Beruflich Dokumente

Kultur Dokumente

ABCS of Fire Alarm Part 13

Hochgeladen von

doclap75Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ABCS of Fire Alarm Part 13

Hochgeladen von

doclap75Copyright:

Verfügbare Formate

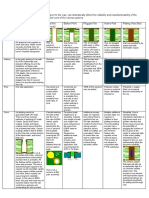

The ABCs of Fire Alarm Systems - Part XIII

Compatibility

By Anthony J. Shalna 2009 Principal IMSA Representative to the Automatic Fire Alarm Association

President: Southeastern Signalmen of Massachusetts

Retired Approvals Manager: Gamewell-FCI by Honeywell

Establishment of compatibility is a

necessity in fire alarm systems. A

simple comparison of voltage and

current draws is insufficient in determining if a piece of equipment

is suitable for use with various fire

alarm systems. With the advent of

microprocessor based equipment

and digital communications, signaling protocol becomes a major factor.

For example, a monitor module

made by a manufacturer will be

programmed for use with certain

protocol. Substituting a physically

identical module with different

protocol will not necessarily operate properly within the fire alarm

system. Different fire alarm manufacturers operate with different

protocol. Therefore substituting a

physically similar module may appear to be workable in a quiescent

condition, but there is a substantial

chance that the module may not

supervise itself or properly signal

an alarm condition.

Compatibility Requirements

This area is often misunderstood

and can present a serious problem.

Establishment of compatibility is

required for 2-wire smoke sensors/

detectors, electronic initiating devices/sensors, addressable monitor

and control modules, notification

appliances, and releasing solenoids.

4-wire smoke detectors are in the

process of being included since

some panel power supplies have

been found to supply voltages outside the operating limits of these

detectors.

Each panel manufacturer issues an

NRTL listed/approved compatibility document that lists the devices

that are compatible with his corresponding control panel. The panel

Installation/Operating Manual

could also contain this informaPage 34

IMSA Jul Aug 11.indd 34

culations are also involved in determining the capacity of the initiating

circuit as to the quantity of detectors

that may be installed on it. The compatibility documents/manuals also

If the device in question is not listed state this information.

in these documents, it is NOT COMA major pitfall of retrofitting is

PATIBLE.

mixing of different quantities of

If the installer intends to re-use ex- different models or brands of 2-wire

isting 2-wire smoke detectors, the detectors in the same circuit. Unless

existing detectors must be listed in this combination is listed in an NRTL

document, any mixing of models/

the compatibility document.

brands would violate the listing. No

one can predict what combination of

models/brands/quantities would

work properly. Only a qualified test

laboratory could verify that.

tion. A smoke sensor manufacturer

may also publish a compatibility

document that is NRTL listed/approved.

Compatibility

Requirements

This area is often

misunderstood

and can present a

serious problem.

Compatibility for 2-wire conventional smoke detectors is not simply

a matter of comparing current ratings of the detectors and initiating

circuits. Unlike a contact device

that places a short circuit across the

initiating device circuit, the 2-wire

detector, when it goes into alarm,

presents an impedance across the

circuit that is low enough to place

the circuit into alarm, but not too

low to prevent enough current to

hold the detector in alarm, keep

the indicating LED lit, etc. This depends on the area of intersection of

response curves of both the detector

and initiating circuit. All these cal-

Another area affecting compatibility

is smoke level compensation. New

generation of microprocessor-based

detectors have the ability to adjust

their own sensitivity to compensate

for dirt build-up in the detector or

gradual changes in the ambient

environment. Re-installation of

compensated detectors could result

in unwanted alarms and subsequent

frustration by the building owner.

Sometimes a smoke detector manufacturer will purchase control panels

on the open market, test his detectors

with these panels, have the results

verified by an NRTL, and publish

the information in his own document. If you choose to use devices

listed in a document published by a

smoke sensor manufacturer rather

than by the panel manufacturer, be

aware of a possible problem. The

panel manufacturer will assume no

responsibility if the devices are not

listed in his own document, since

the detectors, by others werent

furnished by him, or havent been

tested by him. The reasoning here

is the panel manufacturer has nothContinued on page 36

IMSA Journal

5/19/11 1:41:25 PM

Continued from page 34

The ABCs of Fire Alarm Systems Part XIII . . . Continued

from page 34

ing to gain and everything to lose by allowing installation of a product not sold by him. Also, since the

panels tested were purchased on the open market by

the detector manufacturer, there is a possibility that

the individual tested panel may have been damaged,

improperly stored, or is from a production run that

exhibited quality assurance problems, etc. This could

eventually result in litigation that would only be settled

in the courts.

No requirements have yet been established regarding

the useful life of smoke sensors, but the National Fire

Alarm and Signaling Code, NFPA 72, calls for reacceptance testing when equipment is replaced, etc. Components age with time, filter screens may become clogged

or partially clogged, materials

become brittle with age, etc. Plan

on replacing any smoke sensors

that fail the reacceptance test.

Also, remember the big question:

How many computers or cell

phones do you use that are as old

as these detectors?

Notification Appliances

These devices sound straightforward and far less complicated than

sensor installations, but the latest

panels, depending on line voltage

extremes and tolerance build-up,

may present operating voltages

that range outside those of the

notification appliances.

IMSA Jul Aug 11.indd 36

Until recently, some jurisdictions have required that,

after an alarm and before system reset, that the audible

signals be silenced, but the strobes must continue to

flash. Its now being presented to them that, to a hearing impaired person, a flashing strobe is an evacuation

signal. Therefore, this regulation is in conflict with the

codes.

Manual Pull Stations

Pull stations in microprocessor-based systems likewise

are involved in the signaling protocol requirement.

In Short . . .

Compatibility could

become a real

problem, especially

in retrofits.

The ADA requires synchronization of flashes for strobe

lights under most conditions, always wherever more

than one strobe is observable at the same time. This is

due to the fact that certain rapid flash rates have been

known to cause epileptic seizures in persons prone to

this affliction. Older installations may have to be reengineered with this requirement in mind.

Page 36

Current ADA requirements may also affect mounting

heights of appliances, so existing appliances may have

to be relocated.

In addition, with existing conventional pull stations, even

though protocol is not an issue,

older stations may not conform

to Americans with Disabilities Act

(ADA) requirements in regard to

the maximum force required to

operate the station, and mounting heights. Previously it was felt

that a higher mounting height

would discourage malicious

alarms by putting them out of

reach of smaller children, but

ADA requirements require location of stations at a lower height

that could be easier to reach by

an individual in a wheel chair.

In short, compatibility could become a real problem,

especially in retrofits. This adds more importance to

having certified personnel performing the planning

and supervision of the installation.

IMSA Journal

5/19/11 1:41:27 PM

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- DB9 Pin 2 Receive To TX1 Pin 3 To rx1 Pin5 To ComDokument1 SeiteDB9 Pin 2 Receive To TX1 Pin 3 To rx1 Pin5 To Comdoclap75Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Community Newspaper: Extell's Racist Development Would Make Lower East Side Home To The 1%Dokument4 SeitenCommunity Newspaper: Extell's Racist Development Would Make Lower East Side Home To The 1%doclap75Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- NTC Brown Book: Fire Alarm Design and InstallationDokument478 SeitenNTC Brown Book: Fire Alarm Design and Installationdoclap7589% (19)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- ABCS of Fire Alarm Part 5Dokument2 SeitenABCS of Fire Alarm Part 5doclap75Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The ABC's of Fire Alarm Systems-Sec 1Dokument4 SeitenThe ABC's of Fire Alarm Systems-Sec 1Akaka321Noch keine Bewertungen

- ABCS of Fire Alarms Part 2Dokument3 SeitenABCS of Fire Alarms Part 2doclap75Noch keine Bewertungen

- ABCS of Fire AlarmPart 8Dokument2 SeitenABCS of Fire AlarmPart 8doclap75Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- RF Interfacing With 8051 FriendlyDokument14 SeitenRF Interfacing With 8051 Friendlysrinu5890% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- M08 Domestic ApplianceDokument94 SeitenM08 Domestic AppliancebilisummaaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- UA78S40Dokument7 SeitenUA78S40Sreerag Kunnathu SugathanNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- BMI BRG-100RF X-Ray - Circuit Diagrams PDFDokument68 SeitenBMI BRG-100RF X-Ray - Circuit Diagrams PDFeduardoNoch keine Bewertungen

- Bearing Embedment RTD: Features / BenefitsDokument1 SeiteBearing Embedment RTD: Features / BenefitscaseyNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Rr210504-Linear and Digital Ic ApplicationsDokument1 SeiteRr210504-Linear and Digital Ic ApplicationssivabharathamurthyNoch keine Bewertungen

- Kokm For Gis - 1vlc000609 Rev.4, enDokument24 SeitenKokm For Gis - 1vlc000609 Rev.4, enTetianaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Datasheet 2Dokument10 SeitenDatasheet 2miguel angel jaramilloNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- 1SDC007408G0201 - WP Ats 021 022 enDokument36 Seiten1SDC007408G0201 - WP Ats 021 022 enSemih GençNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Stinger GuideDokument13 SeitenStinger GuidejrfjNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- PAT America, Inc.: Operator'S / Service ManualDokument42 SeitenPAT America, Inc.: Operator'S / Service Manualgrineldo84Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Test Specification Number 5Dokument9 SeitenTest Specification Number 5tugba.yilmazNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Circuitrix EventDokument6 SeitenCircuitrix EventNikhil KumarNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Pid Proton PDFDokument27 SeitenPid Proton PDFfeyyazkurtNoch keine Bewertungen

- Advanced Data Communication For M.tech Communication SystemsDokument1 SeiteAdvanced Data Communication For M.tech Communication Systemssrinath02Noch keine Bewertungen

- Cell Site DesignDokument37 SeitenCell Site DesignRina Dwi YunitasariNoch keine Bewertungen

- Project Report On Maximum Power Transfer TheoremDokument28 SeitenProject Report On Maximum Power Transfer TheoremSwapnil PatilNoch keine Bewertungen

- Vietnam Spectrum Occupancy MeasurementsDokument9 SeitenVietnam Spectrum Occupancy MeasurementslaerciomosNoch keine Bewertungen

- 1A Bipolar Linear Regulator: FeaturesDokument7 Seiten1A Bipolar Linear Regulator: FeaturesFelipe silva santanaNoch keine Bewertungen

- Pages From CIGREDokument8 SeitenPages From CIGREiman tabataba'iNoch keine Bewertungen

- Schneider Clipsal ESM32D20NADokument3 SeitenSchneider Clipsal ESM32D20NAUmer Farooq100% (1)

- Detection of Faults in Gearboxes Using Acoustic Emission Signal PDFDokument8 SeitenDetection of Faults in Gearboxes Using Acoustic Emission Signal PDFHanifNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Sharp 2T-C32BG1X Service ManualDokument74 SeitenSharp 2T-C32BG1X Service ManualA NguyenNoch keine Bewertungen

- خطوات عمل جداول الحسابات Panel SchedulesDokument6 Seitenخطوات عمل جداول الحسابات Panel SchedulesMOAZ ASHRAFNoch keine Bewertungen

- 180.5Mbps-8Gbps DLL-based Clock and Data Recovery Circuit With Low Jitter PerformanceDokument4 Seiten180.5Mbps-8Gbps DLL-based Clock and Data Recovery Circuit With Low Jitter PerformanceMinh KhangNoch keine Bewertungen

- 1-Via and SMask Design Guide4Dokument2 Seiten1-Via and SMask Design Guide4Екатерина КорнееваNoch keine Bewertungen

- Please Note That Cypress Is An Infineon Technologies CompanyDokument37 SeitenPlease Note That Cypress Is An Infineon Technologies CompanyWaldo Perez SolisNoch keine Bewertungen

- Fire Alarm KeshavDokument18 SeitenFire Alarm KeshavPrabhat Prabhat60% (5)

- FlowMaster User Manual V2.0Dokument36 SeitenFlowMaster User Manual V2.0Agus MulyadiNoch keine Bewertungen

- Understanding and Dealing With Ferroresonance: Minnesota Power Systems Conference November 7-9, 2006Dokument10 SeitenUnderstanding and Dealing With Ferroresonance: Minnesota Power Systems Conference November 7-9, 2006MuruganNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)