Beruflich Dokumente

Kultur Dokumente

Dubai Metro Project

Hochgeladen von

Mustafa UzyardoğanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dubai Metro Project

Hochgeladen von

Mustafa UzyardoğanCopyright:

Verfügbare Formate

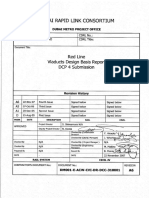

DUBAI RAPID LINK CONSORTIUM

Dubai Metro Project

RED LINE

Viaducts Design Basis Report

November 2007

WS Atkins & Partners Overseas

ATKINS

DUBAI METRO PROJECT

VIADUCT - DESIGN BASIS REPORT

W S Atkins & Partners

Overseas

Revision

Status

Draft

Draft

Working

Originated

By

M.

Badcock

M.

Badcock

Checked

By

Verified By

Issued By

A. Shaw

J. Baber

M.Badcock

A. Shaw

J. Baber

M.Badcock

M.

Badcock

A. Shaw

J. Baber

M.Badcock

For

Comment

M.

Badcock

A. Shaw

J. Baber

M.Badcock

A1-01P

Draft

G. Ziadat

A. Shaw

J. Baber

G.Ziadat

A1-02A

For

Approval

G. Ziadat

A. Shaw

J. Baber

G.Ziadat

B1-02B

Draft

M Chubb

C Hendy

M Chubb

C Hendy

G.Ziadat

J.Sundaram

J.

Sundaram

J.Sundaram

A5

A6

For

approval

For

approval

J.P.Sagar

Date Issued

Issued To

29 July

2005

5 August

2005

12

August

2005

15

August

2005

30 Nov

2005

30 Dec

2005

JT Metro

JV

JT Metro

JV

24 July

2006

7 Nov

2007

JT Metro

JV

JT Metro

JV

JT Metro

JV

JT Metro

JV

JT Metro

JV

JT Metro

JV

Verification Ref:

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 2 of 64

DUBAI METRO PROJECT

Dubai Rapid Link

DUBAI RAPID LINK CONSORTIUM

DUBAI METRO PROJECT OFFICE

Contract No.: DM001

Project Title: DUBAI METRO

CDRL No.:

CDRL Title:

Document Title:

Viaduct Design Basis Report

Revision History

A6

7/11/07

Atkins update for approval

A5

21/7/06

Atkins update for approval

A3

23/6/06

Atkins update

B105B

23-05-06

Atkins internal update

A1

28-12-05

For Approval

15-8-05

First Issue

MARK

DATE

Signed below

DESCRIPTION

RAIL

Project Director

T. Uneda

Deputy Project Director

S. Sasaki

APPROVED

Signed below

CIVIL

Checked By (QA/QC Manager)

Checked By (Safety Manager)

Checked By

Checked By (Project Manager)

Checked By

Checked By (Design Manager)

Prepared By

Prepared By

DATE

DATE

RAIL SYSTEM

CONTRACTORS DOCUMENT No.:

21 July 2006

CIVIL JV

DOCUMENT No.:

DM001/E-ACW-CVI-DR-DCC-310001

REVISION

A6

DUBAI METRO PROJECT

ATKINS

CONTENTS

1.

INTRODUCTION

2.

MATERIALS

3.

DESIGN CRITERIA

11

4.

EARTHQUAKE DESIGN

24

5.

RAIL/STRUCTURE INTERACTION

28

6.

DEFORMATIONS

30

7.

GEOTECHNICAL

32

8.

DESIGN METHODS

38

APPENDICES

A.

SCHEDULE OF DESIGN STANDARDS

43

B.

LOAD COMBINATIONS

45

C.

DESIGN RAIL VEHICLES

47

D.

RAIL CLEARANCES

49

E.

DECK SECTION AND TRACKFORM DIMENSIONS

52

F.

EQUIPMENT ON DECK

56

G.

MOMENT ROUNDING AT SUPPORTS

59

H.

DIFFERENTIAL TEMPERATURE GRADIENT

61

I.

TYPICAL GLOBAL RAIL/STRUCTURE INTERACTION MODEL

63

J.

TYPICAL EARTHQUAKE INERTIA LOADING ANALYSIS MODEL

65

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 3 of 64

DUBAI METRO PROJECT

ATKINS

INTRODUCTION

1.1 This design basis report sets out the parameters and assumptions used in the design

of the viaduct structures for the Dubai Metro project.

1.2 This report is to be applied to the design of the viaducts for the Red Route and covers

the viaduct decks, piers, abutments and foundations, but excludes the trackform.

1.3 The viaduct superstructures consist of the following forms:

Simple Spans. Simply supported U-section decks constructed using post tensioned

segmental construction by the span by span method from an overhead gantry.

Twin Span Continuous. Two span continuous U-section decks constructed using post

tensioned segmental construction by the span by span method from an overhead

gantry and the stitching of both spans together to form a continuous structure.

Three Span Continuous. Three span continuous structures comprising a combination

of U-section and Box-section precast post tensioned segmental decks, erected by

crane using the balanced cantilever method.

Station spans. Three or four span continuous U-section decks constructed using post

tensioned segmental construction by the span by span method from an overhead

gantry and the stitching of both spans together to form a continuous structure

Single Track Decks. Simply supported U-section decks constructed using precast post

tensioned segments erected by the span by span method from an overhead gantry

(similar to Simple Spans)

Special Structures. Simply Supported and continuous post tensioned or reinforced

insitu concrete decks of variable geometry.

Segments are cast either using long line or short line moulds. Straight simply

supported, twin spans and Station spans with a horizontal radius below 2000m are

generally cast flat and straight using long line moulds and erected as a series of

straight chords between piers. Curved spans are cast wider than straight spans using

short line moulds to follow the horizontal curvature down to 300 m radius for twin

tracks and 250m radius for single tracks, but cast as a series of straight chords for

vertical alignment to simplify construction. 3-span continuous deck segments are cast

with a constant width to follow both the horizontal and curved alignments using short

line moulds. Minimum vertical curve radius is 1250m.

1.4 The viaduct substructures will generally comprise reinforced concrete piers with wider

pier caps to support the deck and reinforced concrete abutments. Pier heads for

simple, twin spans, station spans and some special spans are constructed using

precast thin reinforced concrete shells infilled with insitu concrete and prestressed in

stages. For single track spans and 3-span continuous internal piers pierheads are of

insitu reinforced concrete. Piers and abutments will be founded on large diameter

bored pile foundations.

1.5 This report does not consider the at grade sections on the approaches to the viaducts,

or the embankments retained by retaining walls behind the abutments. Consequently,

this report does not cover the requirements for transition structures on the approaches

to the viaducts. Measures to control differential movements and the effects of

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 4 of 64

DUBAI METRO PROJECT

ATKINS

variations in structural support stiffness are described in a separate Design Basis

Report (Ref. 1).

1.6 Stray current and civil earthing systems will be provided on the viaducts but these

requirements are subject to a separate Design Basis Report (Ref 2).

1.7 The Designer has obtained the Engineers agreement to use BS5400 as the design

code for the viaducts instead of AASHTO LFRD subject to the Engineer retaining the

right to refer to AASHTO general requirements. This agreement is documented in the

Engineers Comments on the Viaducts Design Basis Review Doc No DM001-E-ACWCV1-DR-DCC-310001-D.

1

MATERIALS

2.1 Concrete

The following concrete grades will be used

Structural Element

Grade (fc)

Cylinder

Strength

2

Grade (fcu)

Cube

Strength

2

36 kN/mm

2

36 kN/mm

2

38 kN/mm

36 kN/mm2

2

36 kN/mm

2

34 kN/mm

36 kN/mm

2

38 kN/mm

2

36 kN/mm

2

34 kN/mm

Superstructures

Precast - 3 Span

Precast 44/44 straight

Precast 44/44 curved

Precast 36m curved

Precast Type 1 station deck

Precast Other

Insitu continuity stitches:

Precast 44/44 straight

Precast 44/44 curved

Type 1 station deck

Insitu Structures

48 N/mm

2

48 N/mm

2

56 N/mm

48 N/mm2

2

48 N/mm

2

40 N/mm

60 N/mm

2

60 N/mm

2

70 N/mm

60 N/mm2

2

60 N/mm

2

50 N/mm

60 N/mm

2

70 N/mm

2

60 N/mm

2

50 N/mm

Piercaps and Bearing Plinths

Pier Columns (3-span internal

piers)

Other Pier Columns

Abutment walls, Bases and Pile

Caps

40 N/mm

50 N/mm

40 N/mm

50 N/mm

32 N/mm

40 N/mm

32 N/mm

Piles

48 N/mm

2

56 N/mm

2

48 N/mm

2

40 N/mm

32 N/mm *

E (short term)

Modulus of Elasticity

2

34 kN/mm

34 kN/mm

31 kN/mm

40 N/mm

31 kN/mm

31 kN/mm

40N/mm *

Table 2.1 Concrete strengths

* Allowance has been made for the loss of strength due to placement of the concrete under

2

drilling fluid. Design strength, fcu of 50 and 40 N/mm is the characteristic strength before and after

placement respectively.

The long term modulus of elasticity shall be taken as half the short term modulus where

appropriate.

Where required by design constraints a higher concrete grade may be used. The higher grade

shall be recorded in the design calculations and final drawings.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 5 of 64

DUBAI METRO PROJECT

ATKINS

Unit weight of reinforced concrete

See Section 3.2

Coefficient of Thermal Expansion

10.8 x 10 / C

-6

The following table provides the design crack widths and nominal covers to be used in the

Design and specified for construction. The nominal design crack widths and nominal design cover

values specified are based on BS5400 Pt.4 Tables 1 and 13 respectively:

Structural

Element

Environment

Nominal Design

Crack width

Superstructures

Precast - 3 Span

Precast Other

Insitu Structures

Piercaps and

Bearing Plinths

Pier Columns

Pier Bases and

Pile Caps

Piles

Nom.

Specified

Cover

Nominal

Design

Cover

Considered for all

these decks as

Severe to Very

Severe

Severe to Very

Severe

Severe to Very

Severe

Severe

0.20 mm

0.20 mm

0.20 mm

40 mm

40 mm

50 mm

35 mm

35 mm

35 mm

0.20 mm

50 mm

35 mm

0.20 mm

50 mm

40 mm

0.20 mm

100 mm

45 mm

Severe

0.20mm

125 mm

45 mm

Table 2.2 Design crack widths and concrete cover

The environment for the piers and abutment walls above the maximum ground water

level, along with all the above ground concrete, including the decks, are assumed to be

an intermediate classification between a severe and very severe environment. The

benefits of the concrete coating system will be ignored in the design. A tanking system

will be applied to the pile cap below ground level in order to provide added protection.

This will be in addition to the cover requirements given above.

The pier and abutment bases, are to be waterproofed with a proprietary waterproofing

system For the piles the concrete will be of a low permeability C50 concrete mix

approved by the Engineer. In addition 125mm cover is specified throughout its length and

a severe environment is assumed for crack width and nominal design cover calculation.

Up to 3 m above ground level (or top of column) columns shall also be coated with a

sprayed water proofing membrane to minimise evaporation of water from exposed

concrete surface and upward draw of saline water from below ground.

This clarifies the approach to be taken with Tables 1 and 13 of BS 5400 Part 4.

It is proposed to use the recommendations of the Concrete Society Technical Report

TR49, Design for High Strength Concrete to allow for the increased concrete strength

2

above the 40 N/mm limit adopted in some clauses of BS 5400 Part 4. This makes the

best use of the available concrete capacity.

Exposed concrete surfaces (decks, pier and abutment stems) shall be treated with an

elastomeric coating system, with a weather resistant top surface and a penetrating

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 6 of 64

DUBAI METRO PROJECT

ATKINS

primer. The coating shall provide in-depth protection against corrosion associated with

the ingress of chloride and sulphate ions, carbon dioxide and other air-borne acid gasses,

and shall have the ability to allow water vapour to escape from the surface. The coating

will be non-slip over the walkway on top of the deck edge beams.

2.2

Steel Reinforcement

Hot rolled reinforcement to BS 4449: 1997 will be specified with the following properties:

Type

Designation

Elastic Modulus

Characteristic

Strength

Mild Steel

250 N/mm2

200 kN/mm2

High Yield Deformed Type 2

460 N/mm2

200 kN/mm2

Table 2.3 Reinforcement types

2.3

Prestressing Steel

The prestressing steel shall be ASTM A416-85 seven-wire strand, relaxation class 2.

Ducts to be galvanised steel.

The requirements for the temporary prestressing applied to the segmental joints during

the

curing of the epoxy glue will be determined by the viaduct superstructure subcontractor.

The following parameters will be used in the design of the permanent prestressing:

Nominal diameter of strand

15.24 mm

Nominal cross-sectional area of strand

140 mm

Ultimate tensile strength of strand

1860 N/mm

Minimum Breaking Load of strand

260.7 KN

Elastic modulus (circa)

195,000 N/mm

Coefficient of friction ()

0.20

Wobble coefficient (k)*

0.0010 /m

Wedge draw-in at anchorage

6 mm (max.)

Relaxation (after 1000hr at 20C & 70% of breaking load)

2.5 %

* The tendon support spacing shall be consistent with the assumed design

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 7 of 64

DUBAI METRO PROJECT

ATKINS

wobble factor.

The force in the prestressing tendons at the anchorage immediately prior to lock-off shall

be limited to 75% of the guaranteed ultimate tensile strength (GUTS). The jacking force

is to account for any jack losses.

Relaxation losses will be adjusted for 28C and the % of breaking load after lock-off.

None of the prestress tendons will be designed to be replaceable.

All the ducts will be grouted with cementitous grout.

2.4

Assumed Prestressing System Dimensions

Tendon

Size

No

Strands

4T15

12T15

12

13T15

18T15

19T15

22T15

13

18

19

22

Application

3 Span Deck

(transverse)

Simple, Single

Track, Special , 2

Span and 3 Span

Decks

3 Span Decks

3 Span Decks

Pier Crossheads

Pier Crossheads

Duct Diameter

Internal/External

45/50 mm

Minimum

Breaking

Load

1043 kN

Anchorage

Bearing Size

(mm)

150 x 150

80/87 mm

3128 kN

250 x 250

95/102 mm

100/107mm

100/107mm

100/107mm

3389 KN

4693 kN

4953 kN

5735 kN

310 x 310

310 x 310

310 x 310

310 x 310

Table 2.4 Prestressing system details

2.5

Bearings

The bearings supporting the viaduct superstructures will be either pot or elastomeric

bearings. The continuous span structures will use only sliding pot bearings.

Elastomeric bearings will be in accordance with BS 5400 Part 9, 1983 and the following

shear modulus values shall be provided:

2

G = 0.9 N/mm for static conditions (permanent loads)

2

G = 1.8 N/mm for short term loading conditions (live and earthquake loads)

The elastomer shall not have a nominal hardness value greater than 60.

Where transverse forces on elastomeric bearings exceed 10% of the vertical load, as is

expected in all cases, the bearings shall be fitted with an interfacing chequered plate to

provide a minimum coefficient of friction of 0.5 between mating surfaces. This

attachment shall be capable of carrying the entire transverse load.

Pot bearings will be provided with a PTFE sliding surface and will be designed and

specified in accordance with BS 5400 Part 9, 1983. The corrosion protection system

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 8 of 64

DUBAI METRO PROJECT

ATKINS

shall be in accordance with the Contract Specification.

All bearings shall provide electrical isolation between the deck and substructure.

2.6

Expansion Joints

No cover plate will be provided across the gap between decks, but a galvanised

chequered cover plate will be provided across the gap in the emergency walkways. This

plate will be fixed on one side and will not be recessed into the concrete surface but will

be detailed to avoid becoming a tripping hazard to passengers and maintenance

personnel.

2.7

Segmental Joints

The joints between the match cast precast concrete deck segments shall be formed with

shear and location keys during precasting and filled using an appropriate epoxy glue

during erection.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 9 of 64

DUBAI METRO PROJECT

3

3.1

ATKINS

DESIGN CRITERIA

Design Standards

The design will be carried out in accordance with the technical standards listed in

Appendix A. The design will be based on BS 5400 and the associated British Standards,

with additional International Standards introduced to supplement the scope in such areas

as earthquake loading and rail dynamic factors.

The load combinations used in the design are given in Section 3.23 and provided in

Appendix B.

3.2

Dead Loading (DL)

Dead loads will include the weights of the materials and parts of the structure that are

structural and permanent in nature. The following unit weights of materials will be

assumed:

Material

Concrete

Steel

Description

Reinforced concrete

Mass concrete

Structural, Prestressed and

Ordinary Reinforcement

Characteristic Density (kN/m3)

24.5

22.0

77.0

Table 3.1 Dead loads

3.3

Superimposed Dead Loading (SDL)

Superimposed dead loads include all the weights of materials on the structure that are

not structural elements but are permanent. The major part of the superimposed dead

loading is the weight of the trackform plinths. Details can be seen in Appendix E. The

remainder of the loading is the equipment on the deck, and details of these are provided

in Appendix F. The allowance per m run of deck is as follows for each deck type:

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 10 of 64

DUBAI METRO PROJECT

Description

ATKINS

Mainline (Twin

Track) Load

kN / m run / deck

23.0

27.9

2.9

1.0

5.9

0.6

1.2

0.4

Mainline (Single

Track) Load

kN / m run / deck

16.9

15.4

1.5

0.5

2.9

0.6

0.3

Mainline

(Turnout) Load

kN / m run / deck

48.0

3.9

1.0

5.9

0.6

0.5

Trackform plinths (Straight)+

Trackform plinths (Canted)+

Running rails and fixings

Third rail, supports & fixings

Cables trays and cables

Handrails

Soffit lighting*

Miscellaneous equipment

Total (Straight Track to

35.0

17.3

59.9

R=2000m)+

Total (Canted Track to

39.9

19.6

R=250m)+

* Soffit lighting only applies to simple and 2 span continuous twin track decks for 6.23 km

of twin track viaduct, the location of which is yet to be agreed with the Client.

+ For simple twindeck spans additional trackform weights shall be added to account for

camber and alignment vertical curvature where the deck is precast on flat long-line beds

as follows (Maximum vertical curvature of R=1250m is assumed until span arrangements

and alignment are fixed) :

Table 3.2 Superimposed dead loading

The allowance per m run of deck for station structure are:

Description

T1 & T2 Stations

(Twin Track) Load

T3 Stations

(Single Track

Middle ) Load

T3 Stations

(Single Track Side) Load

kN / m run / deck

kN / m run / deck

kN / m run / deck

Trackform plinths (Straight)

30.8

16.9

16.9

Platform Finishes

14.5

14.8

11.2

Platform Screen Doors

5.0

5.0

2.5

Running rails and fixings

2.9

1.5

1.5

Third rail, supports , fixings

1.0

0.5

0.5

Cables trays and cables

8.0

4.0

4.0

Handrails

0.75

0.75

0.75

Soffit lighting / Cladding

2.0

1.0

1.0

Miscellaneous equipment

2.0

1.0

1.0

Total

67.0

44.0

38.0

Table 3.3 Superimposed dead loading on viaduct deck for overground stations

(excluding concourse level loads in Type 2 stations)

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 11 of 64

DUBAI METRO PROJECT

Description

Additional Trackform

Average Weight due

to Camber

Additional Trackform

Average Weight due

to Vertical Curvature

Maximum (not

additive)

ATKINS

28m Span

32m Span

36m Span

44m Span

kN / m run / deck

0.3

kN / m run / deck

0.4

kN / m run / deck

0.8

kN / m run / deck

1.2

3.0

3.9

5.0

12.2

3.0

3.9

5.0

12.2

Table 3.4 Additional trackform weights for Simple twintrack decks precast

on flat long line beds.

Description

Additional Trackform

Average Weight due

to Camber

Maximum (not

additive)

kN / m run / deck

0.38

kN / m run / deck

0.5

kN / m run / deck

1.0

kN / m run / deck

-

0.38

0.5

1.0

Table 3.5 Additional trackform weights for Station span twintrack decks precast

on flat long line beds.

Description

Additional Trackform

Average Weight due

to Camber

Additional Trackform

Average Weight due

to Vertical Curvature

Maximum (not

additive)

kN / m run / deck

0.15

kN / m run / deck

0.2

kN / m run / deck

0.4

kN / m run / deck

0.6

1.5

1.95

2.5

6.1

1.5

1.95

2.5

6.1

Table 3.6 Additional trackform weights for Simple single-track decks precast

on flat long line beds.

3.4

Vertical Train Loading (VTL)

The Red Route is to operate with 5 car trains from the outset. However, the Green Line

will start to operate with 3 car trains, which will be upgraded to 4 then 5 car trains as

patronage increases.

The variable sized trains operating on the Green Route will use the Red Route from

Union Square to the Main Depot. There is also the possibility that the Green Line trains

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 12 of 64

DUBAI METRO PROJECT

ATKINS

may use the remainder of the Red Route to the small depot at the south end of the

scheme. It is therefore considered necessary to design the whole of the Red Route for 3,

4 and 5 car trains.

Details of the maximum axle loads and spacing for the various train configurations

specific to this scheme are given in Appendix C. The choice of vehicle and position of

the vehicle will be chosen to produce the most adverse effect on the structure. The

assumed axle load for all train axles is 140 kN. This is based on the AW4 load case of

gross vehicle weight including the maximum passenger capacity.

The loading from maintenance vehicles and low loaders carrying equipment required

along the route will not be of a magnitude to be critical for the design.

3.5

Rail Vehicle Dynamic Impact Factor (DIF)

The American Concrete Institute technical design standard ACI 358.1R-92, Analysis and

Design of Reinforced and Prestressed Concrete Guideway Structures (Chapter 3 Loads, pg. 358. 1R-15), will be used for determination the dynamic factors to be applied

to the vertical train loading for longitudinal design, except for the simply supported spans

where they are to be derived by dynamic analyses for the respective span lengths. As

stated in the code Cl.3.3.1.2 the DIF will not be applied to design of viaduct foundations.

The maximum operating speed of the rolling stock will be taken as 90 kph and the Design

Speed shall be taken as 100 kph.

For transverse design, the recommendations of BS 5400 Part 2 Cl 8.2.3.2 for RL Loading

will be applied. This gives a dynamic factor of 1.2, which needs to be increased to 1.4 for

the design of the floor slab supporting just a single track. These values are to be verified

using a Finite Element Analysis.

3.6

Longitudinal Rail Forces (braking and traction) (LF)

The longitudinal rail forces at rail level are applied parallel with the tracks at the axle

locations in accordance with the recommendations of BS 5400 Part 2

The positions of the driving/braking axles are given in Appendix C. The Traction force

per axle is 27.5 kN and Braking force per axle is 20.0 kN, based on loads supplied by

the DURL Rail System Designer. ( Note: MHI to provide a basis for these figures)

For twin tracked decks carrying traffic in opposite directions, consideration should be

given to braking forces from one train and traction forces from another, acting

simultaneously to maximise the longitudinal loading on a deck. Additionally

consideration should be given to braking or traction acting in opposite directions to

produce rotational effects. Allowance is also made for one train pushing or pulling a

broken down train.

3.7

Centrifugal Forces (CF)

When the track is curved, centrifugal load will be considered. The centrifugal force

acting radially 1.8m above rail level will be determined in accordance with Cl 8.2.9 of BS

5400 Part 2, assuming a maximum design speed of 100 kph, reducing with cant and a

distributed load of 33 KN/m based on actual train loading. For calculation of f value the

statement for L greater than 2.88m and vt less than 120km/h will be amended to for L

greater than 2.88m and vt greater than 120km/h as corrected in BD37/01.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 13 of 64

DUBAI METRO PROJECT

ATKINS

Where there are twin tracks, centrifugal loading should be considered from rolling stock

on both tracks.

For sections of track with radius in plan less than 400 m, the design speed for calculation

of centrifugal forces shall be reduced as follows:

Plan radius 400 m, design speed = 100 kph

Plan radius = 350 m, design speed = 90 kph

Plan radius = 300 m, design speed = 80 kph

Speeds for intermediate radii may be interpolated.

3.8

Nosing (Hunting Forces) (NF)

The nosing load shall be determined in accordance with Cl 8.2.8 of BS 5400 Part 2 for

RL Loading. A single 100 kN nominal load is required to be taken horizontally at rail

level at right angles in either direction to the track at a point to cause the most severe

effect.

For multi track decks only one load is required to be applied.

3.9

Lurching (LU)

Lurching effects should be determined in accordance with Cl 8.2.7 of BS 5400 Part 2 for

RL Loading. Lurching results from temporary transfer of part of the railway vertical live

loads from one rail to another, the total track load remaining unaltered.

To account for lurching effects on single and two track structures, 0.56 of the vertical

train load should be considered as acting on one rail concurrently with 0.44 of the

vertical train load on the other rail.

This redistribution of load need only be considered on one track where members

support two tracks. This variation in distribution of the vertical train loads is only

considered for local transverse design of the track support element. This variation does

not require consideration in the longitudinal direction.

Lurching can be ignored for elements supporting more than two tracks. It may also not

be required for elements supporting two tracks providing that a Finite Element Analysis

is carried out to demonstrate the actual transverse behaviour.

3.10 Derailment Loading (DF)

The derailment containment is generally provided by the trackform support plinths and

the walkway upstand, which restrain the train transversely and prevent it from derailing

off the tracks. No load cases will be considered therefore for a train displaced

transversely off the track as this displacement will be minimal and the stability of the

deck is not an issue.

The design of the trackform plinths falls outside the scope of this report, as the works

are part of the trackwork, rather than structure. Account will be taken of the transfer of

these loads from the trackform into the structure and down through to the supports, pier

and foundations.

The derailment loading in BS 5400 Part 2 applies a series of displaced vertical loads,

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 14 of 64

DUBAI METRO PROJECT

ATKINS

but no horizontal loads. In our situation the train vehicles will be held in position by the

track plinths and by the deck upstands. Therefore, this loading is not applicable as the

displacements proposed are not possible and the derailment effect is only the horizontal

load component caused by the tilting of the train.

Consequently, it is proposed to use the derailment loading from the American Concrete

Institute technical design standard ACI 358.1R-92, Analysis and Design of Reinforced

and Prestressed-Concrete Guideway Structures. The loading from Cl 3.5.2 of ACI 358

shall be applied to the deck upstands.

The horizontal derailment load applied to the deck upstands will be taken as 50% of the

maximum car weight applied to a 5m length of deck at axle level. For the most heavily

loaded car which has 4 axles of 140 kN each, this amounts to a nominal force of 280 kN

applied over a 5m length.

The maximum eccentricity of a derailed train from the tracks will be assumed to be

250mm and this should be considered in conjunction with the horizontal derailment load.

3.11

Walkway and Platform Loading (WL)

In the Station viaducts Platform loading of 5kN/m2, over 3m width per web shall be

considered.

2

A load of 4 kN/m shall be applied on the upper surface of the deck upstands (emergency

walkways) within the handrails. As this is an emergency condition of a broken down

train, this will only be considered in conjunction with a static unloaded train (no

passengers and no dynamic impact factor) located on the track adjacent to the loaded

emergency walkway. Rail loadings on any remaining tracks will be unaltered.

For loaded lengths greater than 30m the pedestrian loading will be reduced in

accordance with Cl 7.1.1 and 7.2.1 of BS 5400 Part 2.

Loads on the deck upstands which constitute part of the station platforms will include the

loads from the Platform Screen Doors, accounting for pressure from crowd, and air

pressure from ventilation, air conditioning and the passing trains.

3.12

Temperature (TC, TD)

The temperature range from the records of recording station No 41194 at Dubai

International Airport for the period of 1984 to 2001 shows a maximum recorded range of

7.4C to 47.5C.

Provisions shall be made for stresses and movements resulting from uniform temperature

expansion / contraction. A temperature rise of +43C and a temperature fall of -32C shall

be considered.

A positive temperature gradient of 20C and a reverse temperature difference of 10C

shall be considered between the top and bottom surfaces of the deck for both the USection and Box-girder decks, as shown in Appendix H. Only the effects of the moment

generated by this gradient will be considered, the axial effects will be determined by the

temperature changes mentioned above. Temperature gradient effects shall only be

considered at the seviceability state under load combination 3 with a partial safety factor

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 15 of 64

DUBAI METRO PROJECT

ATKINS

of 0.6, as shown in Appendix B.

During construction, a positive gradient of 15C and a reverse temperature difference of

7.5C shall be considered to reflect the short term nature of the construction condition.

The positive temperature gradient cannot co-exist with the maximum temperature rise

and the reverse temperature gradient cannot occur with the maximum temperature fall

and these combinations shall not be considered.

In the stations, the decks are enclosed by the station structures and therefore will not be

subjected to the above temperature gradients in the operating condition after construction

of the stations has been completed.

As the effects of peak rise and fall temperatures are a long term phenomenon, an elastic

modulus of 75% of the short elastic modulus will be used for the temperature rise and fall

analysis. The short term elastic modulus will be used for the temperature gradients.

3.13

Bearing Friction (BF)

The maximum coefficient of friction for the sliding pot bearings shall be taken as 5% of

the applied permanent vertical load. When considering the differential friction from

bearings either side of fixed pier(s) the friction on one side will be taken as 5% and on the

other side 2.5%. These values will be confirmed upon availability of test data from the

chosen bearing supplier / manufacturer. This assumes that both bearings are replaced at

the same time.

The minimum friction shall be taken as 0.5%.

3.14

Differential Settlement (DS)

The design longitudinal differential settlement between any adjacent piers will be:

between piled foundations 5mm

between any piers with spread foundations 15mm

between a pier with a piled foundation and a pier with spread foundation 20mm.

These values will be confirmed based on the findings of the Ground Investigation and

the actual viaduct loading.

Note it is generally not proposed to use spread foundations on any continuous structures.

Differential settlements are not considered in the design of any simply supported

structures. The short term settlement of the pad foundations from the loading during

construction is not considered as it will be built out in the simple spans.

In the transverse direction, a construction tolerance of 2mm will be assumed between the

bearings on either side of the pier cap for the U- section decks. A differential settlement

of 1mm will be considered in the transverse direction post construction, for the rail

alignment.

Combinations of differential settlement movements shall be considered on one or more

piers to produce the most adverse effect on the deck and piers.

Differential settlements between the stations and viaduct shall be established based on

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 16 of 64

DUBAI METRO PROJECT

ATKINS

serviceability requirements and the capacity of the interface movement joints.

Differential settlement is a long term effect and a long term elastic modulus will be used

in the design, equal to half the short term modulus.

3.15

Wind Loading (WL)

The wind loading shall be determined in accordance with BS 5400 Part 2 1978 assuming

a mean hourly wind speed of 30 m/s. This corresponds to a 3 second gust speed of

45m/sec on the standard span decks. Wind loads shall be determined on the deck, piers

and rail vehicle. In addition, the wind loading on the Type 2 Stations will be carried by the

shared substructure. Maximum wind load to be applied to the train travelling on the deck

is to be based on a maximum gust speed of 115km/hr.

The height of the rail vehicle is assumed to be 3.84m above the rail level, with the lower

1m masked by the deck. For wind with Live Load, the train design has been based on a

maximum operating gust wind speed of 32 m/s. This value shall be adopted in the design

for a loaded structure.

Wind loading shall be applied in the transverse (PT), longitudinal (PL) and vertical (PV)

directions in the following combinations:

PT alone

PT in combination with PV

PL alone

0.5PT in combination with PL 0.5PV

In determining the maximum and minimum wind gust speeds the following values will be

adopted:

K1, coefficient for return period = 1.0, for a return period of 120 years and K1 =

0.85 for the reduced return period applicable to the construction period

K2, hourly speed factor is to be taken from Table 2 of BS5400 Part 2.

S1, funnelling factor = 1.0

S2, gust factor to be taken from Table 2.

The deck will be assumed to of the single box or slab, with sloping sides type as shown in

Figure 3 of BS 5400 Part 2.

3.16

Earthquake Loading (EL)

Earthquake loading is not included in BS 5400, so reference is made to AASHTO LRFD

for Seismic Loading. Refer to Section 4 of this report for further information.

Seismic loading will not be considered during construction.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 17 of 64

DUBAI METRO PROJECT

3.17

ATKINS

Collision Loads from Road Vehicles (CL)

Collision of road vehicles with the deck and the piers will be considered in accordance

with the UK Highways Agency technical document BD 60/04, The Design of Highway

Bridges for Vehicle Collision Loads.

Bridge supports within the central reservation or a verge/footway adjacent to a highway

shall be designed for collision loads.

Bridge supports within 4.5m of the edge of a major carriageway will be designed for

impact loading as follows:

Load normal to the

adjacent carriageway

Load parallel to the

adjacent carriageway

Main load

component

500 kN

Residual

load

component

250 kN

1000 kN

500 kN

Point of application to the

Pier

At the most severe point

between 0.75m and 1.5m

above the adjacent

carriageway or ground level

At the most severe point

between 1m and 3m above

the adjacent carriageway or

ground level

Table 3.7 Collision forces for piers within 4.5m of a carriageway

Bridge supports greater than 4.5m from the edge of a major carriageway with a safety

fence, or adjacent to a minor road will be designed for the requirements of BS 5400 Part

2 Cl 6.9, as follows:

Load normal to the

adjacent carriageway

Load parallel to the

adjacent carriageway

Point of application to the

Pier

Main load

component

150 kN

50 kN

0.75m above the adjacent

carriageway or ground level

Residual

load

component

100 kN

100 kN

3m above the adjacent

carriageway or ground level

Table 3.8 Collision forces for piers more than 4.5m from a carriageway

The piers will be capable of resisting the main and residual load components acting

simultaneously. Loads normal to the carriageway are to be considered separately from

loads parallel to the carriageway.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 18 of 64

DUBAI METRO PROJECT

ATKINS

For decks (and pier caps) with headroom less than 0.4m above the minimum headroom

requirement, vehicle collision loads on the superstructure will be considered. The

headroom is measured over the carriageway and adjacent verges and should include

allowance for any sag deflection of the structure, as given below:

Highway

Minimum Headroom

For Roads crossing above

Minimum Headroom below

which Collision Loads applied

Sheikh Zayed Road

6.0 m

6.4 m

Others

5.5 m

5.9 m

Table 3.9 Deck headroom clearance requirements.

Vehicle Collision Loads on the superstructure and pier caps are set out below:

Table 3.10 Deck collision loads if clearance is less than 0.40 m than minimum

requirement

The structure will be checked to ensure adequate capacity at the ultimate limit state only

for a likely and reasonable load path to transfer the impact loads to the bearings,

supports and foundations, with consideration of each structural element in the load path.

For elastomeric bearings the effects due to collision loads will be considered at the

serviceability limit state with a load factor of 1.0.

3.18

Gantry, Transporter, Traveller and Construction Loading (GL)

The majority of the simply supported decks and two-span continuous decks are to be

constructed by overhead gantry. The temporary loading from the various gantries to be

used on the scheme will be defined by the subcontractors appointed to undertake the

deck construction. These loads will include the effects of the most severe loading

configuration carrying deck precast elements and the unloaded case when the gantry is

subject to high winds. These gantries also travel over the 3-span continuous decks in

some locations and their loads need to be considered in the design. 3- span continuous

bridges are all erected in balanced cantilever. Some spans however are erected using a

deck-mounted mobile traveller with a maximum weight of 40 tonnes. Its loads also need

to be considered in these bridge designs. Segments are mostly delivered at ground level

but in some location where access is difficult some segments are delivered over the deck

using special transporters. These loads and their effects on permanent works need to be

checked. When there are no specific construction loads, a load of 0.5 kN/m is considered

2

on the 3-span balanced cantilever and 1.25 kN/m has been considered for all the other

precast Viaducts.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 19 of 64

DUBAI METRO PROJECT

3.19

ATKINS

Shrinkage and Creep Effects (SE, CE)

Shrinkage and Creep effects will be calculated in accordance with the recommendations

of the FIP-CEB 1990 Model Code and shall be considered as permanent load effects.

The average relative humidity ratio will be taken as 70% and average annual mean

temperature as 28C.

Shrinkage and creep factors will be calculated for individual structural elements with

account taken of the member thickness, the age of the concrete when loaded and the

nature and timing of the applied loading.

The reinforced trackform plinths will be effectively discontinuous. Therefore the effects of

differential shrinkage and creep of stress into these plinths will not be considered.

3.20

Bearing Replacement (BR)

The viaducts will be checked for the effects of the deck being jacked to facilitate the

replacement of the bearings. Consideration will be given to the effects of the change in

the support positions due to the transfer of loads to the jacks, and for the displacements

to the continuous structures. The railway shall remain operational during the bearing

replacement.

The deck(s) at a pier will be jacked together to ensure there is no twist placed into the

deck and for a pier with a deck expansion joint, to prevent any adverse effects to the

continuous welded rail which spans the joint. The assumed maximum amount required

to jack each bearing type is:

For replacement of a pot bearing

For replacement of an elastomeric bearing

5mm

10mm

During the jacking operations considerations will be given to any changes to the

articulation. Temporary transverse and longitudinal restraint may be required.

3.21

Buffer Loading

At the end of the viaduct beyond Rashidiya Station buffers will be provided at the end of

the tracks.

The maximum horizontal load to be accommodated by the buffer stop is 960kN applied at

800mm above the top of rail level.

3.22

Earth Pressure

For the design of the abutments the earth pressure coefficients will be determined once

the fill material to be used is known. See also Section 7.6 for seismic earth pressures.

3.23

Load Combinations

For the load combinations for both the serviceability and ultimate limit states refer to

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 20 of 64

DUBAI METRO PROJECT

ATKINS

Appendix B. Moments, shears, axial loads derived from the design loads are to be

multiplied by a further load factor f3 to obtain the design load effects. f3 values will be

taken as 1.0 for the serviceability limit state and 1.1 for the ultimate limit state.

For column design, when calculating the beneficial effect of axial load as a coexistent

effect, f3 at ultimate limit state shall be taken as 1.0.

3.24

Drainage

The drainage system will accommodate a rainfall rate of 20mm/hr. A minimum velocity of

0.6 m/s will be assumed.

3.25

Clearances

The separation of the two tracks is constant at 3.320m and the distance from the

centreline of the alignment to the centrelines of the tracks is a constant 1.660m, where

the alignment is straight or curved down to a radius greater than 2000m. Where the

alignment is curved between horizontal radii of 250m to 2000m these dimensions are

3.3525m and 1.6763m respectively. The only variations occur at Rashidiya and Nakheel

Stations where the twin track layout is replaced by a more complicated multi track layout.

The internal clearance widths between the inside faces of the deck upstands (platform

edge in stations) are as follows:

Location

Straight Track

(R>2000m)

Curved Track

(R=250-2000m)

Outside Station

6.780m

7.100m

Inside Station

6.330m

Not applicable

Table 3.11 Internal dimensions between deck upstands.

On the approaches to the stations, transitions will be required to accommodate the

variation in upstand separation. Also transitions are required to accommodate the

variations between straight and curved sections of track.

Details of the clearance requirements can be seen in Appendix D.

It is possible that additional internal width will be required at the crossover positions. The

final required clearance width has yet to be determined.

3.26

Deck Profile

The 2,040mm height of the Illustrative Design will be retained along with the outer profile

to the deck. A 1 in 100 fall will be maintained on the top surface of the deck upstands

outside stations. The height of the rail level (lower rail on radius) will be a minimum of

400mm above the crown of the deck floor slab on the viaduct centreline and the inside

edge of the deck upstands will be 1095mm above rail level. For simple and twin span

decks the deck will be cast and erected at constant gradients over vertically curved

sections of the alignment. The deck level will be lowered to ensure a minimum trackform

depth of 400mm throughout. The lowering of the deck level on these span types shall be

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 21 of 64

DUBAI METRO PROJECT

ATKINS

taken into account in setting out to see that adequate clearance is provided to obstacles

below rail viaduct.

3.27

Fire Resistance

The viaduct components within the station buildings will be designed to have a design

resistance period of 2 hours. This will include both the deck and the substructure.

3.28

Piling Tolerances

The additional load effects from the most severe application of the pile tolerances will be

allowed for in the design. The following maximum tolerances for the bored piles will be

allowed for in the design:

Positional tolerance 75mm (at pile head level)

Verticality tolerance 1 in 100

The additional load effects are particularly significant with the mono-pile foundation

solution, with the application of an additional bending moment.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 22 of 64

DUBAI METRO PROJECT

4

EARTHQUAKE DESIGN

4.1

Site Classification

ATKINS

The Particular Design Specification states that viaduct earthquake design shall be carried

out in accordance with AASHTO LRFD. The site is classed as Zone 2 with an

acceleration coefficient (A) of 0.12. The structures shall be considered as essential

bridges, as defined in AASHTO LRFD Article 3.10.3. A project wide site-specific seismic

hazard assessment is currently being carried out and the seismic acceleration coefficient

obtained from this will be utilised in design, on approval by the Engineer.

The Site Coefficients shall be determined in accordance with AASHTO LFRD Article

3.10.5 on the basis of the relevant geological profile and geotechnical data for the

foundations. Based on the available data it is anticipated that, in general, Soil Profile

Types I or II will be appropriate for the majority of the route. The Site Coefficients for Soil

Profile Type I and II are 1.0 and 1.2 respectively.

4.2

Loading

4.2.1

Inertia Loading

Seismic forces arising from inertial effects on the viaduct structures will be derived in

accordance with AASHTO LRFD Articles 3.10, 4.7.4.1 and 4.7.4.3.

In general, the single mode elastic method will be used and the fundamental period of

vibration will be determined by modeling individual piers using the computer program

LUSAS, or similar. An example of a typical model is included in Appendix J. The analysis

will model the pile supports either with equivalent cantilevers or complete piles with soil

springs.

Equivalent cantilevers will be based on analysing the soil/structure interaction using the

computer software REPUTE or similar. As the response may be non-linear, initial runs

will be based on assumed seismic pile forces and if these are exceeded it may be

necessary to modify the soil stiffnesses and equivalent cantilever properties.

The pile/soil springs analysis will be based on linear elastic springs to representing the

restraint of the soil. On completion of the analysis it will be necessary to check the

maximum horizontal earth pressures and if they exceed the passive limit then the springs

will be adjusted accordingly.

The mass of the piles will be neglected in the analysis as the soil liquification depths are

expected to be small and the results will then be slightly conservative.

For pile groups, the soil spring properties will take account of the shielding effect on the

horizontal earth pressures between the piles using the factors given in DIN 4014, Cl

7.4.3.

Further information on pile modeling is included in the Geotechnical Section.

The fundamental period will be used to obtain the Elastic Seismic Response Coefficient,

Csm, from AASHTO LFRD Equation 3.10.6.1-1:

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 23 of 64

DUBAI METRO PROJECT

C sm =

ATKINS

1.2AS

2.5A

Tm2 / 3

where:

th

Tm = period of vibration of the m mode (sec).

A = acceleration coefficient specified in Section 7.5.1 below.

S = site coefficient specified in Section 7.5.1 below.

The horizontal seismic design forces will be determined from the product of the Elastic

Seismic Response Coefficient, Csm and the equivalent mass of the structure. This will

include the deck, pier crosshead, pier and pile cap self weights and the superimposed

dead loading (SDL), specified in Section 3.3. In addition live loading from a single train of

33 kN/m, which represents the average axle loading given in Appendix C, will also be

included. Horizontal seismic design forces will be considered to be acting at the centroid

of each individual mass.

Elastic Seismic Design Forces, calculated as described above, will be divided by the

following response factors, R, for the respective elements. This is based on AASHTO

LRFD Table 3.10.7.1-1 and Article 3.10.9.3.

Substructure Element

Pier Crosshead

Pier

Pile Caps and Piles

R

2.0

2.0

1.0

Table 4.1 Seismic Response Factors

These inertial seismic design forces will be considered in both the longitudinal and

transverse axis of the viaduct structure as appropriate. The following two inertial load

cases will be considered in accordance with AASHTO LRFD Article 3.10.8.

Load Case

Load Case 1

Load Case 2

Applied Forces

1.0FL + 0.3FT

0.3FL + 1.0FT

Table 4.2 Seismic load combinations

where:

FL = member forces due to an earthquake in the direction of the longitudinal axis

of the viaduct

FT = member forces due to an earthquake in the direction of the transverse axis

of the viaduct

Generally, the plastic capacity of the base of a pier multiplied by an overstrength factor of

1.3 will be used to design the foundations, in accordance with AASHTO LRFD Article

3.10.9.4.3f. This approach is likely to result in foundation design forces, which are lower

than the Elastic Seismic Design Forces and will provide a more economical design.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 24 of 64

DUBAI METRO PROJECT

ATKINS

Cracked sections will be assumed within the plastic zone at the base of the pier column.

Therefore the stiffness of the pier section is taken as EI/2 which has the effect of

practically reducing the Csm value by up to 10%.

In order to prevent a brittle shear failure, the piers will be designed for a shear force that

corresponds to the overstrength moment of resistance in the plastic hinge zone at the

base of the piers. To ensure that the plastic hinge zone is confined to the base of the pier,

the flexural design of the pier above the plastic hinge will be based on bending moments

which are consistent with the overstrength moment of resistance in the plastic hinge zone

and the corresponding overstrength shear force.

Superstructure/Pier connection forces will be based on the lesser of the Elastic Seismic

Design Forces divided by a response factor, R of 1.0 or the shear force that corresponds

with the overstrength moment of resistance in the plastic hinge zone at the base of the

pier.

4.2.2

Kinematic Loading

There is no requirement in AASHTO Seismic zone 2 to consider soil seismic interaction

as these are deemed to be covered by the Zone 2 design requirements.

Liquefaction of soil strata under seismic events is to be allowed for, as discussed in

Section 7.6.2.

4.3

Reinforcement Detailing

4.3.1

General

Reinforcement detailing shall generally be in accordance with the requirements of BS

5400. However special requirements for seismic detailing will be derived from AASHTO

LRFD.

4.3.2

Seismic Detailing

For bridges in Zone 2, the requirements of AASHTO LRFD Article 5.10.11.3 will apply.

In particular there is a need to ensure that piers have some ductility capacity. This will

be achieved by the provision of adequate transverse reinforcement in the potential

plastic hinge zones, to prevent buckling of the longitudinal reinforcement and to provide

confinement to the concrete core. It is considered that potential plastic hinge zones will

be confined to the base of piers and top of piles. Transverse reinforcement for

confinement will extend into the pile cap in accordance with AASHTO LRFD Article

5.10.11.4.3.

Detailing of laps and anchorages to the confining transverse reinforcement will make

allowance for loss of concrete cover. Spiral reinforcement shall only be spliced in the

potential plastic hinge zones at the base of piers by fully welded splices or by fullmechanical connections. Hoop reinforcement or cross-ties shall be anchored by seismic

hooks, with the extension of the hooks located within the concrete core, as defined in

AASHTO LRFD Articles 5.10.2.2 and 5.10.11.4.1d.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 25 of 64

DUBAI METRO PROJECT

ATKINS

Pier longitudinal reinforcement shall only be spliced outside of the potential plastic hinge

zones. The minimum height of pier plastic hinges is defined in AASHTO LRFD Article

5.10.11.4.1e.

4.4

Dynamic Analysis

The dynamic analysis of the straight sections of simply supported spans will be carried

out in accordance with Clause 4.7.3 of AASHTO LRFD for multi-span bridges with

regular spans provided they meet the span ratio and pier stiffness segments even

though the number of spans will exceed 6. A single mode elastic analysis uniform load

method will be used.

Other structures will be design using a multimode dynamic analysis. The presence of the

rails will be ignored in this analysis.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 26 of 64

DUBAI METRO PROJECT

5

ATKINS

RAIL/STRUCTURE INTERACTION

A rail structure interaction [RSI] analysis is required because the continuously welded

running rails are continuous over the deck expansion joints. The interaction occurs

because the rails are directly connected to the decks by base plate fittings fixed to the

continuous reinforced concrete support plinths, which are monolithic with the deck. The

forces in the rails have a significant effect on the service performances of both the deck

and the track.

The analysis of the rail/structure interaction takes two forms, the local analysis of the rail

spanning the expansion joint between two decks, and the global analysis to consider the

distribution of the longitudinal loading and interaction between the various substructures.

The design of the rails and base plate fixings will be undertaken as part of the trackwork

design.

The temperature range of the continuous welded rail (CWR) is assumed to be relative to

its neutral setting temperature of 40C + or 3C and the maximum and minimum rail

temperatures which are assume to be +75C and +3C respectively. This gives CWR

extreme ranges of +38C and -40C.

The RSI temperature range is governed by the change of structure temperature relative

to deck temperature at the time of installation of the rail. Based on the air temperature

range given in Section 3.12 the maximum and minimum deck temperatures are assumed

to be +55C to +5C. It is further assumed that th e rails are fixed to the deck at deck

temperatures between +20C and 40C which gives max imum and minimum temperature

ranges of + 35C and 35C . This corresponds with the UIC 774 3R Clause 1.4.2

requirements of maximum and minimum bridge temperatures ranges of +/- 35C.

The effect of introduction of a break in the rail by an accident or for maintenance

purposes will be investigated at detailed design stage.

5.1

Local Behaviour

Checks for the stress in the rails will be made on the lengths of continuously welded rail,

which span the expansion joints between two decks. In principle the rails will be checked

against the recommendations in the International Union of Railways technical standard

UIC 774-3, Track/Bridge Interaction, Recommendations for Calculations, 2nd Edition,

dated October 2001. These checks are only to be carried for in service conditions, i.e. no

local analysis will be undertaken for a seismic event.

In addition absolute and relative displacement checks will be carried out against the UIC

774-3 requirements for braking and acceleration and deck end rotation due to vertical

loading. The relative deflection across adjacent decks at rail locations will be limited to

3 mm.

Checks will be made for the stresses introduced into the rails due to the end rotations of

the decks, the differential vertical movements due to the compressibility of the bearings

and the eccentricity of the end of the deck from the centreline of the bearings, and the

variation in the expansion joint gap due to temperature, shrinkage and creep effects. The

values of these various movements will be determined for the various deck types and

forwarded to Mitsubishi Heavy Industries for consideration in their trackwork design.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 27 of 64

DUBAI METRO PROJECT

5.2

ATKINS

Global Behaviour

The global behaviour will be analysed using a 2D model of both the structure and rail to

examine the longitudinal load distribution. These will be modelled as separate members

with spring members connecting them together to represent the base plates.

This

idealisation is not used for dynamic analysis see section 4.4. A sketch of a typical

model is included in Appendix I.

Pandrol track fixings will be used and the slip resistance have been established by

testing. The displacement u0 at the beginning of plastic zone is 0.65mm for the unloaded

case and 0.55mm for the loaded case; and the resistance of the rails, k, to longitudinal

movement relative to the track plinth is assumed to be 30kN/m for an unloaded track and

54kN/m for a loaded track.

For lengths of simply supported spans, the interaction due to deck temperature change

will be analysed using spreadsheets which calculate the force variations in the rail due to

slip/stick of the track fixings. The out of balance effects of different adjacent span lengths

will be analysed using a simple elastic 2D model of at least 5 spans either side of the

design pier in order to quantify the forces on the bearings and piers. This will also be

used for vertical load effects and traction and braking and seismic loading. The results

will be compared with the Capita Symonds previous analytical work described in their

Rail Structure Interaction Report and the requirements of UIC 774-3. The allowable

2

increased rail stresses shall be 92 N/mm in both tension and compression.

This work will be extended to apply to lengths of viaduct spans between fixed piers using

simple methods. The work will then be calibrated using a non-linear analysis model of

simple spans and combinations.

In the transverse direction, the presence of the continuously welded rails between decks

will be ignored, so that each deck will be assumed to behave separately from its

neighbour.

For areas of horizontal curvature radial forces applied to the piers resulting from the

longitudinal analyses shall also be considered.

The complex track arrangements at Rashidiyah and Nakheel stations shall also be

modelled as special cases accordingly.

5.3

Global CWR Effects

The build up of CWR forces in the rail will be considered at points where rail breather

joints are located and for the case of a rail break. Account will be made of the CWR

temperature given above.

For viaducts with horizontal curvature the effects of the radial forces arising from the full

CWR forces will be considered.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 28 of 64

DUBAI METRO PROJECT

6

ATKINS

DEFORMATIONS

The deformations for permanent loads will be determined under the action of all

permanent loads. The deformations due to the live loads will include the appropriate

Dynamic Impact Factor. All the deformations are to be checked for nominal loading,

i.e. with applied load factors of 1.0. The following limiting values for bridge deformation

refer to the total deformations caused to the rails.

6.1

Vertical deflection at mid-span

The vertical deflection at mid-span will be limited to a Span/Deflection ratio given in the

table below based on the advice in UIC 776-3. This assumes the provision of a

reasonable level of passenger comfort for the multi-span viaducts for a Speed Range 1,

up to 120 kph. Intermediate span values are to be interpolated from the table.

Span

20m

Table 3

450

Table 7

0.65

25m

28m

30m

32m

33m

36m

54m

450

660

800

800

800

800

800

0.69

0.72

0.73

0.75

0.76

0.80

1.00

Span/Deflection Ratio

690

650

920

1,095

1,065

1,050

1,000

800

Table 6.1 Deflection limits

The vertical deformations will be determined for the maximum number of trains possible

on a structure and in the most severe locations. The total vertical deflection will be made

up of the deflections of the deck, the deformation of the bearings, and the deflections of

the pier caps.

6.2

Deck Twist

The deformation of the bridge will be checked to limit the twist applied to any of the

tracks to 0.0025 radians. This is to be checked over a length of 3m and is equivalent to

a maximum change of levels between rails of 7.5mm over this length.

6.3

End Deck Rotations

The total change in angle at the simply supported ends of a deck and the vertical

movement caused at this end by its rotation are required to be determined by the

Rail/Structure Interaction analysis. See Section 5 for further information. The check for

these rotations will be undertaken by Mitsubishi Heavy Industries, as part of their

trackwork design exercise and these fall outside the scope of this Design Basis Report.

The total rotations and vertical movements will be made up of the residual long term

effects of creep, shrinkage and foundation settlement after installation of the rails and the

effects of the maximum number of trains possible on the deck in the most adverse

locations.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 29 of 64

DUBAI METRO PROJECT

6.4

ATKINS

Deck Relative Displacements

The serviceability limit state cyclic movements in the vertical direction between

contiguous deck ends (at expansion joints) will be limited to 3mm at the running rail

centreline.

In the ultimate limit state the deck shall be prevented from falling off the pier under

seismic conditions. This is to be achieved by providing sufficient resistance in the

support bearings to restrain the deck during a seismic event.

In the longitudinal direction the stresses in the rail will be checked at the serviceability

limit state under normal operating conditions (non-seismic). These effects will be

checked by Mitsubishi Heavy Industries as part of their trackwork design from the results

of the Rail/Structure Interaction analysis, see Section 5 for further information. At the

ultimate limit state, the gap between decks will be sufficient to prevent pounding of the

adjacent decks together.

6.5

Precamber

For the simply spans, two-span decks and station decks no precamber will be applied to

the deck, with all spans being cast flat.

Other viaduct decks may be built to a precamber so the sum of the anticipated

deflections under dead load, superimposed dead load, differential shrinkage and

prestress effects after long term conditions have occurred, should achieve the desirable

profile. It is proposed to provide a permanent camber to the decks, up to an amount at

midspan of the span divided by 1000, to improve the appearance, as recommended by

UIC 776-3. It is proposed that the loading from the trains are excluded from the

determination of the precambers, contrary to the proposal in the Station and Line,

Particular Design Specification (document PS007-T-ALLI-CWK-TN-SYS-064803-B1).

Additionally, the deflections of the deck will be determined for the trackwork to account

for the long term movements which will occur following the installation of the track. This

deflections will account for the effects of the application of the weight of the trackform, the

differential shrinkage between the trackform plinths and for the deck, the ongoing creep

in the deck and the weight of the equipment on the deck. It will be assumed that the rails

will be installed between 1 and 18 months after the completion of the deck. Deflections

will be determined for both dates and the trackwork installer will be expected interpolate

between the figures provided to suit the actual delay from deck construction to trackwork

installation. An assessment will be made on the sensitivity to the age of the deck

segments when incorporated into the works when undertaking this analysis.

6.6

Horizontal Deck Deflections

Horizontal deck deflections shall be checked as per the requirements of UIC 776-3

Clause 7. The horizontal deformation of the bridge deck shall not cause a horizontal

change of angle at a free end exceeding 3.5 milliradians or a change of radius of

curvature that is less than 3500 m.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 30 of 64

DUBAI METRO PROJECT

7

GEOTECHNICAL

7.1

Overview

ATKINS

A detailed site investigation is proposed for the whole of the route. Prior to receipt of this

information the design will be based on consideration of the limited ground condition

information provided at tender.

The Illustrative Design shows viaduct structures with piers supported on alternatives of

single, twin and four pile foundations. The piles will extend through the overlying sand

into the weak rock to provide the required load bearing capacity. It is noted that other

methods of providing a foundation may be considered, such as shallow pad foundations.

There will be a limited requirement for dewatering during the construction of the viaduct

substructures. Shallow foundations and pile caps may require some local dewatering but

these will be located close to the ground surface and will not require significant

dewatering. Therefore there will be a limited settlement risk to surrounding buildings and

structures adjacent to the elevated alignment.

Ground investigations shall be conducted at every foundation location before construction

commences. The presence of existing structures and obstructions in the ground shall be

investigated through survey, with the aim of recording and resolving conflicts prior to

commencement of construction.

The key geotechnical issues at the pier and station locations are:

7.2

Assessing liquefaction potential, defining water table level, particle size

distribution and the requirement for any ground treatment resulting in the

determination of suitable foundation types.

For piled foundations, determining the local rock-head level, assessing rock

quality through pilot holes and hence determining required pile lengths and rock

socket lengths. Insitu tests or dilatometer tests will be used in test pile boreholes

in the weak rock for correlation with Unconfined Compression Tests.

Obtaining design data from preliminary laboratory testing on bore hole samples

and CPTs and using it to provide design information for use in determining

appropriate foundation sizes.

Geotechnical Design Parameters

Detailed design shall use the data in the site-specific Ground Investigation Reports.

7.3

Foundation Design

The choice of foundation at any location will be driven by the performance, feasibility,

economics and programme. The design of foundations, shallow and deep, will be carried

out in general accordance with BS 8004 and standard reference books such as Bowles

and Tomlinson. The potential for liquefaction will be assessed using available data,

supplemented by the data from the proposed site investigation when received.

Document No.: DM001-E-ACW-CVI-DR-DCC-310001

Date: 7 November 2007

Page 31 of 64

DUBAI METRO PROJECT

7.4

ATKINS

Pile Foundations

A liquefaction assessment is required for the foundation design as stated above. Where

piled foundations are to be used and liquefaction potential is indicated the design will

determine whether the material is replaced or treated. Alternatively the pile foundation will

be designed to resist the loading from liquefaction effects. Piled foundations will be

feasible throughout the elevated alignment. Pile foundation are to be analysed using the

proprietary computer software REPUTE or similar. The stiffness profile adopted for the

design will be appropriate for the design case:- static stiffness profile for normal loads and

degradated small strain stiffness values for the earthquake loading.

Where piled foundations are to be used, insufficient shaft shear stress or bearing will be

provided from the overlying soils. It is a requirement of Section 7.2.4.2 of the Particular

Specification that piles shall be extended to form sockets in the weak rock. A rock socket

of 4 times the pile diameter is proposed for piles up to 1.5m diameter. For piles greater

than 1.5m diameter a minimum penetration of 6m into the weak rock is considered

appropriate. Section 7.1.1 of the specification requires that all piled foundations shall be

bored cast in place concrete piles.

Foundations for the structures may be formed of single piles or groups formed of four

piles. It is anticipated that all pile diameters will be large (greater than 1.0m), in order to

resist the design forces. It is envisaged that drilling fluid such as good quality bentonite

or similar approved will be used to maintain bore stability and that as a minimum, casings

will be required through the loose sand in the near surface. Pile reinforcement will be