Beruflich Dokumente

Kultur Dokumente

Food Authentication by Carbohydrate Chromatography

Hochgeladen von

doga17590 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

142 Ansichten12 SeitenThis paper reviews the application of carbohydrate

chromatography for the assessment of the authenticity

of honey, maple syrup, fruit juice, mushrooms,

UHT milk, natural gums, and soluble coffee.

Examples are given for each commodity and the limitations

of the different techniques are discussed.

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis paper reviews the application of carbohydrate

chromatography for the assessment of the authenticity

of honey, maple syrup, fruit juice, mushrooms,

UHT milk, natural gums, and soluble coffee.

Examples are given for each commodity and the limitations

of the different techniques are discussed.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

142 Ansichten12 SeitenFood Authentication by Carbohydrate Chromatography

Hochgeladen von

doga1759This paper reviews the application of carbohydrate

chromatography for the assessment of the authenticity

of honey, maple syrup, fruit juice, mushrooms,

UHT milk, natural gums, and soluble coffee.

Examples are given for each commodity and the limitations

of the different techniques are discussed.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 12

Part of this paper was presented during the Euro Food Chem

IX Conference, 2426 September 1997, Interlaken, Switzerland

J. Prodolliet 7 C. Hischenhuber (Y)

Nestec Ltd, Nestl Research Center, Vers-chez-les-Blanc,

CH-1000 Lausanne 26, Switzerland

Z Lebensm Unters Forsch A (1998) 207: 112 Q Springer-Verlag 1998

REVIEW

Jacques Prodolliet 7 Claudia Hischenhuber

Food authentication by carbohydrate chromatography

Received: 1 December 1997 / Revised version: 9 February 1998

Abstract This paper reviews the application of carbo-

hydrate chromatography for the assessment of the au-

thenticity of honey, maple syrup, fruit juice, mu-

shrooms, UHT milk, natural gums, and soluble coffee.

Examples are given for each commodity and the limita-

tions of the different techniques are discussed.

Key words Carbohydrate chromatography 7

Adulteration 7 Authenticity

Introduction

Economic adulteration has been practised for centuries

by unscrupulous farmers, manufacturers or traders who

seek substantial benefits by extending or substituting

expensive food products with low cost materials. This

has, of course, triggered the development of new analy-

tical methods for the assessment of food authenticity.

Various techniques such as GC, HPLC, stable isotope

analysis, electrophoresis, immunoassays, DNA analysis,

and NIR spectroscopy have been developed and many

different classes of compounds have been considered as

tracers of adulteration (e.g. proteins, carbohydrates,

fatty acids, pigments and organic acids). This paper re-

views the application of carbohydrate chromatography

as a specific tool for the assessment of authenticity.

However, one analytical technique is generally not suf-

ficient to detect all types of adulteration commonly

practised, and in most cases only a full battery of ana-

lyses can assess the authenticity of a product.

Carbohydrate chromatography has proven particu-

larly useful for the authentication of fruit juices, honeys

and maple syrups, as large amounts of carbohydrates,

mainly in the form of simple sugars such as fructose,

glucose and sucrose, are found in these commodities.

Not surprisingly, the most common technique of adul-

teration consists of adding inexpensive sweeteners, the

sugar compositions of which mimic those found in the

authentic products. Sweeteners can be detected by the

distortion of the natural sugar profile or by the pres-

ence of fingerprint oligosaccharides.

Different substitutes are used to adulterate com-

modities exhibiting a more complex carbohydrate com-

position. In certain cases, specific carbohydrates can

still be used as markers. Undeclared addition of coffee

husks in soluble coffee, detected by the presence of

high levels of xylose and mannitol, is a good example.

The use of carbohydrate chromatography has also

been reported for the detection of mislabelling of the

botanical and geographical origins of foods. For exam-

ple, distortion of the natural mannose to galactose ratio

in locust bean gum strongly suggests the addition of

guar gum.

Finally, the process by which a food product is man-

ufactured is sometimes precisely regulated by official

bodies. Examples where carbohydrate analysis allows

the manufacturing process to be identified have also

been reported, e.g. in discriminating between ultra

heat-treated (UHT) and sterilised milk according to

their lactulose contents.

The following sections give detailed examples of ad-

ulteration which can be detected using carbohydrate

markers and briefly discuss the chromatographic tech-

niques applied. The results presented were taken both

from the literature and from the authors own studies.

Authenticity of honey

Codex Alimentarius defines honey as the natural

sweet substance produced by honey bees from nectar of

blossoms or from secretions of living parts of plants or

excretions of plant sucking insects on the living part of

plants, which honey bees collect, transform and com-

2

bine with specific substances of their own, store and

leave in the honey comb to ripen and mature [1]. Hon-

ey has been appreciated since the stone age and, up to

the eighteenth century, was nearly the only concen-

trated sweetener available. The sale of adulterated or

artificial honey is widespread and has been reported for

many centuries.

Nowadays a number of inexpensive sweeteners and

syrups are commercially available for fraudulently re-

placing the natural carbohydrates of honey. The addi-

tion of sucrose can be detected by simply measuring its

level in the honey; even a small amount added will be

evaluated as being above the natural level. HPLC de-

termination of sucrose, glucose and fructose was colla-

boratively tested in 1979 [2]. As 8595% of the total

carbohydrate content of honey is composed of fructose

and glucose, the average ratio being 1.2: 1.0 [3], high

fructose syrups (HFS) and invert sugars (IS) are the

most favoured adulterants. Beet or cane total IS are

produced from refined beet or cane sucrose by either

acid or enzymatic hydrolysis resulting in a finished

product containing a 1: 1 ratio of glucose:fructose and

low levels of sucrose. HFS are mainly produced by the

enzymatic hydrolysis of either corn, potato, rice or

wheat starch. The resulting glucose syrup is partially

converted to fructose by enzymatic treatment. The fin-

ished products consists of a mixture of glucose and

fructose with ratios of about 0.81.4.

High fructose corn syrup (HFCS) can be detected by

carbon stable isotope ratio analysis (CSIRA). As an al-

ternative, various chromatographic methods based on

the consideration that the di- and oligosaccharide pro-

files of honey and syrups are different have been pro-

posed. Some of these methods are also applicable to

the detection of beet IS that cannot be distinguished

easily from honey by stable isotope analysis tech-

niques.

Doner et al. [4] measured the maltose/isomaltose ra-

tios of honeys and HFCS by GC and showed that ratios

above 0.51 indicated adulteration. Kushnir [5] de-

scribed a TLC separation of oligosaccharides after

clean-up on a charcoal-Celite column, while Lipp et al.

[6] separated these substances by reversed-phase

HPLC. Both methods detected low percentages of

HFCS in honey. More recently, methods using high-

performance anion-exchange chromatography with

pulsed amperometric detection (HPAE-PAD) [7] and

capillary GC [8] have been developed by Low and co-

workers. The HPAE-PAD method involved charcoal-

Celite column clean-up and separated specific marker

peaks for cane IS and HFCS. Capillary GC was per-

formed on diluted, freeze-dried and silylated samples.

Specific marker peaks for IS that were either absent or

present in low amounts in authentic honey were re-

ported. As a matter of fact, all of these procedures yield

quite complex chromatograms due to the presence of a

large number of naturally occurring oligosaccharides in

authentic honeys and, therefore, careful interpretation

of the results is necessary.

Fig. 1A, B HPLC chromatograms of honeys. A Honeydew. B

Acacia. F Fructose; G glucose; S sucrose; TU turanose; MpMA

maltose; TR trehalose; I isomaltose; E erlose; ME melezitose; R

raffinose; x maltulose, nigerose. Reprinted from Mitt Geb

Lebensmittelunters Hyg [12] with the kind permission of the

Bundesamt fr Gesundheit Facheinheit Lebensmittel und

Gebrauchsgegenstnde, Bern

The principal source of honey is nectar, and blossom

honey is preferred in most parts of the world [911].

However, in central Europe honeydew honey prevails

and is more highly prized than blossom honey [911].

Therefore, mislabelling of the origin of a honey is an-

other authenticity issue.

Honeydew honey can be distinguished from blossom

honey by its higher pollen count, electrical conductivity

and salt content, a deeper colour, and by the presence

of spores of sooty moulds, pieces of fungal hyphae and

algal cells [1, 4]. Moreover, it is dextrorotatory, while

blossom honey is invariably laevorotatory [911]. This

is due to major differences in the carbohydrate profile.

Indeed, it was found by many authors that honeydew

honey contains lower levels of fructose and glucose, but

higher levels of oligosaccharides, in particular the tris-

accharides melezitose and raffinose [914].

Bogdanov and Baumann [12] determined the mono-,

di- and trisaccharide profiles of 118 blossom honeys

and 38 honeydew honeys of different origins, all sold

on the Swiss market. Carbohydrates were separated by

HPLC on an amino column using a mixture of acetoni-

trile and water as eluent, and were detected by a refrac-

tive index (RI) detector. Melezitose and raffinose were

found to be very characteristic of honeydew honey.

Melezitose ranged from 1.0% to 22.0% (average 5.3%)

in honeydew honey, and from 0.1% to 1.0% (average

0.5%) in blossom honey. Raffinose ranged from 0.1%

to 1.5% (average 0.5%) in honeydew honey, and was

not detected in any of the blossom honeys analysed.

Examples of the chromatograms are given in Fig. 1.

These results were confirmed by Fldhzi [13] on 34

blossom honeys from different floral sources and one

honeydew honey, using a similar HPLC technique. An-

other trisaccharide, namely erlose, has also been sug-

gested as a tracer of honeydew honey. However, large

amounts of this carbohydrate were found in blossom

honey from alfalfa, alsike and trefoil [12, 15]. In the lat-

ter study, the carbohydrates were analysed by HPAE-

PAD. The technique allows a good separation of 20

honey oligosaccharides and is more sensitive than

3

Fig. 2 Separation of unifloral honeys using canonical

discriminant analysis. Numbered O Group centroids; c bramble,

69 samples; } ling, five samples; x oil seed rape, eight samples; o

white clover, five samples; g hawthorn, two samples; l

willow-herb, one sample. Samples A and B contained 21 and 25%

bramble, respectively. Reprinted from J Chromatogr [18] with

kind permission of Elsevier, Amsterdam

HPLC-RI. The number of species of flowers around

the world that are significant sources of blossom honey

is very large, each giving very distinct organoleptic

characteristics to the final product. In most cases, the

floral source is stated because consumers prefer the fla-

vour, aroma, colour or texture of the honey from a par-

ticular flower. These so-called unifloral honeys, such as

orange blossom or acacia honey, command a premium

price and are an ideal target for stretching with cheaper

honey. For these reasons, reliable analytical tools are

needed to judge the source of each honey.

The most widely used method of authenticating the

particular floral source is based on identification of the

pollen present in the honey [9]. However, this tech-

nique requires a high level of expertise, is very time

consuming and suffers from several limitations [9].

Moreover, pollen is commercially available and a

fraudster could filter out all the pollen and add back a

pollen of his choice [9, 16]. Organoleptic evaluation

also serves to indicate the floral origin, but is too sub-

jective. Analysis of flavours, flavonoids, amino acids,

methyl anthranilate and other trace organics has also

proved fairly useful [1, 4]. In an early study, carbohy-

drate analysis by capillary GC failed to discriminate be-

tween honeys from different floral sources (alfalfa, al-

sike, canola, red clover, sweet clover, trefoil). All sam-

ples exhibited a similar oligosaccharide profile [17].

However, the number of unifloral honeys was very lim-

ited (one per source), and no multivariate statistical

analysis of the data was performed. More recently,

Goodall et al. [18] determined the carbohydrate profile

of 91 unifloral honeys from six different origins by

HPAE-PAD. Canonical discriminant analysis, perform-

ed on the 40 separated, but unidentified oligosacchar-

ides, proved successful in discriminating between hon-

eys from ling, oil seed rape and bramble (Fig. 2). How-

ever, the technique does not apply to all floral types. It

is worth mentioning that acacia honey presented by far

the highest fructose/glucose ratios among all the uniflo-

ral honeys analysed in Fldhzis study [13].

Authenticity of maple syrup

Maple syrup is produced from the sap of the sugar ma-

ple tree (Acer saccharum). Collected during the end of

the winter season, this sap is concentrated to about 677

Brix. As much as 35 l sap is required to produce about

1 l pure syrup. The major components of maple syrup

are the carbohydrates, which account for about 98% of

the total soluble solids. Sucrose is the major carbohy-

drate present, and its concentration ranges from 88%

to 100% of the total carbohydrates depending on the

syrups age and other natural, storage and processing

factors [19]. Other constituents of maple syrup are glu-

cose, fructose, oligosaccharides, organic acids, minerals,

amino acids and vitamins [19, 20]. Profitable adultera-

tion can be readily accomplished by simply adding

inexpensive sweeteners such as cane or beet sugar,

HFCS or beet medium invert sugar (BMIS).

Several methods of assessing authenticity have been

developed, including conductivity measurements, CSI-

RA [21, 22], site-specific natural isotope fractionation

nuclear magnetic resonance spectroscopy (SNIF-NMR)

[22], and mono-, di- and oligosaccharide profiling [20].

Using carbohydrate profiling it is not possible to de-

tect pure cane or beet sugar the methods of choice for

this type of adulteration are CSIRA and SNIF-NMR

but it is an interesting tool to detect HFCS and BMIS.

As non-aged pure maple syrup has a combined glucose

and fructose concentration of less than 1112% [19],

samples with monosaccharide levels greater than 12%

may be indicative of adulteration. Another approach

was reported by Stuckel and Low [19]. They showed

that oligosaccharide fingerprinting by HPAE-PAD can

be used to detect HFCS and BMIS in maple syrup. The

method was tested on 80 authentic maple syrup sam-

ples representing the major geographical regions of

production and 30 samples spiked with HFCS or BMIS.

A detection limit of about 5% for each of the sweeten-

ers was obtained.

Authenticity of fruit juice

Addition of sugar

About 98% of the total soluble solids in fruit juices are

carbohydrates. It is therefore obvious that the most

profitable adulteration of fruit juices involves partial

replacement of the natural sugars with less expensive

ones. Besides sucrose, HFS and IS, BMIS and cane me-

dium invert sugar (CMIS) are popular adulterants.

These materials are produced by either acid or enzy-

matic hydrolysis of refined sucrose resulting in a fin-

4

Fig. 3 Chromatograms of orange juice spiked with various levels

(020%) of beet medium invert sugar (BMIS). Reprinted from J

AOAC Int [31] with kind permission of AOAC International,

Arlington, USA

ished product containing a 1: 1: 2 ratio of glucose:fruc-

tose:sucrose, thus approximating to the sugar distribu-

tion of orange juice.

When assessing the authenticity of fruit juices, the

glucose: fructose: sucrose distribution is routinely

checked and compared to generally accepted guide val-

ues [23, 24]. This gives information about whether

sweeteners that unbalance the natural sugar proportion

have been added. For this analysis several HPLC pro-

cedures involving ion-exchange chromatography with

RI detection [25] or HPAE-PAD [26] are available.

Other methods published in the course of the last 6

years rely on the determination of unusual di-, and/or

tri- and tetrasaccharides formed during the manufac-

ture of syrups. Oligosaccharides may be formed chemi-

cally by the action of acid on sucrose, fructose and glu-

cose (reversion reactions), others by the use of hy-

drolitic enzymes during syrup production. The first

method introduced that used oligosaccharide finger-

printing was a HPAE-PAD method to detect BMIS in

orange juice [27]. The procedure involved a quite labo-

rious clean-up step to remove organic acids and mono-

saccharides, HPAE with gradient elution using two

analytical columns in series and PAD. Later on, the

clean-up step to eliminate monosaccharides was omit-

ted, chromatography was shortened from 3 h to 96 min,

and the method was extended to the detection of other

inexpensive sweeteners such as HFCS and cane and

beet IS [28]. The technique was also applied to other

citrus fruits such as grapefruit [29]. The original proce-

dure was further adapted by other research groups, e.g.

by White and Cancalon [30], who introduced a column

switching technique: the monosaccharides were eluted

from the first column to waste and only the di- and ol-

igosaccharides were transferred to the second analytical

column. Iuliano [31] decreased overall analysis time to

45 min by isocratic elution of the oligosaccharides after

diverting sucrose, glucose and fructose to waste after

the first analytical column. Figure 3 shows chromato-

grams of orange juice spiked with various levels of

BMIS.

However, it must be emphasised that oligosacchar-

ide profiling has several limitations. Besides the general

limitation that it will not detect the addition of pure su-

crose, there are two other important drawbacks. The

concentration of marker oligosaccharides can vary con-

siderably depending on the method of preparation of

the adulterants and consequently, the detection limit

will vary accordingly. The most worrying limitation of

this method can be summarised by the slogan heat or

beet?. Juice concentrates that have undergone impor-

tant heat treatments yield complex chromatograms

5

Fig. 4 Capillary GC chromatogram of an apple juice adulterated

with high fructose syrup from inulin (HFIS). HFIS1

(RTp17.4 min), HFIS2 (RTp23.8 min); HFIS3 (RTp28.5 min);

marker peaks for the presence of HFIS

making interpretation quite difficult. While stable iso-

tope analysis techniques (CSIRA and SNIF-NMR) suf-

fer from other limitations, they do allow the detection

of added beet or cane sucrose as well as the detection

of IS in heat-treated concentrates.

To improve oligosaccharide profiling, Low [32, 33]

developed an alternative method using capillary GC

with flame ionization detection. Specific marker peaks

were used to detect adulterants in orange and apple

juice, i.e. two unidentified disaccharides for tracing IS

and two peaks of isomaltose to trace HFS. The method

involved a column clean-up that was omitted later on

[34], freeze-drying of the sample and trimethylsilylation

of the carbohydrates. Capillary GC was performed on a

0.25 mm!30 m DB-5 column. In pure orange and ap-

ple juices the marker peaks were virtually absent and a

detection limit for HFS and IS of 5% was claimed. At

the beginning of 1996, Lows GC procedure gained

considerable popularity, when strange oligosaccharide

peaks could be observed in a number of apple juice

concentrates. These peaks were finally identified as

fructulin, a high fructose syrup from inulin (HFIS) that

had been used by unscrupulous suppliers to adulterate

apple concentrates [34]. HFIS has a high fructose/glu-

cose ratio which makes this material a good adulterant

for apple juice, which has a fructose/glucose ratio ex-

ceeding 2. Figure 4 shows a chromatogram of a com-

mercial apple juice adulterated with HFIS. The operat-

ing conditions were according to Low and Hammond

[34] without column clean-up and with hydrogen as the

carrier gas for GC. When compared to an HFIS stand-

ard, the adulteration corresponded to about 30% of the

total sugar present. There is no doubt that this oligosac-

charide profiling technique is a valuable tool for fruit

juice authenticity assessment.

Fig. 5AC Capillary GC chromatograms of apple juice

concentrates. A Authentic, untreated. B Authentic, heat treated.

C Sample B spiked with 10% invert sugar (IS). IS1

(RTp38.6 min) and IS2 (RTp39.8 min); marker peaks for the

presence of IS. Peak height ratios IS2/IS1: sample B 1.31, sample

C 1.70

However, the method suffers from limitations simi-

lar to the HPAE-PAD technique discussed earlier.

Heat-treated authentic apple juice concentrates may

show the same marker peaks as IS; only the peak ratios

differ to some extent. The marker peaks generated by

heat have a peak ratio close to 1, while those generated

by IS have a ratio greater than 3. Considerable efforts

have been undertaken to establish analytical conditions

that allow distinguishing between heat and beet [35].

Taking into consideration the reproducibility of the

evaluation of these small marker peaks and fluctuations

in the concentration of the marker oligosaccharides

present in various IS preparations and in heated apple

juices, the detection limit may vary between 5% and

more than 30% of added IS. Figure 5 shows the chro-

matograms of a heat-treated authentic apple concen-

trate and of the same concentrate spiked with 10% IS

containing quite high levels of marker oligosaccharides.

The added concentration corresponds in this case to

the detection limit.

In other juice concentrates, such as berry juice con-

centrates that are produced using enzymes, the detec-

tion of IS is almost impossible. Peaks showing the same

ratio as those originating from IS are observed in auth-

entic juices. However, in some types of berry juice the

detection of HFS is possible. Fig. 6 shows a chromato-

gram of an authentic blackcurrant concentrate and of

the same concentrate spiked with 10% of HFCS. The

second marker peak (isomaltose 2) was virtually absent

in all authentic blackcurrant juices analysed, thus allow-

ing the detection of HFCS. The detection of the differ-

ent adulterants must be carefully evaluated for each

type of juice. For example, the detection of low

amounts of HFS in pineapple juices is difficult, as low

levels of isomaltose may occur naturally in pineapples.

Summarising, it can be said that no single method

available allows the detection of all forms of sugar ad-

dition to fruit juices, but oligosaccharide profiling is a

6

Fig. 6 Capillary GC chromatograms of blackcurrant juice

concentrates. A Authentic, B sample A spiked with 10% high

fructose corn syrup (HFCS). Isomaltose 1 (RTp40.8 min) and

isomaltose 2 (RTp44.2 min); marker peaks for the presence of

HFCS. Arrows show retention times of marker peaks of invert

sugar

method that should be included in the authenticity as-

sessment of juices. Taking as an example apple juice,

Lees et al. [36] demonstrated clearly, that a whole set of

analyses is necessary to cover most types of adultera-

tion. More information will be obtained by carefully as-

sessing the authenticity of a limited number of well-de-

fined batches of fruit concentrates than by testing many

batches with a single method.

Addition of another type of fruit

Another fraud is the partial replacement of one type of

fruit juice/pulp with one which is less expensive, e.g. ad-

dition of apple or pear to expensive berry juices/pulps

or fruit preparations. In these cases, sorbitol present in

apples, pears and other fruits, but virtually absent in

berry fruits such as raspberry, strawberry, blackcurrant,

red currant or blueberry, is an excellent tracer for adul-

teration. An interesting alternative to the enzymatic

sorbitol assay is the simultaneous separation of sorbi-

tol, glucose, fructose and saccharose by HPLC with RI

detection [25] or HPAE-PAD [26].

Addition of pulpwash

In many countries, such as the United States and coun-

tries of the European Union (EU), the addition of

pulpwash to pure juice concentrates is not allowed.

Pulpwash is defined as the water-extracted soluble fruit

solids recovered in the presence of water from unfer-

mented excess fruit pulp removed during the produc-

tion of citrus juice products. US federal regulations al-

low the in-line addition of pulpwash to freshly ex-

tracted juice, while in the EU both in-line and off-line

addition is prohibited.

Various methods for the detection of orange pulp-

wash based on the quantification of components that

occur at higher levels in the pulp and peel than in the

juice have been proposed. However, due to large natu-

ral fluctuations and differences in juice extraction tech-

nology, the detection of pulpwash remains an analytical

challenge. The most well-known methods involve the

determination of water-soluble pectin, calcium, spectro-

photometric determination of the flavonoid glycosides,

HPLC determination of hesperidin and narirutin, or

evaluation of the UV/VIS absorbance and the fluores-

cence at distinct wavelengths.

An alternative to the labour-intensive carbazole

method for the determination of water-soluble pectin

[37] using HPAE-PAD [38] has been proposed. In this

method, the sample is filtered and the water-soluble

pectin is completely hydrolysed with pectolytic en-

zymes to produce free galacturonic acid. The galactu-

ronic acid is then determined by HPAE-PAD. Smaller

pectin fragments formed during enzymatic treatment in

the production of pulpwash concentrates (off-line pulp-

wash) and peel extracts are taken into account with this

procedure, while they are lost when applying the carba-

zole method. In a recent paper this method was applied

to a large number of samples and the results compared

with those obtained with the carbazole method [39]. In

addition, total galacturonic acid is measured in the ex-

tracts before the carbazole reaction. Large differences

between results obtained on the juice and on the ex-

tract would indicate the presence of enzymatically

treated pulpwash. A capillary GC method for the de-

termination of galacturonic acid in orange juice had

been described 10 years earlier by Kauschus and Thier

[40]: the polysaccharides were cleaved by methanolysis

and the resulting galacturonic acid was silylated and

analysed by capillary GC. The chromatograms were

rather complex, silylated galacturonic acid yielding four

peaks.

Another HPAE-PAD method that allows the detec-

tion of enzymatically treated pulpwash or peel extracts

in citrus juices [41, 42] by analysing the oligogalactu-

ronide pattern has been proposed.

Adulteration of mushrooms

Some culinary products, notably soups and sauces, de-

rive their excellent taste and flavour from the use of

wild mushrooms as essential ingredients. Among the

commercially available wild mushrooms, two boletus

species, namely Boletus edulis (cep, king boletus) and

Suillus luteus (brown-yellow boletus, slippery jack), are

undoubtedly the most important. However, B. edulis is

tastier and about four times more expensive than S. lu-

teus. Substitution of the latter fungi for B. edulis is,

therefore, very appealing [43].

7

B. edulis and S. luteus are sufficiently different to be

visually or microscopically identifiable. This is certainly

true for whole or large chunks of fungi. However, ex-

amination of granulates or powders used by the food

industry, in which most of the morphological character-

istics are lost, is much more difficult. More objective

analytical methods are required.

Mushrooms contain, in general, fairly high amounts

of sugar alcohols, mainly mannitol and arabitol [44].

However, their relative proportions differ from one

type of mushroom to another. Stijve [43] measured the

mannitol and arabitol contents of 20 samples of both

boletus species by high-performance thin-layer chroma-

tography (HPTLC). Mannitol ranged from 0 to 4.0%

on dry matter (o.d.m.) (average 2.4%) in B. edulis, and

from 2.0% to 7.5% o.d.m. (average 5.1%) in S. luteus.

Arabitol ranged from 0.3% to 2.0% o.d.m. (average

0.9%) in B. edulis, and from 4.7% to 20.0% o.d.m. (av-

erage 9.7%) in S. luteus. Therefore, high levels of both

sugar alcohols could be indicative of the presence of S.

luteus in B. edulis. However, the technique would only

detect high amounts ( 120%) of the cheaper fungi.

Using a very similar HPTLC technique, Andary et

al. analysed samples of Suillus granulatus, Suillus bel-

linii and S. luteus [45]. All three species presented high

levels of mannitol (4.47.0% o.d.m.) and arabitol

(12.820.0% o.d.m.), and the results obtained for S. lu-

teus fell within the upper range of Stijves data.

Substitution of chanterelle mushrooms (Cantharellus

cibarius) with the cheaper false chanterelle (Hygro-

phoropsis aurantiaca) is another potential authenticity

issue. Laub [46] suggested using the arabitol/total sol-

uble carbohydrate ratio as a tracer for the presence of

false chanterelle. He found that the ratio ranged from

0.25% to 3.00% o.d.m. (average 1.34%, np14) in chan-

terelle mushrooms, and from 27.9% to 55.8% o.d.m.

(average 40.7%, np5) in the false chanterelle. He con-

cluded that the technique could detect as little as 10%

of false chanterelle in the authentic product. Laub and

Woller [47] also suggested that a mannitol content be-

low 300 mg/100 ml infusion could indicate poor manu-

facturing practices in the canning of cultivated white

mushrooms (Agaricus bisporus).

Differentiation between UHT and sterilised milks

The EU gives specific requirements for the manufac-

ture of heat-treated milk and, in particular, defines

what a UHT and a sterilised milk must be [48]. The

Codex Alimentarius has also proposed other defini-

tions [49]. One of the main characteristics is that UHT

milk is sterilised by a continuous flow process and asep-

tically filled into sterile containers, whereas sterilised

milk is produced by in-container sterilisation. The aim

of the two treatments is to destroy all residual spoilage

micro-organisms and their spores [48]. However, it is

known that the in-container process causes a greater

chemical change in the milk than the UHT process for

Table 1 Typical levels of lactulose in UHT and sterilised milks

Study UHT milk

mg/100 ml

Sterilised

milk

mg/100 ml

Martinez-Castro and Olano [57] 1030 80200

Geier and Klostermeyer [50] 1072 87137

Andrews [51] 572 69120

Olano et al. [52] 1075 75175

Andrews and Morant [53] 1072 57173

the same sterilising effect [5052], leading to differ-

ences in organoleptic characteristics [49]. Indeed, steril-

ised milk is generally associated with a lower organo-

leptic acceptability, a stronger cooked defect and a

darker colour [53]. Therefore, indicators by which the

two types of milk may be identified are required.

Lactulose is a disaccharide formed by the isomerisa-

tion of lactose during heat treatment of milk. It has

been shown to occur in different concentrations in

UHT and sterilised milk (Table 1). For this reason, the

EU and the International Dairy Federation (IDF) are

considering the use of lactulose as an indicator for dis-

tinguishing between the two products. However, to our

knowledge, no official standards have been issued so

far, and limits below or above which milk should be

considered as UHT or sterilised are still under debate

[54]. Nevertheless, limits of 60 and 70 mg/100 ml have

been proposed by the IDF [55] and Andrews [56], re-

spectively.

Enzymatic, GC and HPLC methods have been re-

ported for the determination of lactulose in heat-

treated milk [50, 52, 58]. The provisional standards is-

sued by the International Organization for Standardiza-

tion (ISO) and the IDF both describe an HPLC meth-

od, in which lactulose is analysed on an ion-exchange

material in the lead form and quantified by RI detec-

tion [59, 60]. The procedure has been subjected to sev-

eral collaborative studies [61]. The quantification of

lactulose is complicated by the presence of huge

amounts of lactose. Recently, HPAE-PAD has been

proposed as an alternative to the official methods [62].

Using this technique, better separation of lactulose

from lactose is possible (Fig. 7), and it is much more

sensitive. Sample preparation is also more straightfor-

ward. It has been applied to a wide variety of milk

products [62] and certainly deserves further attention.

Authenticity of natural gums

Hydrocolloids are heteropolysaccharide food additives,

incorporated into a very diverse range of food formula-

tions to impart a wide variety of characteristics to the

finished product. They are mainly employed as thicken-

ers, gelling agents and stabilisers, but also as emulsif-

iers, flavour encapsulators, sugar crystallisation inhibi-

tors, or simply as food ingredients. Most of the hydro-

8

Fig. 7 HPAE-PAD chromatogram of UHT milk. Column:

CarboPac PA1, eluent: gradient of 10 mM NaOH and 0.5 mM

Zn(AcO)

2

; lactulose concentation: 27 mg/100 ml

Table 2 Carbohydrate composition for different gum exudates (%)

Species Galactose Arabinose Rhamnose Glucuronic

acid

4-O-methyl

glucuronic acid

References

Acacia senegal 3056 1646 724 1228 0.52 [63, 70, 72, 73,

7578]

Acacia seyal 3238 4151 14 6.517 15.5 [70, 72, 73, 76]

colloids used by the food industry are of natural origin,

such as seaweed extracts (e.g. carrageenans), plant exu-

dates (e.g. gum arabic), plant cell wall extracts (e.g.

pectin) or seed mucilages (e.g. locust bean gum). Hy-

drocolloids can be very expensive and as natural prod-

ucts may be subject to serious shortages. Therefore, the

incentive to adulterate one hydrocolloid by a cheaper

and/or more readily available substitute is always pres-

ent, and fraud has been a common practice in the gum

industry [6365] for many years. Gum arabic and locust

bean gum are still favoured targets.

Gum arabic

The gum exudate from Acacia senegal trees, commonly

known as gum arabic, originates in Africa. The main

producing countries are Sudan, Nigeria, Chad, Ethiopia

and Senegal. It is an approved food additive (E 414),

principally used in confectionery and beverages. The

Joint FAO/WHO Expert Committee on Food Addi-

tives (JECFA) defines gum arabic as a dried exuda-

tion obtained from the stems and branches of Acacia

senegal (L.) Willdenow or closely related species of

Acacia (fam. Leguminosae) [66]. The Committee has

recently revised the specification for gum arabic [66],

taking into account concerns expressed about the po-

tential adulteration of commercial gum arabic with

gums from non-Acacia species [67]. For this reason,

identification tests are described to ensure the absence

of mannose, xylose and galacturonic acid, three sugars

characteristic of common adulterants in gum arabic [66,

67]. However, they did not include limits for specific ro-

tation and nitrogen, two important parameters present

in the previous specification [68].

There has been an extensive polemic in the litera-

ture concerning the meaning of closely related species

of Acacia and different opinions were expressed about

what gum arabic should be [63, 6973]. In particular,

some authors think that gum A. seyal (gum talha),

which is the most commercially abundant Acacia gum

after A. senegal, should not be considered as gum arab-

ic [69, 71, 73, 74] and, therefore, its presence in com-

mercial samples is a fraud. They argue that A. seyal has

never been subjected to any form of toxicological eval-

uation [69, 71]. In fact, A. seyal did not fall within the

limits set for specific rotation and nitrogen in the 1990

JECFA specification [68] and, consequently, could not

be regarded as gum arabic. However, it now completely

meets the new JECFA specification [66] and, accord-

ingly, should be considered as safe [67] and accepted as

food-grade gum arabic. Food manufacturers who want

to stick to more stringent specifications and to purchase

pure A. senegal gum free from A. seyal can nevertheless

rely on different analytical techniques for the control of

their raw material. Some are based on the difference in

the carbohydrate composition of the two gums (Table

2).

All the data show that A. seyal has much lower

rhamnose and higher arabinose contents than A. sene-

gal. However, due to large natural variations in the

concentration of the two monosaccharides, the method

would only detect high amounts of gum talha. Other

parameters should be included in order to improve the

capability of distinguishing between the two gums. In

this connection, principal component analysis perform-

ed on nine physical and chemical parameters (Fig. 8),

including all constitutive carbohydrates analysed by

both HPLC and TLC, proved successful in separating

gums from A. senegal and A. seyal [76]. Recently, an

immunological technique, using an anti-arabinogalac-

tan protein/arabinogalactan monoclonal antibody, has

been proposed to screen for the presence of gum talha

in commercial gum arabic [73].

Locust bean gum

Locust or carob bean gum is primarily the refined en-

dosperm of the seed of the carob tree, Ceratonia sili-

9

Fig. 8 Separation of Acacia senegal and Acacia seyal gums by

PCA. Parameters: specific rotation, nitrogen, viscosity, equivalent

weight, galactose, arabinose, rhamnose, glucuronic acid,

4-O-methyl glucuronic acid. Axes: first and second principal

components, 45% and 19% of total variance, respectively. L

Vulgares; l A. Senegal; c A. Seyal; g Gummiferae. Reprinted

from Food Hydrocoll [76] with kind permission of Oxford

University Press, Oxford

qua, a leguminous tree grown in Mediterranean coun-

tries. It is an approved food additive (E 410) used in

dairy, dessert, bakery and meat products. The price of

locust bean gum (LBG) is relatively high, and varies

greatly depending on the world demand and on some-

what unreliable crops. Therefore, the market is wide

open for fraud. Adulteration of LBG with a much

cheaper gum, namely guar gum, has been reported [65].

Guar gum is obtained from the seed of another legumi-

nous tree, Cyamopsis tetragonolobus, that grows mainly

in the Indian subcontinent. It is also an approved food

additive (E 412), but is available at a much cheaper

price than LBG.

Microscopy [79], double-diffusion lectin assay [80]

and capillary electrophoresis [65] have been suggested

for the detection of guar gum in LBG. Distortion in the

natural carbohydrate profile of LBG can also be indica-

tive of the presence of guar gum. Indeed, both gums

consist mainly of high molecular weight galactoman-

nans. However, the relative proportions of mannose

and galactose, as measured by any chromatographic

technique after acid hydrolysis or methanolysis of the

product [8184], are very different. The carbohydrate

composition of commercial samples of refined LBG

and guar gums from different suppliers was deter-

mined. The gums were dispersed in 12 M H

2

SO

4

and

incubated at 30 7C for 1 h. The samples were then di-

luted with water to reach 0.414 M H

2

SO

4

, and auto-

Table 3 Carbohydrate compositionof commercial refined locust

bean and guar gums (%)

Carbohydrate Locust bean

a

Guar

b

Mannose Range 59.369.9 45.656.5

Average

c

63.9 (3.0) 53.0 (2.6)

Galactose Range 16.018.2 28.637.2

Average 16.8 (0.6) 30.9 (1.9)

M/G

d

Range 3.584.20 1.491.84

Average 3.80 (0.21) 1.72 (0.09)

Arabinose Range 0.801.37 1.292.19

Average 1.01 (0.15) 1.76 (0.22)

Glucose Range 1.492.65 1.474.54

Average 2.05 (0.38) 2.41 (0.79)

a

np12

b

np19

c

Standard deviation in parentheses

d

Mannose: galactose ratio

Fig. 9A, B HPAE-PAD chromatograms of locust bean gums. A

authentic, B suspect. Column: CarboPac PA1, eluent: gradient of

100 mM NaOH and water

claved for 1 h at 125 7C [81]. The constituent monosac-

charides were analysed by HPAE-PAD [82]. The re-

sults are given in Table 3 and a typical chromatogram

of LBG is shown in Fig. 9A.

The total galactomannan content of both gums is

very similar. However, LBG exhibits higher levels of

mannose and lower concentrations of galactose than

guar gum. Consequently, the mannose/galactose ratio

in LBG is about twice that measured in guar gum. In

the course of our survey, one sample sold as pure LBG

presented a mannose/galactose ratio of 1.68 (Fig. 9B).

The latter is typical for guar gum (Table 3) and it is

obvious that the product had been mislabelled. Howev-

er, it should be pointed out that the technique is limited

to the detection of high levels of guar gum.

10

Adulteration of soluble coffee

Coffee trees thrive between latitude 307 north and lati-

tude 307 south, at altitudes ranging from sea level to

more than 2000 m, in a globe-encircling geographical

region known as the coffee belt. The main coffee

producing countries are Brazil, Colombia, Indonesia,

Mexico and the Ivory Coast.

What is green coffee? The International Coffee Or-

ganisation, an inter-governmental body which used to

regulate the world supply and price of coffee beans, de-

fines green coffee as all coffee in the naked bean form

before roasting, roasted coffee as green coffee

roasted to any degree and including ground coffee,

and soluble coffee as the dried water-soluble solids

derived from roasted coffee [85]. ISO [86], the EU

[87] and the United States [88] also define green coffee

in similar terms. Therefore, internationally accepted

definitions clearly establish that a commercial product

sold as pure soluble coffee must not contain any mate-

rial derived from sources other than green coffee

beans.

Whatever its final use, coffee remains an expensive

raw material and over the years many fraudsters have

been tempted to replace it with cheaper substitutes and

to falsify the product declaration. In particular, it has

been reported that commercial products were in fact

adulterated with coffee husks/parchments, cereals,

malt, maltodextrins and caramelised sugar [8995]. The

free and total carbohydrate profiles (after acid hydroly-

sis) of soluble coffee were used for detecting and even-

tually characterising the coffee substitutes. Marker car-

bohydrates include free fructose, free glucose, sucrose,

mannitol, total glucose and total xylose.

Different analytical methods were applied for the

determination of carbohydrates in soluble coffee, in-

cluding HPLC with post-column derivatisation [89, 95],

GC [90] and HPAE-PAD [9194, 96, 97]. The latter

technique is simple, precise and sensitive, and allows a

complete separation of all major carbohydrates in one

single run (Fig. 10). It has been collaboratively tested

within the Association of Soluble Coffee Manufactur-

ers of the European Community (AFCASOLE) [96,

97]. The method has now been published as Interna-

tional Standard ISO 11292: 1995 [98], and has been ad-

opted as a First Action by AOAC International [97].

Carbohydrate profiles of a wide variety of commer-

cial products, all sold as pure soluble coffees, were de-

termined [8995]. Pure soluble coffee is characterised

by low free carbohydrate contents and high amounts of

total galactose and total mannose (Fig. 10A). Products

adulterated with coffee husks or parchments present

high levels of free mannitol, free fructose, total glucose

and total xylose (Fig. 10B); occasionally, sucrose may

be present in relatively high concentrations. Products

adulterated with starch-containing substitutes (e.g. cer-

eals or malt), maltodextrins or caramelised sugar exhi-

bit high amounts of free fructose, free glucose and su-

crose as well as huge levels of total glucose (Fig. 10C).

Fig. 10AC Total carbohydrate profiles of commercial soluble

coffees. A Pure. B Adulterated with coffee husks/parchments.

C Adulterated with cereals. 1 mannitol; 2 arabinose/rhamnose; 3

galactose; 4 glucose; 5 xylose; 6 mannose. Technique:

HPAE-PAD, column: CarboPac PA1, eluent; water

Analysis of the total xylose content in a wide selec-

tion of green coffee beans and the assessment of its fate

during processing allowed the determination of a maxi-

mum total xylose limit of 0.40%, above which a soluble

coffee should be considered as adulterated [93]. Maxi-

mum limits of 0.30% and 2.10% were also proposed for

free mannitol and total glucose contents, respectively

[93]. These limits have been recently taken into account

for the establishment of the Code of Practice for the

Soluble Coffee Industry in the United Kingdom [99],

which, in addition, set up a maximum acceptable con-

tent for free fructose of 0.60%.

Acknowledgements The authors wish to thank C. Martinez, J.-

M. Durgnat, T. Stijve, E. Prior and R. Acheson for their help.

References

1. Codex Alimentarius Commission (1997) Draft Codex Stand-

ards for sugars and honey

2. White JW (1979) J Assoc Off Anal Chem 62: 515526

3. White JW (1975) Composition of honey. In: Crane E (ed)

Honey: a comprehensive survey. Heinemann, London, pp

157206

4. Doner LW, White JW, Phillips JG (1979) J Assoc Off Anal

Chem 62: 186189

5. Kushnir I (1979) J Assoc Off Anal Chem 62: 917920

6. Lipp J, Ziegler H, Conrady E (1988) Lebensm Unters Forsch

187: 334339

7. Swallow KW, Low NH (1994) J AOAC Int 77: 695702

8. Low NH, South W (1995) J AOAC Int 78: 12101218

11

9. Morlan PC (1996) Authenticity of honey. In: Ashurst PR,

Dennis MJ (eds) Food authentication. Blackie, London, pp

259303

10. Siddiqui IR (1970) Adv Carbohydr Chem Biochem

25: 285309

11. Doner LW (1977) J Sci Food Agric 28: 443456

12. Bogdanov S, Baumann E (1988) Mitt Geb Lebensmittelunt-

ers Hyg 79: 198206

13. Fldhzi G (1994) Acta Aliment 23: 299311

14. Krauze A, Zalewski RI (1991) Z Lebensm Unters Forsch

191: 1923

15. Swallow KW, Low NH (1990) J Agric Food Chem

38: 18281832

16. Martin P, Sharman M (1996) Honey. Draft report of the fruit-

based products and honey group of Food Authenticity Issues

and Methodologies (FAIM)

17. Low NH, Nelson DL, Sporns P (1988) J Apic Res

27: 245251

18. Goodall I, Dennis MJ, Parker I, Sharman M (1995) J Chro-

matogr A 706: 353359

19. Stuckel JG, Low NH (1996) Food Res Int 29: 373379

20. Stuckel JG, Low NH (1995) J Agric Food Chem

43: 30463051

21. Morselli MF, Baggett KL (1984) J Assoc Off Anal Chem

67: 2224

22. Martin GG, Martin Y-L, Naulet N, McManus JD (1996) J Ag-

ric Food Chem 44: 32063213

23. A.I.J.N. Code of practice for evaluation of fruit and vegetable

juices (1996) Association of the Industry of Juices and Nec-

tars from Fruits and Vegetables of the European Union

24. RSK-values: the complete manual (1987) Flssiges Obst

GmbH, Schnborn

25. International Federation of Fruit Juice Producers (1996)

Anal Method 67: 15

26. Trotzer A, Hofsommer H-J, Rubach K (1994) Flssiges Obst

61: 581589

27. Swallow KW, Low NH, Petrus DR (1991) J Assoc Off Anal

Chem 74: 341345

28. Wudrich GG, McSheffrey S, Low NH (1993) J AOAC Int

76: 342354

29. Low NH, Wudrich GG (1993) J Agric Food Chem

41: 902909

30. White DR Jr, Cancalon PF (1992) J AOAC Int 75: 584587

31. Iuliano TA (1996) J AOAC Int 79: 13811387

32. Low NH (1995) Fruit Process 11: 362367

33. Low NH (1996) J AOAC Int 79: 724737

34. Low NH, Hammond DA (1996) Fruit Process 4: 135139

35. Stber P, Lamoureux T, Martin GG, Durgnat J-M, Hi-

schenhuber C (1998) Z Lebensm Unters Forsch A (accepted

for publication)

36. Lees M, Martin GG, Rinke P, Caisso M (1996) Fruit Process

7: 273278

37. International Federation of Fruit Juice Producers (1996)

Anal Method 26: 16

38. Balmer DM, McLellan WD (1995) Processing 5: 8689

39. Balmer DM, McLellan WD (1997) Fruit Process 7: 257261

40. Kauschus U, Thier H-P (1985) Z Lebensm Unters Forsch

181: 395399

41. Farnell P, Biesenbruch S (1994) Detection of peel extracts

and pulpwash in orange juice. 3rd European Symposium on

Food Authenticity, Nantes, France

42. Hammond DA (1996) Authenticity of fruit juices, jams and

preserves. In: Ashurst PR, Dennis MJ (eds) Food authentica-

tion. Blackie, London, pp 1559

43. Stijve T (1987) Laboratory News No 56, Nestl Internal Re-

port

44. Laub E (1984) GIT Suppl 4: 810

45. Andary C, Personne D, Privat G (1979) Ann Falsif Expert

Chim 72: 527537

46. Laub E (1985) Lebensm Gerichtl Chem 39: 101103

47. Laub E, Woller R (1984) Mitt Geb Lebensmittelunters Hyg

75: 110116

48. Council Directive 92/46/EEC (1992) Off J European Commu-

nities L 268 of 14.9.92.

49. Codex Alimentarius Commission (1996) Definitions of heat

treatments. Codex Alimentarius Committee on Milk and

Milk Products, CX/MMP 96/5

50. Geier H, Klostermeyer H (1983) Milchwissenschaft

38: 475477

51. Andrews GR (1984) J Soc Dairy Technol 37: 9295

52. Olano A, Calvo MM, Corzo N (1989) Food Chem

31: 259265

53. Andrews GR, Morant SV (1987) J Dairy Res 54: 493507

54. Pellegrino L (1994) Netherlands Milk Dairy J 48: 7180

55. International Dairy Federation (1991) Commission B, B-Doc

198

56. Andrews GR (1986) J Dairy Res 53: 665680

57. Martinez-Castro I, Olano A (1978) Rev Esp Lecheria

110: 213217

58. Kuhlmann B, Klostermeyer H, Fries A (1991) Milchwissen-

schaft 46: 555558

59. International Organization for Standardization, Draft Inter-

national Standard, DIS/ISO 11868: 1997

60. International Dairy Federation (1994) Draft International

Standard, IDF 147 A: 1994

61. Mottar J (1993) Bull IDF 285: 8694

62. Hoyland DV (1994) Nestl Internal Report, York, UK

63. Anderson DMW, Bell PC, McDougall FJ (1986) Food Addit

Contam 3: 305312

64. Soni PL, Bisen SS (1988) Indian For 114: 2628

65. Flurer CL, Wolnik KA (1997) Detection of adulteration of

locust bean gum with guar gum by capillary electrophoresis,

9th International Symposium on high-performance capillary

electrophoresis and related microscale techniques, Anaheim,

California

66. FAO (1995) Compendium of food additive specifications

Addendum 3, FAO Food and Nutrition Paper No. 52 Add.3,

8385

67. WHO (1995) Evaluation of certain food additives and con-

taminants. WHO Tech Rep Ser 859: 39

68. FAO (1990) Specifications for identity and purity of certain

food additives. FAO Food and Nutrition Paper No.

49: 2325

69. Dibb S (1991) Food Magazine April/June: 7

70. Phillips GO, Williams PA (1993) The specification of the gum

arabic of commerce. In: Nishinari K, Doi E (eds) Food hydro-

colloids structure, properties, and functions. Plenum Press,

New York, pp 4563

71. Anderson DMW (1993) Br Food J 95: 3032

72. Jurasek P, Kosik M, Phillips GO, Varmuza K (1993) Food

Food Ingredients J 157: 7891

73. Menzies AR, Osman ME, Malik AA, Baldwin TC (1996)

Food Addit Contam 13: 991999

74. Anderson DMW, Morrison NA (1990) Food Addit Contam

7: 181188

75. Anderson DMW, Brown Douglas DM, Morrison NA, Weip-

ing W (1990) Food Addit Contam 7: 303321

76. Jurasek P, Varga S, Phillips GO (1995) Food Hydrocoll

9: 1734

77. Jurasek P, Phillips GO, Varga S, Chikamai BN, Banks WB

(1994) Food Hydrocoll 8: 567588

78. Jurasek P, Kosik M, Phillips GO (1993) Food Hydrocoll

7: 7385

79. Flint FO (1990) Analyst 115: 6163

80. Patel PD, Hawes GB (1988) Food Hydrocoll 2: 179185

81. Theander O, man P, Westerlund E, Andersson R, Petters-

son D (1995) J AOAC Int 78: 10301044

82. Englyst HN, Quigley ME, Hudson GJ (1994) Analyst

119: 14971509

83. LMBG (1986) Amtliche Sammlung von Untersuchungsver-

fahren nach 35 LMBG, Methode L-00.00-13

12

84. Harris P, Morrison A, Dacombe C (1995) A practical ap-

proach to polysaccharide analysis. In: Stephen AM (ed) Food

polysaccharides and their applications. Dekker, New York,

pp 577606

85. International Coffee Organization (1982) International Cof-

fee Agreement 1983, Article 3, 5

86. International Organization for Standardization (1989) Inter-

national Standard, ISO 3509: 1989

87. Council Directive 85/573/EEC (1992) Off J European Com-

munities No L 372 of 31.12.85, 2224

88. Federal Specification (1981) HHH-C-575D

89. Blanc MB, Davis GE, Parchet J-M, Viani R (1989) J Agric

Food Chem 37: 926930

90. Davis GE, Garwood VW, Barfuss DL, Husaini SA, Blanc

MB, Viani R (1990) J Agric Food Chem 38: 13471350

91. Prodolliet J, Blanc MB, Brlhart M, Obert L, Parchet J-M

(1991) ASIC, 14th Colloque, San Francisco, pp 211219

92. Prodolliet J, Bruelhart M, Lador F, Martinez C, Blanc MB,

Parchet J-M (1995) J AOAC Int 78: 749761

93. Prodolliet J, Bruelhart M, Blanc MB, Leloup V, Cherix G,

Donnelly CM, Viani R (1995) J AOAC Int 78: 761767

94. Ministry of Agriculture, Fisheries, and Food (1995) Food Sur-

veillance Paper No. 46

95. Oestreich-Janzen S (1995) ASIC, 16th Colloque, Kyoto, pp

286291

96. Prodolliet J, Bugner E, Feinberg M (1995) J AOAC Int

78: 768782

97. Prodolliet J, Bugner E, Feinberg M (1996) J AOAC Int

79: 14001407

98. International Organization for Standardization (1995) Inter-

national Standard, ISO 11292: 1995

99. Code of Practice for the Soluble Coffee Industry in the UK

(1995) BSCPIA/BSCMA Publ, 1st edn. London, UK

Das könnte Ihnen auch gefallen

- Wang Et Al, 2015. Detection of Honey Adulteration With Starch Syrup by HPLCDokument6 SeitenWang Et Al, 2015. Detection of Honey Adulteration With Starch Syrup by HPLCHardyantiPutriNoch keine Bewertungen

- Determination and Occurrence of 5-Hydroxymethyl-2-Furaldehyde inDokument4 SeitenDetermination and Occurrence of 5-Hydroxymethyl-2-Furaldehyde inThiago VillaNoch keine Bewertungen

- Jsfa 9105Dokument33 SeitenJsfa 9105Daniel Armando Martinez ZabarainNoch keine Bewertungen

- Physicochemical Properties and Pharmacokinetic Profiles of Selected Malaysian HoneyDokument6 SeitenPhysicochemical Properties and Pharmacokinetic Profiles of Selected Malaysian Honeysalsabil abdouNoch keine Bewertungen

- EmeraldInsight Citations 20221222212040Dokument1 SeiteEmeraldInsight Citations 20221222212040pollopuponNoch keine Bewertungen

- Journal 2 - Effect of Storage and Processing Temperatures On Honey QualityDokument10 SeitenJournal 2 - Effect of Storage and Processing Temperatures On Honey QualityYoanda AlisaNoch keine Bewertungen

- Li2020Dokument9 SeitenLi2020Minh Quang HàNoch keine Bewertungen

- HMF and Diastase Activity in HoneysDokument30 SeitenHMF and Diastase Activity in HoneysТетяна КозицькаNoch keine Bewertungen

- Analiza HMF MiereDokument4 SeitenAnaliza HMF MiereAbramiuc AlexandruNoch keine Bewertungen

- Comparative Studies On The Production of Glucose and High Fructose Syrup From Tuber StarchesDokument8 SeitenComparative Studies On The Production of Glucose and High Fructose Syrup From Tuber StarchesDebora Pasaribu100% (1)

- Authenticity of Honey and Other Bee ProductsDokument12 SeitenAuthenticity of Honey and Other Bee ProductsmohNoch keine Bewertungen

- FTIR-ATR Characterization of Commercial Honey Samples and Their Adulteration With Sugary Syrups Using Chemometric AnalysisDokument1 SeiteFTIR-ATR Characterization of Commercial Honey Samples and Their Adulteration With Sugary Syrups Using Chemometric AnalysisAmerican LabNoch keine Bewertungen

- HoneyDokument8 SeitenHoneyjapoleonaNoch keine Bewertungen

- Enzymes in HoneyDokument4 SeitenEnzymes in HoneyWJ NgNoch keine Bewertungen

- Adulteration of Honey and Available Methods For deDokument18 SeitenAdulteration of Honey and Available Methods For deMohammed NabeelNoch keine Bewertungen

- N Fructo OligosaccharidesDokument5 SeitenN Fructo Oligosaccharidesphuongdung2012Noch keine Bewertungen

- Cir Sucrose Hal 25Dokument36 SeitenCir Sucrose Hal 25Mellisa Laura MintoroNoch keine Bewertungen

- 159 380 1 SM 1Dokument9 Seiten159 380 1 SM 1brilianaNoch keine Bewertungen

- Lcentrone 9510 BeykayaDokument7 SeitenLcentrone 9510 BeykayadscaoNoch keine Bewertungen

- 10 HidromProdDokument11 Seiten10 HidromProdCarlos Barrios SánchezNoch keine Bewertungen

- 1 s2.0 S1878535214001737 MainDokument10 Seiten1 s2.0 S1878535214001737 MainmouhoubiNoch keine Bewertungen

- Identification of Volatile Organic Compounds in Honeydew HoneysDokument10 SeitenIdentification of Volatile Organic Compounds in Honeydew Honeysasel ppNoch keine Bewertungen

- Production of Wine From Over Ripe Guava (Psidium Guajava L Cv. Safada) and Ber (Ziziphus Mauritiana L Cv. Umran) Fruits Using Saccharomyces Crevices Var. HAU 1Dokument4 SeitenProduction of Wine From Over Ripe Guava (Psidium Guajava L Cv. Safada) and Ber (Ziziphus Mauritiana L Cv. Umran) Fruits Using Saccharomyces Crevices Var. HAU 1International Organization of Scientific Research (IOSR)Noch keine Bewertungen

- Beverages 08 00006Dokument13 SeitenBeverages 08 00006Waleed FahmyNoch keine Bewertungen

- DocumentDokument3 SeitenDocumentTinotenda ChapfudzaNoch keine Bewertungen

- Honeys From MoliseDokument4 SeitenHoneys From MolisefabiandionisioNoch keine Bewertungen

- A Modified Method To Determine HydrogenDokument13 SeitenA Modified Method To Determine HydrogenWJ NgNoch keine Bewertungen

- 8 PaperDokument8 Seiten8 PaperDr. Nilesh Baburao JawalkarNoch keine Bewertungen

- Low Energy Kombucha Fermented Milk-Based BeveragesDokument10 SeitenLow Energy Kombucha Fermented Milk-Based BeveragesLaís MelquíadesNoch keine Bewertungen

- Sample Pfund Scale Grade LH1 LH2 LH3 LH4: Figure. Pfund Scale For Honey (Source: WWW - Oxfordhoney.uk)Dokument3 SeitenSample Pfund Scale Grade LH1 LH2 LH3 LH4: Figure. Pfund Scale For Honey (Source: WWW - Oxfordhoney.uk)Nindya SulistyaniNoch keine Bewertungen

- Conde BaezDokument8 SeitenConde BaezandreaNoch keine Bewertungen

- tmp5EFA TMPDokument8 Seitentmp5EFA TMPFrontiersNoch keine Bewertungen

- Hu 2016Dokument40 SeitenHu 2016Yng TangNoch keine Bewertungen

- Analysis of Phospho-And Sphingolipids in Dairy Products by A New HPLC MethodDokument7 SeitenAnalysis of Phospho-And Sphingolipids in Dairy Products by A New HPLC MethodRafael BarrosNoch keine Bewertungen

- Honey Composition and PropertiesDokument13 SeitenHoney Composition and PropertiessubsoniqueNoch keine Bewertungen

- HoneyDokument10 SeitenHoneymissmew91Noch keine Bewertungen

- Optimisation of Enzymatic Hydrolysis of Apple PomaceDokument13 SeitenOptimisation of Enzymatic Hydrolysis of Apple PomaceDea Inthay WulanNoch keine Bewertungen

- Chapter 6-10Dokument167 SeitenChapter 6-10Mansoor Ahmad100% (2)

- Effect of Storage On Hydroxymethylfurfural (HMF) and Color of Some Algerian HoneyDokument7 SeitenEffect of Storage On Hydroxymethylfurfural (HMF) and Color of Some Algerian Honeywildan dwipaNoch keine Bewertungen

- Food Chemistry: Sarah Erich, Theresa Anzmann, Lutz FischerDokument4 SeitenFood Chemistry: Sarah Erich, Theresa Anzmann, Lutz Fischerdumi-dumiNoch keine Bewertungen

- Carob AnalysisDokument7 SeitenCarob Analysisfree-thinker :)Noch keine Bewertungen

- 9 Honey ControlDokument10 Seiten9 Honey ControlAttiqa ArshadNoch keine Bewertungen

- FOOD AND NUTRITIONAL ANALYSIS Fruits and Fruit Products-334-341Dokument8 SeitenFOOD AND NUTRITIONAL ANALYSIS Fruits and Fruit Products-334-341fernandoferozNoch keine Bewertungen

- Novo BitnoDokument11 SeitenNovo BitnoKristina FilipovićNoch keine Bewertungen

- InglesFT-RAMAN Methodology For The Monitoring of Honeys' Spirit DistillationDokument7 SeitenInglesFT-RAMAN Methodology For The Monitoring of Honeys' Spirit DistillationKewen Santiago da Silva LuzNoch keine Bewertungen

- Comparison of The Concentration of Phenolic Constituents SugarcaneDokument7 SeitenComparison of The Concentration of Phenolic Constituents SugarcaneMolly0630Noch keine Bewertungen

- Lorencini 2016Dokument13 SeitenLorencini 2016barti koksNoch keine Bewertungen

- Buchin2017 Article LactobacillusDelbrueckiiSubspLDokument13 SeitenBuchin2017 Article LactobacillusDelbrueckiiSubspLKassandra Balbuena MadridNoch keine Bewertungen

- 00-Effect of Roselle Extracts On The Selected Quality Characteristics of Ice CreamDokument13 Seiten00-Effect of Roselle Extracts On The Selected Quality Characteristics of Ice CreamC023Anastasya Vina WardhaniNoch keine Bewertungen

- Food ChemistryDokument10 SeitenFood ChemistryAlex AndruNoch keine Bewertungen

- Determination of SugarsDokument8 SeitenDetermination of SugarsNatzi MonsalvoNoch keine Bewertungen

- The Sugars of Honey-A ReviewDokument14 SeitenThe Sugars of Honey-A ReviewsedianpoNoch keine Bewertungen

- 10 5923 J Food 20140403 04 PDFDokument6 Seiten10 5923 J Food 20140403 04 PDFERIKA MARIE BECERRELNoch keine Bewertungen

- Chemistry Project 2023-2024Dokument15 SeitenChemistry Project 2023-2024J. Mohan SriNoch keine Bewertungen

- Determination of Sugars and Polyols by HPLC PDFDokument7 SeitenDetermination of Sugars and Polyols by HPLC PDFyouni_2005Noch keine Bewertungen

- Effect of Sucrose Concentration On The Products of Kombucha Fermentation On MolassesDokument7 SeitenEffect of Sucrose Concentration On The Products of Kombucha Fermentation On MolassesNayeli MartinezNoch keine Bewertungen

- Renovando Tradiciones Una Caracterización Sensorial y Química de Las Cervezas Mexicanas de Maíz PigmentadoDokument24 SeitenRenovando Tradiciones Una Caracterización Sensorial y Química de Las Cervezas Mexicanas de Maíz PigmentadoJorge Ruiz CervantesNoch keine Bewertungen

- Intertek Article - Honey Authenticity - SonderdruckDokument8 SeitenIntertek Article - Honey Authenticity - SonderdruckmaralexNoch keine Bewertungen

- Malcolm T. Sanford: A Primer On Honey and Its AdulterationDokument9 SeitenMalcolm T. Sanford: A Primer On Honey and Its AdulterationAlex AkNoch keine Bewertungen

- Mead and Honey Wines: A Comprehensive GuideVon EverandMead and Honey Wines: A Comprehensive GuideBewertung: 3 von 5 Sternen3/5 (1)

- Sugar AlcoholsDokument7 SeitenSugar AlcoholslimtekkaunNoch keine Bewertungen

- US5942443 High Throughput Screening Assay SystemsDokument31 SeitenUS5942443 High Throughput Screening Assay Systemsdoga1759Noch keine Bewertungen

- Satellite L645-S4102 PDFDokument4 SeitenSatellite L645-S4102 PDFdoga1759Noch keine Bewertungen

- Formation of Flavor Oil Microemulsions, Nanoemulsions and EmulsionsDokument10 SeitenFormation of Flavor Oil Microemulsions, Nanoemulsions and Emulsionsdoga1759Noch keine Bewertungen

- Quantitative Estimation of Sugar AlcoholsDokument5 SeitenQuantitative Estimation of Sugar Alcoholsdoga1759Noch keine Bewertungen

- Evidence That Intermittent, Excesive Sugar Intake Causes Endogenous Opioid DependenceDokument11 SeitenEvidence That Intermittent, Excesive Sugar Intake Causes Endogenous Opioid Dependencedoga1759Noch keine Bewertungen

- Blakeney - A Simple and Rapid Preparation of Alditol Acetates ForDokument9 SeitenBlakeney - A Simple and Rapid Preparation of Alditol Acetates ForPriscilla Botelho100% (1)

- Comparison of HPLC Method and FT-NIR For Quantification Glucose, Fructose, SucroseDokument6 SeitenComparison of HPLC Method and FT-NIR For Quantification Glucose, Fructose, Sucrosedoga1759Noch keine Bewertungen

- Mannitol Determination in Plasma and UrineDokument7 SeitenMannitol Determination in Plasma and Urinedoga1759Noch keine Bewertungen

- Colorimetric Assay of Alditols in Complex Biological SamplesDokument4 SeitenColorimetric Assay of Alditols in Complex Biological Samplesdoga1759Noch keine Bewertungen

- Agave Fructans As PrebioticsDokument14 SeitenAgave Fructans As Prebioticsdoga1759Noch keine Bewertungen

- Acetylation ProcedureDokument2 SeitenAcetylation Proceduredoga1759Noch keine Bewertungen

- Gas-Chromatographic Assay of Lactulose and MannitolDokument5 SeitenGas-Chromatographic Assay of Lactulose and Mannitoldoga1759Noch keine Bewertungen

- Non Absorbable Lipid BinderDokument7 SeitenNon Absorbable Lipid Binderdoga1759Noch keine Bewertungen

- Intake of Sugar-Sweetened Beverages and Wight GainDokument15 SeitenIntake of Sugar-Sweetened Beverages and Wight Gaindoga1759Noch keine Bewertungen

- Tacsa ReportDokument226 SeitenTacsa ReportRitu GargNoch keine Bewertungen

- Chem12 U3 ReviewDokument8 SeitenChem12 U3 ReviewdawaNoch keine Bewertungen

- Robert Lustig-Tooth Decay and Liver Decay-The Nexus of Doctors and DentistsDokument154 SeitenRobert Lustig-Tooth Decay and Liver Decay-The Nexus of Doctors and DentistsEmine Alaaddinoglu100% (2)

- Cholesterol Does Not Cause Heart Disease PDFDokument20 SeitenCholesterol Does Not Cause Heart Disease PDFRani Oktaviani Sidauruk100% (2)

- The Canadian Soft Drink IndustryDokument36 SeitenThe Canadian Soft Drink Industryravi_nyseNoch keine Bewertungen

- Disadvantages of Soft Drinks I.E. Cold Soda Water DrinksDokument8 SeitenDisadvantages of Soft Drinks I.E. Cold Soda Water DrinksMuhammad RiazNoch keine Bewertungen

- Brochure - Facts About FructoseDokument2 SeitenBrochure - Facts About FructoseRaf'at ShafaNoch keine Bewertungen

- Marc Lobliner - Fat Loss Factor BookDokument77 SeitenMarc Lobliner - Fat Loss Factor Bookcleudimartins100% (2)

- Top 10 Most Unhealthy, Cancer-Causing Foods - Never Eat These Again! PDFDokument4 SeitenTop 10 Most Unhealthy, Cancer-Causing Foods - Never Eat These Again! PDFJarrett RobinsonNoch keine Bewertungen

- Bagel ProductionDokument2 SeitenBagel ProductiondekaymailNoch keine Bewertungen

- Liebman, "10 Common Food Goofs"Dokument4 SeitenLiebman, "10 Common Food Goofs"sleeschott@hotmail.com0% (1)

- Maize (Corn) Products in IndiaDokument41 SeitenMaize (Corn) Products in IndiaAjjay Kumar GuptaNoch keine Bewertungen

- Glycemic Index and Glycemic LoadDokument18 SeitenGlycemic Index and Glycemic LoadKristine ReyesNoch keine Bewertungen

- High Fructose Corn SyrupDokument3 SeitenHigh Fructose Corn SyrupAaron's EliteTransportNoch keine Bewertungen

- Glycemic IndexDokument5 SeitenGlycemic IndexftmtanNoch keine Bewertungen

- Soda Politics Taking On Big Soda (And Winning)Dokument525 SeitenSoda Politics Taking On Big Soda (And Winning)wasiuddin100% (1)

- Food Authentication by Carbohydrate ChromatographyDokument12 SeitenFood Authentication by Carbohydrate Chromatographydoga1759Noch keine Bewertungen

- Viscosity GLC SyrupsDokument18 SeitenViscosity GLC SyrupsJán PeterNoch keine Bewertungen

- Blood Sugar Secrets For Health and Longevity John Douillard OnlineDokument30 SeitenBlood Sugar Secrets For Health and Longevity John Douillard OnlineAditya Sharma100% (1)

- Rife Handbook 2011 BDokument43 SeitenRife Handbook 2011 BDavid Brown100% (2)

- Sugar AnalysisDokument8 SeitenSugar AnalysisSanjay SinhaNoch keine Bewertungen

- Why You Should Never Eat High Fructose Corn Syrup - Mark Hyman, MDDokument6 SeitenWhy You Should Never Eat High Fructose Corn Syrup - Mark Hyman, MDcendekiaNoch keine Bewertungen

- Sucrose - Properties and ApplicationsDokument307 SeitenSucrose - Properties and ApplicationsSharini_Mu_oz_137100% (1)

- The Production of Ice Cream Using Stevia As A SweetenerDokument5 SeitenThe Production of Ice Cream Using Stevia As A SweetenerLola PerezNoch keine Bewertungen

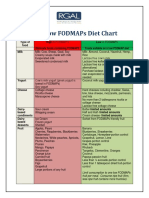

- Fodmap Diet ChartDokument3 SeitenFodmap Diet Chartelisadone7001100% (4)

- Sugar Consumption at A CrossroadsDokument23 SeitenSugar Consumption at A Crossroadsdavidsun1988Noch keine Bewertungen

- David Hammond Eurofins PresentationDokument51 SeitenDavid Hammond Eurofins Presentationmarifa16Noch keine Bewertungen

- National Geographic Magazine - Sugar LoveDokument4 SeitenNational Geographic Magazine - Sugar LoveSatish BabuNoch keine Bewertungen

- The Sugarmaker's Companion: Chapter 1 Why Maple MattersDokument14 SeitenThe Sugarmaker's Companion: Chapter 1 Why Maple MattersChelsea Green PublishingNoch keine Bewertungen