Beruflich Dokumente

Kultur Dokumente

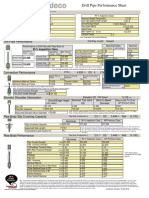

Drill Pipe Performance Sheet

Hochgeladen von

jinyuan74Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Drill Pipe Performance Sheet

Hochgeladen von

jinyuan74Copyright:

Verfügbare Formate

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Advisory: Drill string connection operational tension at Maximum MUT is less than 80% inspection class pipe body in tension, a lower MUT should be considered. Warning: Connection ID is too

large. Advisory: Elevator Capacity is weaker than nominal pipe in tension. Note: Connection torsional strength is less than 80% pipe body torsional strength.

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

10.40

(ft) 31.5

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

EU

(in) 3.125

Max Upset OD (DTE)

Friction Factor

1.0

2.875

0.362

G-105

Range2

HT 2-7/8 PAC

3.125

1.500

9

14

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

5,100

Minimum MUT

4,300

Tension Only

Combined Loading

Tension Only

Combined Loading

0

4,300

213,300

213,300

0

3,400

233,100

224,200

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

11.08

0.17

(Bbls/ft) 0.0040

(gal/ft) 0.18

(Bbls/ft) 0.0042

(in) 1.375

HT 2-7/8 PAC

3.125

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

5,100

4,300

(ft-lbs)

(lbs)

Tensile Limited

Tensile Limited

SmoothEdge Height

(in)

(lbs)

3/32 Raised

3.312

52,900

Assumed Elevator Bore Diameter

10.67

0.16

0.0039

0.18

0.0043

(lbs/ft)

0.17

0.0041

(lbs)

OD X

(in)

1.500

Tension at Connection

Yield

(lbs)

213,300

263,200

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

3.071

Not Applicable

2.946

8,500

266,300

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 4,200 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

3.125

0

Not Applicable

0

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

245,000

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

2.875 (in) OD

80 % Inspection Class

192,400

Pipe Body Configuration

(lbs)

0.362 (in) Wall

G-105 )

API Premium Class

192,400

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

3.219

Slip Crushing Capacity

3.063

0

3.312

300,100

16,200

0.53

12,900

23,137

23,112

2.875

0.362

2.151

2.858

6.492

3.634

1.602

3.204

2.875 (in) OD

80 % Inspection Class

233,100

12,400

0.69

9,900

21,153

19,912

2.730

0.290

2.151

2.220

5.854

3.634

1.228

2.456

0.362 (in) Wall

G-105 )

API Premium Class

233,100

12,400

0.69

9,900

21,153

19,912

2.730

0.290

2.151

2.220

5.854

3.634

1.228

2.456

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 11-15-2014

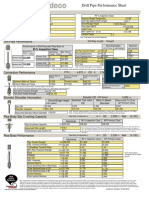

Operational Limits of Drill Pipe

Connection

Pipe Body

HT 2-7/8 PAC

80 % Inspection Class

Tool Joint OD

(in)

3.125

Tool Joint ID

Pipe Body OD

(in)

2.875

Wall Thickness (in) 0.362

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 5,100

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

200

400

700

900

1,100

1,300

1,600

1,800

2,000

2,200

2,500

2,700

2,900

3,100

3,400

3,600

3,800

4,000

4,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

213,300

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

(lbs)

233,100

233,100

263,200

233,100

213,300

233,100

213,300

200

233,100

233,100

263,200

213,300

400

233,000

233,000

263,200

263,200

233,000

232,800

213,300

500

233,000

233,000

232,500

213,300

700

232,800

232,800

263,200

232,200

213,300

900

232,500

232,500

263,200

231,900

213,300

1,100

232,200

232,200

263,200

213,300

1,300

231,900

231,900

263,200

213,300

1,400

231,700

231,700

263,200

213,300

1,600

231,200

231,200

263,200

263,200

231,200

230,700

230,100

229,500

213,300

1,800

230,700

230,700

228,400

213,300

2,000

230,100

230,100

263,200

227,600

213,300

2,200

229,500

229,500

263,200

226,700

213,300

2,300

229,100

229,100

263,200

213,300

2,500

228,400

228,400

263,200

213,300

2,700

227,600

227,600

263,200

226,700

226,700

263,200

263,200

225,700

224,200

223,100

G-105

Minimum Make-up Torque = 4,300

(ft-lbs)

(lbs)

Pipe Body Grade

Combined Loading for Drill Pipe at

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

1.500

2,900

213,300

221,900

213,300

3,100

225,700

225,700

220,700

213,300

3,200

225,300

225,300

263,200

219,000

213,300

3,400

224,200

224,200

263,200

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

4,300

4,400

4,500

4,600

4,700

4,700

4,800

4,900

5,000

5,100

Connection Max

Tension

(lbs)

263,200

257,600

251,900

246,300

240,700

235,700

230,100

224,500

218,900

213,300

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

11-15-2014

Connection Wear Table

Connection

HT 2-7/8 PAC

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

3.125

3.109

3.092

3.076

3.06

3.044

3.027

3.011

2.995

2.979

2.962

2.946

Worn OD

(in)

3.125

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

1.500

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

8,500

8,500

8,500

8,500

8,400

8,200

8,000

7,800

7,600

7,400

7,200

7,000

5,100

5,100

5,100

5,100

5,000

4,900

4,800

4,700

4,500

4,400

4,300

4,200

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

213,300

212,000

210,600

209,200

213,800

218,100

222,300

226,500

236,500

240,400

244,100

247,800

4,300

263,200

4,300

261,600

4,300

259,800

4,300

258,200

4,200

262,400

4,100

266,100

4,000

261,900

3,900

257,500

3,800

253,200

3,700

248,800

3,600

244,500

3,500

240,100

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

2.875

Wall Thickness (in) 0.362

Pipe Body Grade

G-105

1,100

2,300

3,400

4,500

5,600

6,800

7,900

9,000

10,100

11,300

12,400

232,200

229,100

224,200

217,300

208,000

195,000

179,700

160,400

135,300

96,100

3,500

(ft-lbs)

Pipe Body Max

233,100

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

11-15-2014

Das könnte Ihnen auch gefallen

- Measurement While Drilling: Signal Analysis, Optimization and DesignVon EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNoch keine Bewertungen

- Drill CollarDokument1 SeiteDrill CollarGuillermo Rangel AvalosNoch keine Bewertungen

- FloatValve 4-13 PDFDokument8 SeitenFloatValve 4-13 PDFcaballero_tigreNoch keine Bewertungen

- FORUM General Catalog Handling Tools 2017Dokument88 SeitenFORUM General Catalog Handling Tools 2017Eduardo Braga100% (1)

- Min - TJL API RP 7G-2 - For MSDokument1 SeiteMin - TJL API RP 7G-2 - For MSQuality controllerNoch keine Bewertungen

- Drill Pipe Float Valves CatalogueDokument14 SeitenDrill Pipe Float Valves Cataloguecorsini999100% (1)

- All Sizes and TorquesDokument13 SeitenAll Sizes and TorquesMohammad RizwanNoch keine Bewertungen

- GrantPrideco Drill Pipe Data TablesDokument25 SeitenGrantPrideco Drill Pipe Data TableschoaybNoch keine Bewertungen

- Shock Sub Tool: Impact and Vibration Reduction ToolDokument4 SeitenShock Sub Tool: Impact and Vibration Reduction ToolLeonardo Barrios0% (1)

- Fishing Tools: Tubular, Drilling and Worover ToolsDokument16 SeitenFishing Tools: Tubular, Drilling and Worover ToolsAchraf Ben DhifallahNoch keine Bewertungen

- Drilling&Connection PDFDokument199 SeitenDrilling&Connection PDFRazvan RaduNoch keine Bewertungen

- Down HoleDokument14 SeitenDown HoleGhinet Teodor-ioanNoch keine Bewertungen

- Tubulars and Tubular Services Catalog: DrilcoDokument29 SeitenTubulars and Tubular Services Catalog: DrilcoDoni KurniawanNoch keine Bewertungen

- TM 120 Daily and Weekly Inspection and Maintenance TasksDokument23 SeitenTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNoch keine Bewertungen

- Drill Pipe Spec's SheetDokument10 SeitenDrill Pipe Spec's SheetAhmed BakrNoch keine Bewertungen

- OKC Millhead ModificationDokument22 SeitenOKC Millhead ModificationRazvan RaduNoch keine Bewertungen

- Bowen Fishing Magnets - Instruction ManualDokument9 SeitenBowen Fishing Magnets - Instruction Manualmturri100% (1)

- Canrig torque wrench specificationsDokument16 SeitenCanrig torque wrench specificationsaris4silveyraNoch keine Bewertungen

- Rotary and Handling Tools Catalog PDFDokument190 SeitenRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- Servco Mills HandbookDokument90 SeitenServco Mills HandbookGhinet Teodor-ioan100% (1)

- Study of Dies and InsertsDokument14 SeitenStudy of Dies and InsertstraidenNoch keine Bewertungen

- BHA - Drill StemDokument44 SeitenBHA - Drill StemKaleem UllahNoch keine Bewertungen

- Logan Lubricated Bumper Sub (English)Dokument20 SeitenLogan Lubricated Bumper Sub (English)Gianfranco Exequiel Sebastian GarciaNoch keine Bewertungen

- Rotary SystemDokument17 SeitenRotary Systemgo25101992Noch keine Bewertungen

- Drill Pipe ManDokument46 SeitenDrill Pipe ManMohamed SaeedNoch keine Bewertungen

- MKT 001 Rev 02 Rotary Shoulder Handbook RS PDFDokument116 SeitenMKT 001 Rev 02 Rotary Shoulder Handbook RS PDFKarla Hernandez0% (1)

- Griffith Double Acting Hydraulic-Mechanical Drilling Jar - Series 431-428-440-441-480-411-437 - Operating Manual PDFDokument0 SeitenGriffith Double Acting Hydraulic-Mechanical Drilling Jar - Series 431-428-440-441-480-411-437 - Operating Manual PDFMEUBRONoch keine Bewertungen

- Junk Milling - Description and UsageDokument2 SeitenJunk Milling - Description and UsageCarlos Alberto100% (1)

- 6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualDokument19 Seiten6 Griffith Double Acting Hydraulic Mechanical Drilling Jar Series 431 428 440 441 480 411 437 Operating ManualAnonymous F2tu2TrzVtNoch keine Bewertungen

- External CatchDokument1 SeiteExternal CatchMicNoch keine Bewertungen

- Thread CompoundDokument5 SeitenThread CompoundJas SumNoch keine Bewertungen

- Full-Circle Casing Scraper: Instruction Manual 6255Dokument6 SeitenFull-Circle Casing Scraper: Instruction Manual 6255Jubin JacobNoch keine Bewertungen

- Teoria SidetrackDokument5 SeitenTeoria SidetrackAndres LojaNoch keine Bewertungen

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonDokument2 SeitenEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranNoch keine Bewertungen

- 20-1718 Rig Tongs AOTDokument10 Seiten20-1718 Rig Tongs AOTRahul M.R100% (1)

- F620 Casing Scrapers ManualDokument8 SeitenF620 Casing Scrapers Manualazeem1236100% (1)

- Series 150 Overshot Strength Data 4-12-2012Dokument1 SeiteSeries 150 Overshot Strength Data 4-12-2012Razvan Radu100% (1)

- Internal Pressure Pipe Cutters Manual R2Dokument16 SeitenInternal Pressure Pipe Cutters Manual R2RourouNoch keine Bewertungen

- Cement Plug SidetrackDokument2 SeitenCement Plug SidetrackAnilNoch keine Bewertungen

- Barco BJ PDFDokument9 SeitenBarco BJ PDFJose CamachoNoch keine Bewertungen

- Series 150 Overshot Make Up Torques PDFDokument8 SeitenSeries 150 Overshot Make Up Torques PDFRazvan RaduNoch keine Bewertungen

- Logan Standard Releasing Spear ManualDokument37 SeitenLogan Standard Releasing Spear ManualSamuel Arévalo GNoch keine Bewertungen

- 8.5 In. (215.9 MM) TD506X: Hughes Christensen Talon™ PDC BitsDokument1 Seite8.5 In. (215.9 MM) TD506X: Hughes Christensen Talon™ PDC BitsLeonardo BarriosNoch keine Bewertungen

- B2 Anchor Catcher Technical DatasheetDokument3 SeitenB2 Anchor Catcher Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- Understanding IU, EU and IEU Drill Pipe UpsetsDokument2 SeitenUnderstanding IU, EU and IEU Drill Pipe Upsetsmadonnite3781Noch keine Bewertungen

- Drill Pipe Performance DataDokument35 SeitenDrill Pipe Performance DatasnatajNoch keine Bewertungen

- Z Type Hydraulic Fishing Jar - Logan Oil ToolsDokument38 SeitenZ Type Hydraulic Fishing Jar - Logan Oil Toolsdiv02Noch keine Bewertungen

- IADC Vol-1 08 Directional DrillingDokument35 SeitenIADC Vol-1 08 Directional Drillingballa bammouneNoch keine Bewertungen

- Inverted Washpipe ManualDokument9 SeitenInverted Washpipe ManualGhassan ALkikiNoch keine Bewertungen

- Fishing Tools For 12 and A Quarter HoleDokument1 SeiteFishing Tools For 12 and A Quarter Holehamid100% (1)

- Fishing Tools For 17 and Half Inch HoleDokument2 SeitenFishing Tools For 17 and Half Inch Holehamid0% (1)

- Motor Head AssemblyDokument16 SeitenMotor Head AssemblyAhmed100% (1)

- TIANHE Product CatalogDokument86 SeitenTIANHE Product CatalogShag ShaggyNoch keine Bewertungen

- Drill Pipe Float Valve Catalog - WebDokument24 SeitenDrill Pipe Float Valve Catalog - Webcaballero_tigreNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- Drill Pipe Performance Data SheetDokument3 SeitenDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Dokument3 SeitenDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNoch keine Bewertungen

- Drill Pipe Performance and SpecificationsDokument3 SeitenDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokument3 SeitenDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNoch keine Bewertungen

- DC 4.75Dokument11 SeitenDC 4.75jinyuan74Noch keine Bewertungen

- Fire PumpDokument1 SeiteFire Pumpjinyuan74Noch keine Bewertungen

- DPDokument19 SeitenDPMohammad HusanNoch keine Bewertungen

- Mud HopperDokument2 SeitenMud Hopperjinyuan74Noch keine Bewertungen

- LAKELAND Chemical Resistant ApronDokument4 SeitenLAKELAND Chemical Resistant Apronjinyuan74Noch keine Bewertungen

- FIS Services Spec BookDokument22 SeitenFIS Services Spec BookLuis A G. C.Noch keine Bewertungen

- Offshore and Onshore Rig Cables - 1 PDFDokument152 SeitenOffshore and Onshore Rig Cables - 1 PDFjinyuan74Noch keine Bewertungen

- HWDPDokument15 SeitenHWDPjinyuan74Noch keine Bewertungen

- Rotary and Handling Tools Catalog PDFDokument190 SeitenRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- CG - Eng .223 Drill Pipe Care and HandlingDokument12 SeitenCG - Eng .223 Drill Pipe Care and Handlingjinyuan74Noch keine Bewertungen

- Ellk92led CsaDokument12 SeitenEllk92led Csajinyuan74Noch keine Bewertungen

- The Life-Saving Rules (April)Dokument1 SeiteThe Life-Saving Rules (April)jinyuan74Noch keine Bewertungen

- DME Exhaust Catalog 2013 PDFDokument72 SeitenDME Exhaust Catalog 2013 PDFjinyuan74Noch keine Bewertungen

- Osborn Loadrunners English PDFDokument92 SeitenOsborn Loadrunners English PDFjinyuan74Noch keine Bewertungen

- PR-1947 - Electrical Safety RulesDokument58 SeitenPR-1947 - Electrical Safety Rulesjinyuan74Noch keine Bewertungen

- Flfe Series Lighting Fixtures For Fluorescent Tubes-1Dokument5 SeitenFlfe Series Lighting Fixtures For Fluorescent Tubes-1jinyuan74Noch keine Bewertungen

- Chemistry Revision Pack - 2012Dokument20 SeitenChemistry Revision Pack - 2012api-21735041071% (7)

- MHD56251 Ed4Dokument152 SeitenMHD56251 Ed4jinyuan74100% (1)

- The Life-Saving Rules (April)Dokument1 SeiteThe Life-Saving Rules (April)jinyuan74Noch keine Bewertungen

- Physics Notes RevisionDokument43 SeitenPhysics Notes RevisionMatthew LiNoch keine Bewertungen

- HL Series Addendum - 08-26-14Dokument1 SeiteHL Series Addendum - 08-26-14jinyuan74Noch keine Bewertungen

- 50Hz UP5 11, UP5 15, UP5 18, UP5 22 60Hz UP6 15, UP6 20, UP6 25, UP6 30Dokument10 Seiten50Hz UP5 11, UP5 15, UP5 18, UP5 22 60Hz UP6 15, UP6 20, UP6 25, UP6 30jinyuan74Noch keine Bewertungen

- Material Safety Data Sheet: Effective Date 15.11.2011Dokument7 SeitenMaterial Safety Data Sheet: Effective Date 15.11.2011jinyuan74Noch keine Bewertungen

- Loc TiteDokument2 SeitenLoc Titejinyuan74Noch keine Bewertungen

- Lufkin CatalogDokument48 SeitenLufkin Catalogjinyuan74Noch keine Bewertungen

- Product Compare: Products OverviewDokument2 SeitenProduct Compare: Products Overviewjinyuan74Noch keine Bewertungen

- Ball ValveDokument12 SeitenBall ValvemohamedfirozNoch keine Bewertungen

- Loc TiteDokument2 SeitenLoc Titejinyuan74Noch keine Bewertungen

- Lewis Oilfield ProductsDokument4 SeitenLewis Oilfield Productsjinyuan74Noch keine Bewertungen

- 1907 - T - CardDokument1 Seite1907 - T - Cardjinyuan74Noch keine Bewertungen

- ARMOR Winter-Spring 2018 EditionDokument84 SeitenARMOR Winter-Spring 2018 Editionmai100Noch keine Bewertungen

- As 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsDokument6 SeitenAs 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsSAI Global - APACNoch keine Bewertungen

- Gates em Ingles 2010Dokument76 SeitenGates em Ingles 2010felipeintegraNoch keine Bewertungen

- FEM Lecture Notes-2Dokument18 SeitenFEM Lecture Notes-2macynthia26Noch keine Bewertungen

- Fundamentals of Marketing NotebookDokument24 SeitenFundamentals of Marketing NotebookMorrisa AlexanderNoch keine Bewertungen

- Defect Prevention On SRS Through ChecklistDokument2 SeitenDefect Prevention On SRS Through Checklistnew account new accountNoch keine Bewertungen

- ASCE - Art Competition RulesDokument3 SeitenASCE - Art Competition Rulesswarup babalsureNoch keine Bewertungen

- Digital Booklet - Bach ConcertosDokument14 SeitenDigital Booklet - Bach Concertosppopgod33% (3)

- Supplier Quality Requirement Form (SSQRF) : Inspection NotificationDokument1 SeiteSupplier Quality Requirement Form (SSQRF) : Inspection Notificationsonnu151Noch keine Bewertungen

- Credentials List with Multiple Usernames, Passwords and Expiration DatesDokument1 SeiteCredentials List with Multiple Usernames, Passwords and Expiration DatesJOHN VEGANoch keine Bewertungen

- Chill - Lease NotesDokument19 SeitenChill - Lease Notesbellinabarrow100% (4)

- 5.0 A Throttle Control H-BridgeDokument26 Seiten5.0 A Throttle Control H-Bridgerumellemur59Noch keine Bewertungen

- Ieee Research Papers On Software Testing PDFDokument5 SeitenIeee Research Papers On Software Testing PDFfvgjcq6a100% (1)

- Jurisdiction On Criminal Cases and PrinciplesDokument6 SeitenJurisdiction On Criminal Cases and PrinciplesJeffrey Garcia IlaganNoch keine Bewertungen

- Fundamental of Investment Unit 5Dokument8 SeitenFundamental of Investment Unit 5commers bengali ajNoch keine Bewertungen

- Fabric Bursting StrengthDokument14 SeitenFabric Bursting StrengthQaiseriqball100% (5)

- Sta A4187876 21425Dokument2 SeitenSta A4187876 21425doud98Noch keine Bewertungen

- Rebranding Brief TemplateDokument8 SeitenRebranding Brief TemplateRushiraj Patel100% (1)

- 9 QP - SSC - MOCK EXAMDokument5 Seiten9 QP - SSC - MOCK EXAMramNoch keine Bewertungen

- Operation Roman Empire Indictment Part 1Dokument50 SeitenOperation Roman Empire Indictment Part 1Southern California Public RadioNoch keine Bewertungen

- Philippine Architecture, Film Industry EvolutionDokument4 SeitenPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelNoch keine Bewertungen

- 50TS Operators Manual 1551000 Rev CDokument184 Seiten50TS Operators Manual 1551000 Rev CraymondNoch keine Bewertungen

- Compressive Strength Beam DesignDokument70 SeitenCompressive Strength Beam DesignDjuned0% (1)

- Planning For Network Deployment in Oracle Solaris 11.4: Part No: E60987Dokument30 SeitenPlanning For Network Deployment in Oracle Solaris 11.4: Part No: E60987errr33Noch keine Bewertungen

- Sample Property Management AgreementDokument13 SeitenSample Property Management AgreementSarah TNoch keine Bewertungen

- Binaural Recording Technology: A Historical Review and Possible Future DevelopmentsDokument22 SeitenBinaural Recording Technology: A Historical Review and Possible Future DevelopmentsNery BorgesNoch keine Bewertungen

- Employee Central Payroll PDFDokument4 SeitenEmployee Central Payroll PDFMohamed ShanabNoch keine Bewertungen

- 01 Automatic English To Braille TranslatorDokument8 Seiten01 Automatic English To Braille TranslatorShreejith NairNoch keine Bewertungen

- Tata Group's Global Expansion and Business StrategiesDokument23 SeitenTata Group's Global Expansion and Business Strategiesvgl tamizhNoch keine Bewertungen

- Dairy DevelopmentDokument39 SeitenDairy DevelopmentHemanth Kumar RamachandranNoch keine Bewertungen