Beruflich Dokumente

Kultur Dokumente

MAGEBA Reference Brochure

Hochgeladen von

briankimbjCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MAGEBA Reference Brochure

Hochgeladen von

briankimbjCopyright:

Verfügbare Formate

Infrastructure Products

Project References - the Americas

Matthias Gtz

International

www.mageba.net

Infrastructure Products

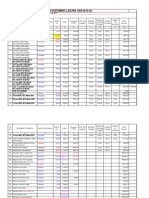

Index

Region/Project

Place/Country

Completion

Bearings

Expansion

joints

Seismic

protrcion

Monitoring

& Services

Golden Ears Bridge

Vancouver, Canada

2009

Port mann Bridge

Vancouver, Canada

2012

Angus L. MacDonald and MacKay

Bridge

Halifax, Canada

2012

Highway A20/A73 Interchange

Quebec, Canada

2013

Ohio River Bridges

Louisville, USA

2014

Verrazano Narrows Bridge

New York, USA

2015

Bayonne Bridge

Staten Island, NY, USA

2016

John James Audubon Bridge

Louisiana, USA

2011

Manhattan West Development

New York, USA

2015

Telmex Building Dampers

Mexico City, Mexico

2014

12

Hotel Mexico LRB

Mexico City, Mexico

2015

13

Oceania Business Plaza

Calgary, Canada

2013

14

Panama City Metro Line

Panama City, Panama

2013

15

Tocumen Airport, Panama

Panama City, Panama

2014

16

Oil refinery seismic isolation

Falcn State, Venezuela

2012

17

Sky Building, Ecuador

Guayaquil, Ecuador

2014

Chilina Bridge

Arequipa, Peru

2014

Page

5

6

7

10

11

18

19

Infrastructure Products

Golden Ears Bridge (Canada)

Matthias Gtz

Project description

The Golden Ears Bridge, near Vancouver,

British Columbia, creates an important

new transportation link across the Fraser River. The bridge, with three main

spans each 242m (795ft) long, features

an unusual hybrid cable stayed system

designed to ensure a specified performance in the case of defined earthquake

events. The bearings and expansion joints

for the bridge are also subjected to such

demands, making their design and fabrication an interesting challenge.

magebas scope

Main Span Bearings:

mageba supplied four custom-designed

uplift bearings, pre-compressed for frequent load reversal. Each bearing weighs

The bridge crosses the Fraser River near Vancouver,

Canada

a massive 17 tons and can accommodate

a wide range of loads from 4,170kN to

2,790kN (uplift), longitudinal movements of 3,100mm (122in), transverse

movements of 50mm (2in) and rotations

of 0.039 radians about the x-axis and 0.010

radians about the y-axis.

Expansion Joints:

In addition to the bearings, 12

TENSAMODULAR LR expansion joints

were supplied by mageba. The largest,

type LR17 with 17 individual gaps, will allow longitudinal movements of 1,350mm

(53in). The joints are also equipped with

Fuse-Box earthquake protection devices

which prevent serious damage to the joint,

and the connecting bridge structure, in the

event of an earthquake. The Fuse-Box

also enables the modular expansion joint

to continue to allow passage of emergency

vehicles after a seismic event.

An uplift bearing during installation on the bridge

Highlights & Facts

magebas products:

Type:

12 TENSAMODULAR

expansion joints, with up

to 17 gaps, and 4 special

uplift bearings

Features:

Uplift bearings

Installation: 2009

Structure details:

Location:

Vancouver

Country:

Canada

Type:

Hybrid cable stay design

Completed: 2009

Length:

2,410m (1.45 mi) with

3 main spans each 242m

(794 ft) long

Contractor: GCCJV (Bilfinger Berger

and others)

Owner:

TransLink

Installation of LR17 expansion joint featuring

Fuse-Box seismic protection

Canada

USA

2012 Google

Infrastructure Products

Port Mann Bridge (Canada)

Project description

magebas scope

The Port Mann Bridge is one of British

Columbias most significant bridge structures, carrying the Trans-Canada Highway

(Canadas Highway 1) across the Fraser

River to the west of Vancouver. As part

of the major Port Mann Highway 1 project, which also includes the widening and

upgrading of 23 miles (37 km) of highway,

the bridge has been replaced with a new

structure, and was opened to traffic at the

end of 2012.

mageba has delivered the modular expansion joints required for the entire bridge

including both approaches. The joints have

up to 11 movement gaps and thus can

facilitate movements of up to 35 inches

(880mm). In noise-sensitive areas, several

joints are equipped with noise-reducing

sinus plates on the surface.

The new bridge is designed for 10 lanes of

traffic, and with its main span of 1,542ft

(470m), it is the second longest cablestayed span in North America. At 164ft

(50m) wide, the new bridge is also the

widest span bridge of any type in the

world.

mageba also supplied, in cooperation

with R.J. Watson Inc., disc bearings for the

bridge. These are designed for loads of up

to 19,000 kN and a number feature double discs to achieve this load capacity.

Highlights & Facts

mageba products:

Type:

Features:

Installed:

Modular expansion joints

and disc bearings*

Expansion joints with

movements of up to

35in (880mm), some

featuring sinus plates

2012

Bridge:

City:

Country:

Built:

Type:

Length:

Maintained:

Vancouver

Canada

20082012

Cable stayed bridge

1.37mi (2,200m)

Transportation Invest

ment Corporation

Contractor: Kiewit Flatiron General

Partnership

* in cooperation with R.J. Watson Inc.

Location of the bridge in British Columbia

1

Vancouver

Canada

USA

2012 Google

A modular expansion joint featuring noise-reducing

sinus plates on its surface

Disc bearings (with double discs per bearing) ready

for delivery

Infrastructure Products

MacDonald & MacKay Bridges (Canada)

onepony

Project description

magebas scope

The Angus L. Macdonald and A. Murray

MacKay bridges are critically important

structures for the city of Halifax, capital

of the Canadian province of Nova Scotia.

Having been opened to traffic in 1955 and

1970 respectively, both structures have

already endured several decades of service, and reconstruction and maintenance

works must be planned and implemented.

The Angus L. Macdonald Bridge, in fact,

will receive an entire new deck, and computer modeling of the deck, verified by

measured data, will play a key role in the

design process. The A. Murray MacKay

Bridge, on the other hand, will retain its

existing deck, but will be subjected to significant renovation work.

It was determined that a ROBOCONTROL

monitoring system should be used to

meas-ure and record the movements

and rotations of the bridge decks, providing the data needed by the computer

modeling of the new deck of one bridge,

and assisting in the planning of remedial

works of the existing deck of the other.

The fully automated system makes the

data available to authorized users, via a

secure online interface, from wherever

they may be in the world. By enhancing

their understanding of the behavior and

performance of the bridge decks, this use

of the ROBOCONTROL monitoring system

will be of great value to the bridges engineers, helping them to optimize their designs and minimize the life-cycle costs of

the bridges.

Location of the bridges in Halifax, Canada

Presentation of measured data in graphic form

(tabular form also possible)

Highlights & Facts

mageba products:

Type:

ROBOCONTROL

automated monitoing

system

Installed:

2012

Bridges:

City:

Halifax

Country:

Canada

Type:

Suspension bridges

Maintained: Halifax-Dartmouth Bridge

Commission

Angus L. MacDonald Bridge

Built:

1955

Length:

4,265ft (1,300m)

Main span 1,447ft

(441m)

A. Murray MacKay Bridge

Built:

1970

Length:

3,937ft (1,200m)

Main span 1,398ft

(426m)

Viewing of recorded data on site using a tablet

computer (e.g. iPad)

Canada

USA

2012 Google

Infrastructure Products

Highway A20/A73 Interchange (Canada)

Project description

magebas scope

A new highway viaduct was constructed in

2013, serving the city of Levis in Quebec,

Canada. The viaduct, at an interchange

between Highways 20 and 73, was constructed adjacent to an existing structure

in order to increase highway capacity.

The end spans of the deck are supported

by conventional pot bearings, but the central spans, which are more prone to damage from movements, are supported by

Lead Rubber Bearings (LRB) which will protect the structure during an earthquake by

isolating it from destructive ground movements.

The viaduct is a six-span structure with a

steel girder deck, with spans of between

40m and 60m and a total length of over

300m. With a horizontal radius of 270m,

it has a prominent curve which heightens the risk of serious damage during an

earthquake and thus increases the need

for its deck to be seismically isolated from

its supports.

The highway viaduct serves the city of Levis, Quebec

Levis, Quebec

Canada

2012 Google

USA

Each internal pier has six LRBs, one supporting each of the decks main girders.

Each LRB has a vertical load capacity of

approximately 3,200 kN. Due to the structures location, the LRBs were designed for

temperatures as high as 40C (104F) and

as low as 30C (22F).

Lead rubber bearing installed in the bridge guided

type, allowing longitudinal movements

Highlights & Facts

mageba products:

Type:

Features:

Installed:

LRB seismic isolators

For temperatures as low

as 30C (22F)

2013

Bridge:

City:

Country:

Built:

Type:

Length:

Levis, Quebec

Canada

2013

Steel girder deck

317m

Lead rubber bearing installed in the bridge

multi-directional type, allowing all movements

Infrastructure Products

Ohio River Bridges Downtown (USA)

Project description

magebas scope

The Ohio River Bridges project involves the

construction of two new bridges across the

Ohio River between the states of Indiana

and Kentucky. The Downtown Crossing will

connect the downtown areas of the cities

of Louisville in Kentucky and Jeffersonville

in Indiana, and the East End Bridge is located eight miles upstream.

The Downtown Crossing project is a cablestayed bridge with three sets of twin towers. When opened in 2016, it will be tolled

to partially refinance its construction.

mageba is supplying 20 structural bearings

to support the deck of the new bridge. 10

of these are of the elastomeric type, and

10 are of the disc type. A number of the

disc bearings will be installed vertically

to primarily resist horizontal forces at the

pylons. With a service life of 50 years, the

sliding bearings feature ROBOSLIDE highgrade sliding material instead of the commonly used PTFE, to enhance resistance

to wear and abrasion, and therefore maximize overall durability.

The Ohio River Bridges Downtown Crossing connects

Louisville (KY) and Jeffersonville (IN)

Cut-out view of a mageba disc bearing

Highlights & Facts

mageba products:

Type:

Disc bearings and

elastomeric bearings

Special:

50-year service life

Installation: 2014

Structure:

City:

Country:

Type:

Built:

Contractor:

Owner:

Louisville, KY

USA

Cable-stayed bridge

20132016

Walsh Construction Co.

KY DOT

Cut-out view of a mageba elastomeric bearing

Indiana

Ohio River Bridges, Louisville

2012 Google

Kentucky

Infrastructure Products

Verrazano Narrows Bridge (USA)

Project description

magebas scope

The Verrazano Narrows, a body of water

which separates the New York boroughs

of Brooklyn and Staten Island to the south

of Manhattan, is the gateway to New York

Citys harbor. The bridge that spans the

Narrows creates a vital connection for

road traffic, carrying about 200,000 vehicles per day.

The bridges existing finger joints, each accommodating enormous deck movements

of 2,700mm (approx. 9ft) are to be replaced with new finger joints. Due to the

great length of the individual fingers, they

will receive intermediate support at midspan. The challenge of designing and supplying these exceptional joints is increased

by the need to tailor them to precisely

match existing geometry and conditions.

The double-decked suspension bridge has

a central span of 4,260 feet (1,298m), and

was the longest suspension bridge in the

world from the time its upper level opened

in 1964 until 1981. Currently, it has the

longest bridge span in the Americas.

The bridge spans the Verrazano Narrows - the gateway to New York Citys harbor

New York

New Jersey

Verrazano Narrows Bridge

2012 Google

Various single gap joints, also tailored to

suit the existing structure, are also being

supplied to accommodate much smaller

movements at other locations.

The bridges sliding finger joints, designed for enormous movements, must be replaced

Highlights & Facts

mageba products:

Type:

Features:

Installed:

Sliding finger joints

Enormous movements

2015

Bridge:

City:

New York, NY

Country:

USA

Construction: Suspension bridge

Type:

Road bridge

Built:

19591969

Length:

4,260 feet (1,298 m)

Contractor: Tutor Perini

Owner:

City of New York

3D view of a new sliding finger joint, facilitating

longitudinal movements of 2,700mm

Infrastructure Products

Bayonne Bridge (USA)

Project description

magebas scope

The Bayonne Bridge connects the City of

Bayonne, NJ with Staten Island, NY. After its completion in 1931, the Bayonne

Bridge was the longest steel arch bridge in

the world, but today it sits in fifth place.

In 2013, prompted by the expansion of

the Panama Canal, a $743.3 million project was awarded to raise the bridge deck

within the original steel arch in order to

accommodate larger post-Panamax class

ships. The significance of this project cannot be overvalued as fully 12% of all USbound international container ships currently pass under the Bayonne Bridge.

To support the newly raised deck, mageba

is supplying 158 RESTONDISC bearings.

All of the approach span bearings are being specially fabricated with the capability

to be temporally locked against longitudinal movements during the construction

phase, but allowing free movement after

construction is completed.

The bridge is one of three that connect Staten Island,

New York to New Jersey

A RESTONDISC bearing featuring custom pintle pins

for easy installation in the approach span

The new bridge deck will also be equipped

with 18 TENSAMODULAR expansion

joints, designed with up to 6 gaps to accommodate 17.7in (450mm) of movement, and 4 TENSAFINGER sliding finger

joints to accommodate 31.5in (800mm)

of movement. Additionally, mageba is supplying sliding plate expansion joints for the

shared use pedestrian and cycle paths.

Highlights & Facts

magebas products:

Type:

TENSAMODULAR LR

expansion joints,

TENSAFINGER GF sliding

finger joints,

RESTONDISC bearings

Features:

Uplift Bearings

Installation: 20142016

Bridge:

Location:

Type:

Completed:

Length:

Contractor:

Owner:

Staten Island, NY, USA

Steel arch

1931

5,780 ft (1,762 m)

Skanska Koch-Kiewit JV

Port Authority of NY and NJ

Deck movements will be facilitated by modular joints

(as shown) and sliding finger joints

New York

New Jersey

Bayonne Bridge

2012 Google

Infrastructure Products

John James Audubon Bridge (USA)

Photo 2012, Jason Griffith, All Rights Reserved

Project description

In 2011, The John James Audubon Bridge

opened in southern Louisiana. With a

1,581ft (482m) main span supported by

two 492ft (150m) towers, and an overall

length of 12,883ft (3,927m), the John J.

Audubon Bridge became the longest cable

stayed bridge in North America. The structure carries four lanes of traffic 65 ft (20 m)

above the Mississippi River and replaces

the unreliable ferry service. It is the only

Mississippi crossing between Natchez and

Baton Rouge, a distance of approximately

93 mi (150 km).

magebas scope

TENSAFINGER sliding finger joints, Type

GF and Type RSFD, were selected to fulfill

the requirements of both the client and

the designer. Finger joints were preferred

The bridge spans the Mississippi River in Louisiana,

upriver from New Orleans

USA

Louisiana

Mexico

2012 Google

10

by the client for their low maintenance demands, and the specific type of finger joint

was determined by the movement demands of the bridge at each joint location.

Cantilever finger joints, type RSFD, were

chosen to facilitate the smaller movements of 12in (305mm) at one bridge

axis, while sliding finger joints, type GF,

were chosen for the bridge axes requiring

movements of 28in (710mm) and 49in

(1,240mm). The GF joints feature sliding

support for the ends of the finger plates

which span across the bridge gap, and a

downward pre-tensioning of the finger

plates to ensure that they remain in contact with the sliding surface below. Weighing 24 tons each, the joints, which allow

49in (1,240mm) of movement, are the

largest sliding finger joints of their type

ever manufactured.

Sliding finger joint with transportation and installation frame, ready for delivery

Highlights & Facts

magebas products:

Type:

Installation:

TENSAFINGER joints of

Type GF (sliding) and

Type RSFD (cantilever)

2010

Structure details:

City:

New Roads, LA

Country:

USA

Built:

20072011

Type:

Cable stayed bridge

Length:

2.44mi (3,927m)

Main span 1,581 ft (482m)

Contractor: Audubon Bridge

Constructors (Flatiron

and others)

Owner:

LA DOT

Installation of a TENSAFINGER sliding finger joint

Infrastructure Products

Manhattan West Development (USA)

Project description

magebas scope

Manhattan West is comprised of seven

million square feet of office, residential,

hotel, retail and open space located in the

Hudson Yards District of Manhattan, New

York City. Two office towers will soar up

to 67 stories above railroad tracks leading in and out of Penn Station (at 65 feet

below grade). Post-tension segmental

bridge technology is being used to build a

120,000-square-foot platform (of 16 precast box girders, each weighing 2100 tons

and spanning 240 feet) over these tracks,

allowing for the construction of the office

towers without disrupting the passage of

the trains.

To support the enormous platform that

will enable the towers to be constructed

above the busy railway tracks, mageba

supplied 64 RESTONSPHERICAL bearings. These bearings, of types KF (fixed),

KA (free sliding) and KE (guided sliding),

are designed to carry vertical loads of up

to 23,000 kN (5,680 kips). They all feature

ROBOSLIDE high-grade sliding material instead of the commonly-used PTFE,

maximizing strength and thus minimizing

the size of the bearings. ROBOSLIDEs far

superior resistance to wear and abrasion

also maximizes durability, ensuring a long

service life.

The development is located just one block from Penn

Station in west Manhattan, New York

Construction site with railway tracks to Penn Station

being covered by the huge box girders

Highlights & Facts

magebas products:

Type:

RESTONSPHERICAL

bearings

Features:

ROBOSLIDE

Installation: 2014

Structure:

Country:

Location:

Completed:

Type:

Contractor:

USA

New York

2015

Platform beneath

building development

Rizzani de Eccher USA

A RESTONSPHERICAL bearing (guided sliding type)

before installation to support a box girder

New York

New Jersey

2012 Google

11

Infrastructure Products

Lerma Building Telmex (Mexico)

Project description

magebas scope

Telmex, the largest telephone company in

Mexico, owns several buildings in Mexico

City. One of these buildings is currently

obsolete due to the new seismic specifications in the city. The Lerma Building is

a 17-floor structure including 4 parking

levels, 12 office floors and 1 penthouse.

The buildings dimensions is 25m x 15.3m

with an area per floor plan of 393m2. The

high risk of damaged in a highly likely

earthquake, motivated the development

of a retrofitting plan. After a detail evaluation of the options, it was decided to add

dampers in different levels in order to improve the dynamic response.

To improve the seismic response of the

building, the engineers in charge of the

seismic retrofitting studied multiple configurations of dampers, evaluating variations of loads, displacements and number of devices. After a detailed analysis

of several configurations, it was decided

to install 76 mageba RESTONSA (Shock

Absorbers) in strategic location along the

building.

The structure is located in Mexico City, Mexico

Mexico

12

Two types of SA were chosen, one for 800

kN of maximum load (50 units), and another one for 600 kN (26 units). The displacement capacity of both types is 50 mm.

Typical RESTONSA shock aborbers similar to the

ones to be installed in Lerma Building

Highlights & facts

mageba products:

Type:

RESTONSA

(800&600 kN)

Installation: 2014

Structure:

City:

Country:

Completed:

Type:

Contractor:

Mexico City

Mexico

2014

Office Building

CTBR SA de CV (Telmex)

RESTONSA ready to be shipped for installation on

a building

Infrastructure Products

Hotel Via Vallejo, Mexico City (Mexico)

Project description

magebas scope

This building will be housing two different Marriot hotels, the Courtyard and the

Fairfield. The whole building will be constructed on top of a large new mall called

Via Vallejo, located in the centre of Mexico

City.

To improve the seismic response of the

building, the engineers in charge of the

structural design performed complex dynamic analysis, which confirmed that the

best strategy was to seismically isolate the

hotel from the large mall. Therefore, it was

decided that 18 mageba LASTOLRB (Lead

Rubber Bearings) will be supporting the

entire hotel. These devices will isolate the

structure, which is rather flexible, from the

much stiffer malls structure.

The 10-floor building will has been designed to not only withstand the effects of

the severe earthquakes in Mexico City, but

also to ensure the serviceability of the hotel during and after the seismic event. To

do this, the engineers have chosen to use

seismic isolation as a protective strategy.

The structure is located in Mexico City, Mexico

This strategy has been confirmed after extensive three-dimensional dynamic analysis of the structure seismic response.

3D-View of one of the LASTOLRB (seismic isolators)

to be installed in the building

Highlights & facts

mageba products:

Type:

LASTOLRB Lead Rubber

Bearings (Isolators)

Installation: 2014-2015

Structure:

City:

Country:

Completed:

Type:

Contractor:

Mexico City

Mexico

2014

Gallegos Consultores

SIESA

Three-dimensional model of the hotel including the

mageba LASTOLRB supporting the hotel

Mexico

13

Infrastructure Products

Oceania Business Plaza (Panama City)

Project description

magebas scope

Oceania Business Plaza is a perfect example of Ultra-Contemporary architectural

design. A great tower with all the modern

comfort and luxury located in dowtown of

Panama City. Belonging to one of the highest skyscrapers of the city, the Oceania

Business Plaza constitutes an innovative

structure within a group of buildings which

have been erected on the latest economical boom. The complex Oceania Business

Plaza is conformed by two towers which

are connected by a 2-levels bridge at store

30. The highest skyscraper is 204 meters

tall and 53 stories high. magebas scope

was the supply of bearings for supporting

the bridge and allowing both structures

move independently. Bringing into service

is planed for end of 2011.

For this project mageba supplied 15

RESTONSPHERICAL bearings types KA,

KE and KF. Bearings were produced at

magebas 100% mageba-owned subsidiary

mageba-Shanghai.

The Oceania Business Plaza located in downtown

Panama City

Panama

14

Design requirements demanded bearings

which should be able to take max. vertical

loads up to approx. 850 kN, min. vertical

loads of 0 kN, horizontal loads of 1332 kN

and movements of 410mm. The structure

is supported by 15 bearings. The Bridge

structure is fixed to one of the buildings

through one fixed spherical bearing at

each level. On all other positions, support

is provided with respectively two KA and

two KE bearings, allowing bridges dilatation and buildings movements due to

wind and other external forces.

Construction of the Plaza

Highlights & Facts

mageba products:

Type:

RESTONSPHERICAL

bearings

Installed:

2011

Structure:

City:

Country:

Built:

Structure:

Type:

Height:

Panama City

Panama

2011

Building

Skyscraper

207 m

The Oceania Business Plaza

Infrastructure Products

Panam City Metro Line 1 (Panama)

Project description

magebas scope

The city of Panam is currently constructing a new metro system, which is scheduled to open in January 2014.

mageba supplied bearings of type

LASTOBLOCK Type B for this project. Due

to the length of the railway lines and the

associated structures, more than 1,600

bearings were required.

Line 1 of the system generally follows a

north-south route, from Los Andes to the

Albrook bus station, and is 13.7 km long,

including 7 km of tunnel and 6.3 km of viaduct. There will be 16 stations, including

five elevated stations and a partially-subsurface station at Albrook.

The project is being carried out by Lnea

Uno Consortium (Odebrecht and FCC),

based on a detailed design by Systra.

Panam City Metro Line 1 located in downtown

Panama City.

The mageba LASTOBLOCK bearing is a

reinforced elastomeric bearing, featuring

high-strength steel sheeting vulcanized

into its core. The steel plates are fully enclosed in elastomer to ensure absolute

corrosion protection and complete freedom from maintenance an important

consideration for a transport system which

should not be subjected to closures for

maintenance and repair.

An underground tunnel

Highlights & Facts

mageba products:

Type:

LASTOBLOCK Type B

Installed:

2012

Structure:

City:

Country:

Built:

Structure:

Type:

Panama City

Panama

Since 2010

Railway

Metropolitan railway

One of the metro systems 16 new stations

Panama

Columbia

15

Infrastructure Products

Tocumen Airport Access Road (Panama)

Project description

magebas scope

Panama Citys Tocumen International Airport is currently being extended with the

addition of a new terminal. Designed by

Foster & Partners, it will increase floor

space by over 800,000 square feet, with

20 new boarding gates, a duty free area,

a new control tower and a third runway.

To support the structures decks, mageba

supplied 80 RESTONPOT HP bearings

with uplift resistance. These bearings are

based on the standard RESTONPOT bearing which has been a most popular bearing in magebas range for many years,

having proven its worth in countless applications. The recently developed version of the bearing, with HP standing for

High Performance, represents a major

advance in the bearings technology. Durability is much increased, thanks to the use

of improved materials, and the increased

strength enabled the bearings to be made

small enough to suit the main structures

design.

Access to the new terminal from the

Corredor Sur highway that bypasses the

airport is provided by a four-lane road,

part of which is elevated. The non-continuous elevated structure of each carriageway is supported by ten piers, requiring a

bearing solution.

The new viaduct provides access to Tocumen

International Airport, Panama City, Panama

Panama

Columbia

16

Exploded view of a typical RESTONPOT bearing,

showing elastomeric pad at its core

Highlights & facts

mageba products:

Type:

RESTONPOT HP

(high performance)

bearings

Features:

Uplift resistance

Installation: 2014

Structure:

City:

Country:

Completed:

Type:

Contractor:

Panama City

Panama

2014

Airport access viaduct

Construtora Norberto

Odebrecht

A typical RESTONPOT bearing featuring uplift

resisting clamps at sides, as fabricated

Infrastructure Products

Oil refinery seismic isolation (Venezuela)

Project description

magebas scope

In the process of making an oil refinery

in a seismically active part of Venezuela

safe from the destructive effects of earthquakes, heat exchange tanks were seismically isolated from ground movements in

2012. The ongoing operation of such refineries is of great importance to the Venezuelan economy, with revenue from petroleum exports accounting for over 50%

of the countrys GDP and roughly 95% of

total exports. Venezuela has the worlds

largest proven oil reserves (20% of global

reserves), and is one of the top four suppliers of foreign oil to the United States.

mageba supplied six LASTOLRB lead rubber bearings with a diameter of 220mm

and height of 165mm including 20mm

steel connection plates. Each bearing is designed for a vertical service load of 780kN

and to allow seismic displacements of up

to 100mm. The lead core at the bearings

vertical axis has a diameter of 44mm and

provides dissipation of seismic energy,

while the natural rubber (NR) elastomer

around it provides the desired re-centering after the earthquake. To ensure proper

installation and functioning, mageba also

supervised the installation.

The refinery is located in Falcn State, one of

Venezuelas 23 states, in northern Venezuela

A LASTOLRB lead rubber bearing of the type supplied with 220mm diameter

Highlights & facts

mageba products:

Type:

LASTOLRB isolators

Installation: 2012

Supervision: Installation supervised

by mageba

Structure:

Location:

Country:

Type:

Client:

Falcn State

Venezuela

Oil refinery

PDVSA

The LASTOLRBs protect heat exchange tanks from

ground vibrations during earthquakes

Venezuela

2014 Google

Brazil

17

Infrastructure Products

Sky Building, Guayaquil (Ecuador)

Project description

magebas scope

The Sky Building in Guayaquil Ecuador will

be part of a commercial complex called

Aerocity located near the Guayaquil International Airport.

The seismic protection strategy chosen for

this building is based on the seismic isolation principle. 64 mageba LASTOLRB

(Lead Rubber Bearings) will be installed on

top of the parking levels in order to isolate

the severe movement at the ground level,

this will provide a comfortable movement

on the structure, and most importantly

the protection against any seismic damage

during the earthquake.

This 15-floor building consists of 4 parking

levels and 11 office floors. Sky Building has

been designed with the latest advances in

terms of seismic protection by the leading

structural engineering company in Ecuador. The structure has been conceived to

withstand severe earthquake without suffering damages that could jeopardize the

serviceability of the building at any time.

The building is located in Guayaquil, Ecuador

Ecuador

Peru

2014 Google

18

There were considered three different

types of seismic isolator for different loading conditions. Additionally, 44 sliders will

also contribute with the isolation system.

3D-View of one of the LASTOLRB (seismic isolators)

to be installed in the Sky Building

Highlights & facts

mageba products:

Type:

LASTOLRB Lead Rubber

Bearings (Isolators)

Installation: 2014-2015

Structure:

City:

Country:

Completed:

Engineer:

Contractor:

Guayaquil

Ecuador

2014

Consulsismica

Construdipro S.A.

Full-Scale Sample LASTOLRB prepared to be tested under actual seismic conditions in Italy

Infrastructure Products

Chilina Bridge (Peru)

Project description

magebas scope

The Chilina Bridge in the Peruvian city of

Arequipa, opening 2014, is a segmental

continuous pre-stressed concrete viaduct.

With an overall length of 562m, it is the

longest urban bridge in the country, with

spans of up to 157m. Its two 11.3m-wide

decks are box girders with variable depths.

These were constructed by the balanced

cantilever method with 5.1m-long insitu

segments built using form travellers. It is

in a highly seismic area, requiring large

seismic movements to be allowed for in

the design.

The bridge is equipped with 4

TENSAMODULAR expansion joints - two

at each end, one per structure. These are

of type LR7 (with 7 individual movement

gaps), allowing service movements of up

to 560mm (80mm per gap). The joints

feature Fuse-Box seismic protection, designed to ensure that the expansion joint

will break free of the deck in a controlled

manner during an earthquake, avoiding

serious damage to the deck or the joint itself. This will enable the bridge to be used

in the immediate aftermath of an earthquake, when it might be needed most for

emergency purposes.

Arequipa is Perus second most populous city, with a

population 10% that of the capital, Lima

Sectional view of a TENSAMODULAR expansion joint

with 5 gaps (Type LR5)

Peru

Highlights & facts

mageba products:

Type:

TENSAMODULAR

expansion joints (LR7)

Features:

Fuse-Box (seismic)

Installation: 2014

Structure:

City:

Country:

Completed:

Type:

Length:

Contractor:

Arequipa

Peru

2014

Concrete viaduct

562m

Consorcio Constructor

Puente Chilina

The joints feature Fuse-Boxes, enabling them to break

free from the deck during an earthquake

Bolivia

19

Infrastructure Products

Worldwide network

Companies & agents worldwide

Jordan

Australia

Kuwait

Austria

Latvia

Belarus

Lithuania

Brazil

Mexico

Cambodia

Netherlands

Chile

New Zealand

China

Nigeria

Colombia

Norway

Costa Rica

Oman

Croatia

Peru

Czech Republic

Poland

Denmark

Romania

Ecuador

Russia

Egypt

Serbia

Estonia

Singapore

Finland

South Africa

France

South Korea

Germany

Spain

Ghana

Sweden

Great Britain

Switzerland

Hong Kong

Thailand

India

Turkey

Indonesia

UAE

Iran

Ukraine

Israel

USA

Italy

Vietnam

Japan

Companies of mageba group

mageba distributors / licensees

Contact us at

mageba headquarters

mageba International LLC

mageba sa

575 Lexington Avenue, 4th Floor

New York, NY 10022

Tel. +1-212-317-1991

Fax +1-212-317-1993

info@mageba.net

Solistrasse 68

8180 Blach - Switzerland

Tel. +41 44 872 40 50

Fax +41 44 872 40 59

info@mageba.ch

Active membership at various organizations

American Concrete Institute

American Segmental

Bridge Institute

International Association for

Bridge Maintenance and Safety

International Association for

Bridge and Structural Engineers

mageba on the internet

Visit us on www.mageba.net for more information or watch our videos on

www.youtube.com/magebagroup.

mageba infrastructure and building products

International

Bearings

2014.10INT-ENmageba

Expansion joints

Seismic protection

www.mageba.net

Monitoring & Services

mageba International - 575 Lexington Avenue, 4th Floor - New York, NY 10022 - T +1-212-317-1991 - info@mageba.net

Das könnte Ihnen auch gefallen

- Tac 2006Dokument21 SeitenTac 2006Chewfy1Noch keine Bewertungen

- Technical Journal: Plan Design EnableDokument107 SeitenTechnical Journal: Plan Design EnablegullipalliNoch keine Bewertungen

- Ajay Goyal - HSS Bridge Over Chenan BridgeDokument8 SeitenAjay Goyal - HSS Bridge Over Chenan BridgemalevolentNoch keine Bewertungen

- Nepean Conveyors Projects CapabilityDokument13 SeitenNepean Conveyors Projects CapabilityFelipe RibeiroNoch keine Bewertungen

- Mathieu Angers CV 2024-02-20Dokument2 SeitenMathieu Angers CV 2024-02-20Mehul JainNoch keine Bewertungen

- Sika Solutions For Concrete BridgesDokument48 SeitenSika Solutions For Concrete BridgeskjhyNoch keine Bewertungen

- Bandra Worli ProjectDokument17 SeitenBandra Worli ProjectvarunikakhareNoch keine Bewertungen

- ACECC Civil Engineering Project Award Nomination Form - Japek II ElevatedDokument9 SeitenACECC Civil Engineering Project Award Nomination Form - Japek II ElevatedFebrian Dian PamungkasNoch keine Bewertungen

- TerraDokument30 SeitenTerraSUBHAMNoch keine Bewertungen

- 0783f83a-a395-4d5f-a25d-6548c52ac9a0Dokument14 Seiten0783f83a-a395-4d5f-a25d-6548c52ac9a0Tiago SilvaNoch keine Bewertungen

- Structural Steel Design Awards 2018Dokument32 SeitenStructural Steel Design Awards 2018bachNoch keine Bewertungen

- 1.040 Project Management: Mit OpencoursewareDokument40 Seiten1.040 Project Management: Mit OpencoursewareRia GalangNoch keine Bewertungen

- DOD - Handbook of Paints & CoatingsDokument20 SeitenDOD - Handbook of Paints & Coatingsjohn_p47Noch keine Bewertungen

- Retaining StructuresDokument2 SeitenRetaining Structurescamelia_pirjan5776Noch keine Bewertungen

- Bridge Construction: Dr. Ahmed Abdel-Atty Gab-AllahDokument32 SeitenBridge Construction: Dr. Ahmed Abdel-Atty Gab-Allahselva_651950Noch keine Bewertungen

- 05-Multi-Cell Prestressed Box Girder Bridge Design As Per AASHTODokument36 Seiten05-Multi-Cell Prestressed Box Girder Bridge Design As Per AASHTOJames McguireNoch keine Bewertungen

- Gumjae Bridge - Extradosed Bridge Parametric StudyDokument48 SeitenGumjae Bridge - Extradosed Bridge Parametric StudyKhaled Elbanna100% (1)

- Underground StructuresDokument12 SeitenUnderground StructuresmctrtNoch keine Bewertungen

- Modular Precast Concrete Bridges CBDG PDFDokument42 SeitenModular Precast Concrete Bridges CBDG PDFBalty ShedyNoch keine Bewertungen

- The Design of Padma Multipurpose Bridge - Challenges and Solutions.Dokument10 SeitenThe Design of Padma Multipurpose Bridge - Challenges and Solutions.Jahidul IslamNoch keine Bewertungen

- Advantages of Prestressed Concrete BridgesDokument44 SeitenAdvantages of Prestressed Concrete Bridgeskavya1811Noch keine Bewertungen

- Repairs and Strengthening Diversification Strategies Mega Tower in Hong KongDokument32 SeitenRepairs and Strengthening Diversification Strategies Mega Tower in Hong KongDrPadipat ChaemmangkangNoch keine Bewertungen

- RaviabstractDokument21 SeitenRaviabstractSunil Kumar IndiaNoch keine Bewertungen

- Final Presentation ProjectDokument31 SeitenFinal Presentation ProjectSUBHAMNoch keine Bewertungen

- 05-Multi-Cell Prestressed Box Girder Bridge Design As Per AASHTO PDFDokument36 Seiten05-Multi-Cell Prestressed Box Girder Bridge Design As Per AASHTO PDFJeong Woon KangNoch keine Bewertungen

- Advatages of Prestress ConcreteDokument44 SeitenAdvatages of Prestress ConcreteVivek PremjiNoch keine Bewertungen

- Ibdas: Integrated Bridge Design and Analysis SystemDokument12 SeitenIbdas: Integrated Bridge Design and Analysis SystemChun Fai ChoNoch keine Bewertungen

- CHAPTER IDokument4 SeitenCHAPTER Imaddih gayeNoch keine Bewertungen

- Detailed Design of The Main Bridge - Viaduct Spans in Padma Multipurpose Bridge Project, BangladeshDokument10 SeitenDetailed Design of The Main Bridge - Viaduct Spans in Padma Multipurpose Bridge Project, BangladeshS S Reddy SomuNoch keine Bewertungen

- Lessons From Building The World's Highest Rail Bridge - New Civil EngineerDokument8 SeitenLessons From Building The World's Highest Rail Bridge - New Civil EngineerMohamed AlmaimaniNoch keine Bewertungen

- 2011 Bridge SarkadyDokument17 Seiten2011 Bridge SarkadyTan Duy LeNoch keine Bewertungen

- Bandra Worli Sea Link (BWSL)Dokument24 SeitenBandra Worli Sea Link (BWSL)Akshata Patil ParvatikarNoch keine Bewertungen

- Millau Viaduct Term PaperDokument13 SeitenMillau Viaduct Term Paperfan_luc89Noch keine Bewertungen

- Bridge Engineering Major BridgesDokument56 SeitenBridge Engineering Major BridgesMilind GuptaNoch keine Bewertungen

- Eposter Trab Aceito 0284 1 PDFDokument9 SeitenEposter Trab Aceito 0284 1 PDFdejejuniorNoch keine Bewertungen

- I S S U E T W O 1 9 9 7: Mount Rushmore Parking Garage - USADokument16 SeitenI S S U E T W O 1 9 9 7: Mount Rushmore Parking Garage - USADrPadipat ChaemmangkangNoch keine Bewertungen

- Study and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadDokument5 SeitenStudy and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadMananNoch keine Bewertungen

- DLT Heavy Lifting Contractor, Construction ConsultantDokument12 SeitenDLT Heavy Lifting Contractor, Construction ConsultantUhrin ImreNoch keine Bewertungen

- Slide Cable Stayed PDFDokument117 SeitenSlide Cable Stayed PDFpu3bsdNoch keine Bewertungen

- Bandra Worli Sea LinkDokument6 SeitenBandra Worli Sea LinkSabeesh Antony0% (1)

- UHPC Perspective From A Specialist Construction CompanyDokument10 SeitenUHPC Perspective From A Specialist Construction Companywong.dennis517Noch keine Bewertungen

- Civil BURJ KHALIFADokument17 SeitenCivil BURJ KHALIFASrujana KanapurNoch keine Bewertungen

- Footbridge Design For The DubaiDokument14 SeitenFootbridge Design For The Dubaiqatarstructz30Noch keine Bewertungen

- Mega Bridges Using Precast Technology SKDDokument47 SeitenMega Bridges Using Precast Technology SKDpvrk_78100% (1)

- Design of The Dubai Metro Light Rail Viaducts SubstructureDokument12 SeitenDesign of The Dubai Metro Light Rail Viaducts SubstructureUvie M. Ptwolan100% (2)

- 2000 Present Situation and Development of BridgesDokument16 Seiten2000 Present Situation and Development of BridgesStevan Zimbi IvkovicNoch keine Bewertungen

- Al Marja BridgeDokument7 SeitenAl Marja BridgeAhmad Yassine KouacheNoch keine Bewertungen

- DPR CorrectedDokument23 SeitenDPR CorrectedVikhyat GoudNoch keine Bewertungen

- Totaly Precast ConcreteDokument27 SeitenTotaly Precast Concreterizky100% (1)

- Segmental Concrete Bridges: International Case StudiesDokument4 SeitenSegmental Concrete Bridges: International Case StudiesSantosoNoch keine Bewertungen

- Michels Canada Completes Canada's Longest HDD Installation - World PipelinesDokument3 SeitenMichels Canada Completes Canada's Longest HDD Installation - World PipelinesNutthakarn WisatsiriNoch keine Bewertungen

- Career Profile ofDokument26 SeitenCareer Profile ofShreya MuleNoch keine Bewertungen

- G&P Digest Issue 6Dokument8 SeitenG&P Digest Issue 6Chua Chim HueeNoch keine Bewertungen

- UntitledDokument24 SeitenUntitledESON LOHNoch keine Bewertungen

- Presentasi LRT AlsiITB Nov19Dokument51 SeitenPresentasi LRT AlsiITB Nov19ilham wahyudiNoch keine Bewertungen

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsVon EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNoch keine Bewertungen

- A Guide to Some of the Equations used in Constructing a Suspension BridgeVon EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNoch keine Bewertungen

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksVon EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNoch keine Bewertungen

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12Von EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12Noch keine Bewertungen

- 입찰가이드 08 ADBDokument83 Seiten입찰가이드 08 ADBbriankimbjNoch keine Bewertungen

- As 7642 (2013) - Turnouts and Other Special TrackworkDokument9 SeitenAs 7642 (2013) - Turnouts and Other Special TrackworkbriankimbjNoch keine Bewertungen

- As 7635 (2013) - Track GeometryDokument7 SeitenAs 7635 (2013) - Track GeometrybriankimbjNoch keine Bewertungen

- AS 7636 (2013) - Railway Structures PDFDokument8 SeitenAS 7636 (2013) - Railway Structures PDFbriankimbjNoch keine Bewertungen

- As 7634 (2017) - Railway Infrastructure - SurveyDokument7 SeitenAs 7634 (2017) - Railway Infrastructure - SurveybriankimbjNoch keine Bewertungen

- AS 7636 (2013) - Railway Structures PDFDokument8 SeitenAS 7636 (2013) - Railway Structures PDFbriankimbjNoch keine Bewertungen

- As 7630 (2017) - Railway Infrastructure - Track ClassificationDokument6 SeitenAs 7630 (2017) - Railway Infrastructure - Track ClassificationbriankimbjNoch keine Bewertungen

- As 7638 (2013) - Railway EarthworksDokument8 SeitenAs 7638 (2013) - Railway EarthworksbriankimbjNoch keine Bewertungen

- As 7639 (2013) - Track Structure and SupportDokument8 SeitenAs 7639 (2013) - Track Structure and SupportbriankimbjNoch keine Bewertungen

- AS 7643 (2018) - Track Stability PDFDokument7 SeitenAS 7643 (2018) - Track Stability PDFbriankimbjNoch keine Bewertungen

- Project 15 AlleDokument13 SeitenProject 15 AllebriankimbjNoch keine Bewertungen

- Kien Stay Cable Bridge - VietnamDokument2 SeitenKien Stay Cable Bridge - VietnambriankimbjNoch keine Bewertungen

- Design and Construction of New Zealand's First 1825 Super Tee BeamDokument16 SeitenDesign and Construction of New Zealand's First 1825 Super Tee BeambriankimbjNoch keine Bewertungen

- Construction Products BS 5896Dokument3 SeitenConstruction Products BS 5896briankimbjNoch keine Bewertungen

- AS 7630 SampleDokument6 SeitenAS 7630 SamplebriankimbjNoch keine Bewertungen

- Son La Bridge - VietnamDokument2 SeitenSon La Bridge - VietnambriankimbjNoch keine Bewertungen

- Sheikh Zayed Bridge - Abu DhabiDokument2 SeitenSheikh Zayed Bridge - Abu DhabibriankimbjNoch keine Bewertungen

- 2019 Queensland Major Projects PipelineDokument116 Seiten2019 Queensland Major Projects PipelinebriankimbjNoch keine Bewertungen

- Mageba Brochure enDokument16 SeitenMageba Brochure enbriankimbjNoch keine Bewertungen

- Setra Prestress Concrete BridgeDokument291 SeitenSetra Prestress Concrete BridgepsinguliNoch keine Bewertungen

- VSL Technical Report - PT ExternalDokument36 SeitenVSL Technical Report - PT ExternalTran Nguyen KhiemNoch keine Bewertungen

- VSL News - 2013 - 1Dokument40 SeitenVSL News - 2013 - 1Lau Kim HwaNoch keine Bewertungen

- AECOM Corporate BrochureDokument20 SeitenAECOM Corporate BrochurebriankimbjNoch keine Bewertungen

- HDRB 2nd Penang BridgeDokument44 SeitenHDRB 2nd Penang BridgebriankimbjNoch keine Bewertungen

- Port Shipping Warehouse Business Develop Etc1Dokument9 SeitenPort Shipping Warehouse Business Develop Etc1Subhankar MahapatraNoch keine Bewertungen

- Edoc - Pub - The Pharmaceutical Industry Project PDFDokument156 SeitenEdoc - Pub - The Pharmaceutical Industry Project PDFMaimoonakhangmail.com KhanNoch keine Bewertungen

- Spares ListDokument56 SeitenSpares ListVinod Kumar Verma100% (1)

- Space Frame Manufacturer - WWW - Alcox.inDokument13 SeitenSpace Frame Manufacturer - WWW - Alcox.inNarendra ShahNoch keine Bewertungen

- Coal SopDokument8 SeitenCoal SopRizal TengkuNoch keine Bewertungen

- Dixit SCN ICD Dixit - Under-Sec-112 Smuggling HawalaDokument42 SeitenDixit SCN ICD Dixit - Under-Sec-112 Smuggling HawalajainNoch keine Bewertungen

- Distortion in Aluminum Welded StructuresDokument3 SeitenDistortion in Aluminum Welded StructuresRaron1Noch keine Bewertungen

- Transportation Law NotesDokument25 SeitenTransportation Law NotesNovern Irish PascoNoch keine Bewertungen

- Spotface: Machined Faced Cast Forged Roughness Flatness Tolerances Counterbore BossDokument2 SeitenSpotface: Machined Faced Cast Forged Roughness Flatness Tolerances Counterbore Bossmamasita25Noch keine Bewertungen

- Tender Specification Klaus Multiparking Multibase 2072I Eb / Multibase 2072I DBDokument6 SeitenTender Specification Klaus Multiparking Multibase 2072I Eb / Multibase 2072I DBama29Noch keine Bewertungen

- Rolling (Metalworking) : Roller MillDokument45 SeitenRolling (Metalworking) : Roller MilldnyaneshwarNoch keine Bewertungen

- Undercarriage Handbook Low Res 1Dokument24 SeitenUndercarriage Handbook Low Res 1govindsrNoch keine Bewertungen

- Model PMGSY Road Datas 2013-14-SSRDokument91 SeitenModel PMGSY Road Datas 2013-14-SSRChManikumarNoch keine Bewertungen

- Steel Materials CatalogDokument70 SeitenSteel Materials Catalogkimyt250651Noch keine Bewertungen

- Presentation: Meti - JetroDokument26 SeitenPresentation: Meti - JetroSejal_chirag0% (1)

- Pandrol ProductsDokument6 SeitenPandrol Productsmirakel000Noch keine Bewertungen

- Xazbdikxco - Technical Specification-Vol 1Dokument39 SeitenXazbdikxco - Technical Specification-Vol 1Balamurugan ArumugamNoch keine Bewertungen

- Documentation Fabric CompensatorsDokument8 SeitenDocumentation Fabric CompensatorsAhmet HamamcıoğluNoch keine Bewertungen

- AE301 Process and ProceduresDokument12 SeitenAE301 Process and ProceduresVetri Vela100% (1)

- Boeing (Mcdonnell Douglas) Dc-10-30F: Aircraft VariantsDokument2 SeitenBoeing (Mcdonnell Douglas) Dc-10-30F: Aircraft VariantsNadeemNoch keine Bewertungen

- List of Major Private Companies of IndiaDokument2 SeitenList of Major Private Companies of IndiaRaghav TalwarNoch keine Bewertungen

- By William B. Tracy, MBA, NCARB: A Brief Overview of The New BOMA Measurement Standards For LawyersDokument7 SeitenBy William B. Tracy, MBA, NCARB: A Brief Overview of The New BOMA Measurement Standards For Lawyersxxmorph3u5xxNoch keine Bewertungen

- Module 7-Material HandlingDokument74 SeitenModule 7-Material HandlingSang Ka KalaNoch keine Bewertungen

- Corespondenta Comerciala CURSDokument9 SeitenCorespondenta Comerciala CURSAdela BudeNoch keine Bewertungen

- How To Make Bricks From ConcreteDokument12 SeitenHow To Make Bricks From ConcreteCheyzeeNoch keine Bewertungen

- A973A973M-07 (2012) Standard Specification For Grade 100 Alloy Steel ChainDokument4 SeitenA973A973M-07 (2012) Standard Specification For Grade 100 Alloy Steel ChainDiego Egoávil MéndezNoch keine Bewertungen

- A 814 - A 814M - 03 Qtgxnc9bode0tqDokument6 SeitenA 814 - A 814M - 03 Qtgxnc9bode0tqsachinguptachdNoch keine Bewertungen

- Equipment Supplies 1Dokument77 SeitenEquipment Supplies 1alltheloveintheworldNoch keine Bewertungen

- Welcome To Anderson Workone. Your Career Starts HereDokument28 SeitenWelcome To Anderson Workone. Your Career Starts HereHilary TerryNoch keine Bewertungen

- ESAB Ship Building by Svetsaren 2003Dokument44 SeitenESAB Ship Building by Svetsaren 2003Abu Akhtar Aira AlthafNoch keine Bewertungen