopted a system with l = 4

components.

C. Fault detection and isolation

Once the modeling phase is achieved, we will present the

fault detection and isolation results.

As explained previously, two faults in two different time

zones have been injected to the spacecrafts thrusters.

Figure 5 presents the evolution of the SPE detection index

applied on the thrusters measurement vector.

where:

SPE-Fault1 (blue curve) refers to the results of the

SPE detection index after the injection of the rst fault,

SPE-Fault2 (green curve) refers to the results of the

SPE detection index after the injection of the second

fault,

SPE-Threshold (red line) refers to the SPE indexs

threshold.

The simulation results in gure 5 show two principal

peaks exceeding the SPE threshold. Thus, two failures in the

thrusters may be considered. As explained, the VPCA method

consists on transforming an interval valued data matrix (with

m variables and N observations) into a new single valued one

(with m variables and N 2

m

observations). Then, if a fault

has been injected at an instant k, it will appear at an instant

k

= k 2

m

. As shown in gure 5 faults appear in two zones;

the srt one in the interval [5.12e+005, 5.376e+005] and the

second one in [1.024e + 006, 1.0496e + 006].

Once a fault is detected, it is important to locate the faulty

variable. To do so, we have used the variable reconstruction

approach.

Figure 6 and gure 7 present the evolution of the thrusters

isolation indices A

spe

R

, computed after the reconstruction of

each variable at an instant k of zone

1

and zone

2

respectively.

The evolution of the thrusters isolation indices A

spe

R

,

computed after the reconstruction of each variable in zone

1

and zone

2

, are presented respectively in gures 6 and 7. As

we can see, the two indexes A

spe

1

and A

spe

2

are lower than

1. These results conrm that the thrusters number 1 and 2 are

the faulty ones.

0 0.5 1 1.5 2 2.5 3 3.5

x 10

6

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

X: 5.12e+005

Y: 0.1579

S

P

E

/

2

(time)

X: 1.024e+006

Y: 0.1432

SPE_Threshold

SPE_FAULT2

SPE_FAULT1

Fig. 5. Thrusters fault detection with SPE index

1 2 3 4 5 6 7 8

0

0.5

1

1.5

2

2.5

3

(m)

A

s

p

e

R

(

z

o

n

e

1

)

Fig. 6. Thrusers fault localization using the index A

spe

R

Z1

.

1 2 3 4 5 6 7 8

0

0.5

1

1.5

2

2.5

3

3.5

(m)

A

s

p

e

R

(

z

o

n

e

2

)

Fig. 7. Thrusers fault localization using the index A

spe

R

Z2

.

V. CONCLUSION

The centers PCA and the vertices PCA are considered as

the most common method that extended the classical PCA to

interval valued data. In fact, the centers method is essentially

an analysis between the observations while the vertices method

is an analysis using both between and within observations

variations.

The present paper has presented a fault diagnosis process

based on the vertices principal component analysis. This

approach has been used to perform the fault detection and

isolation of spacecraft thrusters during the rendez-vous phase

of the Mars Sample Return mission.

In order to estimate the VPCA model, we have used

interval valued data matrix consisting of all measures of the

nominal spacecraft thrusters.

Once the VPCA model is built, and to put in evidence the

predened faults, we have applied the classical detection index

SPE to the new matrix of single valued data.

After the detection phase, an isolation fault approach, based

on the reconstruction principle highlighted the predened

thrusters faults.

According to this paper, the VPCA method is considered

computationally cumbersome since it requires the transforma-

tion of the interval valued data matrix into a single valued

data matrix. The number of rows of this matrix depends

exponentially on the number of variables and linearly on the

number of observation units.

The intended purpose of this research is then to develop a

new optimized approach that generalizes the principal compo-

nent analysis to interval valued data.

ACKNOWLEDGMENT

The research work presented in this paper falls within

a collaboration between the LRI (Laboratory for Computer

Science) and Thales Alenia Space. The authors would like to

thank Thales Alenia Space for providing the MSR high-delity

simulator.

REFERENCES

[1] R. Fonod, D. Henry, C. Charbonnel and E. Bornschlegl, Robust Thruster

Fault Diagnosis : Application to the rendezvous phase of the Mars

Sample Return mission, 2nd CEAS Specialist Conference on Guidance,

Navigation & Control, pp. 1496-1510, 2013.

[2] Ch. Gao and G. Duan, Fault diagnosis and fault tolerant control

for nonlinear satellite attitude control systems, Aerospace Science and

Technology, vol. 33, no. 1, pp. 9-15, 2014.

[3] H.M. Odendaal and Th. Jones, Actuator fault detection and isolation:

An optimised parity space approach, ELSEVIER, Control Engineering

Practice, vol. 26, pp. 222-232, 2014.

[4] M. REGAIEG, O. NASRI and Ph. DAGUE, Fault Detection and Iso-

lation of Spacecraft Thrusters by Using Principal Component Analysis,

4th European Conference For Aerospace SCiences, Proceedings of the

3rd International Conference on Systems and Control, Algiers, Algeria,

October, pp. 29-31, 2013.

[5] R. Isermann, Fault-Diagnosis Applications. Model-Based Condition

Monitoring: Actuators, Drives, Machinery, Plants Sensors, and Fault-

Tolerant Systems, Springer, Berlin, Germany, 2011.

[6] F. Kimmich, A. Schwarte and R. Isermann, Fault detection for modern

Diesel engines using signal- and process model-based methods, ELSE-

VIER, Control Engineering Practice, vol.13, no. 2, pp. 189-203, February

2005.

[7] E.J. Manders, S. Narasimhan, G. Biswas and P.J. Mosterman, A combined

qualitative/quantitative approach for fault isolation in continuous dy-

namic systems, Proc. of the 4

t

h IFAC Safeprocess Symposium, Budapest,

Hungary, pp. 1074-1079, 2000.

[8] S. Dinga, P. Zhanga, E. Dingb, S. Yina, A. Naika, P. Dengc and W. Guic,

On the Application of PCA Technique to Fault Diagnosis, ELSEVIER,

Tsinghua Science & Technology, vol. 15, no. 2, pp. 138-144, April 2010.

[9] S.M. Zanoli and G. Astol, Application of a Fault Detection and Isolation

System on a Rotary Machine, Hindawi, International Journal of Rotating

Machinery, 2013.

[10] M.F. Harkat, G. Mourot and J. Ragot, An improved PCA scheme for

sensor FDI: application to an air quality monitoring network, Journal

of Process Control, vol. 16, pp. 625-634, 2006.

[11] Y. Tharrault, G. Mourot, J. Ragot, and D. Maquin, Fault detection and

isolation with robust principal component analysis, International Journal

of Applied Mathematics and Computer Science, vol. 18, no. 4, pp. 429-

442, 2008.

[12] F. Palumbo, and C.N. Lauro, A PCA for interval valued data based on

midpoints and radii, In New Developments in Psychometrics, H. Yanai,

A. Okada, K. Shigematu, Y. Kano, and J.J. Meulman, eds. Japan,

Springer-Verlag, pp. 641648, 2003.

[13] P. Giordani, and H.A.L. Kiers, A comparison of three methods for

principal component analysis for fuzzy interval data, ELSEVIER, Com-

putational Statistics & Data Analysis, vol. 51, pp. 379-397, 2006.

[14] A.D. Chouakria, L. Billard and E. Diday, Principal Component Analysis

for Interval-Valued Observations, Statistical Analysis and Data Mining:

The ASA Data Science Journal, vol. 4, no. 2, pp. 229-246, April 2011.

[15] S. Wold, K. Esbensen, and P. Geladi, Principal Component Analysis,

ELSEVIER, Chemometrics and Intelligent Laboratory Systems, vol. 2,

no. 1-3, pp. 37-52, 1987.

[16] R. Dunia, S. Qin, and T.F. Edgar, Identication of faulty sensors using

principal component analysis, American Institute Of Chemical Engineers

Journal, vol. 42, no. 10, pp. 2797-2812, 1996.

[17] S. Valle, W. Li, W. and S. Qin, Selection of the number of principal

components : The variance of the reconstruction error criterion with

a comparaison to other methods, Industrial & Engineering Chemistry

Research, vol. 38, pp. 4389-4401, 1999.

[18] S.J. Qin, R. Dunia, Determining the number of principal components

for best reconstruction, Journal of Process Control, vol. 10, pp. 245-250,

2000.

[19] Y. Tharrault, G. Mourot, J. Ragot and D. Maquin, Sensor fault detection

and isolation by robust principal component analysis, Fault Detection,

Wei Zhang (Ed.), In-Tech, Chap. 16, 2010.

[20] G.E.P. Box, Some theorems on quadratic forms applied in the study of

analysis of variance problems: Effect of inequality of variance in one-

way classication, The Annals of Mathematical Statistics, vol. 25, pp.

290-302, 1954.

[21] A. Ben Aicha, G. Mourot, K. Benothman and J. Ragot, Determination

of Principal Component Analysis models for sensor fault detection and

isolation, International Journal of Control, Automation and Systems, vol.

11, no. 2, pp. 296-305, 2013.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Topical Revision Notes Biology O Level PDFDokument140 SeitenTopical Revision Notes Biology O Level PDFBilal Akram79% (19)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- INFO-Sheet Fumis ALPHADokument2 SeitenINFO-Sheet Fumis ALPHAAnthony GilmoreNoch keine Bewertungen

- Mustang Timing Belts D e 0616Dokument50 SeitenMustang Timing Belts D e 0616xyz008Noch keine Bewertungen

- Sahana MSE.1Dokument29 SeitenSahana MSE.1Dadi YashwantNoch keine Bewertungen

- Tests For Gas Permeability of ConcreteDokument6 SeitenTests For Gas Permeability of ConcreteAzuriak1Noch keine Bewertungen

- B-290 - Spray Dry ManualDokument57 SeitenB-290 - Spray Dry ManualAnonymous KzgvEj1Noch keine Bewertungen

- Least Cost PathDokument29 SeitenLeast Cost PathGaneshan ParamathmaNoch keine Bewertungen

- ValveTypesSelection - ControlsWikiDokument42 SeitenValveTypesSelection - ControlsWikiMayur PatelNoch keine Bewertungen

- Tank Design CalculationDokument20 SeitenTank Design CalculationHairil HerliansyahNoch keine Bewertungen

- PDFDokument2 SeitenPDFbhavesh patelNoch keine Bewertungen

- Formsat 5Dokument6 SeitenFormsat 5gramuiitmNoch keine Bewertungen

- TB Welding-English PDFDokument20 SeitenTB Welding-English PDFdanghpNoch keine Bewertungen

- Form 4 Chemistry Yearly Plan 2019Dokument2 SeitenForm 4 Chemistry Yearly Plan 2019Jenny WeeNoch keine Bewertungen

- Int Endodontic J - 2022 - Terauchi - Present Status and Future Directions Removal of Fractured InstrumentsDokument25 SeitenInt Endodontic J - 2022 - Terauchi - Present Status and Future Directions Removal of Fractured Instruments吳國豪Noch keine Bewertungen

- Adavances in Positioning and FramesDokument407 SeitenAdavances in Positioning and Framesoliwia.tolloczkoNoch keine Bewertungen

- MIT16 842F15 Ses 8 Sys IntDokument42 SeitenMIT16 842F15 Ses 8 Sys IntssvivekanandhNoch keine Bewertungen

- Modeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Dokument51 SeitenModeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Samuel ChanNoch keine Bewertungen

- CC Relief DoorDokument7 SeitenCC Relief DoorHim SatiNoch keine Bewertungen

- Apd125c 6Dokument4 SeitenApd125c 6selvamejiaNoch keine Bewertungen

- Nastran DST Group TN 1700Dokument69 SeitenNastran DST Group TN 1700Minh LeNoch keine Bewertungen

- Fundamentals of AC and All Air SystemDokument36 SeitenFundamentals of AC and All Air Systemnareshbv749Noch keine Bewertungen

- A Nimbus Cloud Is A Cloud That Produces PrecipitationDokument2 SeitenA Nimbus Cloud Is A Cloud That Produces PrecipitationMarianne FelixNoch keine Bewertungen

- AP Physics 1 FinaleDokument188 SeitenAP Physics 1 FinaleEvan ThompsonNoch keine Bewertungen

- English Download FanProtectionDokument14 SeitenEnglish Download FanProtectionSubhankar UncertainityNoch keine Bewertungen

- The Andromedan Compendium - 7bDokument10 SeitenThe Andromedan Compendium - 7bAnonymous XSNBQQ4yNoch keine Bewertungen

- ST/ST Fiber Optic Patch CableDokument9 SeitenST/ST Fiber Optic Patch CableMathivanan AnbazhaganNoch keine Bewertungen

- HAZOP Work Sheet ZaltoprofenDokument26 SeitenHAZOP Work Sheet Zaltoprofenkirandevi1981Noch keine Bewertungen

- (19MT18302) Modeling and Analysis of Electrical Machines (Theory)Dokument3 Seiten(19MT18302) Modeling and Analysis of Electrical Machines (Theory)Prabhu MoorthyNoch keine Bewertungen

- General Contractor, Supplier, Independent Survey, Ship Service & IndustrialDokument24 SeitenGeneral Contractor, Supplier, Independent Survey, Ship Service & IndustrialNicoNoch keine Bewertungen

- BBS10 PPT MTB Ch04 ProbabiltyDokument37 SeitenBBS10 PPT MTB Ch04 ProbabiltyAgenttZeeroOutsiderNoch keine Bewertungen