Beruflich Dokumente

Kultur Dokumente

CIRT, Bhopal Turbomachinery (ME 502) Tutorial/Assignment Sheet 2 (Impulse Turbine)

Hochgeladen von

AnkurTripathi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

111 Ansichten1 SeiteCIRT MECHANICAL

Originaltitel

TURBO 2

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCIRT MECHANICAL

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

111 Ansichten1 SeiteCIRT, Bhopal Turbomachinery (ME 502) Tutorial/Assignment Sheet 2 (Impulse Turbine)

Hochgeladen von

AnkurTripathiCIRT MECHANICAL

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

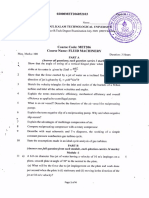

CIRT, Bhopal

Turbomachinery (ME 502)

Tutorial/Assignment Sheet 2 (impulse turbine)

1. Explain the difference between an impulse turbine and a reaction turbine.

2. Give the detailed classification of steam turbines. Why compounding is necessary in

turbines? Discuss 2-stage Curtis with the help of neat sketch.

3. Derive an expression for optimizing blade efficiency in an impulse turbine.

4. What is the condition of maximum blade efficiency in a single stage impulse turbine and

impulse reaction turbine?

5. Show that the maximum value of utilization factor for an axial flow impulse turbine is (single

stage)

, where is the nozzle angle at inlet.

6. Write short notes on (i) velocity and pressure compounding (ii) bleeding.

7. Enlist the advantages of velocity compounded impulse turbine.

8. The following data relates to a single stage impulse turbine: steam velocity = 600 m/s, Blade

speed = 250 m/s, Nozzle angle = 200, Blade outlet angle = 250. Neglecting the effect of

friction, calculate the work developed by the turbine for the steam flow rate of 20 kg/s. Also

calculate the axial thrust on the bearing.

9. Steam issues from a nozzle to a De Laval turbine at a velocity of 1000 m/sec. The nozzle

angle is 200. The mean blade velocity is 400 m/sec. The blades are symmetrical. The mass

flow rate is 1000 kg/hr, friction factor is 0.8, nozzle efficiency is 0.95. Calculate: (i) Blade

angle, (ii) Axial thrust, (iii) W.D./kg, (iv) Power developed, (v) Blade efficiency, (vi) Stage

efficiency.

10. In an impulse turbine the following observations are recorded: steam velocity = 500 m/s,

blade speed = 200 m/s, exit angle of moving blade = 250 measured from tangential direction,

nozzle angle = 200. Neglecting the effect of friction, when passing through blade passages,

calculate (i) inlet angle of moving blade, (ii) exit velocity and direction, (iii) work done per kg

of steam, (iv) blade efficiency.

11. A stage of steam turbine is supplied with steam at a pressure of 50 bar and 350 0C and

exhausts at a pressure of 5 bar. The isentropic efficiency of the stage is 0.82 and steam

consumption is 2270 kg/min. Determine the power output of the stage.

12. The following particulars relate to a two row velocity compounded impulse wheel which forms

the first stage of combination turbine: steam velocity at nozzle outlet = 650 m/s, mean blade

velocity = 125 m/s, nozzle outlet angle = 160, outlet angle first row of moving blade = 180,

outlet angle of fixed guide blade = 220, outlet angle of second row of moving blades = 360,

steam flow per second = 2.5 kg/s. The ratio of the relative velocity at outlet to that at inlet is

0.84 for all blades. Determine for each row of moving blades (i) the velocity of whirl, (ii) the

tangential thrust on the blades, (iii) the axial thrust on the blades, (iv) the power developed.

13. The blade speed of a single ring of impulse blading is 300 m/s and the nozzle angle is 200.

The isentropic heat drop is 473 kJ/kg and the nozzle efficiency is 0.85. Given that the blade

velocity coefficient is 0.7 and the blades are symmetrical, calculate for a unit mass of steam

(i) axial thrust on the bearing (ii) steam consumption per kW if the mechanical efficiency is

90%.

14. The mean diameter of the blade of an impulse turbine with a single row wheel is 105 cm and

the speed is 3000 rpm. The nozzle angle is 180, the ratio of the blade velocity to steam

velocity is 0.42 and the ratio of the relative velocity at outlet from the blades to that at inlet is

0.84. The outlet angle of the blade is to be made 30 less than the blade angle at inlet. The

steam flow is 8 kg/s. Draw the velocity diagram for the blades and calculate the following (i)

velocity of whirl, (ii) resultant thrust on blades, (iii) tangential thrust on the blade, (iv) axial

thrust on bearing, (v) blade angles, (vi) power developed on the blades, and (v) blade

efficiency.

15. At a stage of an impulse turbine, the mean blade diameter is 75 cm, rotational speed 3500

rpm. The absolute velocity of fluid discharging from a nozzle inclined at 200 to the plane of

wheel is 275 m/s. If the utilization factor is 0.9 and the relative velocity at the rotor exit is 0.9

times that at inlet, find the inlet and exit rotor angles. Also find the power output from the

stage for a mass flow rate of 2 kg/s and axial thrust on the shaft.

Das könnte Ihnen auch gefallen

- Etrade Bank-StatementDokument5 SeitenEtrade Bank-StatementMark Galanty100% (4)

- Manual of Avionics PDFDokument300 SeitenManual of Avionics PDFJhony BhatNoch keine Bewertungen

- Aesa Vs PesaDokument30 SeitenAesa Vs Pesakab11512100% (1)

- Understanding Terrorism and Political Violence PDFDokument304 SeitenUnderstanding Terrorism and Political Violence PDFmihaela buzatuNoch keine Bewertungen

- Missouri Department of Transportation: Standard Inspection and Testing Plan (ITP)Dokument32 SeitenMissouri Department of Transportation: Standard Inspection and Testing Plan (ITP)mohamedamine.zemouriNoch keine Bewertungen

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationVon EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNoch keine Bewertungen

- Classical Electromagnetism 1st Edition Franklin Solutions ManualDokument21 SeitenClassical Electromagnetism 1st Edition Franklin Solutions ManualBrianYorktnqsw100% (15)

- Activity Diagram Airline Reservation System PDFDokument4 SeitenActivity Diagram Airline Reservation System PDFAnonymous zSn6IALuabNoch keine Bewertungen

- Design and Analysis of Centrifugal CompressorsVon EverandDesign and Analysis of Centrifugal CompressorsNoch keine Bewertungen

- Steam Turbine ProblemsDokument6 SeitenSteam Turbine ProblemsAkash Bhange80% (5)

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 2 (Impulse Turbine)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 2 (Impulse Turbine)AnkurTripathiNoch keine Bewertungen

- Unit 5Dokument3 SeitenUnit 5Rohit GhulanavarNoch keine Bewertungen

- THERMO FLUID ENGINEERING - Assignment - 02Dokument1 SeiteTHERMO FLUID ENGINEERING - Assignment - 02sameershaik16797Noch keine Bewertungen

- Wa0027.Dokument2 SeitenWa0027.Md. SunmunNoch keine Bewertungen

- Tut6 PDFDokument2 SeitenTut6 PDFmanish guptaNoch keine Bewertungen

- Assignment TMDokument3 SeitenAssignment TMBeesam Ramesh KumarNoch keine Bewertungen

- TM AssignmentDokument2 SeitenTM Assignmentsanjay kushwahNoch keine Bewertungen

- BE 2019 TurbomachinaryDokument5 SeitenBE 2019 TurbomachinarySuyash Shinde.Noch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)AnkurTripathiNoch keine Bewertungen

- Propulsion Ii Question BankDokument13 SeitenPropulsion Ii Question BankSathya NarayananNoch keine Bewertungen

- Assignment I 3rd RegularDokument2 SeitenAssignment I 3rd RegularRoha EngineeringNoch keine Bewertungen

- Page 1 of 3Dokument3 SeitenPage 1 of 3yashvantNoch keine Bewertungen

- Coaching - I TEDokument2 SeitenCoaching - I TEtagoreboopathyNoch keine Bewertungen

- Mechanical Engineering DepartmentDokument1 SeiteMechanical Engineering DepartmentAMIT PRAJAPATINoch keine Bewertungen

- Assignment 7Dokument1 SeiteAssignment 7sujit kcNoch keine Bewertungen

- Session 16 Turbine Blading Session 16 Turbine BladingDokument25 SeitenSession 16 Turbine Blading Session 16 Turbine BladingColin SchneiderNoch keine Bewertungen

- Sheatpoweer Steam Turbine22Dokument3 SeitenSheatpoweer Steam Turbine22Omeed ArtsNoch keine Bewertungen

- R7320306 Thermal Engineering - IIDokument1 SeiteR7320306 Thermal Engineering - IIsivabharathamurthyNoch keine Bewertungen

- Ajay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringDokument3 SeitenAjay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringMradul GuptaNoch keine Bewertungen

- AE321-Tutorial 7Dokument3 SeitenAE321-Tutorial 7Hritik singh parmarNoch keine Bewertungen

- AssignmentDokument2 SeitenAssignmentAnirudh MuraliNoch keine Bewertungen

- Tutorial Sheet No 5 https://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7Dhttps://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7Dhttps://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7Dhttps://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7DDokument1 SeiteTutorial Sheet No 5 https://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7Dhttps://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7Dhttps://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7Dhttps://www.scribd.com/archive/plans?doc=37188066&metadata=%7B"context"%3A"archive"%2C"page"%3A"read"%2C"action"%3A"toolbar_download"%2C"platform"%3A"web"%2C"logged_in"%3Atrue%7DعبدالرحمنكركوكيNoch keine Bewertungen

- ATD Tutorial 3Dokument2 SeitenATD Tutorial 3Dheeraj PatelNoch keine Bewertungen

- Assignment 4-1Dokument2 SeitenAssignment 4-1ashutoshNoch keine Bewertungen

- TM 1Dokument4 SeitenTM 1Ketan JoshiNoch keine Bewertungen

- Propulsion 1 Unit-V Question Bank (Compressors)Dokument4 SeitenPropulsion 1 Unit-V Question Bank (Compressors)kevintsubasa0% (2)

- Impulse Turbine Questions g3Dokument8 SeitenImpulse Turbine Questions g3VipulKukkarNoch keine Bewertungen

- Assignment Questions ME603 (A) TurbomachineryDokument2 SeitenAssignment Questions ME603 (A) Turbomachineryगौरव साहूNoch keine Bewertungen

- Practice ProblemsDokument2 SeitenPractice Problemsk2kkhanna105Noch keine Bewertungen

- ATD UNIT 3 & 4 AssignmentsDokument4 SeitenATD UNIT 3 & 4 AssignmentsOm PrakashNoch keine Bewertungen

- Turbomachines Jan 2014Dokument2 SeitenTurbomachines Jan 2014Prasad C M100% (1)

- Rr312405 Thermal Engineering IIDokument8 SeitenRr312405 Thermal Engineering IISrinivasa Rao GNoch keine Bewertungen

- Chapter 4-Power Turbines 5Dokument20 SeitenChapter 4-Power Turbines 5Abdullatif AlOmair100% (1)

- 7ADC8292A41A4EB196A3FFDEE99589FDDokument4 Seiten7ADC8292A41A4EB196A3FFDEE99589FDyashvantNoch keine Bewertungen

- Assignment IIDokument3 SeitenAssignment IIPawan SubediNoch keine Bewertungen

- Met206 Fluid Machinery, July 2021Dokument4 SeitenMet206 Fluid Machinery, July 2021AkashNoch keine Bewertungen

- Muzeyin FocusDokument3 SeitenMuzeyin FocuseyobNoch keine Bewertungen

- 9A03501 Thermal Engineering IIDokument4 Seiten9A03501 Thermal Engineering IIsivabharathamurthyNoch keine Bewertungen

- Late Submission Is Strictly Not PermittedDokument2 SeitenLate Submission Is Strictly Not PermittedChandru ANoch keine Bewertungen

- Assignment and WorksheetDokument2 SeitenAssignment and WorksheetAbebe AyingdaNoch keine Bewertungen

- Fluid MachinesDokument14 SeitenFluid MachinesNishankzattNoch keine Bewertungen

- Unit 2Dokument2 SeitenUnit 2sarathkumararasu007Noch keine Bewertungen

- Assignment 5Dokument2 SeitenAssignment 5harsh gargNoch keine Bewertungen

- 9A01308 Fluid Mechanics and Hydraulic MachineryDokument4 Seiten9A01308 Fluid Mechanics and Hydraulic MachinerysivabharathamurthyNoch keine Bewertungen

- Me2301 QBDokument7 SeitenMe2301 QBbalajigandhirajanNoch keine Bewertungen

- Internal-II Question Paper TE - SET-IIDokument2 SeitenInternal-II Question Paper TE - SET-IItagoreboopathyNoch keine Bewertungen

- UNIT 2 (Steam Power Plant)Dokument2 SeitenUNIT 2 (Steam Power Plant)mohd azeemNoch keine Bewertungen

- Problem Set ADokument3 SeitenProblem Set AAldrich BaldonadoNoch keine Bewertungen

- Tutorial: 6: ........... (Degree)Dokument3 SeitenTutorial: 6: ........... (Degree)Rudra Sai SandeepNoch keine Bewertungen

- Turbo MachinesDokument2 SeitenTurbo MachinesDarani PriyaNoch keine Bewertungen

- Fluid Power EngineeringDokument2 SeitenFluid Power EngineeringNilesh Mistry (Nilesh Sharma)Noch keine Bewertungen

- Propulsion II QBDokument14 SeitenPropulsion II QBPavan KishoreNoch keine Bewertungen

- Fpe DBC 5th Sem AssignmentDokument10 SeitenFpe DBC 5th Sem AssignmentJain shahilkumarNoch keine Bewertungen

- MCE 508 Problem SetDokument4 SeitenMCE 508 Problem SetDavid AkinrinolaNoch keine Bewertungen

- Turbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineDokument4 SeitenTurbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineEchebiri Collins100% (1)

- Turbo 3Dokument1 SeiteTurbo 3AnkurTripathiNoch keine Bewertungen

- Tu RBO6Dokument1 SeiteTu RBO6AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 5 (Centrifugal Pump)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 5 (Centrifugal Pump)AnkurTripathiNoch keine Bewertungen

- Tu RBO8Dokument1 SeiteTu RBO8AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 8 (Power Transmitting Turbo Machines)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 8 (Power Transmitting Turbo Machines)AnkurTripathiNoch keine Bewertungen

- Tu RBO8Dokument1 SeiteTu RBO8AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 8 (Power Transmitting Turbo Machines)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 8 (Power Transmitting Turbo Machines)AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 5 (Centrifugal Pump)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 5 (Centrifugal Pump)AnkurTripathiNoch keine Bewertungen

- Tu RBO6Dokument1 SeiteTu RBO6AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 4 (Water Turbine)AnkurTripathiNoch keine Bewertungen

- Turbo 3Dokument1 SeiteTurbo 3AnkurTripathiNoch keine Bewertungen

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 1 (Energy Transfer in Turbo Machines)Dokument1 SeiteCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 1 (Energy Transfer in Turbo Machines)AnkurTripathiNoch keine Bewertungen

- Huawei FusionServer RH2288 V3 Data Sheet PDFDokument2 SeitenHuawei FusionServer RH2288 V3 Data Sheet PDFMartenMattisenNoch keine Bewertungen

- 226-Article Text-601-1-10-20210702Dokument12 Seiten226-Article Text-601-1-10-20210702Leni NopriyantiNoch keine Bewertungen

- Most Essential Learning Competencies English 4: Dagundon Elementary SchoolDokument6 SeitenMost Essential Learning Competencies English 4: Dagundon Elementary SchoolGhie DomingoNoch keine Bewertungen

- Pro Tester ManualDokument49 SeitenPro Tester ManualRobson AlencarNoch keine Bewertungen

- Chapter Two Sector Analysis: (MBAM)Dokument23 SeitenChapter Two Sector Analysis: (MBAM)Ferlyn PelayoNoch keine Bewertungen

- 3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectDokument3 Seiten3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectShehbaz ThakurNoch keine Bewertungen

- Term Paper On Strategic ManagementDokument8 SeitenTerm Paper On Strategic Managementea7j5ys3100% (1)

- Stylus - Pro - 4400 201 300 (067 100)Dokument34 SeitenStylus - Pro - 4400 201 300 (067 100)Joso CepuranNoch keine Bewertungen

- Toyota Motor Manufacturing (TMM)Dokument20 SeitenToyota Motor Manufacturing (TMM)Lekha ShahNoch keine Bewertungen

- Cellular Respiration MDL361Dokument46 SeitenCellular Respiration MDL361Krystal CraigNoch keine Bewertungen

- Fragility Curves For Mixed Concrete-Steel Frames Subjected To SeismicDokument5 SeitenFragility Curves For Mixed Concrete-Steel Frames Subjected To SeismicJulián PovedaNoch keine Bewertungen

- SeptalkanDokument5 SeitenSeptalkanReniNoch keine Bewertungen

- BFC+43103. 1213 SEM1pdfDokument19 SeitenBFC+43103. 1213 SEM1pdfAdibah Azimat100% (1)

- Bioinformatics Computing II: MotivationDokument7 SeitenBioinformatics Computing II: MotivationTasmia SaleemNoch keine Bewertungen

- Eng Essay For PresentationDokument8 SeitenEng Essay For Presentationctn batrisyiaNoch keine Bewertungen

- Mindfulness For Two An Acceptance and Commitment TDokument5 SeitenMindfulness For Two An Acceptance and Commitment TNilton SantosNoch keine Bewertungen

- Methley Railway Station: A Proposal To The Department For Transport.Dokument38 SeitenMethley Railway Station: A Proposal To The Department For Transport.Rt Hon. Alec Shelbrooke, M.P.0% (1)

- Unit 9: Cities of The World I. ObjectivesDokument4 SeitenUnit 9: Cities of The World I. ObjectivesTrang Hoang NguyenNoch keine Bewertungen

- Slot 22-23-24 Real Time CommunicationDokument50 SeitenSlot 22-23-24 Real Time CommunicationLinh BuiNoch keine Bewertungen

- Lean ConstructionDokument37 SeitenLean ConstructionMohamed Talaat ElsheikhNoch keine Bewertungen

- Problems Involving Sequences: Grade 10Dokument9 SeitenProblems Involving Sequences: Grade 10Jhiemalyn RonquilloNoch keine Bewertungen

- Audio Level Meter - ProjectDokument4 SeitenAudio Level Meter - ProjectMircea PanzariuNoch keine Bewertungen