Beruflich Dokumente

Kultur Dokumente

Introduction To Mems

Hochgeladen von

iagooOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Introduction To Mems

Hochgeladen von

iagooCopyright:

Verfügbare Formate

Introduction to MEMS

November 1, 2014

INTRODUCTION TO MEMS

1 Introduction

MEMS is a process technology used to create tiny integrated devices or systems that

combine mechanical and electrical components. They are fabricated using integrated

circuit (IC) batch processing techniques and can range in size from a few micrometers

to millimetres. These devices (or systems) have the ability to sense, control and actuate

on the micro scale, and generate effects on the macro scale.

The interdisciplinary nature of MEMS utilizes design, engineering and manufac-

turing expertise from a wide and diverse range of technical areas including integrated

circuit fabrication technology, mechanical engineering, materials science, electrical en-

gineering, chemistry and chemical engineering, as well as uid engineering, optics,

instrumentation and packaging. The complexity of MEMS is also shown in the ex-

tensive range of markets and applications that incorporate MEMS devices. MEMS

can be found in systems ranging across automotive, medical, electronic, communi-

cation and defence applications. Current MEMS devices include accelerometers for

airbag sensors, inkjet printer heads, computer disk drive read/write heads, projection

display chips, blood pressure sensors, optical switches, microvalves, biosensors and

many other products that are all manufactured and shipped in high commercial vol-

umes.

1

MEMS, an acronym that originated in the United States, is also referred to as Mi-

crosystems Technology (MST) in Europe and Micromachines in Japan. Regardless of

terminology, the uniting factor of a MEMS device is in the way it is made. While the

device electronics are fabricated using computer chip IC technology, the microme-

chanical components are fabricated by sophisticated manipulations of silicon and other

substrates using micromachining processes. Processes such as bulk and surface mi-

cromachining, as well as high-aspect-ratio micromachining (HARM) selectively re-

move parts of the silicon or add additional structural layers to form the mechanical and

electromechanical components. While integrated circuits are designed to exploit the

electrical properties of silicon, MEMS takes advantage of either silicons mechanical

properties or both its electrical and mechanical properties.

In the most general form, MEMS consist of mechanical microstructures, mi-

crosensors, microactuators and microelectronics, all integrated onto the same silicon

chip.Microsensors detect changes in the systems environment by measuring mechan-

ical, thermal, magnetic, chemical or electromagnetic information or phenomena. Mi-

croelectronics process this information and signal the microactuators to react and create

some form of changes to the environment.

2 History of Mems

The historical progress of Mems is shown below [?]

2

1958: Silicon strain gauges commercially available

1961: First silicon pressure sensor demonstrated

1967: Invention of surface micromachining. Westinghouse creates the Resonant Gate

Field Effect Transistor, (RGT). Description of use of sacricial material

to free micromechanical devices from the silicon substrate

1970: First silicon accelerometer demonstrated

1979 First micromachined inkjet nozzle

1982: Disposable blood pressure transducer

1982: Silicon as a Mechanical Material Instrumental paper to entice the scientic

community - reference for material properties and etching data for silicon.

1982: LIGA Process

1988: First MEMS conference

1992: MCNC starts the Multi-User MEMS Process (MUMPS) sponsored by

Defense Advanced Research Projects Agency (DARPA)

1992: First micromachined hinge

1993: First surface micromachined accelerometer sold (Analog Devices, ADXL50)

1994: Deep Reactive Ion Etching is patented

1995: BioMEMS rapidly develops

2000: MEMS optical-networking components become big business

3 MEMS Fabrication

MEMS fall into three general classications; bulk micromachining, surface microma-

chining and high-aspect-ratio micromachining (HARM), which includes technology

such as LIGA (a German acronym from Lithographie, Galvanoformung, Abformung

translated as lithography, electroforming and moulding).

Conventional macroscale manufacturing techniques e.g. injection moulding,

turning, drilling etc, are good for producing three dimensional (3D) shapes and ob-

jects, but can be limited in terms of low complexity for small size applications. MEMS

fabrication, by comparison, uses high volume IC style batch processing that involves

the addition or subtraction of two dimensional layers on a substrate (usually silicon)

3

based on photolithography and chemical etching. As a result, the 3D aspect of MEMS

devices is due to patterning and interaction of the 2D layers. Additional layers can be

added using a variety of thin-lm and bonding techniques as well as by etching through

sacricial spacer layers.

3.1 Basic MEMS Microfabrication Processes

3.1.1 Deposition Processes

Depositing thin lms over the surface of substrates and other MEMS components is

a common practice in micromachining.Deposition adds thin lms instead of consum-

ing the substrates unlike diffusion and thermal oxidation processes.

There are generally two types of deposition processes in micromachining. These

are (a) chemical vapor deposition (CVD) and (b) physical vapor deposition (PVD).

PVD involves the direct impingement of particles on the hot substrate surfaces. CVD,

on the other hand, involves convective heat and mass transfer as well as diffusion with

chemical reactions at the substrate surfaces.

a)Chemical Vapor Deposition

Chemical Vapor Deposition (CVD) involves the ow of a gas with diffused reac-

tants over a hot substrate surface. While the carrier gas ows over the hot solid surface,

the energy supplied by the temperature causes chemical reactions of the reactants.The

reaction of these species produces a solid phase, which is absorbed to the surface. The

by-products of the chemical reactions are removed. Continuous reaction causes a layer

of material to be built on the wafer surface.

For example , deposition of Silicon Nitride on Silicon substrates is done by the

following chemical reaction.

3SiH

4

+ 4NH

3

Si

3

N

4

+ 12H

2

(700 to 900

C)

4

Apart from CVD at atmospheric pressure(APCVD), there are two variants of

CVD. They are (1) Low pressure CVD (LPCVD) and (2) Plasma-enhanced CVD

(PECVD). In LPCVD , the reaction takes place at very low pressures of the order of 1

to 8 torr. The reduction of gas pressure will increase the rate of deposition. PECVD

utilizes the radio-frequency (RF) plasma to transfer energy into the reactant gases

which allows the substrates to remain at lower temperature.

b) Physical Vapor Deposition

Sputtering is a process that is often used to deposit thin metallic lms of the

order of hundreds of angstroms. Plasma is made of positively charged gas ion. The

positive ions of the metal in an inert argon gas carrier bombard the surface of the target

at high velocity that the momentum transfer on impingement causes the metal ions to

evaporate.The metal vapor is then led to the substrate surface and is deposited after

condensation.

3.1.2 Pattern Transfer

Integrated circuits and microfabricated MEMS devices are formed by dening patterns

in the various layers created by wafer-level process steps [?] . Pattern transfer consists

of two parts: a photo-process, whereby the desired pattern is photographically trans-

ferred from an optical plate to a photosensitive lm coating the wafer, and a chemical

or physical process of either removing materials to create the pattern. Most processes

remove unwanted material by etching away chemically.

5

Photolithography

Optical lithography is very much like the photographic process of producing a

print from a negative. The enabling materials of optical lithography are photoresists,

polymeric optically-sensitive materials that are deposited onto the wafer surface by

spin casting. Following spinning, the resists are prebaked at low temperature to re-

move solvent, but are not fully hardened. Completion of the hardening process occurs

after optical exposure.

Figure 1 illustrates the lithographic process analogous to contact printing.A pho-

tomask contains the pattern to be transferred as a set of opaque and transparent regions.

It is brought into contact with an oxidized silicon wafer coated with photoresist. Ul-

traviolet light is directed through the mask onto the wafer, exposing the unprotected

portions of the resist, which change their chemical properties as a result of the light ex-

posure.The photochemical processes in the photoresist are relatively high in contrast,

and develop sharp boundaries between exposed and protected regions. Contact lithog-

raphy is one of the standard processes used in MEMS manufacture.

Figure 1: Contact Photolithography

6

There are two types of photolithography as illustrated in gure 2a Negative pho-

toresist functions much like the photographic printing process. The regions of the

photoresist that are exposed to the ultraviolet light become cross-linked and insolu-

ble in the developer, while the protected regions remain soluble. After immersion in

the developer or exposure to a continuous spray of developer, the soluble portions are

removed.

7

(a) Negative Photoresist

(b) Positive Photoresist

Figure 2: Photolithography using Negative and Positive Photoresists

8

The net result is a transfer of pattern into the photoresist so that after etching, the

opaque regions of the mask become regions cleared of photoresist.

To transfer the pattern into the oxide, the resist must rst be hardened by baking to

make it more chemically inert. After this postbake, the silicon dioxide can be removed

by an etching process.Following the etching, the photoresist is removed, leaving the

mask pattern transferred into the oxide layer.

Positive photoresist works oppositely to negative photoresist. The chemistry of the

photoresist is different. Regions exposed to the UV light become more soluble in the

developer than the protected regions. After development and postbake, the protected

regions of resist remain on the wafer so that after etching, the opaque regions of the

mask remain as oxide and the clear regions are removed.

Because direct contact between the wafer and the mask can eventually cause dam-

age to the mask, a variant of the contact lithography is to leave a small air gap between

the mask and the photoresist-covered wafer. This is called proximity lithography [?].

The achievable resolution is somewhat less than with contact lithography, because

diffraction can occur at the edges of the opaque regions.When using contact lithog-

raphy, the mask must be the same size as the wafer, and every feature to be transferred

must be placed on the mask at its exact nal size.

Electron Beam Lithography

Electron beam lithography ( e-beam lithography) is the practice of scanning a

beam of electrons in a patterned fashion across a surface covered with a lm ( re-

sist), [?] ("exposing" the resist) and of selectively removing either exposed or non-

exposed regions of the resist ("developing"). The purpose, as with photolithography,

is to create very small structures in the resist that can subsequently be transferred to

the substrate material, often by etching. It was developed for manufacturing integrated

circuits, and is also used for creating nanotechnology architectures.

The primary advantage of electron beam lithography is that it is one of the ways

to beat the diffraction limit of light and make features in the nanometer regime. This

9

form of maskless lithography has found wide usage in photomask-making used in pho-

tolithography, low-volume production of semiconductor components, and research and

development.

The key limitation of electron beam lithography is throughput, i.e., the very long

time it takes to expose an entire silicon wafer or glass substrate. A long exposure

time leaves the user vulnerable to beam drift or instability which may occur during the

exposure.

Track Technology

Ion track technology is a deep cutting tool with a resolution limit around 8 nm ap-

plicable to radiation resistant minerals, glasses and polymers. It is capable to generate

holes in thin lms without any development process. Structural depth can be dened

either by ion range or by material thickness. Aspect ratios up to several 104 can be

reached. The technique can shape and texture materials at a dened inclination angle.

Random pattern, single-ion track structures and aimed pattern consisting of individual

single tracks can be generated.

X-ray Lithography

X-ray lithography, is a process used in electronic industry to selectively remove

parts of a thin lm. It uses X-rays to transfer a geometric pattern from a mask to a

light-sensitive chemical photoresist, or simply "resist," on the substrate. A series of

chemical treatments then engraves the produced pattern into the material underneath

the photoresist.

3.1.3 Etching

Etching is one of the most important processes in microfabrication.It involves the

removal of materials in desired areas by physical or chemical means. It establishes

permanent patterns developed at the substrate by photolithography.There are two types

of etching techniques. They are (1) Chemical or Wet Etching and (2)Physical or Dry

Etching .

10

In plasma etching, high energy plasma containing gas molecules, free electrons,

and gas ions bombards the surface of the target substrate and knock off the substrate

material from its surface.

1)Wet Etching

Wet etching involves using solutions with diluted chemicals to dissolve substrates.

For example, diluted hydrouoric (HF) solution is used to dissolve SiO

2

, Si

3

N

4

etc.

whereas potassium peroxide (KOH) is used to etch the silicon substrates as described

in section (1.3.1)

In wet etching, the part of the substrate that is not covered by the protective

mask id dissolved in the etchants and removed.The etching can undercut the part that

is immediately under the protective mask after a lengthy period of time.

(a) Substrate in wet etching (b) Partially etched substrate

Figure 3: Wet Etching

Isotropic Wet Etching

Isotropic etchants etch the material at the same rate in all directions, and con-

sequently remove material under the etch masks at the same rate as they etch through

the material; this is known as undercutting . The most common form of isotropic

silicon etch is HNA,which comprises a mixture of hydrouoric acid (HF), nitric acid

(HNO3) and acetic acid(CH3COOH). Isotropic etchants are limited by the geometry

11

of the structure to be etched. Etch rates can slow down and in some cases (for example,

in deep and narrow channels) they can stop due to diffusion limiting factors. However,

this effect can be minimized by agitation of the etchant, resulting in structures with

near perfect and rounded surfaces.

Figure 4: Under Cut during Wet etching

Anisotropic Wet Etching

Anisotropic etchants etch faster in a preferred direction. Potassium hydroxide

(KOH) is the most common anisotropic etchant as it is relatively safe to use. Struc-

12

tures formed in the substrate are dependent on the crystal orientation of the substrate or

wafer. Most such anisotropic etchants progress rapidly in the crystal direction perpen-

dicular to the (110) plane and less rapidly in the direction perpendicular to the (100)

plane. The direction perpendicular to the (111) plane etches very slowly if at all. Fig-

ures 19c and 19d shows examples of anisotropic etching in (100) and (110) silicon.

Silicon wafers, originally cut from a large ingot of silicon grown from single seed sili-

con, are cut according to the crystallographic plane. They can be supplied in terms of

the orientation of the surface plane.

Figure 5: Crystallographic Planes in Silicon

2)Dry Etching

Dry etching relies on vapour phase or plasma-based methods of etching using

suitably reactive gases or vapours usually at high temperatures. The most common

form for MEMS is Reactive Ion Etching (RIE) which utilizes additional energy in the

form of radio frequency (RF) power to drive the chemical reaction. Energetic ions are

accelerated towards the material to be etched within a plasma phase supplying the ad-

ditional energy needed for the reaction; as a result the etching can occur at much lower

temperatures (typically 150 - 250

C) ,sometimes room temperature) than those usu-

ally needed (above 1000

C). RIE is not limited by the crystal planes in the silicon, and

as a result, deep trenches and pits, or arbitrary shapes with vertical walls can be etched .

13

Figure 6: Reactive Ion Etching(RIE)

Deep Reactive Ion Etching (DRIE) is a much higher-aspect-ratio etching method

that involves an alternating process of high-density plasma etching (as in RIE) and

protective polymer deposition to achieve greater aspect ratios.

14

Figure 7: Deep Reactive Ion Etching(DRIE)

Chemically reactive vapors are some times used as etchants.This technique is

called Vapor Etching.There is one vapor etchant that has become commercially im-

portant in micromachining processes. The gas xenon diouride,XeF

2

is a highly se-

lective vapor etchant for silicon, with virtually no attack of metals, silicon dioxide, or

other materials [?]. As a result, it is ideal for the dry release of surface micromachined

structures in which polysilicon is used as the sacricial layer. This process is used in

the manufacture of the electrostatically actuated projection display chip .

3.2 Basic MEMS Manufacturing Technologies

3.2.1 Bulk Micromachining

Bulk micromachining is an important class of MEMS process. In bulk micromachining

processes, a portion of the substrate(bulk) is removed in order to create freestanding

mechanical structures (beams and membranes) or unique three-dimensional features

15

(such as cavities , through-wafer holes, and mesas).Bulk micromachining can be ap-

plied to silicon, glass, gallium arsenide and other materials of interests.

There are two major categories of processes for bulk silicon etching. They are Wet

Etching and Dry Etching.Wet silicon etching processes use liquid chemical solutions

in contact with silicon as described in page 11. Dry etching processes use plasma (high

energy gas containing ionized radicals) or vapor-phase etchants to remove materials

as described in page 13. So the various microfabrication processes involved in bulk

micromachining technique are isotropic wet etching, anisotropic wet etching,Reactive

Ion Etching (RIE), Deep Reactive Ion Etching etc.

3.2.2 Surface Micromachining

Unlike Bulk micromachining, where a silicon substrate (wafer) is selectively etched

to produce structures, surface micromachining builds microstructures by deposition

and etching of different structural layers on top of the substrate [?]. Generally polysil-

icon is commonly used as one of the layers and silicon dioxide is used as a sacricial

layer which is removed or etched out to create the necessary void in the thickness direc-

tion. Added layers are generally very thin with their size varying from 2-5 Micro me-

tres. The main advantage of this machining process is the possibility of realizing mono-

lithic microsystems in which the electronic and the mechanical components(functions)

are built in on the same substrate. The surface micromachined components are smaller

compared to their counterparts, the bulk micromachined ones.

As the structures are built on top of the substrate and not inside it, the substrates prop-

erties are not as important as in bulk micromachining, and the expensive silicon wafers

can be replaced by cheaper substrates, such as glass or plastic. The size of the substrates

can also be much larger than a silicon wafer, and surface micromachining is used to

produce TFTs on large area glass substrates for at panel displays. This technology

can also be used for the manufacture of thin lm solar cells, which can be deposited on

glass, but also on PET substrates or other non-rigid materials.

16

3.2.3 High Aspect Ratio(HAR) Micromachining

HAR Micromachining is used to increase the aspect ratio of structures. The main

HAR process used now are LIGA and SLIGA processes.

LIGA process

The LIGA process for manufacturing MEMS and microsystems does not have the ma-

jor short comings of surface micromachining and bulk micromachining. These major

short comings are 1) low geometric aspect ratio and 2) the use of silicon-based ma-

terials.This process offers a a great potential for manufacturing non-silicon-based mi-

crostructures. The single most important feature of this process is that it can produce

thick microstructures that have extremely at and parallel surfaces such as microgear

trains, motors and generators.

The term LIGA is an acronym for the German terms Lithography (Lithographie),

electroforming (Galvanoformung), and molding(Abformung).

Figure 8: Major fabrication steps in the LIGA process

As shown in gure 8 , the LIGA process begins with deep x-ray lithography that

sets the desired patterns on a thick lm of photoresist. X-rays are used as the light

source in photolithography because of their short wavelength, which provides higher

17

penetration power into the photoresist materials This high penetration power is neces-

sary for high resolution in lithography and for a high aspect ratio in the depth The short

wavelength of x-ray allows an aspect ratio of more than 100:1 to be achieved.

The LIGA process outlined in gure may be demonstrated bya a specic example

as illustrated in gure 9. The desired product in this example is a microthin-wall metal

tube of square cross-section.The process begins by depositing a thick lm of photresist

material on the surface of a substrate as shown in gure 9 (b).A popular photoresist

material that is sensitive to x-ray is polymethylmethacrylate(PMMA). Masks are used

in the x-ray lithography. Most masking materials are transparent to x-rays , so it is

necessary to apply a thin lm of gold to the area that will block x-ray transmission.

The thin mask used for this purpose is silicon nitride with a thickness varying from

1-1.5m.

The deep x-ray lithography will cause the exposed area to be dissolved in the sub-

sequent development of the resist material gure 9 (c). The PMMA photoresist after

the development will have the outline of the product, i.e. the outside prole of the

tube.This is followed by electroplating of the PMMA photoresist with a desired metal,

usually nickel, to produce the tubular product of the required wall thickness gure 9

(d). The desired tubular product is produced after the removal of the photoresist materi-

als(PMMA in this case)by oxygen plasma or chemical solvents.For most applicatioons

the desired product is metal molds for subsequent injection molding of microplastic

products as shown in gure 8.

SLIGA process

From gures 8 and 9, the nished product, whether it is a microstructure or a

metal mold, is attached to the substrate, or base plate.The attachment to the electrically

conductive substrate is necessary for the electroplating process. However, this attach-

ment is considered as a redundancy in the LIGA process. For instance, the hollow

square tube produced in the LIGA process as described in gure 9 would not be sepa-

rated after electroplating of metal lm on the inner walls . A modied process called

sacricial LIGA (SLIGA) has been developed to solve this problem. The principle of

SLIGA is to introduce a sacricial layer between the PMMA resist and the substrate

thereby to allow the separation of the nished mold from the substrate after the electro-

18

plating. The separation is achieved by the removal of the sacricial layer by etching.

Polyimide with a metal-lm coating is used as a common sacricial layer material for

that purpose.

19

Figure 9: Major steps in the LIGA process

20

Das könnte Ihnen auch gefallen

- Quantum Analysis of Degenerate Three-Level LaserDokument6 SeitenQuantum Analysis of Degenerate Three-Level LaserSitotaw Eshete GebremeskelNoch keine Bewertungen

- Ece-1006 ProjectDokument22 SeitenEce-1006 ProjectAdarsh RajNoch keine Bewertungen

- Acoustic MetamaterialsDokument29 SeitenAcoustic MetamaterialsJoeMcSnowNoch keine Bewertungen

- Cat 290Dokument137 SeitenCat 290AlexNoch keine Bewertungen

- Electron Beam MachiningDokument25 SeitenElectron Beam MachiningAbhay P John100% (2)

- Real-Time Analysis, in SuperCollider, of Spectral Features of Electroglottographic Signals DENNIS JOHANSSONDokument71 SeitenReal-Time Analysis, in SuperCollider, of Spectral Features of Electroglottographic Signals DENNIS JOHANSSONMichael Przybylski100% (1)

- Calculation of Heat and Mass BalanceDokument18 SeitenCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- Planetary Power PlantDokument1 SeitePlanetary Power PlantMarc JustMarc100% (1)

- Oal Ed Ethahne: Prof. P. K. SinghDokument67 SeitenOal Ed Ethahne: Prof. P. K. SinghViplove RajurkarNoch keine Bewertungen

- David Peat On David BohmDokument13 SeitenDavid Peat On David BohmfranciscocalvoNoch keine Bewertungen

- 1.photolithography (ECE209) Unit 2Dokument23 Seiten1.photolithography (ECE209) Unit 2RajaNoch keine Bewertungen

- Torqueo Pikotek PDFDokument4 SeitenTorqueo Pikotek PDFjast111100% (1)

- Kilmartin Dissertation Worldviews in TransitionDokument334 SeitenKilmartin Dissertation Worldviews in Transitionr8b8l100% (2)

- Seasonal Influences On Safety of Substation Grounding Systems Seminar ReportDokument26 SeitenSeasonal Influences On Safety of Substation Grounding Systems Seminar Reportiagoo50% (4)

- Restrepo 2006 Emergence 2Dokument9 SeitenRestrepo 2006 Emergence 2pastafarianboyNoch keine Bewertungen

- Remote Sensing: Application of ScienceDokument19 SeitenRemote Sensing: Application of ScienceAlia100% (1)

- Optical Properties & CharacteristicsDokument21 SeitenOptical Properties & CharacteristicsRogelyn JosolNoch keine Bewertungen

- Formulation Development and Evaluation of Sustained Release Tablets of AceclofenacDokument128 SeitenFormulation Development and Evaluation of Sustained Release Tablets of Aceclofenacraju narayana padala0% (1)

- APPENDIX B Filler Metal Comparison Chart ABS-AWSDokument3 SeitenAPPENDIX B Filler Metal Comparison Chart ABS-AWSplkv100% (1)

- Plasma TechnologyDokument27 SeitenPlasma TechnologyAtul Mittal100% (2)

- New Sensors and Processing ChainVon EverandNew Sensors and Processing ChainJean-Hugh ThomasNoch keine Bewertungen

- Lecture 10Dokument4 SeitenLecture 10Akshay DimpuNoch keine Bewertungen

- A Brief Introduction To MEMS and NEMSDokument29 SeitenA Brief Introduction To MEMS and NEMS9894786946Noch keine Bewertungen

- Microelectromechanical Systems (MEMS) Materials and Fabrication ProcessesDokument7 SeitenMicroelectromechanical Systems (MEMS) Materials and Fabrication ProcessesGajanan BirajdarNoch keine Bewertungen

- Introduction To Plasma Physics and Contr PDFDokument10 SeitenIntroduction To Plasma Physics and Contr PDFshamsudeenNoch keine Bewertungen

- The Elusive Plasma-A Journey To The Plasma Wonderland-Facebook Physicist Group 02-19-2017Dokument90 SeitenThe Elusive Plasma-A Journey To The Plasma Wonderland-Facebook Physicist Group 02-19-2017Ali AbdouNoch keine Bewertungen

- Semiconductor Interview QuestionsDokument2 SeitenSemiconductor Interview QuestionssmydyNoch keine Bewertungen

- Led DocumentDokument48 SeitenLed DocumenthappysinhaNoch keine Bewertungen

- Electron Beam LithographyDokument11 SeitenElectron Beam LithographySaqib ZargarNoch keine Bewertungen

- Enrico Rodrigo - Wormholes, Void Bubbles and Vacuum Energy SuppressionDokument15 SeitenEnrico Rodrigo - Wormholes, Void Bubbles and Vacuum Energy SuppressionGijke3Noch keine Bewertungen

- Introduction To Plasma ModuleDokument42 SeitenIntroduction To Plasma ModuleRanjithPerumalNoch keine Bewertungen

- Electron Beam LithographyDokument14 SeitenElectron Beam LithographyAmey RanjekarNoch keine Bewertungen

- Three-Dimensional Sound Source Localization UsingDokument15 SeitenThree-Dimensional Sound Source Localization UsingWill D'Andrea FonsecaNoch keine Bewertungen

- Metamaterials and Negative Refractive IndexDokument6 SeitenMetamaterials and Negative Refractive IndexRohan KulkarniNoch keine Bewertungen

- STP 122.. THEORY Optics and WavesDokument142 SeitenSTP 122.. THEORY Optics and Wavesangelinapatrick257Noch keine Bewertungen

- Electron and PhotonDokument20 SeitenElectron and Photonnitin100% (2)

- CST Charged Particle Simulation LowDokument2 SeitenCST Charged Particle Simulation Low9999igi100% (1)

- Wireless Headphone User ManualDokument288 SeitenWireless Headphone User ManualMihai MosneaguNoch keine Bewertungen

- Laser Study MaterialDokument8 SeitenLaser Study MaterialMohammed Rizwan MalikNoch keine Bewertungen

- Nanotechnology PresentationDokument12 SeitenNanotechnology PresentationUrsuConstantinNoch keine Bewertungen

- Bernard P. Binks, Tommy S. Horozov Colloidal Particles at Liquid Interfaces PDFDokument519 SeitenBernard P. Binks, Tommy S. Horozov Colloidal Particles at Liquid Interfaces PDFTanvir Hossain100% (1)

- The Formation of the Solar SystemDokument21 SeitenThe Formation of the Solar SystemBella PesquiraNoch keine Bewertungen

- Methods to estimate stakeholder views of sustainabilityDokument7 SeitenMethods to estimate stakeholder views of sustainabilityAlireza FatemiNoch keine Bewertungen

- USR P B: Etail Rice OokDokument84 SeitenUSR P B: Etail Rice OokDanielTrasNoch keine Bewertungen

- Organic Potting Mix BasicsDokument11 SeitenOrganic Potting Mix BasicsEl-Elohei Yeshua JesheuaNoch keine Bewertungen

- Electro Masgnetic Propulsion SystemDokument2 SeitenElectro Masgnetic Propulsion Systemfsilassie8012Noch keine Bewertungen

- Tesis Finalcorrections PDFDokument166 SeitenTesis Finalcorrections PDFdaniej25Noch keine Bewertungen

- Largest Space Manipulation Breakthrough Enables Warp Bubble PropulsionDokument9 SeitenLargest Space Manipulation Breakthrough Enables Warp Bubble PropulsiongeicoblacksNoch keine Bewertungen

- Python For SeismologyDokument4 SeitenPython For SeismologyKanita Nur IzzatiNoch keine Bewertungen

- Polarization 4Dokument36 SeitenPolarization 4wartNoch keine Bewertungen

- Semiconductor ParametersDokument40 SeitenSemiconductor ParameterssulaimanNoch keine Bewertungen

- Light Emitting PolymersDokument17 SeitenLight Emitting PolymersAbhishek Parmar100% (1)

- E08 Handbook LedDokument13 SeitenE08 Handbook LedlaekemariyamNoch keine Bewertungen

- Spectroscopy Primer: Introduction to Atomic, Rotational, Vibrational, Raman, Electronic, Photoelectron and NMR SpectroscopyDokument141 SeitenSpectroscopy Primer: Introduction to Atomic, Rotational, Vibrational, Raman, Electronic, Photoelectron and NMR SpectroscopyJohn Paolo MirandaNoch keine Bewertungen

- Gas LasersDokument4 SeitenGas LasersPayal SinghalNoch keine Bewertungen

- CRT InformationDokument5 SeitenCRT InformationA CNoch keine Bewertungen

- Bomaker SiFi User ManualDokument54 SeitenBomaker SiFi User ManualstefanlindmarkNoch keine Bewertungen

- What Is FL & Its Applications - 1Dokument95 SeitenWhat Is FL & Its Applications - 1rmehfuzNoch keine Bewertungen

- Additive Manufacturing Using Selective Electron Beam MeltingDokument8 SeitenAdditive Manufacturing Using Selective Electron Beam MeltingHiki ChannelNoch keine Bewertungen

- Location Through ConsciousnessDokument2 SeitenLocation Through ConsciousnessAravindan MuthuNoch keine Bewertungen

- HST 362 Sources 2011 PDFDokument27 SeitenHST 362 Sources 2011 PDFLéo LacerdaNoch keine Bewertungen

- Disk Management From The Command-Line, Part 1 - The InstructionalDokument10 SeitenDisk Management From The Command-Line, Part 1 - The Instructionalscribd-123Noch keine Bewertungen

- Plastic Electronics Printing ProcessesDokument12 SeitenPlastic Electronics Printing ProcessesgandharvsikriNoch keine Bewertungen

- MicroDokument17 SeitenMicroShakeel EngyNoch keine Bewertungen

- Mems Production TechnologyDokument33 SeitenMems Production Technologyb bbNoch keine Bewertungen

- Mechatronics Module 2-MemsDokument26 SeitenMechatronics Module 2-MemsRahul DasNoch keine Bewertungen

- Kerala University B Tech Part Time Syllabus (2013)Dokument7 SeitenKerala University B Tech Part Time Syllabus (2013)iagooNoch keine Bewertungen

- Industrial Networks PDFDokument39 SeitenIndustrial Networks PDFlakshmi_innovatorNoch keine Bewertungen

- Cathode Ray OscilloscopesDokument17 SeitenCathode Ray OscilloscopesiagooNoch keine Bewertungen

- Business Information SystemsDokument21 SeitenBusiness Information SystemsEng Abdulkadir MahamedNoch keine Bewertungen

- PSC SyllabusDokument5 SeitenPSC SyllabusiagooNoch keine Bewertungen

- Automation PDFDokument13 SeitenAutomation PDFiagooNoch keine Bewertungen

- National Conference On Technological Trends 2013Dokument21 SeitenNational Conference On Technological Trends 2013iagooNoch keine Bewertungen

- Vibration Energy HarvestingDokument53 SeitenVibration Energy HarvestingiagooNoch keine Bewertungen

- Introduction To MemsDokument24 SeitenIntroduction To MemsiagooNoch keine Bewertungen

- PhotolithographyDokument1 SeitePhotolithographyiagooNoch keine Bewertungen

- Piezoelectric Energy HarvestingDokument26 SeitenPiezoelectric Energy Harvestingiagoo100% (1)

- NCTT PresentationDokument6 SeitenNCTT PresentationiagooNoch keine Bewertungen

- NCTT PresentationDokument6 SeitenNCTT PresentationiagooNoch keine Bewertungen

- Vibration Energy HarvestingDokument29 SeitenVibration Energy HarvestingiagooNoch keine Bewertungen

- Visakh SeminarDokument20 SeitenVisakh SeminariagooNoch keine Bewertungen

- Vibration Energy HarvestingDokument53 SeitenVibration Energy HarvestingiagooNoch keine Bewertungen

- National Conference On Technological Trends 2013Dokument21 SeitenNational Conference On Technological Trends 2013iagooNoch keine Bewertungen

- Laser Cladding Melt Pool Temperature ControlDokument26 SeitenLaser Cladding Melt Pool Temperature ControliagooNoch keine Bewertungen

- Laser Cladding Melt Pool Temperature ControlDokument26 SeitenLaser Cladding Melt Pool Temperature ControliagooNoch keine Bewertungen

- CDMA Principles of Spread Spectrum CommunicationDokument258 SeitenCDMA Principles of Spread Spectrum Communicationfaizazohra80% (5)

- Cet M Tech Ec SyllabusDokument47 SeitenCet M Tech Ec SyllabusiagooNoch keine Bewertungen

- M Tech ElectiveDokument32 SeitenM Tech ElectiveiagooNoch keine Bewertungen

- PresentationDokument23 SeitenPresentationiagooNoch keine Bewertungen

- An Actuator Failure Tolerant Control Scheme For On Underwater Remotely Operated VehicleDokument46 SeitenAn Actuator Failure Tolerant Control Scheme For On Underwater Remotely Operated VehicleiagooNoch keine Bewertungen

- The Intel Microprocessor Barry B Brey PDFDokument920 SeitenThe Intel Microprocessor Barry B Brey PDFKuludip Kumar Gupta88% (16)

- Pamphlet 152 - Edition 4 - April 2018Dokument29 SeitenPamphlet 152 - Edition 4 - April 2018acidoanimalNoch keine Bewertungen

- Weld Design-GrDokument58 SeitenWeld Design-Grvenky100% (1)

- Soil Pollution: Causes, Effects and Simple SolutionsDokument7 SeitenSoil Pollution: Causes, Effects and Simple SolutionsVon MorenNoch keine Bewertungen

- Deformation and Fracture Mechanics of Engineering MaterialsDokument44 SeitenDeformation and Fracture Mechanics of Engineering MaterialsSyed Muhammad AliNoch keine Bewertungen

- ACOT21 Round 2 - Gold TierDokument7 SeitenACOT21 Round 2 - Gold Tierjoe mamaNoch keine Bewertungen

- FAME - Automated Fatty Acid Derivatization & GC - MS AnalysisDokument3 SeitenFAME - Automated Fatty Acid Derivatization & GC - MS AnalysisHushla ShudriNoch keine Bewertungen

- Engineering Failure Analysis: Lucjan Witek, Micha Ł Sikora, Feliks Stachowicz, Tomasz TrzepiecinskiDokument10 SeitenEngineering Failure Analysis: Lucjan Witek, Micha Ł Sikora, Feliks Stachowicz, Tomasz TrzepiecinskisobhanNoch keine Bewertungen

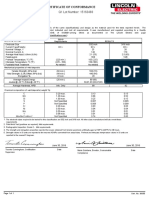

- Certificate of Conformance: Q1 Lot Number: 15163483Dokument1 SeiteCertificate of Conformance: Q1 Lot Number: 15163483interx00Noch keine Bewertungen

- 12.co Ordination CompoundsExerciseDokument34 Seiten12.co Ordination CompoundsExerciseMaster Of HakingNoch keine Bewertungen

- Internship Format1Dokument44 SeitenInternship Format1Prajwal ChavanNoch keine Bewertungen

- Energy and FluctuationDokument10 SeitenEnergy and Fluctuationwalid Ait MazouzNoch keine Bewertungen

- Assignment Open and Closed Thermodynamic SystemDokument1 SeiteAssignment Open and Closed Thermodynamic SystemJenellie BahintingNoch keine Bewertungen

- Study of Gas-Condensate Well Productivity in Santa Barbara Field, Venezuela, by Well Test AnalysisDokument9 SeitenStudy of Gas-Condensate Well Productivity in Santa Barbara Field, Venezuela, by Well Test AnalysisWaleed Barakat MariaNoch keine Bewertungen

- Henkel Industrial Solutions Surface Treatment Selector GuideDokument2 SeitenHenkel Industrial Solutions Surface Treatment Selector GuideMax JunghannsNoch keine Bewertungen

- Physico-chemical Water Treatment Processes AssignmentDokument6 SeitenPhysico-chemical Water Treatment Processes AssignmentAbir HasanNoch keine Bewertungen

- Chem 2 Chemistry in Your World 2nd Edition Hogg Solutions ManualDokument35 SeitenChem 2 Chemistry in Your World 2nd Edition Hogg Solutions Manualcriedhieraticoxqs100% (24)

- Folder ILF Upstream Facilities enDokument4 SeitenFolder ILF Upstream Facilities enSterling GordianNoch keine Bewertungen

- Ch E 441 - Chemical Kinetics and Reaction Engineering Residence Time DistributionsDokument35 SeitenCh E 441 - Chemical Kinetics and Reaction Engineering Residence Time Distributionsbenjy8769Noch keine Bewertungen

- Analysis QBDokument167 SeitenAnalysis QBChethan PrabhuNoch keine Bewertungen

- Bitumen Colloidal and Structural Stability CharacterizationDokument16 SeitenBitumen Colloidal and Structural Stability CharacterizationAnonymous x7VY8VF7100% (1)

- Tooth Colour Restorative Materials in Ped DentDokument27 SeitenTooth Colour Restorative Materials in Ped DentNilay ShahNoch keine Bewertungen

- Build Up MaterialsDokument5 SeitenBuild Up MaterialsMishell CarolinaNoch keine Bewertungen

- Lecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaDokument565 SeitenLecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaSumanth VarmaNoch keine Bewertungen

- Chem 2 Q1 Module 1 Attractive ForcesDokument9 SeitenChem 2 Q1 Module 1 Attractive ForcesPrincess Venita BerganteNoch keine Bewertungen

- Compressed Air SystemDokument29 SeitenCompressed Air Systemsk sajidNoch keine Bewertungen