Beruflich Dokumente

Kultur Dokumente

Gear Manufacturing To Teach

Hochgeladen von

samanaveen100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

87 Ansichten44 Seitengear manufacturing Tech

Originaltitel

86728006 Gear Manufacturing to Teach

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldengear manufacturing Tech

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

87 Ansichten44 SeitenGear Manufacturing To Teach

Hochgeladen von

samanaveengear manufacturing Tech

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 44

Gear Manufacturing

Selection of Gear Materials

Allowable bending stress

Wear resistance

Impact strength

Water and corrosion resistance

Manufacturing cost

Size

Weight

Reliability

Lubrication requirements

No Moisture Absorption

Dimensionally Stable

Stress-Free structure

Environmental and surface temperature.

Gear Materials

Metallic Gears

Cast Iron Gears

Steel Gears

Aluminium Gears

Bronze Gears

Brass Gears

Ductile Iron Gears

Non Metallic Gears

Plastic Gears

Gear Manufacturing Methods

Gear Forming (non-cutting) Processes

Gear Cutting Processes

Gear Finishing Processes

Sand Casting

Characteristics:

The characteristics of sand cast gears are,

Cheaper low quality gear in small numbers

The tooling costs are reasonable

Poor Surface finish and dimensional accuracy

Due to low precision and high backlash, they are noisy.

They are suited for non- critical applications

Applications:

Sand casting is used for gear manufacture which are used in variety of

applications such as for toys, small appliances, cement-mixer barrels,

hoist gearbox of dam gate lifting mechanism, hand operated crane etc.,

Materials:

The materials that can be sand cast are C I, cast steel, bronzes, brass and

ceramics. The process is confined to large gears that are machined later

to required accuracy.

Die casting

Characteristics:

The characteristics of die cast gears are,

Better surface finish and accuracy (tooth spacing and concentricity)

High tooling costs

Suited for large scale production Applications:

Applications:

Gears that are die cast are used in instruments, cameras, business

machines, washing machines, gear pumps, small speed reducers, and

lawn movers.

Materials:

Materials used to manufacture these gears are zinc, aluminium and

brass. The gears made from this process are not used for high speeds

and heavy tooth loading. They are normally applied for small size

gears.

Investment casting or lost wax process

Characteristics:

The characteristics of gears that are manufactured by investment casting

are,

Reasonably accurate gears

Applicable for a variety of materials

Refractory mould material

Allows high melt-temperature materials

Accuracy depends on the original master pattern used for the mold.

Materials:

Tool steel, nitriding steel, monel, beryllium copper are the materials that

can be investment casted for the manufacture of gears. The process is

used only if no other process is suitable since production cost is high. Fig.

shows investment casting process.

Complicated shape of gear manufactured by Investment casting

Sintering or P/M process:

The powder metallurgy technique used for gear manufacture is shown in fig.

Characteristics:

Accuracy similar to die-cast gears

Typically suited for small sized gears

Economical for large lot size only

Injection Molding:

Injection molding is used to make nonmetallic gears in various thermoplastics such

as nylon and acetal. These are low precision gears in small sizes but have the

advantages of low cost and the ability to be run without lubricant at light loads.

Applications:

Injection molded gears are used in cameras, projectors, wind shield wipers,

speedometer, lawn sprinklers, washing machine.

Materials:

The materials for injection molding components are Nylon, cellulose acetate,

polystyrene, polyimide, phenolics.

Extruding

Extruding is used to form teeth on long rods, which are then cut into usable

lengths and machined for bores and keyways etc. Nonferrous materials such

as aluminum and copper alloys are commonly extruded rather than steels.

This result in good surface finishes with clean edges and pose free dense

structure with higher strength.

Extruded gears

Materials:

Aluminum, copper, naval brass, architect-ural bronze and phosphor bronze are

the materials that are commonly extruded.

Applications:

Splined hollow & solid shafts, sector gears are extruded and various gears are

shown in fig

Cold Drawing:

Cold drawing forms teeth on steel rods by drawing them through hardened dies. The cold

working increases strength and reduces ductility. The rods are then cut into usable lengths

and machined for bores and keyways, etc.

Stamping:

Sheet metal can be stamped with tooth shapes to form low precision gears at low cost in

high quantities. The surface finish and accuracy of these gears are poor.

Applications:

Stamped gears are used as toy gears, hand operated machine gears for slow speed

mechanism.

Precision stamping:

In precision stamping, the dies are made of higher precision with close tolerances wherein

the stamped gears will not have burrs.

Applications:

Clock gears, watch gears etc.

Forging:

The steps in forging process are represented in fig.

MACHINING

The bulk of power transmitting metal gears of machinery are produced by machining

process from cast, forged, or hot rolled blanks. Roughing processes include milling the

tooth shape with formed cutters or generating the shape with a rack cutter, a shaping

cutter or a hob cutter which are shown in fig.

Despite its name, the roughing processes actually produce a smooth and accurate gear

tooth. Only for high precision and quiet running, the secondary finishing operation is

justified at added cost.

Roughing processes:

Roughing process consists of forming, generation, shaping and hobbing processes. By this

method gears are made to an accuracy which is more than adequate for the slow speed

operations. These processes are dealt here.

Form milling:

Forming is sub-divided into milling by disc cutters and milling by end mill cutter which are

having the shape of tooth space.

(a) Form milling by disc cutter:

The disc cutter shape conforms to the gear tooth space. Each gear needs a separate cutter.

However, with 8 to 10 standard cutters, gears from 12 to 120 teeth can be cut with fair

accuracy. Tooth is cut one by one by plunging the rotating cutter into the blank as shown in

fig .

(b) Form milling by end mill cutter:

The end mill cutter shape conforms to tooth spacing. Each tooth is cut at a time and then

indexed for next tooth space for cutting. A set of 10 cutters will do for 12 to 120 teeth gears. It

is suited for a small volume production of low precision gears. The form milling by end mill

cutter is shown in fig .

Form milling by end mill cutter

To reduce costs, the same cutter is often used for the multiple-sized gears resulting in profile

errors for all but one number of teeth. Form milling method is the least accurate of all the

roughing methods.

Rack generation:

In rack cutter the tooth shape is trapezoid and can be made easily. The hardened and

sharpened rack is reciprocated along the axis of the gear blank and fed into it while gear

blank is being rotated so as to generate the involute tooth on the gear blank as shown in fig.

Generation of involute tooth on gear blank

The rack and gear blank must be periodically repositioned to complete the circumference.

This introduces errors in the tooth geometry making this method less accurate than

shaping and hobbing.

The process is limited to small gears since the length of the rack has to be equal to

circumference of the gear at pitch diameter. The generation of spur gear by planing is shown

in fig

generation of spur gear by planing

Gear shaping:

Gear shaping used a cutting tool in the shape of a gear which is reciprocated axially across

the gear blank to cut the teeth while the blank rotates around the shaper tool. It is a true

shape-generation process in which the gear-shaped tool cuts itself into mesh with the gear

blank as shown in fig. The accuracy is good, but any errors in one tooth of the shaper cutter

will be directly transferred to the gear. Internal gears can be cut with this method as well.

Gear shaping

GEAR HOBBING

Hobbing is a machining process for making gears, splines,

and sprockets on a hobbing machine, which is a special type

of milling machine. The teeth or splines are progressively cut into

the workpiece by a series of cuts made by a cutting tool called

a hob. Compared to other gear forming processes it is relatively

inexpensive but still quite accurate, thus it is used for a broad range

of parts and quantities.

It is the most widely used gear cutting process for creating spur

and helical gears and more gears are cut by hobbing than any

other process since it is relatively quick and inexpensive.

Process Characteristics

Is a gear generating process that uses a hob

cutter

Cutters and blanks rotate in a timed relationship

Maintains a proportional feed rate between the

gear blank and the hob

Cuts several teeth on a progressive basis used for

high production runs

Process

Hobbing uses a hobbing machine with two skew spindles, one mounted with a

blank workpiece and the other with the hob. The angle between the hob's spindle

and the workpiece's spindle varies, depending on the type of product being

produced. For example, if a spur gear is being produced, then the hob is angled

equal to the helix angle of the hob; if a helical gear is being produced then the angle

must be increased by the same amount as the helix angle of the helical gear. The two

shafts are rotated at a proportional ratio, which determines the number of teeth on

the blank; for example, if the gear ratio is 40:1 the hob rotates 40 times to each turn

of the blank, which produces 40 teeth in the blank. Note that the previous example

only holds true for a single threaded hob; if the hob has multiple threads then the

speed ratio must be multiplied by the number of threads on the hob. The hob is then

fed up into workpiece until the correct tooth depth is obtained. Finally the hob is fed

into the workpiece parallel to the blank's axis of rotation.

Up to five teeth can be cut into the workpiece at the same time. Oftentimes multiple

gears are cut at the same time.

For larger gears the blank is usually gashed to the rough shape to make hobbing

easier.

Equipment

Modern hobbing machines, also known as hobbers, are fully automated machines that

come in many sizes, because they need to be able to produce anything from tiny

instrument gears up to 10 ft (3.0 m) diameter marine gears. Each gear hobbing machine

typically consists of a chuck andtailstock, to hold the workpiece or a spindle, a spindle

on which the hob is mounted, and a drive motor.

For a tooth profile which is a theoretical involute, the fundamental rack is straight-

sided, with sides inclined at the pressure angle of the tooth form, with flat top and

bottom. The necessary addendum correction to allow the use of small-numbered

pinions can either be obtained by suitable modification of this rack to a cycloidal form

at the tips, or by hobbing at other than the theoretical pitch circle diameter. Since

the gear ratio between hob and blank is fixed, the resulting gear will have the correct

pitch on the pitch circle, but the tooth thickness will not be equal to the space width.

Hobbing machines are characterized by the largest module or pitch diameter

it can generate. For example, a 10 in (250 mm) capacity machine can

generate gears with a 10 in pitch diameter and usually a maximum of a 10 in

face width. Most hobbing machines are vertical hobbers, which means the

blank is mounted vertically. Horizontal hobbing machines are usually used

for cutting longer workpieces; i.e. cutting splines on the end of a shaft.

.

Hob

The hob is the cutter used to cut the teeth into the workpiece. It is cylindrical

in shape with helical cutting teeth. These teeth have grooves that run the

length of the hob, which aid in cutting and chip removal. There are also

special hobs designed for special gears such as the spline and sprocket gears.

The cross-sectional shape of the hob teeth are almost the same shape as

teeth of a rack gear that would be used with the finished product. There are

slight changes to the shape for generating purposes, such as extending the

hob's tooth length to create a clearance in the gear's roots.

Each hob tooth is

relieved on the back side to reduce friction.

Most hobs are single-thread hobs, but double-, and triple-thread hobs

increase production rates. The downside is that they are not as accurate as

single-thread hobs

This list outlines types of hobs:

Roller chain sprocket hobs

Worm wheel hobs

Spline hobs

Chamfer hobs

Spur and helical gear hobs

Straight side spline hobs

Involute spline hobs

Serration hobs

Semitopping gear hobs

Advantages of Gear Hobbing Process

High productivity rate

Economical and efficient operation

Accuracy

Close tolerances

Versatility of operations

Smooth finishes

Grinding:

In grinding, a contoured grinding wheel is run over machined surface of the gear teeth using

computer control. With a small amount of metal removal high surface finish is obtained. Fig.

shows grinding operations and dressing of the wheel.

(a) Grinding the flanks only,

(b) Grinding root and flanks,

(c) Grinding each flank

separately with twin

grinding wheels and

(d) Pantograph dressing of

the wheel

Grinding is used to correct the heat-treatment distortion in gears hardened after roughing.

Improvement in surface finish and error correction of earlier machining are added

advantages. Grinding operation for gears can be done by profile grinding or form grinding

as shown in fig.(a) and (b)

(a) (b)

(a) Maag zero pressure angle profile grinding and (b) Maag profile grinding

David Brown form grinding of worm threads

Burnishing:

In burnishing, a specially hardened gear is run over rough machined gear. The high forces at

the tooth interface cause plastic yielding of the gear tooth surface which improves finish

and work hardens the surface creating beneficial compressive residual stresses.

Lapping and Honing:

Lapping and honing both employ an abrasive-impregnated gear or gear-shaped tool that is

run against the gear to abrade the surface. In both cases, the abrasive tool drives the gear

in what amounts to an accelerated and controlled run-in to improve surface finish and the

accuracy. Fig. shows lapping operation for bevel gears.

Special bevel gears being lapped

Quality of the Gear:

The quality of gear gives its accuracy, dimensional and profile which dictates the suitability of

gears for different operations.

Various standards for assuring the quality of gears are,

The AGMA standard 2000-A88 defines dimension tolerance for gear teeth and a quality index

Qv that ranges from the lowest quality 3 to the highest precision 16.

DIN 3962 defines quality index in another way. Highest quality is assigned number 1 and the

lowest quality is assigned number 12.

Based on the machining/production techniques the accuracy of gears varies viz., with the pitch

error, profile errors and surface finish, the Qv varies. These errors give rise to vibration in the

gears and affect their smooth running. Consequently the gear quality limits their speed of

operation. The various gear manufacturing processes and the corresponding dynamic load

factors at various speeds are depicted in Fig. The limiting speeds and dynamic load factors for

various quality of gears is shown in Fig.

Various gear manufacturing processes, their operating speed limits and dynamic load factors

Various gear manufacturing processes, their operating speed limits and dynamic load

factors

Gear quality, their limiting speeds and dynamic load factors

Allowable velocities and applications of gears of various accuracy grades

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- 0 Deec 521 de 35888476000000Dokument4 Seiten0 Deec 521 de 35888476000000samanaveenNoch keine Bewertungen

- Saej 4004 V 001Dokument35 SeitenSaej 4004 V 001samanaveenNoch keine Bewertungen

- Development of Turbocharger For Improving Passenger Car AccelerationDokument9 SeitenDevelopment of Turbocharger For Improving Passenger Car AccelerationsamanaveenNoch keine Bewertungen

- Development of Advanced Model of Turbocharger For Automotive EnginesDokument9 SeitenDevelopment of Advanced Model of Turbocharger For Automotive EnginessamanaveenNoch keine Bewertungen

- pm038 Maziasz 2012 oDokument13 Seitenpm038 Maziasz 2012 osamanaveenNoch keine Bewertungen

- Echnica : Improvement of Turbocharger Life For Diesel and Gasoline EnginesDokument12 SeitenEchnica : Improvement of Turbocharger Life For Diesel and Gasoline EnginessamanaveenNoch keine Bewertungen

- A Small Turbocharger For Passenger Car and Truck ApplicationsDokument9 SeitenA Small Turbocharger For Passenger Car and Truck ApplicationssamanaveenNoch keine Bewertungen

- DI1Dokument13 SeitenDI1Getapune PunegetaNoch keine Bewertungen

- Evaluation of A Multi Leaf Hybrid Springs For Automotive SuspensionsDokument8 SeitenEvaluation of A Multi Leaf Hybrid Springs For Automotive SuspensionsBharatiyulamNoch keine Bewertungen

- Evaluation of A Multi Leaf Hybrid Springs For Automotive SuspensionsDokument8 SeitenEvaluation of A Multi Leaf Hybrid Springs For Automotive SuspensionsBharatiyulamNoch keine Bewertungen

- 2005 01 1747Dokument7 Seiten2005 01 1747samanaveenNoch keine Bewertungen

- Evaluation of A Multi Leaf Hybrid Springs For Automotive SuspensionsDokument8 SeitenEvaluation of A Multi Leaf Hybrid Springs For Automotive SuspensionsBharatiyulamNoch keine Bewertungen

- People Courses 24 Strengths of Adhesive JointsDokument18 SeitenPeople Courses 24 Strengths of Adhesive JointsaenymaNoch keine Bewertungen

- ACD Manufacturing TechnologyDokument2 SeitenACD Manufacturing Technologylavinkg7681Noch keine Bewertungen

- People Courses 24 Strengths of Adhesive JointsDokument18 SeitenPeople Courses 24 Strengths of Adhesive JointsaenymaNoch keine Bewertungen

- Introduction To Gear DesignDokument35 SeitenIntroduction To Gear DesignAsela Bollegala100% (1)

- AdhesivesDokument176 SeitenAdhesivesm_gobara100% (11)

- AdhesivesDokument12 SeitenAdhesivesOmair Ali KhanNoch keine Bewertungen

- AdhesivesDokument458 SeitenAdhesivesArturs Stangainis100% (6)

- 851572Dokument24 Seiten851572samanaveenNoch keine Bewertungen

- 2013 32 9102Dokument8 Seiten2013 32 9102samanaveenNoch keine Bewertungen

- Gear Materials, Properties, and ManufactureDokument347 SeitenGear Materials, Properties, and ManufactureFrançois Steinmetz91% (11)

- 2008 28 0055Dokument9 Seiten2008 28 0055samanaveenNoch keine Bewertungen

- Gear Manufacturing MethodDokument89 SeitenGear Manufacturing MethodRamalingam AlagarajaNoch keine Bewertungen

- Sae Technical Paper Series: Edward H. Williams IIIDokument9 SeitenSae Technical Paper Series: Edward H. Williams IIIsamanaveenNoch keine Bewertungen

- Module 2 - GEARS Lecture 5 - Gear ManufacturingDokument25 SeitenModule 2 - GEARS Lecture 5 - Gear ManufacturingNikhil B RamNoch keine Bewertungen

- 851572Dokument24 Seiten851572samanaveenNoch keine Bewertungen

- New Gear Locking Design in Synchromesh Gearbox Which Reduces Gear Shift EffortDokument8 SeitenNew Gear Locking Design in Synchromesh Gearbox Which Reduces Gear Shift EffortsamanaveenNoch keine Bewertungen

- Influence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationDokument7 SeitenInfluence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationsamanaveenNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Perth Freight Link FOI DocumentsDokument341 SeitenPerth Freight Link FOI DocumentsYarra Campaign for Action on Transport (YCAT)Noch keine Bewertungen

- Waterman Industries of Egypt - Stop Logs Typical SpecificationsDokument3 SeitenWaterman Industries of Egypt - Stop Logs Typical Specifications2267airportNoch keine Bewertungen

- Dry Docking NotesDokument16 SeitenDry Docking NotesIshan Vyas100% (1)

- BS 1881-110 CONCRETE Making Test Cylinders From Fresh ConDokument12 SeitenBS 1881-110 CONCRETE Making Test Cylinders From Fresh ConhajimakNoch keine Bewertungen

- History of Cauayan IsabelaDokument18 SeitenHistory of Cauayan IsabelaLisa MarshNoch keine Bewertungen

- WJMDokument18 SeitenWJMSharath Chandra PalleNoch keine Bewertungen

- Extended Downtime ChecklistDokument4 SeitenExtended Downtime Checklistsigmasundar100% (1)

- McDonalds Ground LeaseDokument12 SeitenMcDonalds Ground LeasenetleaseNoch keine Bewertungen

- Airbus Family CCQMMF JOEB Report (120304)Dokument36 SeitenAirbus Family CCQMMF JOEB Report (120304)pedatiNoch keine Bewertungen

- Skynet Courier Tracking Dubai PDFDokument7 SeitenSkynet Courier Tracking Dubai PDFRODEWAY INN ERIENoch keine Bewertungen

- Vietnam Market Insight: Q4 2019 in VNDDokument16 SeitenVietnam Market Insight: Q4 2019 in VNDTuan Nguyen100% (1)

- Cable Tray InstallationDokument6 SeitenCable Tray InstallationsbpathiNoch keine Bewertungen

- I-Rod Pipe Supports BrochureDokument4 SeitenI-Rod Pipe Supports BrochureNamcha TechaveerapongNoch keine Bewertungen

- Gold Jewellery Manufacturing Process: Step-1 Step-2 Step-3Dokument2 SeitenGold Jewellery Manufacturing Process: Step-1 Step-2 Step-3Siva KumarNoch keine Bewertungen

- Well SinkingDokument153 SeitenWell SinkingHari Krishna AaryanNoch keine Bewertungen

- CargoDokument70 SeitenCargoAnonymous hF1hhmInm3Noch keine Bewertungen

- Fits and TolerancesDokument15 SeitenFits and TolerancesJohn Victor KamelNoch keine Bewertungen

- Industry Data BaseDokument14 SeitenIndustry Data BaseJamalSultan100% (1)

- Traffic Signs & Symbols. Road Signs. Street Signs. Traffic SignalsDokument5 SeitenTraffic Signs & Symbols. Road Signs. Street Signs. Traffic Signalsmark_torreonNoch keine Bewertungen

- Introduction To Tourism and The Hospitality ManagementDokument45 SeitenIntroduction To Tourism and The Hospitality ManagementManny HermosaNoch keine Bewertungen

- Millau Viaduct Term PaperDokument13 SeitenMillau Viaduct Term Paperfan_luc89Noch keine Bewertungen

- Pdfjoiner PDFDokument86 SeitenPdfjoiner PDFvictor saikiaNoch keine Bewertungen

- Cruise Line Industry PresentationDokument45 SeitenCruise Line Industry PresentationCindy Ortiz GastonNoch keine Bewertungen

- 2016-09 - Centra - HF BrochureDokument8 Seiten2016-09 - Centra - HF BrochureMatias BerriosNoch keine Bewertungen

- Product Catalogue 2016Dokument24 SeitenProduct Catalogue 2016sineadNoch keine Bewertungen

- Gard Legal Guidance To MastersDokument150 SeitenGard Legal Guidance To Mastersmoe_htwe_1Noch keine Bewertungen

- Profile RyalienggDokument11 SeitenProfile Ryalienggnavs_711Noch keine Bewertungen

- Ce2026 Traffic EngineeringDokument276 SeitenCe2026 Traffic EngineeringArun Ethiraj0% (1)

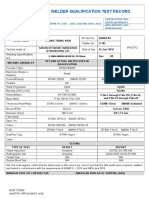

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Dokument3 SeitenHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNoch keine Bewertungen

- Proveedores TWDokument33 SeitenProveedores TWMarx WillianNoch keine Bewertungen