Beruflich Dokumente

Kultur Dokumente

Hip For SLBP

Hochgeladen von

HaleemUrRashidBangashOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hip For SLBP

Hochgeladen von

HaleemUrRashidBangashCopyright:

Verfügbare Formate

HAZARD IDENTIFICATION PLAN FOR SKID MODIFICATION

AT SLBP

Contractor Name: HADI HAMMAD AL-HAMMAM GROUP

Work Location: SULAYYIL BULK PLAN

PO ! Work Or"er No:

Contract No:

Work De#cri$tion: SKID MODI%ICAION A SLBP

&'(i$ment to )e U#e": COLD PIP& CU&R* M&CHANICAL SOPP&R*

W&LDING MACHIN&* HAND OOLS* CRAN&*

GRIND&RS* RANSPORAION M&DIAS* CHAIN

PULLYS* &C

&#timate" Start Date: NA

&#timate" Com$+etion Date: NA

Workin, Ho(r#: NA

N(m)er o- Worker#: NA

Sa("i Aramco Pro.ect

&n,ineer:

DHA%AR S/ AL-DOSSARY

Pre$are" )0: HAL&&M UR RASHID BANGASH 1S&* &W&2

HAZARD IDENTIFICATION PLAN

1. OBJECTIVE

This HIP [Hazard Identifcation Plan] has been formulated for implementation in accordance with applicable Saudi Aramco General Instructions,

safety polices and standards. This is a confrmation of the commitment of East Western General Contracting Est. (EWE) to safeguard, protect lives,

and property of Saudi Aramco; and any other third party in connection with the work to be performed.

To achieve this objective, the EWE management, in coordination with the concerned Saudi Aramco Maintenance/Operation Engineer,

Environmental Protection Dept., Loss Prevention Department and other applicable agencies as required, are to make a joint site visit to identify the

potential hazards of the work to be undertaken and to initiate control measures to maintain adequate safety for the duration of the work.

2. SCOPE OF WORK

The purpose of this work order is to update/modify the skid at Sulayyil bulk plant facility, to increase the efciency of the skid as mentioned in the

MOC provided and submitted.

3. HAZARD CLASSIFICATION

Class A Hazards:

A condition or practice likely to cause permanent disability, loss of life or body part and/or extensive loss of structure, equipment or material

Class B Hazards:

A condition or practice likely to cause serious injury or illness (resulting in temporary disability) or property damage that is disruptive, but

less severe than Class A

Class C Hazards:

A condition or practice likely to cause minor (non-disabling injury or illness or non-disruptive property damage

4. HAZARD IDENTIFICATION

SLBPs OPERATION, MAITENANCE AND LPD WILL BE WORKING CLOSELY WITH CONTRACTOR (EWE) DURING ALL ISOLATION,

LOCKOUT, TAGGING, SHUTDOWN AND EQUIPMENT INSTALLATION INCLUDING CRITICAL ACTIVITIES FOR THIS JOB.

The following summaries of work activities have already been identifed as potentially hazardous [detailed information on the hazard

classifcation analysis is included later in this document)

1.MOBILIZATION/PREPARATION

2.SCAFFOLDING

3.POWER OPERATING / GENERATING TOOLS AND EQUIPMENTS

4.CRANE OPERATION (LIFTING)

5.CUTTING THE PIPE SPOOL

6.FABRICATION AND WELDING

7.MECHANICAL TESTS

4.1. MOBILIZATION/PREPARATION

No.

Location/Area Specifc Hazards

Identifed

Classifcation

(A/B/C)

Contractors

Recommended Actions

(Proposed actions to the specifc Hazards identifed)

4.1.1 SLBP, BAY # 7 TO 5 Improper parking trafc fow

of vehicle, truck

B

Provide trafc fow plan as needed

Install applicable trafc signs in compliance with SA G.Is

Implement Trafc and Vehicle Safety as per, G.I. 6.030

Park in designated parking area

No vehicle is allowed inside the barricade area

No vehicle unattended while the engine is running

4.1.2 SLBP, BAY # 7 TO 5 Improper lifting of materials,

equipment, etc.

A Orient workers in the proper lifting technique

Worker should wear proper PPEs

Proper lifting techniques are to be observed

4.1.3 SLBP, BAY # 7 TO 5 Scattered materials,

equipment, tools

B Orient workers regarding Good Housekeeping

Designate and Install barricade tapes or orange plastic barricades

for storage of materials, equipment, tool boxes and coordinate with

proponent

Provide tool belts for workers, provide tool boxes, racks,

4.1.4 SLBP, BAY # 7 TO 5 Absence of temporary

shelter for workers

C Construct a temporary bunk house for workers and materials if

required

4.1.5 SLBP, BAY # 7 TO 5 Motor vehicle accident A Implement G.I. 06.030 Trafc and Vehicle Safety

Provide trafc fow plan as needed

Install applicable trafc signs in compliance with Manual on

Uniform trafc control devices Kingdom of Saudi Arabia, Ministry

of communication

4.1.6 SLBP, BAY # 7 TO 5 Lack of trafc signs,

barricades

B Install applicable trafc signs in compliance with SA GIs

4.1.6 SLBP, BAY # 7 TO 5 Lack of fagman B Provide fagman with FLAG and PPEs to control the trafc

4.1.7 SLBP, BAY # 7 TO 5 Poor road visibility on the

excavation at night

A Provide trafc light at night

4.2. SCAFFOLD ERECTION AND DISMENTLING

No. Location/Area Specifc Hazards

Identifed

Classifcation

(A/B/C)

Contractors

Recommended Actions

(Proposed actions to the specifc Hazards identifed)

4.2.1. SLBP, BAY # 7 TO 5 Falling and personal injury A Certifed scafold supervisor shall erect scafold per G.I. 08.001 Safety

Requirements for Scafolding and Saudi Aramco scafold safety

handbook and SACSM

Use FULL BODY SAFETY HARNESS

Before commencing work the scafold tag must be signed by scafold

supervisor/inspector or both

4.2.2. SLBP, BAY # 7 TO 5 Personal injury A Don not stay under the scafold working platform

Use all PPEs FBSH

4.3. POWER OPERATING / GENERATING EQUIPMENTS

No. Location/Area Specifc Hazards

Identifed

Classifcation

(A/B/C)

Contractors

Recommended Actions

(Proposed actions to the specifc Hazards identifed)

4.3.1. SLBP, BAY # 7 TO 5 Electrical shock B Implement Shoring protective systems, Excavation, Saudi

Aramco Construction Safety Manual

4.3.2. SLBP, BAY # 7 TO 5

Explosion /fre

A Implement work permit system G.I. 2.100

Coordinate with SA LPD, OPS, MAINT.

Remove fammables, combustibles and oxidizing agents from site

Conduct gas test, it must show a reading of ZERO

Ground the Equipment properly

No Gasoline operated engines, use Diesel engines/tools only

No leaking of the equipment /machine

Use extensions and keep the equipment away as much as possible

Ground all the holes and stop any gas release

Do not operate until the gas tester shows ZERO reading

4.3.3 SLBP, BAY # 7 TO 5 Motor vehicle accident A Provide trafc fow plan as needed

Install applicable trafc signs in compliance with Manual on

Uniform trafc control devices Kingdom of Saudi Arabia, Ministry

of communication

4.3.4 SLBP, BAY # 7 TO 5 Lack of trafc signs,

barricades

B

4.3.5. SLBP, BAY # 7 TO 5 Lack of fagman B Implement trafc controls G.I. 1021.000

4.3.6. SLBP, BAY # 7 TO 5 Poor road visibility on the

excavation at night

A Install stead burning light on the barricades

4.4 CRANE OPERATION AND LIFTING

No. Location/Area Specifc Hazards

Identifed

Classifcation

(A/B/C)

Contractors

Recommended Actions

(Proposed actions to the specifc Hazards identifed)

4.4.1. SLBP, BAY # 7 TO 5 Damage to the facility and

load

A Certifed operator and rigger should perform the crane job

Critical lift plan must be provided as per GI 7.028 form SA 9644

Crane daily inspection checklist be flled and signed

Hoist and chains must be load rated and in good conditions

Use tag line for load balance

4.4.2. SLBP, BAY # 7 TO 5 Personal injury A Isolate the job site

No employee remain under the load

4.5 CUTTING THE PIPE SPOOL

No. Location/Area Specifc Hazards

Identifed

Classifcation

(A/B/C)

Contractors

Recommended Actions

(Proposed actions to the specifc Hazards identifed)

4.5.1. SLBP, BAY # 7 TO 5 Falling of spool A Fastened and support the spool from the two ends before cutting starts

Use specifed chemicals for smooth operation of cutter

4.5.2. SLBP, BAY # 7 TO 5 Personal injury A Use PPEs and lift down the cut piece with crane

SLBP, BAY # 7 TO 5 Release of toxic and

fammables product and

gases

A Use proper respirators

Switch of all mobiles phones and other sources of ignition

Utilize Isolation lockout and use of hold tag procedures as per G.I.

06.012 Isolation, Used of Hold Tags

4.6FABRICATION AND WELDING

No. Location/Area Specifc Hazards

Identifed

Classifcation

(A/B/C)

Contractors

Recommended Actions

(Proposed actions to the specifc Hazards identifed)

SLBP, BAY # 7 TO 5 Drain and spill A The pipe must be drained to zero state

Utilize Isolation lockout and use of hold tag procedures as per G.I.

06.012 Isolation, Used of Hold Tags

The pipe must be purged with nitrogen or water washed and mechanical

stopper be installed before fabrication, welding

4.6.1. SLBP, BAY # 7 TO 5 Electrocution A Certifed welder and fabricator shall conduct the job

Use proper PPEs

Inspect the cords for exposure and cuts

No splices within 10 feet of the tools and machines

Implement work permit system G.I. 2.100

4.6.2. SLBP, BAY # 7 TO 5 Fire hazard A No fabrication and welding before gas tests

Utilize Isolation lockout and use of hold tag procedures as per G.I.

06.012 Isolation, Used of Hold Tags

Certifed and valid gas tester should be used by certifed person during

the job period as frequent as required

Mechanical stopper shall be installed before welding

4.7 MECHANICAL TESTS

No. Location/Area Specifc Hazards

Identifed

Classifcation

(A/B/C)

Contractors

Recommended Actions

(Proposed actions to the specifc Hazards identifed)

4.7.1 SLBP, BAY # 7 TO 5 Personal hazard A Isolate the area and

Only authorized persons are allowed at site

Wear proper PPEs during mechanical tests

4.7.2 SLBP, BAY # 7 TO 5 Fire hazard A Use only 110 V electrical tools only for test

Conduct gas tests before performing the mechanical tests

Das könnte Ihnen auch gefallen

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Dokument1 SeiteBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNoch keine Bewertungen

- BI 10-02133, WEEK 06, Safety Statistics Reoport NDokument1 SeiteBI 10-02133, WEEK 06, Safety Statistics Reoport NHaleemUrRashidBangash100% (1)

- BI 10-02133, March 23 2020, SAFETY STATISTICSDokument2 SeitenBI 10-02133, March 23 2020, SAFETY STATISTICSHaleemUrRashidBangashNoch keine Bewertungen

- BI 10-02133, March 2020, Safety Statistics ReoportDokument3 SeitenBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Dokument1 SeiteBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNoch keine Bewertungen

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Dokument27 Seiten20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- BI 10-02133, March 2020, Safety Statistics ReoportDokument3 SeitenBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Dokument31 Seiten13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashNoch keine Bewertungen

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Dokument31 Seiten14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- 01 Safety Statistics by Haleem Ur Rashid, BI 10-02185Dokument3 Seiten01 Safety Statistics by Haleem Ur Rashid, BI 10-02185HaleemUrRashidBangashNoch keine Bewertungen

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDokument31 SeitenHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNoch keine Bewertungen

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Dokument27 SeitenHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNoch keine Bewertungen

- Hse Organization Chart: Industrial Projections Contracting EstablishmentDokument1 SeiteHse Organization Chart: Industrial Projections Contracting EstablishmentHaleemUrRashidBangash100% (1)

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDokument31 SeitenHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNoch keine Bewertungen

- 11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020Dokument36 Seiten11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020HaleemUrRashidBangashNoch keine Bewertungen

- Hazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Dokument27 SeitenHazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNoch keine Bewertungen

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Dokument36 Seiten5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNoch keine Bewertungen

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Dokument36 Seiten4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNoch keine Bewertungen

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Dokument36 Seiten9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNoch keine Bewertungen

- Haleem Ur Rashid - Lac - QMS - IrcaDokument1 SeiteHaleem Ur Rashid - Lac - QMS - IrcaHaleemUrRashidBangashNoch keine Bewertungen

- Hse Organization Chart: Industrial Projections Contracting EstablishmentDokument1 SeiteHse Organization Chart: Industrial Projections Contracting EstablishmentHaleemUrRashidBangash100% (2)

- Branch of Egyptian Projects Co.: Hse Organization ChartDokument1 SeiteBranch of Egyptian Projects Co.: Hse Organization ChartHaleemUrRashidBangashNoch keine Bewertungen

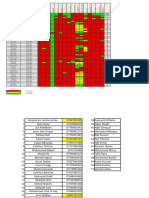

- 60 Training MatrixDokument4 Seiten60 Training MatrixHaleemUrRashidBangashNoch keine Bewertungen

- SAOO Safety Orientation Registration Form - PETROJET 03-Mar-20Dokument1 SeiteSAOO Safety Orientation Registration Form - PETROJET 03-Mar-20HaleemUrRashidBangashNoch keine Bewertungen

- Fa 1 PDFDokument1 SeiteFa 1 PDFHaleemUrRashidBangashNoch keine Bewertungen

- FA BleedingDokument1 SeiteFA BleedingHaleemUrRashidBangashNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Nanostructural State of AlloysDokument6 SeitenNanostructural State of AlloysCristina PostolacheNoch keine Bewertungen

- S01 Hydraulic and Eletric DiagramDokument18 SeitenS01 Hydraulic and Eletric DiagramgadeharogNoch keine Bewertungen

- PDF 1sz Fe Workshop Manual - CompressDokument2 SeitenPDF 1sz Fe Workshop Manual - CompressJose Luis Apaza Machaca75% (4)

- Buongiorno - Etal - 2009 The Big Experimental CheckDokument15 SeitenBuongiorno - Etal - 2009 The Big Experimental CheckMikhail TarabrinNoch keine Bewertungen

- OSC - 2015 - Revised - Oct (Power Cables) PDFDokument118 SeitenOSC - 2015 - Revised - Oct (Power Cables) PDFIván P. MorenoNoch keine Bewertungen

- DH-IPC-HDBW1231E: 2MP WDR IR Mini-Dome Network CameraDokument3 SeitenDH-IPC-HDBW1231E: 2MP WDR IR Mini-Dome Network CameraDeltaz AZNoch keine Bewertungen

- Grade 11 Learning GuideDokument28 SeitenGrade 11 Learning GuideMary-Rose Casuyon100% (1)

- Chapter 34 Area MethodDokument14 SeitenChapter 34 Area Methodthorgod941500% (1)

- Selulitis Orbita Pada Laki-Laki Usia 64 Tahun: Laporan KasusDokument8 SeitenSelulitis Orbita Pada Laki-Laki Usia 64 Tahun: Laporan KasusLuh Dita YuliandinaNoch keine Bewertungen

- SN3308 Installation Manual Rev J PDFDokument132 SeitenSN3308 Installation Manual Rev J PDFsav33Noch keine Bewertungen

- Aldehyde Keto. Ncert Book PDFDokument32 SeitenAldehyde Keto. Ncert Book PDFAshraf KhanNoch keine Bewertungen

- 14 Parabola Formula Sheets QuizrrDokument9 Seiten14 Parabola Formula Sheets QuizrrChandanNoch keine Bewertungen

- INERT-SIEX 200-300 IG-100: Design ManualDokument54 SeitenINERT-SIEX 200-300 IG-100: Design ManualSaleh Mohamed0% (1)

- SURELAM-380,540II (User Manual)Dokument25 SeitenSURELAM-380,540II (User Manual)kamran.sefyaliyevNoch keine Bewertungen

- SLC Past and Future Hustrulid KvapilDokument26 SeitenSLC Past and Future Hustrulid KvapilkinsaeyaNoch keine Bewertungen

- Portégé R930 (3G) PT331A-0DE043: Toshiba Recommends Windows 10Dokument2 SeitenPortégé R930 (3G) PT331A-0DE043: Toshiba Recommends Windows 10josecarlosvjNoch keine Bewertungen

- EN 14103 - ThermoDokument4 SeitenEN 14103 - ThermoLuciana TrisnaNoch keine Bewertungen

- Customer - Reprint DhoniDokument1 SeiteCustomer - Reprint DhoniBaljit SinghNoch keine Bewertungen

- Test Intensiv Engleza 5Dokument30 SeitenTest Intensiv Engleza 5Simona Singiorzan90% (30)

- Squad3.fire NSD GPMDokument7 SeitenSquad3.fire NSD GPMMac CorpuzNoch keine Bewertungen

- Single Nozzle Air-Jet LoomDokument7 SeitenSingle Nozzle Air-Jet LoomRakeahkumarDabkeyaNoch keine Bewertungen

- Unit 1Dokument175 SeitenUnit 1Karthikeya SharmaNoch keine Bewertungen

- Dmbi Assignment 2: Q.1. Explain STAR Schema. Ans-1Dokument6 SeitenDmbi Assignment 2: Q.1. Explain STAR Schema. Ans-1Kanishk TestNoch keine Bewertungen

- SG5.0 20RT UEN Ver13 202101Dokument105 SeitenSG5.0 20RT UEN Ver13 202101Asep SaepudinNoch keine Bewertungen

- Microbiology QuestionsDokument5 SeitenMicrobiology QuestionsNaeem AminNoch keine Bewertungen

- Photovoltaic Water Heater: The Ecological Revolution MADE IN ITALYDokument4 SeitenPhotovoltaic Water Heater: The Ecological Revolution MADE IN ITALYDani Good VibeNoch keine Bewertungen

- Practice 4Dokument11 SeitenPractice 4Justine Rs Dela TorreNoch keine Bewertungen

- Crop Prot 2 Final Edited (Checked)Dokument108 SeitenCrop Prot 2 Final Edited (Checked)Cortez ReztyNoch keine Bewertungen

- Design Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Dokument20 SeitenDesign Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Anonymous oTrMzaNoch keine Bewertungen