Beruflich Dokumente

Kultur Dokumente

Art:10 1007/BF02472669

Hochgeladen von

Tarek ChikerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Art:10 1007/BF02472669

Hochgeladen von

Tarek ChikerCopyright:

Verfügbare Formate

Materials and Structures, 1992, 25, 2 8 4 - 2 9 2

Water absorption in cover concrete

L. J. PARROTT

British Cement Association, Wexham Springs, Slough SL3 6PL, UK

Measurements of initial water absorption are reported for concretes exposed indoors or

outside for 1.5 years. Water absorption after a 9iven wettin9 time was increased with an

increase of water/cement ratio, a reduction of moist curin9 and partial replacement of the

Portland clinker component of the cement. Absorption after outdoor exposure was less than

that after laboratory exposure, especially if rain could fall on the concrete surface. Absorption

results correlated approximately with weight losses durin9 initial exposure and with

compressive strengths at the start of exposure. There was a near-linear relationship between

carbonation depths and absorption measured in cover concrete after 1.5 years of exposure

1. I N T R O D U C T I O N

The rate at which water is absorbed into concrete by

capillary suction can provide useful information relating

to the pore structure, permeation characteristics and

durability of the concrete surface zone that is penetrated

[1-18]. Water absorption tests on concrete can be

conducted in the laboratory, normally using specimens

dried in a standard way, or in the field.

In the laboratory the penetration depth after various

periods of wetting can be determined by direct observation

on split specimens [14], nuclear magnetic resonance

imaging [19] or by deduction based upon measured

specimen weight gains and a measured value of porosity

(e.g. [16]). The depth of water penetration usually

increases linearly with the square root of wetting time in

many porous materials, provided that porosity and initial

moisture content are uniform throughout the test

specimen [20]. The slope of this linear plot is termed

sorptivity [t2,14,16] and its units are m s -1/2. The term

sorptivity has also been used to describe the slope for

plots of volume (or weight) of water imbibed per unit

area of wetted surface versus square root of wetting time,

but the term 'absorption rate' is preferred in these cases.

It is worth noting that calculations of the depth of water

penetration from the weight or volume of water imbibed

involve the assumptions that porosity does not vary with

depth and that water penetrates as a sharp liquid front.

These assumptions are only approximations of reality in

a material like concrete [1,2,8,10,19-21]. A further

problem associated with laboratory testing is that the

method of drying can significantly affect the relative

values of absorption rate that are obtained. For example

drying to constant weight at either 105 or 50~ gave

relative values for various concretes that were quite

different to the relative values obtained by drying at 20~

[22,23]. Also differences of absorption rate between

concretes were less marked when drying to constant

weight at elevated temperature was used.

Under practical exposure conditions the moisture

conditions and pore structure in concrete will vary with

0025-5432/92 (~ RILEM

age and with depth from an exposed surface (e.g.

[1,21,24,25]): hydration of cement can be restricted in

cover concrete and the average capillary porosity can be

higher than that of the interior concrete. Carbonation

will normally cause a counterbalancing reduction of

capillary porosity in the outer layers of cover concrete

(e.g. [21,26]). Thus it is evident that a linear relationship

between absorption depth and the square root of wetting

time may not be obtained under field conditions. The

problem is compounded when the amount of water

required to saturate the test volume is indeterminate and

when the geometry of the wetted volume is not well

defined, e.g. when a selected region of a concrete surface

is wetted [-9,27]. It is then more appropriate to report

test results in terms of the water absorbed per unit area

wetted for given wetting times. It could be argued that

such results are equally or more relevant than sorptivity

to comparisons of field performance for concretes

subjected to periodic wetting by rain or immersion.

RILEM Recommendation 11.2 suggests that both the

weight of absorbed water and the depth of penetration

should be reported [28]. It should be noted that samples

of equal sorptivity will have different absorption rates if

they differ in porosity.

Most publications dealing with water absorption in

concrete are concerned with samples that have been

oven-dried to constant weight. In contrast, this report

investigates water absorption in concretes that have been

dried under more realistic conditions. The test specimens

were uniaxially dried at normal temperatures and natural

carbonation was permitted. All specimens were exposed

for 1.5 years, either indoors or outside, prior to uniaxial

water absorption measurements. The main experimental

variables were exposure conditions, water/cement ratio,

initial curing and replacement of Portland cement with

pulverized fuel ash, ground granulated blast-furnace slag

or limestone filler.

Water absorption is particularly relevant to concrete

durability: freeze-thaw damage, sulphate attack, disruptive alkali-aggregate expansion, chloride ingress and

reinforcement corrosion can be stimulated by water

Materials and Structures

absorption, while carbonation will be inhibited. In

relation to the control of concrete durability, correlations

between water absorption after prolonged exposure and

results from tests that can be conducted at an early age

are of interest. Thus the test programme included

measurements of initial weight loss during exposure and

of compressive strength. The initial weight loss was a

measure of the emptied porosity in cover concrete that

reflects the combined effects of capillary porosity and the

severity of environmental drying. Compressive strength

at the start of exposure was an indirect indication of the

initial porosity of the cement paste matrix in cover

concrete. Compressive strength at the start of exposure

is not regarded as being fundamentally related to water

absorption and it clearly cannot reflect any change of

moisture conditions or pore structure during exposure.

Correlations between carbonation depth and water

absorption are also reported because in situ absorption

results may be used to assess the condition and future

performance of existing structures (e.g. [4,5,9]).

2. E X P E R I M E N T A L P R O C E D U R E

The reported work examines the effects of five exposure

conditions, five water/cement ratios, three periods of

moist curing and four cements upon water absorption:

the 30 combinations of these variables that were used in

the experimental programme are summarized in Table 1.

Workability of the concrete was measured 10 min after

the start of mixing; slump values were normally in the

range 10 to 30 mm. Weight changes of the test specimens

were monitored during the 1.5 year exposure period, and

carbonation depths were determined on the test specimens

immediately after completion of the absorption tests.

Carbonation depths were also measured on similar

companion specimens after a six-month exposure period.

Compressive strengths were measured on saturated,

100 mm cubes at ages of 1 day, 3 days, 28 days and 1.5

years. The cements used were blended from the materials

detailed in Table 2. Table 3 indicates the blend

proportions and the cement types according to draft ENV

197 [29].

The test specimens for the absorption and carbonation

tests were 100 mm cubes sealed against moisture exchange

on five faces. Sealing was accomplished firstly by applying

a bituminous waterproofing coat to the concrete; this

acted as an adhesive for the aluminium foil water-vapour

barrier. The final stage of sealing involved wrapping with

self-adhesive, weatherproof plastic tape to give mechanical

protection to the foil vapour barrier. The test specimens

were cured at 100% relative humidity and 20~ in their

moulds up to an age of 24 h. Subsequent moist curing

involved storage in sealed conditions at 20~ (without

loss or gain of moisture). The laboratory conditions

during exposure were 58 + 3% relative humidity and

20 _+ I~ Specimens exposed outside were stored on an

exposure site in South East England. Meteorological data

for the area indicated that relative humidities, tempera-

285

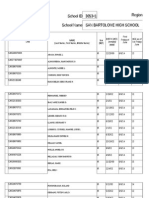

Table l Data for each test series a

Series

Water/ Cement Length Exposure c Cube strength

cement

of cure

(N mm- 2)

ratio b

(days)

End of 28 days

cure

A & L 0.59

C

0.59

E

0.59

B

0.59

D

0.59

F

0.59

G

0.59

H

0.59

I

0.59

M

0.59

N

0.59

O

0.59

P

0.59

Q

0.59

R

0.59

S

0.71

T

0.71

U

0.71

V

0.47

W

0.47

X

0.47

Y

0.83

Z

0.83

1

0.83

2

0.35

3

0.35

4

0.35

5

0.59

6

0.59

opc

pfa

ggbfs

opc

pfa

ggbfs

opc

opc

opc

opc

pfa

ggbfs

opc

pfa

ggbfs

opc

pfa

ggbfs

opc

pfa

ggbfs

opc

pfa

ggbfs

opc

pfa

ggbfs

Filler

Filler

3

3

3

3

3

3

3

3

3

1

1

I

28

28

28

3

3

3

3

3

3

3

3

3

3

3

3

3

3

Lab

Lab

Lab

OS

OS

OS

OV

OH

Office

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

Lab

OS

22.6

13.3

10.0

22.3

13.3

9.8

20.4

21.0

21.0

11.0

5.8

3.0

44.0

28.2

30.7

13.6

7.0

6.6

29.7

20.8

17.2

10.9

5.4

4.9

53.8

34.0

31.2

21.0

20.6

42.1

29.5

33.9

42.8

30.0

33.1

40.5

39.7

41.6

41.7

29.5

30.9

44.0

28.2

30.7

28.5

18.8

21.1

55.0

40.5

46.6

19.6

12.3

16.0

70.8

56.9

60.5

40.7

39.9

a Fine aggregate: Thames Valley sand, 0-5 mm; coarse aggregate: Chertsey irregular gravel, 5-10 mm; fine:coarse aggregate

ratio = 1: 1.5 by weight.

b Free water content of concretes = 188 kg m -3.

c Lab = 60% relative humidity, 20~ OS = outside, concrete

exposed face sheltered; OV = outside, concrete exposed face

vertical; OH = outside, concrete exposed face horizontal.

tures and rain fall were typically in the ranges 58 to 90%,

6 to 21~ and 40-70 mm per month, respectively.

An indoor office exposure was also used where relative

humidity was not controlled and the temperature was

normally between 15 and 25~ The long-term trends of

relative humidity within a 15 mm surface layer of concrete

were as follows [30]:

Laboratory

Office

Outside sheltered from

rain

Outside vertical exposed

surface

Outside horizontal exposed

surface

Steady drop to 58%

Steady drop to 45%

Fluctuated between 70 and

85%

Fluctuated between 80 and

95%

Fluctuated between 85 and

100%

286

Parrott

3. RESULTS AND D I S C U S S I O N

Table 2 Analyses of materials used in cements

F

(limestone

filler)

Composition (wt%):

SiO2

2.5

A1203

0.3

Fe203

0.1

CaO

54.1

MgO

SO 3

0.04

K 2 0 (total)

Insoluble

residue

LOI

Free lime

Apparent

particle density

(kg m - 3)

SSA (m 2 kg -1)

Residue (%):

45 I~m

150 lam

90 ~_m

0.05

42.5

-

P

(Portland

cement)

A

S

(pulverized (ground

fly ash)

granulated

blastfurnace

slag)

20.3

5.02

3.23

64.8

1.30

2.96

47.7

26.6

9.1

1.7

1.3

0.8

0.86

1.19

3.4

-

1.59

2.06

5.8

-

0.55

-

34.5

12.6

0.6

41.6

6.9

0.81

sulphide

0.68

0.43

2700

3110

2400

2920

1180

395

375

455

8.3

-

0.14

-

7.0

-

11.6

1.9

Table 3 Cement types

Cement

name

opc

pfa

ggbfs

Filler

Components by

weight (%)

100% P

70% P + 30% A

50% P + 50% S

95% P + 5% F

ENV 197 cement

Type

Class

CEI

CEIV ~

CEIII

CEI

42.5R

32.5R

42.5

42.5R

Fly ash near 28% limit for CEIIC [29].

Uniaxial wetting was achieved by placing the single

exposed face of the test specimen on a wire grid that was

1 mm below a water surface. Water absorption was

measured after 1, 2, 4, 6, 24 and 30 h of wetting. Wetting

and weight gain measurements were continued until half

of the exposure weight loss was regained. The test

specimens were then oven-dried at 105~ for 18 h prior

to carbonation measurements. The depth of carbonation

was determined by lightly spraying split concrete surfaces

with a phenolphthalein pH indicator solution and

measuring the average depth of the magenta, uncarbonated region using an illuminated magnifier that was fitted

with a measuring graticule. The indicator solution was

prepared by dissolving 5 g of phenolphthalein in 950 ml

of industrial alcohol (95% ethanol + 5% methanol) and

adding 50 ml of distilled water.

Some typical plots of water absorbed versus the square

root of time are illustrated in Fig. 1. None of the tests

yielded a linear relationship and the exponent for a

power-law time function averaged 0.32 rather than 0.5.

The non-linearity in Fig. 1 may be due to moisture and

porosity gradients. Higher moisture contents and lower

porosities with increasing distance from the exposed

surface have been observed in mature, companion

specimens [-24,30] and in other studies (e.g. [1,2]). More

detailed measurements of porosity gradients are planned

in order to clarify their role in controlling the relationship

between the weight of water absorbed and the time of

wetting. The shape of each absorption curve appeared

to be geometrically similar and this observation was

supported by the results shown in Fig. 2. The absorption

after 4 h of wetting was closely and almost linearly related

to the absorption after l h regardless of exposure

condition, water/cement ratio, curing or cement type. The

relationship between the absorption results for 24 and

1 h was more scattered. The range of absorption values

in Fig. 2 are comparable in magnitude to those obtained

by Torrent and Jornet [3]. It may be noted that the water

absorbed after 4 h typically constitutes 15 to 35% of the

water lost during exposure. Thus on average the 4 h value

represents the absorption characteristics of a surface zone

approximately 15 to 35 mm deep, and corresponding

roughly to cover concrete. These depths of penetration

are consistent with other reported data 1-12,14-16,32].

Since the role of cover concrete in controlling durability

is of prime concern, attention will be focused upon

absorption values measured after 4 h of wetting.

Fig. 3 illustrates the effect of water/cement ratio upon

the 4 h absorption value. Absorption increased with

water/cement ratio in agreement with other data

I-3,11,22,23] and a similar pattern was observed for the

ordinary Portland, pulverized fuel ash and ground

granulated blast-furnace slag cements. There was no

evidence to suggest that prolonged exposure encouraged

microstructural development that was especially beneficial to the absorption characteristics of concretes made

with blended cements: the Portland cement concretes

generally exhibited the lowest absorption values at a

given water/cement ratio. The replacement of 5% of the

Portland cement with limestone filler caused a small

increase in absorption.

The effect of exposure condition upon absorption is

shown in Fig. 4. It was evident that absorption was much

smaller in wetter concretes. The effect was particularly

significant where rain could fall upon the exposed

concrete surface. Outdoor exposure with the concrete

sheltered from rain caused only a limited reduction of

absorption relative to the values for laboratory exposure.

The sensitivity of absorption to the moisture condition

of the concrete has also been recognized in other

investigations [13,23,32,33].

The beneficial effects of curing upon the resistance of

concrete to water absorption are demonstrated in Table 4

Materials and Structures

A

tN

287

w/0-0.83,

opt

3 d c u r e , lab

9

w/c-0.59,

pfa

l d c u r e , lab

.Q

w/c=0.59,

opt

l d c u r e , lab

Q

(n

.Q

(. 3

w/c'0.59,

opt

3 d c u r e , lab

2

[]

--~1

opt

w/c-0.59,

[]

3d c u r e , o s h e l t

0

0

50

100

150

200

250

300

S q u a r e root of absorption time ( s89 )

Fig. 1 Examples of water absorption results for a range of experimental conditions.

4 hour absorption

A

(N

24 hour sbsorptlon

~A

==4

A

"t3

O

~3

0

W

..Q

t~

1

O

0.5

1.5

2.5

W a t e r a b s o r b e d after 1 hour ( k g / m 2

Fig. 2 Water absorption after 1, 4 and 24 h of wetting.

1 0 0 % opc

==s

[]

30% pfa

A

50%

ggbfs

[]

o

r- 4

5% limestone

[]

~2

0

W

.Q

[]

,- 1

0

0.3

/k

0

i

0.4

0.5

0.6

0.7

0.8

Free w a t e r / c e m e n t

0.9

ratio by w e i g h t

Fig. 3 Effect of water/cement ratio and cement type upon water absorption after 1.5 years of laboratory exposure (3 days moist

curing).

288

Parrott

4 hour absorption ( kg/m2

2

(XX~

(XX)<

~XX~

~'XX)<

1.5

~/

" /

,,,xx~ k54,x-~

1

0.5

0

KXXN

//.",

KXXN

, /

,vvv

;.'" ." ; ." ]

K./VvN~

KXX~

///-'

, / / /

x;z;z: Kxx~

0

Q.

0

O.

0

Q.

0

"~

0

ID.

,-

>

|

"l~

-~

~

"J

~

0

|

"0

....

//'/i,

, / /,,

CA

.-

el

/ /

to

Q

eO

Q

cO

~L.

6

e,

...i

Exposure condition

Fig. 4 Effect of exposure condition upon water absorption after 1.5 years of exposure (3 days moist curing, 0.59 water/cement ratio).

Table 4 Effects of curing and Portland cement replacement

upon water absorption (kg m-2) after 1.5 years of laboratory

exposure and wetting for various times (0.59 water/cement

ratio)

Moist

100% opc

30% pfa

50% ggbfs

cure

(days)

lh

4h

24h

lh

4h

24h

lh

4h

24h

1

3

28

1.46 2.07 3.58 1.84 2.85 4.71 1.39 2.40 4.70

0.77 1.19 1.99 1.31 1.86 2.70 1.08 1.75 2.97

0.71 1.08 1.88 0.95 1.34 2.09 0.97 1.37 1.92

and are in good agreement with other data [2,12,14,22].

Similar effects of curing were observed for 1, 4 and 24 h

of wetting, even though the different periods correspond

to increasing depths of water penetration. Curing beyond

3 days reduced the absorption levels for concretes made

with pulverized fuel ash or ground granulated blastfurnace slag but for ordinary Portland cement concrete

long-term curing had only a small effect. When Portland

cement was partially replaced with pulverized fuel ash

or ground granulated blastfurnace slag it was necessary

to increase the curing time from 3 to 28 days in order

to achieve similar absorption results; this is consistent

with European code requirements for longer curing

periods when these cements are used at constant

water/cement ratio. The sensitivity of absorption to the

effects of curing has encouraged its use for evaluating the

effectiveness of membranes and sheet materials as

concrete curing aids [34].

The rate of water absorption into cover concrete

should be less in material with finer pores and the results

in Fig. 5 are consistent with this idea if we assume that

finer pores are associated with a lower porosity in the

cover concrete and a lower weight loss during initial

exposure. The results for different water/cement ratios,

exposure conditions, cements and curing periods conform

approximately to a single relationship with the exception

of two results. These two results were for outdoor

exposure where rain could fall on the exposed concrete

surface. The dry conditions during the initial 4 days of

exposure were not representative of the wetter, average

conditions during the 1.5 year exposure period. The

initial, 4 day weight loss was a more sensitive indicator

of long-term absorption performance for the less porous

concretes.

Compressive strength is often regarded as a general

measure of concrete quality. The standard 28-day

strength obviously cannot account for any effect of initial

moist curing, but if absorption is plotted against strength

at the start of exposure then a broad relationship is

obtained (Fig. 6). Analysis of the initial surface absorption

results of Dhir et a l . [22] for oven-dried test specimens

also yielded a broad relationship with compressive

strength at the start of exposure. Fig. 6 shows that

strength is a more sensitive indicator of absorption for

the less porous concretes. The results in Figs 5 and 6

indicate that measurements of weight loss during initial

exposure or strength at the start of exposure could be

used for concrete control purposes in order to avoid concrete with a potential for high levels of water absorption.

Compressive strengths were also determined for

unsealed cubes that were exposed in parallel with the

partially sealed specimens used for absorption and

carbonation tests. To obtain a standard test condition

the cubes were resaturated for 30 min prior to crushing

at an age of 1.5 years. As shown in Fig. 7 this measure

of strength gave a plot against absorption similar in

appearance to that illustrated in Fig. 6 although scatter

was slightly smaller. Possibly the relatively dry conditions

in the unsealed cubes better represented the surface zone

penetrated by water in the absorption test. These results,

coupled with the data in Fig. 6, suggest that differences

of absorption are primarily due to differences between

concretes that are present at the start of exposure.

Materials and Structures

~

O4

289

o p t , lab

0

[]

pfa, lab

v

m

ggbf=, lab

[]

o

4

r-

l i m e s t o n e , lab

0

-=3

All cements, outside

v,.

[]

"O

O

==2

0

m

..Q

~- I

o

A

v

Ii

0.5

15

2.5

W e i g h t loss in f i r s t 4 d a y s of e x p o s u r e ( % )

Fig. 5 Water absorption after 1.5 years of exposure versus weight loss during initial exposure.

o p t , lab

,, 5

to-

[]

pfa, lab

g g b f s , lab

A

[]

l i m e s t o n e , lab

O

[]

--

All c e m e n t s , o u t s i d e

[]

ID

~2

O

w

[]

AN

9 9

O []

0

o

10

20

30

40

50

60

C u b e s t r e n g t h at s t a r t of e x p o s u r e ( M P a )

Fig. 6 Water absorption after 1.5 years of exposure versus cube strength at start of exposure.

"" 6

opc, lab

0

[]

,,~ 5

pfa, lab

(I)

ggbfsT l a b

[]

o 4

l i m e s t o n e , lab

O

[]

All r

[]

0

~2

0

w

0

[]

'-. 1

99

0

0

J-

15

30

~O

45

0

l

60

/k

[]

O

.L~

75

90

S t r e n g t h of c u b e e x p o s e d 1 5 y e a r s ( M P a )

Fig. 7 Water absorption versus cube strength after 1.5 years of exposure.

outside

290

Parrott

25

0.5 yr r

lab

9

0.5 yr 9

"E 2 0

E

1.5 y r r

outside

lab

_o

r

1.5 yr r

15

outside

(3

(3

10

9

9 Qk

(3

(3(3~

e~

(3

~

0

W a t e r absorbed a f t e r 4 hours ( k g / m 2

Fig. 8 Carbonation depths at 0.5 and 1.5 years versus water absorption after 1.5 years of exposure.

The results in Fig. 8 show that the relationship between

carbonation and absorption, both measured 1.5 years

after the start of exposure, is virtually linear and is not

affected greatly by exposure conditions or other experimental factors. The results for carbonation measured

after 6 months exhibited a non-linear relationship with

1.5 year absorption. Further measurements are required

but it seems possible that high water absorption results

could be indicative of high rates of long-term carbonation

and vice versa. The results at the higher levels of

absorption appear to conform approximately to a

square-root time function for carbonation. Rostasy and

Bunte [4-1 suggested that field measurements of absorption

could be used for the prediction of in situ carbonation.

A realistically wide range of experimental conditions

was used for the present tests and therefore some practical

observations seem warranted:

(a) Indications of long-term water absorption performance can be obtained from rapid and convenient

early-age measurements of strength at the start of

exposure or weight loss during initial exposure. They

both account approximately for effects of water/cement

ratio, cement and curing. Clearly the effects of long-term

exposure cannot be accounted for with the strength

measurements, but weight loss data may be useful in this

respect if initial exposure is representative of long-term

exposure.

(b) Carbonation depths could be approximated from

water absorption data.

(c) Field measurements of water absorption in damp

concrete should not necessarily be preceded by attempts

at artificial drying: a measured value of absorption

associated with naturally occurring moisture conditions

seems to be of greater significance for durability

assessment. Parallel arguments could be applied to the

need for unrealistic pre-drying in laboratory absorption

tests.

4. C O N C L U S I O N S

The water absorption measurements on various concretes

exposed for 1.5 years under a range of environmental

conditions led to the following conclusions:

1. Water absorption after a given wetting time was

increased with an increase of water/cement ratio, a

reduction of moist curing time and partial replacement

of the Portland component of the cement with pulverized

fuel ash or ground granulated blastfurnace slag.

2. The 4 hour absorption after outdoor exposure was

less than that after laboratory exposure, especially if rain

could fall on the concrete surface.

3. Absorption results correlated approximately with

weight losses during initial exposure and with cube

strengths at the start of exposure for a wide range of

experimental conditions.

4. There was a near-linear relationship between

carbonation depths and absorption meas.ured in cover

concrete after 1.5 years of exposure for a wide range of

experimental conditions, including different exposure

conditions.

ACKNOWLEDGEMENTS

The conscientious assistance with the experimental

measurements of Mr P. Pearson and other technical staff

at BCA is gratefully acknowledged. This work was

supported by The British Cement Association and U K

cement manufacturers.

REFERENCES

1. Kreijger, P. C., 'Inhomogeneity in concrete and its effect

on degradation: a review of technology', in Proceedings

of Conference on Protection of Concrete, University of

Dundee, September 1990, pp. 32-52.

Materials and Structures

2. Senbetta, E., 'Development of a laboratory technique to

quantify curing quality', Report on Project C-36-65G

(Purdue University, 1981).

3. Torrent, R. J. and Jornet, A., 'The quality of the covercrete

of low-, medium- and high-strength concretes', in

Proceedings of CANM ET/ACI Conference on Durability

of Concrete, Montreal, August 1991, 1142-1161.

4. Rostasy, F. S. and Bunte, D., 'Assessment of durability of

concrete surfaces exposed to weather - measurement

techniques and criteria', in Proceedings of Conference

on Durability of Non-metallic Inorganic Building

Materials, Karlsruhe, October 1988, pp. 101-114.

5. ldem, 'Evaluation of on-site conditions and durability of

concrete panels exposed to weather', in Proceedings of

IABSE Symposium on Durability of Structures, Lisbon,

September 1989, pp. 145-149.

6. Johansson, L., Sundbom, S. and Woltze, K., 'Permeability

Tests and Influence on the Durability of Concrete',

Report 2:89 (Swedish Cement and Concrete Research

Institute, Stockholm, 1989).

7. Bamforth, P. B. and Pocock, D. C., 'Minimizing the risk

of chloride induced corrosion by selection of concreting

materials', in Proceedings of Conference on Corrosion

of Reinforcement in Concrete, Wishaw, May 1990, pp.

119-131.

8. Ballim, Y. and Alexander, M. G., 'Carbonic acid water

attack of Portland cement based matrices', in Proceedings of Conference on Protection of Concrete, University

of Dundee, September 1990, pp. 93-t04.

9. Levitt, M., 'The USAT - A non-destructive test for the

durability of concrete', Br. J. Non-Destr. Testg (July

1971) 106-112.

10. Senbetta, E. and Scholer, C. F., 'A new approach for testing

concrete curing efficiency', ACI J. (January-February

1984) 82-86.

11. Sadegzadeh, M. and Kettle, R., 'Indirect and nondestructive methods for assessing abrasion resistance

of concrete', Mag. Concr. Res. 38(137) (1986) 183190.

t2. Concrete Society Working Party, 'Permeability testing of

site concrete - a review of methods and experience',

Concrete Society Technical Report (1985).

13. Parrott, L. J., 'Influence of environmental parameters upon

permeability: a review', RILEM Technical Committee

116-PCD Report (1990).

14. Ho, D. W. S., Beresford, F. D. and Lewis, R. K., 'Durability

of above ground structures as affected by concrete

constituents', in Proceedings of Conference on Durability

of Building Materials and Components, Espoo, August

1984, Vol. 3, pp. 163-175.

15. Ho, D. W. S. and Lewis, R. K., 'The specification of concrete

for reinforcement protection - performance criteria and

compliance by strength', Cement Coner. Res. 18(4)

(1988).

16. Kelham, S., 'A water absorption test for concrete', Mag.

Coner. Res. 40(143) (1988) 106-110.

17. Moir, G. K. and Kelham, S., 'Durability', in Proceedings of

Seminar on Performance of Limestone-Filled Cements,

Building Research Establishment, November 1989,

Paper No. 7.

18. Thomas, M. D. A., Osborne, G. J., Matthews, J. D. and

-

29I

Cripwell, J. B., 'A comparison of the properties of OPC,

pfa and ggbs concretes in reinforced concrete tank walls

of slender section', Mag. Concr. Res. 42(152) (1990)

127-134.

19. Gummerson, R. J., Hall, C., Hoff, W., Hawkes, R., Holland,

G. and Moore, W., 'Unsaturated water flow within

porous materials observed by NMR imaging', Nature

281 (6 September 1979) 56-57.

20. Hall, C.r

sorptivity of mortars and concretes: a

review', Mag. Coner. Res. 41(147) (1989) 51-61.

21. Parrott, L. J., 'Measurement and modelling of porosity in

drying cement paste', Mater. Res. Soe. Symp. Proc. 85

(1987) 91-104.

22. Dhir, R. K , Hewlett, P. C. and Chart, Y. N., 'Near-surface

characteristics of concrete: assessment and development

of in situ test methods', Mag. Coner. Res. 39(141) (1987)

183-195.

23. Hudd, R. W., 'The effect of moisture content on in situ

permeability readings', in Proceedings of Workshop on

In Situ Measurement of Concrete Permeability, Loughborough University, December 1989.

24. Parrott, L. J., 'Moisture profiles in drying concrete', Adv.

Cement Res. 1(3) (1988) 164-170.

25. Idem, 'Characteristics of surface layers that affect the

durability of concrete', in Proceedings of Engineering

Foundation Conference on Advances in Cement Manufacture and Use, Potosi, July 1988, pp. 137-142.

26. Kropp, J. and Hilsdorf, H. K., 'Influence of carbonation

on the structure of hardened cement paste and water

transport', in Proceedings of International Colloquium

on Materials Science and Restoration, Esslingen, 1983,

pp. 153-157.

27. British Standard 1881: Part 5: 197, 6, 'Test for determining

the initial surface absorption of concrete' (British

Standards Institution, 1970) pp. 27-35.

28. RILEM Technical Committee 14-CPC Recommendation

No. 11.2, 'Absorption of water by capillarity', Mater.

Struct. 7(40) (1974) 295-297.

29. CEN Draft Standard, prENV 197, ' C e m e n t - Composition,

Specifications and Conformity' (June 1989).

30. Parrott, L. J., 'Factors influencing relative humidity in

concrete', to be published; also available as BCA Report

PP/525 (British Cement Association, Wexham Springs,

1990).

31. Chart, K. S. and Tan, T. H., 'Water movement and

durability of concrete structures', in Proceedings of

Fourth International Conference on Durability of

Building Materials and Components, Singapore, 1987,

pp. 404-411.

32. Hall, C., Hoff, W. D. and Skeldon, M., 'The sorptivity of

brick: dependence on the initial water content', J. Phys.

D: Appl. Phys. 16 (1983) 1875-80.

33. Millard, S. G., 'Effects of temperature and moisture upon

concrete permeability and resistivity measurements', in

Proceedings of Workshop on In Situ Measurement

of Concrete Permeability, Loughborough University,

December t989.

34. ASTM Committee C-9, 'Evaluating the effectiveness of

materials for curing concrete', Proposed ASTM Test

Method P198, in 'ASTM Standards' (February 1987)

pp. 915-918.

292

RESUME

Absorption d'eau dans le b~ton d'enrobage

On rend compte de mesures de l'absorption d'eau initiale

sur des bdtons exposbs pendant 18 mois en milieu fermb et

en plein air. Aprbs un temps donni d'humidification,

l'absorption d'eau augmentait avec l'accroissement du

rapport eau/ciment, la diminution de la conservation ~ l Ytat

humide et le remplacement partiel du composant de clinker

Parrott

Portland du ciment. A la suite de l'exposition ~ l'air libre,

l'absorption, en particulier si la pluie dtait tombOe sur la

surface du bbton, btait moindre qu'en laboratoire. Les

rOsultats de l'absorption correspondaient approximativement avec les pertes de poids durant l'exposition initiale,

et aux risistances en compression au dbbut de l'exposition.

On a constatO une relation non linOaire entre les profondeurs

de carbonatation et l'absorption mesurdes dans le bbton

d'enrobage aprOs une exposition de 18 mois.

Das könnte Ihnen auch gefallen

- 1 s2.0 S0008884600003860 Main PDFDokument8 Seiten1 s2.0 S0008884600003860 Main PDFTarek ChikerNoch keine Bewertungen

- Pr125. Harrison.c. 03Dokument2 SeitenPr125. Harrison.c. 03Tarek ChikerNoch keine Bewertungen

- What Causes Differences of C-S-H Gel Grey Levels in Backscattered Electron Images?Dokument7 SeitenWhat Causes Differences of C-S-H Gel Grey Levels in Backscattered Electron Images?Tarek ChikerNoch keine Bewertungen

- Research in Economics: Lonnie K. StevansDokument12 SeitenResearch in Economics: Lonnie K. StevansTarek ChikerNoch keine Bewertungen

- Pr7.Irassar Disc. 2000Dokument2 SeitenPr7.Irassar Disc. 2000Tarek ChikerNoch keine Bewertungen

- Construction and Building Materials: Md. Safiuddin, J.S. West, K.A. SoudkiDokument6 SeitenConstruction and Building Materials: Md. Safiuddin, J.S. West, K.A. SoudkiTarek ChikerNoch keine Bewertungen

- Technical Committees: Chloride Ions Can Penetrate Into The Concrete and CauseDokument4 SeitenTechnical Committees: Chloride Ions Can Penetrate Into The Concrete and CauseTarek ChikerNoch keine Bewertungen

- MS-A.4 Determination of The Durability of Hardened MortarDokument5 SeitenMS-A.4 Determination of The Durability of Hardened MortarTarek ChikerNoch keine Bewertungen

- The Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsDokument11 SeitenThe Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsTarek ChikerNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Auto Fuel Policy Vision 2025Dokument294 SeitenAuto Fuel Policy Vision 2025Rejith RajanNoch keine Bewertungen

- ALP 9th Bio. Ch. 3 MCQs - Nauman SadafDokument2 SeitenALP 9th Bio. Ch. 3 MCQs - Nauman SadafSohail AfzalNoch keine Bewertungen

- CWMP-00 Construction Waste Management PlanDokument23 SeitenCWMP-00 Construction Waste Management PlanMohammad Imtiaz AliNoch keine Bewertungen

- ZR Handbook Rev2 PDFDokument80 SeitenZR Handbook Rev2 PDFmyungkwan haNoch keine Bewertungen

- Vol 30 Profiles - of - Drug - Substances, - E (BookSee - Org) Vol 30Dokument329 SeitenVol 30 Profiles - of - Drug - Substances, - E (BookSee - Org) Vol 30Gabriel Bianco100% (1)

- Formatof Indenity BondDokument2 SeitenFormatof Indenity BondSudhir SinhaNoch keine Bewertungen

- Guidance ProgramDokument4 SeitenGuidance ProgramShainajoy BoterNoch keine Bewertungen

- Red Oxide PrimerDokument2 SeitenRed Oxide Primermarsha.fsdNoch keine Bewertungen

- Digital Voltmeter (DVM) : Elementary Measurement SystemDokument4 SeitenDigital Voltmeter (DVM) : Elementary Measurement SystemRounakNoch keine Bewertungen

- (PDF) Teach Your Baby Math - Glenn DomanDokument200 Seiten(PDF) Teach Your Baby Math - Glenn Domansugapovex0% (1)

- SPA - PRC IdDokument3 SeitenSPA - PRC IdGracelyn Enriquez Bellingan67% (6)

- BalClor BWMS Principle and CompositionDokument34 SeitenBalClor BWMS Principle and Compositiongprasad2006Noch keine Bewertungen

- Á641Ñ Completeness of Solution: 310 Á631ñ Color and Achromicity / Physical Tests USP 37Dokument2 SeitenÁ641Ñ Completeness of Solution: 310 Á631ñ Color and Achromicity / Physical Tests USP 37David SRNoch keine Bewertungen

- Class 8 Cbse Science Question Paper Fa 1Dokument2 SeitenClass 8 Cbse Science Question Paper Fa 1Sunaina Rawat100% (1)

- How To Be A Multi-Orgasmic Woman: Know Thyself (And Thy Orgasm Ability)Dokument3 SeitenHow To Be A Multi-Orgasmic Woman: Know Thyself (And Thy Orgasm Ability)ricardo_sotelo817652Noch keine Bewertungen

- Inspection and Repair: Inspection of Totally Enclosed Lift Bags 1.0Dokument8 SeitenInspection and Repair: Inspection of Totally Enclosed Lift Bags 1.0Ali KuliNoch keine Bewertungen

- Recent Advances in Natural Polymer-Based Drug Delivery SystemsDokument18 SeitenRecent Advances in Natural Polymer-Based Drug Delivery SystemsTelmoNoch keine Bewertungen

- 2300 - Performing The EngagementDokument1 Seite2300 - Performing The EngagementAlexandra AvîrvareiNoch keine Bewertungen

- Opiods MorphineDokument4 SeitenOpiods MorphinevysakhmohanannairNoch keine Bewertungen

- Eip-Agri Brochure Soil Organic Matter Matters 2016Dokument8 SeitenEip-Agri Brochure Soil Organic Matter Matters 2016Ernesto Alonso Orrillo AguirreNoch keine Bewertungen

- (D E Watt) Quantities For Generalized Dosimetry of (BookFi)Dokument388 Seiten(D E Watt) Quantities For Generalized Dosimetry of (BookFi)Νικος ΜατσαφλοκοςNoch keine Bewertungen

- Sf1 Cinderella JuneDokument60 SeitenSf1 Cinderella JuneLaLa FullerNoch keine Bewertungen

- Fujiwara2011 New Molten Salt Systems For High Temperature Molten Salt Batteries Ternary and QuaternaryDokument7 SeitenFujiwara2011 New Molten Salt Systems For High Temperature Molten Salt Batteries Ternary and QuaternaryThirupathi ThippaniNoch keine Bewertungen

- The Neurovascular Bundle of The Anterior Compartment ofDokument30 SeitenThe Neurovascular Bundle of The Anterior Compartment ofAnnapurna Bose100% (2)

- ScimagojrDokument1.653 SeitenScimagojrKomariah ErvitaNoch keine Bewertungen

- Bible Secrets of Moses and Solomon Vol2Dokument40 SeitenBible Secrets of Moses and Solomon Vol2jamjam_9567885389% (80)

- 2015 Pri XLDokument2 Seiten2015 Pri XLTimmyJuriNoch keine Bewertungen

- Starbucks Managing High Growth BrandDokument15 SeitenStarbucks Managing High Growth BrandSumit BansalNoch keine Bewertungen

- Introduction To IoT PDFDokument94 SeitenIntroduction To IoT PDFsolbahiaNoch keine Bewertungen

- Group Mediclaim Tailormade - Endorsement ScheduleDokument2 SeitenGroup Mediclaim Tailormade - Endorsement ScheduleSneha SinghNoch keine Bewertungen