Beruflich Dokumente

Kultur Dokumente

Alcorn State University - Shittake Mushrooms

Hochgeladen von

molecule112Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alcorn State University - Shittake Mushrooms

Hochgeladen von

molecule112Copyright:

Verfügbare Formate

15/12/2556

Alcorn State University

Athle tics | Alum ni and Frie nds | Giving to Alcorn |

C ale ndar | Hom e

Search:

Welcome

About Alcorn

Prospective Students

Current Students

Academics

Se arch

Administration

MSFAC Home

Mission Statement

MSFAC Programs

Marketing

Food Safety Program

Cooperative Loans

Farm Loans

MSFAC Staff

Outreach and Research

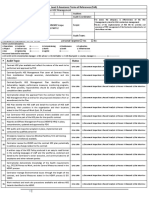

Growing Shiitake Mushrooms on Sawdust Blocks

An Overview

Spawn is used to start Shiitake mushroom growth on sawdust blocks. Spawn used for blocks is normally grain spawn, sawdust spawn or liquid

spawn with Shiitake actively growing on it. There are several different strains of Shiitake spawn to meet a variety of farmer and market

needs. The strain characteristics are also influenced by the substrate formulation.

Below are some characteristics to be considered when ordering spawn from a commercial supplier to produce sawdust substrate blocks:

Size, shape and color of mushrooms

Speed of incubation

Temperature range for incubation and crops

Resistance to disease

Speed of cropping

The effect of transportation on the active spawn

Production

High volume, space efficiencies and economies of scale are strengths of this method of Shiitake mushroom production. A good amount of

Shiitake production experience is required in order to control expenses and maximize profits. Production of Shiitake mushrooms on sawdust

blocks is the method used by most commercial growers in the United States. Since production occurs in an environmentally controlled space,

the quality and quantity can be managed to meet market demands. The following is a brief description of this production process:

Substrate Mixing

Sawdust should be course (approximately 1/8 inch) Sweet gum or Oak trees

Supplements of grains and ban are added to speed growth and increase yields

One common formula is 70% sawdust and 30% supplement

Substrate Sterilization

Substrate is bagged in heat resistant plastic bags, normally 5-6 each.

Bagged substrate is heated from 212-250 degrees o F (Fahrenheit) to eliminate or reduce competing organisms.

The substrate is heated for 2-12 hours, depending on temperature and total volume of substrate in the heated chamber.

Inoculation

www.alcorn.edu/Academics/Schools/AREAS/MSSmallFarm/Default.aspx?id=8424

1/3

15/12/2556

Alcorn State University

The substrate must be cooled to 86% degrees F or below before inoculation.

After the closed bags are removed from the heat chamber, they are placed in sterile air

Bags are opened in front of sterile airflow

Between 1/8-1/4 cup of grain spawn is added to the substrate in front of a sterile airflow

The bag is then heat-sealed in front of a sterile airflow

The spawn is spread through the substrate by shaking the bag

Incubation

Incubation is the process that occurs when the Shiitake mycelium moves through the bag and begins to consume the sawdust

substrate

The optimum temperature for vegetative growth stage is 72-77 degrees o F

Light is required

The length of incubation depends on the substrate formulation and will require from 30-120 days

Cropping

During incubation, the Shiitake Mycelium binds the sawdust substrate into a firm block, so the bag can be removed

The temperature of the cropping room will vary from 50-77 degrees o F, depending on the crop stage, strain and substrate formulation

Water, temperature, humidity & oxygen are controlled and varied during each cropping cycle

The cropping cycle includes induction, pinning, fruiting and resting

Biological efficiencies can be managed from 40% to 90%

Each cropping cycle will require 20-64 days, depending on substrate formulation and management practices

The total number of crops produced on each block depends on size and formulation and can vary from one to six

Harvest

The mushrooms are picked after they have opened but are not fully expanded about 70% open

Store in a cooler at a 34-36 degrees o F and at 85-95% relative humidity

The United States market is for fresh Shiitake; however, drying can preserve overproduction and discards

Equipment

Equipment will vary greatly, depending on business decisions made by the farmer. Some of the considerations are volume and speed of

production, capital investment, available labor and whether to manufacture or purchase the substrate blocks. For example, if the decision is

made to purchase cured blocks, only cropping equipment is required. The following list of equipment is a very general description of

equipment that may be required.

Substrate Mixing

Ribbon Mixer

Scales

Substrate sterilization

Heat-resistant bags with filter for gas exchange.

Pressure vessel for 15 pounds of pressure and 250 degrees o F or unpressurized vessel for steam at 212 degrees o F.

Boiler or steam generator

Inoculation Requirements

C lean room

Laminar flow hood with HEPA filter

Bench top heat-sealer for bags

Inoculation rooms with temperature controls

Substrate bag racks

Cropping

C ropping room

Block racks

Temperature controls

Humidity controls

Air exchange controls

Lighting controls

C arbon dioxide measurement instrument

Soak tank

Water

Harvest Equipment

C ooler

Scales

Dehydrator

For additional information on Growing Shiitake

http://www.scribd.com/doc/11052661/Growing-Shiitake-Mushrooms

in

Mississippi

C ontact

Mississippi Small Farm and Agribusiness Center

Alcorn State University

www.alcorn.edu/Academics/Schools/AREAS/MSSmallFarm/Default.aspx?id=8424

2/3

15/12/2556

Alcorn State University

Alcorn State University

1000 ASU Drive #1080

Alcorn State, MS, 39096

601-877-6449

Q uick Link s

1000 ASU DRIVE | ALCORN STATE MISSISSIPPI 39096-7500 | PHONE: 601.877.6100

www.alcorn.edu/Academics/Schools/AREAS/MSSmallFarm/Default.aspx?id=8424

3/3

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Contractor Hse Management: Level 2 Assurance: Terms of References (Tor)Dokument3 SeitenContractor Hse Management: Level 2 Assurance: Terms of References (Tor)molecule112100% (1)

- Petroleum CSG: Hsec Management System ProcedureDokument18 SeitenPetroleum CSG: Hsec Management System Proceduremolecule112Noch keine Bewertungen

- Safety Moment: The Seasick SSEDokument3 SeitenSafety Moment: The Seasick SSEmolecule112Noch keine Bewertungen

- Nor Captain - DLB Support VesselDokument1 SeiteNor Captain - DLB Support Vesselmolecule112Noch keine Bewertungen

- 'General' Effective Existing Safeguards 'Lifting' Effective Existing SafeguardsDokument2 Seiten'General' Effective Existing Safeguards 'Lifting' Effective Existing Safeguardsmolecule112Noch keine Bewertungen

- ChronOS InjecDokument24 SeitenChronOS Injecmolecule112Noch keine Bewertungen

- Safe Operating Procedure Ice MakerDokument1 SeiteSafe Operating Procedure Ice Makermolecule112Noch keine Bewertungen

- LTW MK15 Operation Manual - Vol 2 Rev CDokument25 SeitenLTW MK15 Operation Manual - Vol 2 Rev Cmolecule112100% (2)

- Safety Alert - ElectrocutionDokument2 SeitenSafety Alert - Electrocutionmolecule112Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Thermal Test Procedure For Box-Type Solar Cookers'IDokument8 SeitenThermal Test Procedure For Box-Type Solar Cookers'Irejeesh_rajendran100% (1)

- PDFDokument14 SeitenPDFMixa SazonovNoch keine Bewertungen

- Conductometry Titrations PDFDokument4 SeitenConductometry Titrations PDFkomalseemi97Noch keine Bewertungen

- 69NT40-561-001 To 199: Container RefrigerationDokument136 Seiten69NT40-561-001 To 199: Container RefrigerationMAYMODERN STEELNoch keine Bewertungen

- 1N4728 - 1N4764 - Z1110 - Z1200 Zener DiodesDokument2 Seiten1N4728 - 1N4764 - Z1110 - Z1200 Zener DiodesFabian BordaNoch keine Bewertungen

- SMiRT-23 Paper107 RCCCW CourtoisClauzon-v1Dokument11 SeitenSMiRT-23 Paper107 RCCCW CourtoisClauzon-v1CourtoisNoch keine Bewertungen

- Hydro ExecutionDokument2 SeitenHydro ExecutionMohit .kNoch keine Bewertungen

- Establishment of Standard X-Ray Qualities To Be Used in Diagnostic Level at SsdlsDokument50 SeitenEstablishment of Standard X-Ray Qualities To Be Used in Diagnostic Level at SsdlsHoomi ShbNoch keine Bewertungen

- BOP RusiaDokument8 SeitenBOP RusiaRidhota MadiniNoch keine Bewertungen

- Welding InspectorDokument5 SeitenWelding InspectorqaqcnaviNoch keine Bewertungen

- Vertical VaporizersDokument2 SeitenVertical VaporizersMeravigliorso76Noch keine Bewertungen

- Report PDFDokument12 SeitenReport PDFShailendra RajputNoch keine Bewertungen

- Catalogo Invt gd100 PVDokument10 SeitenCatalogo Invt gd100 PVSergio RecabarrenNoch keine Bewertungen

- Mvaw11 - 21 Brochure en 2018 12 Grid Ga 1657Dokument4 SeitenMvaw11 - 21 Brochure en 2018 12 Grid Ga 1657selva rajaNoch keine Bewertungen

- LiFePO4 DIY ESS - Kit Building DocumentationDokument28 SeitenLiFePO4 DIY ESS - Kit Building DocumentationohobohoNoch keine Bewertungen

- Quick Reference GC Detectors 5994 4919en AgilentDokument2 SeitenQuick Reference GC Detectors 5994 4919en AgilentSasan FaniNoch keine Bewertungen

- Chapter 14 - Shop SafetyDokument11 SeitenChapter 14 - Shop Safetymega87_2000Noch keine Bewertungen

- Wa0010.Dokument6 SeitenWa0010.Zaid Hasan KhanNoch keine Bewertungen

- Innovation in ConstructionDokument165 SeitenInnovation in Constructionfoush bashaNoch keine Bewertungen

- Technical System Catalogue RilineDokument21 SeitenTechnical System Catalogue RilineTomislav ŠeplNoch keine Bewertungen

- ONR Chief Nuclear Inspector Report of EDF Energy and Hinkley Point C Supply ChainDokument30 SeitenONR Chief Nuclear Inspector Report of EDF Energy and Hinkley Point C Supply ChainThe GuardianNoch keine Bewertungen

- Introduction LetterDokument2 SeitenIntroduction Letterbllimbani100% (1)

- AirMMax Aeration Equipment Co., Ltd-AquacultureDokument38 SeitenAirMMax Aeration Equipment Co., Ltd-AquacultureHaley HeNoch keine Bewertungen

- Wheelchairchart - 7 31 19Dokument4 SeitenWheelchairchart - 7 31 19lucholadeNoch keine Bewertungen

- TPE331-14 Turboprop Engine PDFDokument2 SeitenTPE331-14 Turboprop Engine PDFJoaquinBarretoNoch keine Bewertungen

- Qualification of Compressed Air ProtocolDokument18 SeitenQualification of Compressed Air ProtocolBRIJENDRA KUMAR SINGH100% (2)

- L Series Lubricated Reciprocating Air Compressors and BoostersDokument4 SeitenL Series Lubricated Reciprocating Air Compressors and Boostersatorresh090675Noch keine Bewertungen

- Dynamics of Rigid BodiesDokument10 SeitenDynamics of Rigid BodiesJohn Michael SalasNoch keine Bewertungen

- Questionbank Physics CoreDokument532 SeitenQuestionbank Physics CoreJojobaby51714100% (1)

- Brodholt p1049-1053 97Dokument5 SeitenBrodholt p1049-1053 97mauricio rojas alvarezNoch keine Bewertungen