Beruflich Dokumente

Kultur Dokumente

Aloy High Pressure Filters 20 Bar

Hochgeladen von

DANIZACH0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten2 Seitenfiltration

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenfiltration

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten2 SeitenAloy High Pressure Filters 20 Bar

Hochgeladen von

DANIZACHfiltration

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

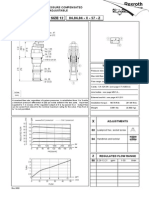

Alloy High Pressure Filters

20 barg (300 psig)

Walker Filtration manufacture a range of 20 barg

(300 psig) high pressure filters using machined

or diecast aluminium components. There are a

total 13 models in this silicone free range from

1

4 to 3 pipe connections with flow rates up to

4383Nm

3

/h (2580 scfm) at 20 barg (300 psig).

All models feature the Walker push-in filter

element design with double O ring seals

for extra security and are available in all standard

grades including water separators.

Full corrosion protection is given by use of

an electrophoretic painting both inside and out

followed by a tough polyester powder coating

on the outside.

This filter range is ideally suited for general high

pressure industrial use i.e. high pressure testing.

The ultimate filtration and drying technology

Manufactured from aluminium, the 20 barg (300 psig) range of filters

offer flows up to 2580 scfm (4383 Nm

3

/h).

Alloy High Pressure Filters

20 barg (300 psig)

Manufactured from aluminium, the 20 barg (300 psig) range of filters

offer flows up to 2580 scfm (4383 Nm

3

/h).

Walker Filtration Ltd,

Spire Road, Glover East, Washington, Tyne & Wear, NE37 3ES, UK

Tel: +44 (0) 191 417 7816 Fax: +44 (0) 191 415 3748

email: sales@walkerfiltration.co.uk www.walkerfiltration.com

13

Models 20HP50 (grade) -

20HP302 (grade)

Models 20HP25 (grade) -

20HP37 (grade)

FILTER

MODELS

ELEMENT MODEL DIMENSIONS mm

A B C D

DIMENSIONS inch

A B C D

PIPE

SIZE

FLOW RATE

Nm

3

/h SCFM

WEIGHT

Kg Ib

Dust filter element grades

Particle removal 25 micron 5 micron 1 micron 0.01 micron 0.01 micron

Maximum oil carryover

0.003 0.003

at 20C (68F)

- - - -

mg/m

3

ppm

Maximum temperature 120C 248F 120C 248F 120C 248F 120C 248F 25C 77F

Pressure loss - clean & dry 30 mbar 0.4 psi 40 mbar 0.6 psi 75 mbar 1.1 psi 100 mbar 1.5 psi 75 mbar 1.1psi

Pressure loss - oil saturated - - - - see notes

Pressure loss - change element 400 mbar 6 psi 400 mbar 6 psi 400 mbar 6 psi 400 mbar 6 psi see notes

Maximum working pressure 20 barg (300 psig)

Element end cap - colour

SPECIFICATION GRADE RX25

Black

GRADE RX5 GRADE RX1 GRADE RXA GRADE RAC

Particle removal - 25 micron 5 micron 1 micron 0.01 micron 0.01 micron

Maximum oil carryover

10 8.2 5 4.1 0.1 0.1 0.01 0.01 0.003 0.003

at 20C (68F)

- -

mg/m

3

ppm mg/m

3

ppm mg/m

3

ppm mg/m

3

ppm mg/m

3

ppm

Maximum temperature 120C 248F 120C 248F 120C 248F 120C 248F 120C 248F 25C 77F

Pressure loss - clean & dry - - 30 mbar 0.4psi 40 mbar 0.6 psi 75 mbar 1.1psi 100 mbar 1.5 psi 75 mbar 1.1 psi

Pressure loss - oil saturated - 50 mbar 0.7psi 75 mbar 1.1psi 150 mbar 2.2 psi 300 mbar 4.4 psi see notes

Pressure loss - change element - 400 mbar 6psi 400 mbar 6 psi 400 mbar 6 psi 400 mbar 6 psi see notes

Maximum working pressure 20 barg (300 psig)

Element end cap - colour

SPECIFICATION GRADE WS

Black

GRADE X25 GRADE X5 GRADE X1 GRADE XA GRADE AC

Coalescing filter element grades

Technical Notes

1. Filter element end caps are colour coded BLACK. Direction of air flow, in to out through filter element for

coalescing grades and out to in through filter element for dust grades.

2. Grade AC and RAC activated carbon filters must not operate in oil saturated conditions and will not

remove certain types of gases including carbon monoxide (CO) and carbon dioxide (CO2).

3. Grade AC and RAC elements must be changed periodically to suit application but at least every 6 months.

4. All alloy high pressure filters are supplied with a drain plug, high pressure drains are available.

5. Alloy high pressure filters and filter elements are suitable for use with mineral and synthetic oils, plus oil-

free compressed air applications.

6. Alloy high pressure filters and filter elements are silicone free.

A

B

C

D

A

B

C

D

Operating Pressure barg 4 6 8 10 12 14 16 18 20

psi 58 87 116 145 174 203 232 261 290

Correction Factor 0.45 0.55 0.63 0.71 0.77 0.84 0.9 0.95 1

NEW

20HP25 (grade)

1

/4 59 35 72 184 75 35 0.65 1.43 3 7

1

/2 3 1

1

/2 E1503 (grade)

20HP37 (grade)

3

/8 85 50 72 184 75 35 0.65 1.43 3 7

1

/2 3 1

1

/2 E1503 (grade)

20HP50 (grade)

1

/2 110 65 114 270 152 38 2.0 4.5 4

1

/2 10 6 1

1

/2 E2005 (grade)

20HP75 (grade)

3

/4 219 129 114 270 152 38 2.0 4.5 4

1

/2 10 6 1

1

/2 E2005 (grade)

20HP100 (grade) 1 292 172 114 352 152 38 2.5 5.5 4

1

/2 13

1

/2 6 1

1

/2 E2008 (grade)

20HP101 (grade) 1 438 258 114 352 152 38 2.5 5.5 4

1

/2 13

1

/2 6 2 E2008 (grade)

20HP150 (grade) 1

1

/2 658 387 146 490 165 51 5.0 12.0 6 18

1

/2 6

1

/2 2 E3012 (grade)

20HP151 (grade) 1

1

/2 877 516 146 490 165 51 5.0 12.0 6 18

1

/2 6

1

/2 2 E3012 (grade)

20HP200 (grade) 2 1315 774 146 490 165 51 5.0 12.0 6 18

1

/2 6

1

/2 2 E3012 (grade)

20HP201 (grade) 2 1899 1118 146 685 165 51 6.0 12.5 6 26 6

1

/2 2 E3020 (grade)

20HP300 (grade) 3 2922 1720 229 681 178 64 15.0 32.0 9 27 7 2

1

/2 E5020 (grade)

20HP301 (grade) 3 3653 2150 229 810 178 64 15.0 33.5 9 32 7 2

1

/2 E2024 (grade)

20HP302 (grade) 3 4383 2580 229 962 178 64 16.0 33.5 9 38 7 2

1

/2 E5030 (grade)

CORRECTION FACTOR

For maximum flow rate, multiply model flow rate shown in the above table by the correction factor corresponding to the pressure

Das könnte Ihnen auch gefallen

- Nema Chart 04Dokument1 SeiteNema Chart 04zguy360Noch keine Bewertungen

- Baldor MotorsDokument124 SeitenBaldor Motorsangel_basualdoNoch keine Bewertungen

- 305 TransmissionDokument2 Seiten305 TransmissionDANIZACHNoch keine Bewertungen

- Valve configuration and solenoid directional valvesDokument8 SeitenValve configuration and solenoid directional valvesFabinhoTowerNoch keine Bewertungen

- Check d180 - HR KRDokument4 SeitenCheck d180 - HR KRDANIZACHNoch keine Bewertungen

- Valvula Tn10 - Dke E025Dokument4 SeitenValvula Tn10 - Dke E025DANIZACHNoch keine Bewertungen

- Valvula de Acc Manual - E150Dokument4 SeitenValvula de Acc Manual - E150DANIZACHNoch keine Bewertungen

- Alivio - d120 - HM - KMDokument4 SeitenAlivio - d120 - HM - KMDANIZACHNoch keine Bewertungen

- Series 34Dokument10 SeitenSeries 34DANIZACHNoch keine Bewertungen

- Sun - Hydraulics CatalogDokument44 SeitenSun - Hydraulics CatalogAndreea75% (4)

- Hsr-300e - CC PATINES LINEALES THKDokument26 SeitenHsr-300e - CC PATINES LINEALES THKDANIZACHNoch keine Bewertungen

- Allround Line Floor 100 250kNDokument4 SeitenAllround Line Floor 100 250kNDANIZACHNoch keine Bewertungen

- Single and double acting hydraulic cylinders specificationsDokument1 SeiteSingle and double acting hydraulic cylinders specificationsDANIZACHNoch keine Bewertungen

- Check en Linea - c406Dokument2 SeitenCheck en Linea - c406DANIZACHNoch keine Bewertungen

- En - b1 - 070 PATINES LINEALESDokument2 SeitenEn - b1 - 070 PATINES LINEALESDANIZACHNoch keine Bewertungen

- Catalogo Componentes 2007Dokument39 SeitenCatalogo Componentes 2007DANIZACHNoch keine Bewertungen

- 742Dokument52 Seiten742DANIZACHNoch keine Bewertungen

- Absorb Shock and Reduce Vibration with Flexible Grid CouplingsDokument18 SeitenAbsorb Shock and Reduce Vibration with Flexible Grid CouplingsRafo Vega GuerovichNoch keine Bewertungen

- Pump Magnun SeriesDokument63 SeitenPump Magnun SeriesDANIZACHNoch keine Bewertungen

- Pump KappaDokument112 SeitenPump KappaDANIZACHNoch keine Bewertungen

- MPHDokument16 SeitenMPHDANIZACHNoch keine Bewertungen

- 4 - Way Directional Control Valve "HPV4": FeaturesDokument2 Seiten4 - Way Directional Control Valve "HPV4": FeaturesDANIZACHNoch keine Bewertungen

- Baldor MotorsDokument124 SeitenBaldor Motorsangel_basualdoNoch keine Bewertungen

- Pump Polaris SeriesDokument47 SeitenPump Polaris SeriesDANIZACHNoch keine Bewertungen

- Gear flow dividers technical specifications and application guideDokument20 SeitenGear flow dividers technical specifications and application guideDANIZACHNoch keine Bewertungen

- Basic Training: Motors, Gears & DrivesDokument80 SeitenBasic Training: Motors, Gears & DrivesDANIZACH50% (2)

- Re26892 2003-02Dokument10 SeitenRe26892 2003-02DANIZACHNoch keine Bewertungen

- 040404X57ZDokument1 Seite040404X57ZDANIZACHNoch keine Bewertungen

- 742Dokument52 Seiten742DANIZACHNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Measurement of Pressure BasicsDokument8 SeitenMeasurement of Pressure BasicsMoiz AamirNoch keine Bewertungen

- BS - 01 - 2 - Percentage Refusal Density PDFDokument7 SeitenBS - 01 - 2 - Percentage Refusal Density PDFHafa LabNoch keine Bewertungen

- Pressure 130723134649 Phpapp02Dokument76 SeitenPressure 130723134649 Phpapp02Syazwana ElleasNoch keine Bewertungen

- Jharkhand University of Technology 3rd Semester Course StructureDokument196 SeitenJharkhand University of Technology 3rd Semester Course StructureAbhishek 18CED31Noch keine Bewertungen

- Sodium Silicate Moulding ProcessDokument82 SeitenSodium Silicate Moulding ProcessRahul KhoslaNoch keine Bewertungen

- Marcet Boiler ExperimentDokument13 SeitenMarcet Boiler ExperimentSatiah WahabNoch keine Bewertungen

- TWH N Torque Pressure Conversion ChartS PDF273201694527Dokument10 SeitenTWH N Torque Pressure Conversion ChartS PDF273201694527Ciprian BalcanNoch keine Bewertungen

- Calculating stack effect draft flow rate for flue gas stacks and chimneysDokument2 SeitenCalculating stack effect draft flow rate for flue gas stacks and chimneysKarthick VelayuthamNoch keine Bewertungen

- Experiment (10) Center of Pressure: Page Lab. Supervisor: Eng. Walaa AraydahDokument8 SeitenExperiment (10) Center of Pressure: Page Lab. Supervisor: Eng. Walaa Araydahmohammad. 21Noch keine Bewertungen

- Compare Properties of Gases, Liquids and SolidsDokument4 SeitenCompare Properties of Gases, Liquids and SolidsRaymond MaristelaNoch keine Bewertungen

- CalandriaDokument2 SeitenCalandriaRahul PancholiNoch keine Bewertungen

- B30C ADT ElectricsDokument59 SeitenB30C ADT Electricswtn2013100% (2)

- Fluid Mechanics July 2013Dokument0 SeitenFluid Mechanics July 2013Prasad C MNoch keine Bewertungen

- Select PSV Type and Size for Oil & Gas FacilitiesDokument10 SeitenSelect PSV Type and Size for Oil & Gas FacilitiesArnie NEaNoch keine Bewertungen

- SHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationDokument42 SeitenSHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationOliver JimmyNoch keine Bewertungen

- Is 3624Dokument53 SeitenIs 3624Sundar Guna100% (1)

- Fisher 627 RegulatorDokument20 SeitenFisher 627 RegulatorSomnath ChatterjeeNoch keine Bewertungen

- Medidor de Nivel ConcentradoDokument100 SeitenMedidor de Nivel ConcentradoSegundo Teofilo Cadenillas CabanillasNoch keine Bewertungen

- PSV Preliminary Documents - Oxidizer BurnerDokument8 SeitenPSV Preliminary Documents - Oxidizer BurnerEsneyNoch keine Bewertungen

- Kvpy Archive Class-Xi PhysicsDokument28 SeitenKvpy Archive Class-Xi PhysicsRayanNoch keine Bewertungen

- Wind Load AnalysisDokument4 SeitenWind Load AnalysisNiraj ShindeNoch keine Bewertungen

- European Standard Norme Européenne Europäische Norm: Test Gases - Test Pressures - Appliance CategoriesDokument0 SeitenEuropean Standard Norme Européenne Europäische Norm: Test Gases - Test Pressures - Appliance CategoriesBladimir SantacruzNoch keine Bewertungen

- Most General Applications of Bernoulli's Equation - PhysicsDokument2 SeitenMost General Applications of Bernoulli's Equation - PhysicsSushantNoch keine Bewertungen

- Flexible Cement Waterproof CoatingDokument2 SeitenFlexible Cement Waterproof CoatingDharryl Dharryl DharrylNoch keine Bewertungen

- Series 74 Positioner ManualDokument25 SeitenSeries 74 Positioner ManualhcalderonmarinNoch keine Bewertungen

- Pipe Bend ExperimentDokument9 SeitenPipe Bend ExperimentNaga Manohar UmmadiNoch keine Bewertungen

- Providing Solutions For Your Most Demanding Applications: Teflon HoseDokument12 SeitenProviding Solutions For Your Most Demanding Applications: Teflon HoseRhdh kldmkNoch keine Bewertungen

- True and Reid Vapor PressuresDokument10 SeitenTrue and Reid Vapor PressuresWil Vasquez CNoch keine Bewertungen

- A1 C2 L8 Solution Key Worked OutDokument27 SeitenA1 C2 L8 Solution Key Worked OutVhenSerdanNoch keine Bewertungen

- Filtro Tipo H x43h EsDokument2 SeitenFiltro Tipo H x43h EseselcosacNoch keine Bewertungen