Beruflich Dokumente

Kultur Dokumente

Heat Shrink Sleeves

Hochgeladen von

jay2kay5793Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Shrink Sleeves

Hochgeladen von

jay2kay5793Copyright:

Verfügbare Formate

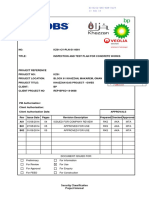

QA Date of Issue: 23/07/09

Section: 1.0

Page 1 of 3

Technical Data Sheet

Pipelines & Fittings

DENSO 50 Heat Shrink Sleeve

DENSO 50 Heat Shrink Sleeve (DENSO 50HSS)

Description:

Denso 50HSS is a two layer field joint coating system designed for corrosion

protection of pipelines that operate at ambient temperature.

Composition:

Two-layer structure

First layer: Low pre-heat modified bitumen sealant adhesive.

Second layer: Thick-wall irradiated cross linked Polyolefin.

Characteristics:

Denso 50HSS is compatible with standard pipe coatings, and can also be used for

coating bare, replacement pipe sections and large radius bends.

Purpose formulated compound gives excellent adhesion results, excellent

resistance to cathodic disbondment, and long term corrosion protection.

The high performance backing is engineered for standard or high soil stress

environments.

The installed sleeve offers the structural integrity of a seamless tube and offers

superior resistance against abrasion and chemical attack.

The sealing adhesive automatically flows and repairs minor mechanical

damage. This self-healing effect saves extra intervention steps.

Stable in composition and plasticity over a wide temperature range.

Non-hardening and non-cracking. Tough, but flexible even at low temperatures!

Accommodates vibration and extreme movement of substrate.

Highly resistant to mineral acids, alkalis and salts.

Will adhere and remain attached to all cleaned, sound, dry metal surfaces.

No special equipment or skills required

Uses:

Denso 50HSS is available as a wrap around heat shrinkable, ready to fit assembly

for the corrosion protection of field weld joints in distribution and transmission

systems.

Surface

Preparation

and Application:

Installation is carried out directly on the cleaned and dried (pre-heated) pipe

surface (as per application instructions), without any primer being required. The

system is designed to be applied with minimum pre-heating and is ideal for large

diameter water pipe.

The heat shrink sleeve is wrapped and shrunk to form a tight fit around the joint.

During recovery, the adhesive softens and flows to form a perfect bond with the

pipe surface providing protection against corrosion. The irradiated polyolefin outer

layer forms a tough barrier against mechanical damage and moisture

transmission.

Shelf Life:

Service Life:

Indeterminably long, > 30 years expected.

Expected > 30 years.

Denso Australia warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when

used in compliance with Densos written instructions. Since many installation factors are beyond the control of Denso Australia, the user shall determine the

suitability of the products for the intended use and assume all risks and liabilities in connection herewith. Denso Australias liability is stated in the standard terms

and conditions of sale. Denso Australia makes no other warranty either expressed or implied. All information contained in this technical data sheet is to be used as

a guide and is subject to change without notice. This technical data sheet supersedes all previous data sheets on this product.

QA Date of Issue: 23/07/09

Section: 1.0

Page 2 of 3

Technical Data Sheet

Pipelines & Fittings

DENSO 50 Heat Shrink Sleeve

Recommended

Temperatures:

Application Temperature:

Max. Operating Temperature:

Availability:

Custom made ready to use sleeve, with the closure patch pre-attached.

60 C

50 C

Can be supplied in a bulk roll form which can be cut to size on site. Closure

patches available separately.

Dimensions:

Length: 30 metre rolls or custom made to suit individual pipe joints.

Width: 450mm, 600mm & 900mm

Physical

Properties:

Test

Backing:

Adhesive:

Sleeve:

Method

Value

Total Thickness

DIN 30672

(ASTM D374)

2600 m

Adhesive Thickness

DIN 30672

(ASTM D374)

1500 m

Backing Thickness

As supplied:

Fully free recovered:

DIN 30672

(ASTM D374)

1100 m

1300 m

Specific Gravity

ASTM D-792

0.95

Tensile Strength

ASTM D-638

20 MPa

(2900 psi)

Elongation at Break

ASTM D-638

550%

Hardness, Shore D

ASTM D-2240

48

Dielectric Strength

ASTM D-149

20 kV/mm

Water absorption

ASTM D-570

0.05 w/w%

Shrink force

ASTM D-638

240 KPa

(35 psi)

Volume Resistivity

ASTM D-257

1.0x1016 Ohm-cm

ASTM E-28

85C (185F)

Lap shear

ASTM D-1002

40 psi

Peel to Steel

ASTM D-4541

35 N/cm

Low Temperature Flexibility

ASTM D-2671

-20C

Softening point

Cathodic disbondment

ASTM G8,

30 days, @23C

10 mm radius

Impact resistance

DIN EN 12068

Pass

Indentation resistance

DIN EN 12068

Pass

ASTM D-149

35 kV

Dielectric Breakdown

Denso Australia warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when

used in compliance with Densos written instructions. Since many installation factors are beyond the control of Denso Australia, the user shall determine the

suitability of the products for the intended use and assume all risks and liabilities in connection herewith. Denso Australias liability is stated in the standard terms

and conditions of sale. Denso Australia makes no other warranty either expressed or implied. All information contained in this technical data sheet is to be used as

a guide and is subject to change without notice. This technical data sheet supersedes all previous data sheets on this product.

QA Date of Issue: 23/07/09

Section: 1.0

Page 3 of 3

Technical Data Sheet

Pipelines & Fittings

DENSO 50 Heat Shrink Sleeve

Ordering

Information:

One piece sleeve (pre-cut sleeve with pre-attached closure patch).

Two piece sleeve (pre-cut sleeve with closure patch supplied separately).

Roll form (with closure patch roll to be ordered separately).

Select the sleeve width that will overlap onto the mill applied coating by 50mm (2

inches) minimum on each side of the weld joint.

Sleeve Ordering

for a Cut piece or a

one piece sleeve

e.g. for 710mm Dia.

Pipe

Roll Ordering

in roll form

Closure Patch Roll

When ordering rolls

the Closure patches

are to be ordered

separately

When calculating the minimum sleeve width allow for a 10% shrinkage during

installation of sleeve.

Denso 50HSS 710-450-Uni, Denso 50HSS 710-600-Uni or Denso 50HSS

710-900-Uni

Product type Denso 50HSS

710mm Outside pipe diameter

450 mm (17), 600mm (24) or 900mm (34) roll width

-Uni Designates pre-attached closure patch (optional)

Denso 50HSS -450-RL, Denso 50HSS-600-RL or Denso 50HSS -900-RL

Product type Denso 50HSS

in 30 metre length rolls

450 mm (17), 600mm (24) or 900mm (34) roll width

Denso Closure Patch

Denso CL100-15M or CL150-15M

CL100-15M Closure patch roll: 100 mm (4") x 15 metre

CL150-15M Closure patch roll: 150 mm (6") x 15 metre

DENSO (AUSTRALIA) PTY LTD

411 - 413 Victoria Street, Brunswick Vic 3056, Australia

Tel: (03) 9356 7600 Fax: (03) 9387 6973

Email: info@densoaustralia.com.au

The Leaders in Corrosion Prevention"

Check out our web site at www.densoaustralia.com.au

Denso Australia warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when

used in compliance with Densos written instructions. Since many installation factors are beyond the control of Denso Australia, the user shall determine the

suitability of the products for the intended use and assume all risks and liabilities in connection herewith. Denso Australias liability is stated in the standard terms

and conditions of sale. Denso Australia makes no other warranty either expressed or implied. All information contained in this technical data sheet is to be used as

a guide and is subject to change without notice. This technical data sheet supersedes all previous data sheets on this product.

Das könnte Ihnen auch gefallen

- WPC120 PDFDokument2 SeitenWPC120 PDFHamzaHashimNoch keine Bewertungen

- Canusa Wrap Benzi Termocontractibile Izolatii Conducte OtelDokument2 SeitenCanusa Wrap Benzi Termocontractibile Izolatii Conducte Oteleugen_alexutzNoch keine Bewertungen

- Polyken 932 TapeDokument2 SeitenPolyken 932 TapeKyaw Kyaw AungNoch keine Bewertungen

- Dirax PDFDokument2 SeitenDirax PDFTom Henry Bernabe Castro100% (1)

- PDS A4 DDXDokument2 SeitenPDS A4 DDXRahadianLabigaAmidarmo100% (1)

- IsoTek Manual 8-18-14Dokument13 SeitenIsoTek Manual 8-18-14usamazarifehNoch keine Bewertungen

- WPCT Heat Shrink SleevesDokument4 SeitenWPCT Heat Shrink SleevesHamzaHashimNoch keine Bewertungen

- DS HLTP 60 Rev12 1107Dokument2 SeitenDS HLTP 60 Rev12 1107Luisito Aguilar RojasNoch keine Bewertungen

- Wrapid Sleeve PDSDokument2 SeitenWrapid Sleeve PDSjayhuacat7743Noch keine Bewertungen

- PDS Na GTS80 PDFDokument2 SeitenPDS Na GTS80 PDFAnant RubadeNoch keine Bewertungen

- Covalence WPC100M Shrink Sleeves PDFDokument2 SeitenCovalence WPC100M Shrink Sleeves PDFJMROMANTNoch keine Bewertungen

- Amex Seals Product Data SheetsDokument13 SeitenAmex Seals Product Data SheetscloantafNoch keine Bewertungen

- Polyken 905 TapeDokument2 SeitenPolyken 905 TapeKyaw Kyaw AungNoch keine Bewertungen

- Gall5231328512232fip PDFDokument15 SeitenGall5231328512232fip PDFAndres CortezNoch keine Bewertungen

- TDS - Bronco Pre HDPE Membrane (S)Dokument3 SeitenTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniNoch keine Bewertungen

- Global Transmission Sleeve: Product Data SheetDokument2 SeitenGlobal Transmission Sleeve: Product Data SheetgoumrisalimaNoch keine Bewertungen

- K-Flex Tapes BrochureDokument16 SeitenK-Flex Tapes BrochuregetashishvaidNoch keine Bewertungen

- Ds Dirax PP Rev8 0309 1Dokument2 SeitenDs Dirax PP Rev8 0309 1Elias KapaNoch keine Bewertungen

- Proofex Engage PDFDokument2 SeitenProofex Engage PDFmilanbrasinaNoch keine Bewertungen

- Polyken 1600 High TempDokument2 SeitenPolyken 1600 High TempKyaw Kyaw AungNoch keine Bewertungen

- BossBro Q4Dokument12 SeitenBossBro Q4mahotkatNoch keine Bewertungen

- Retrowrap HD Specifications (2014)Dokument15 SeitenRetrowrap HD Specifications (2014)Alfredo Solorzano MaloNoch keine Bewertungen

- ITEM 564.00010001 - Bridge Hanger Fabrication and InstallationDokument14 SeitenITEM 564.00010001 - Bridge Hanger Fabrication and InstallationKY PengNoch keine Bewertungen

- Denso Pipe Wrapping SolutionsDokument8 SeitenDenso Pipe Wrapping SolutionsVinoth MechNoch keine Bewertungen

- Titanium UDL-50 BROCHURE PDFDokument2 SeitenTitanium UDL-50 BROCHURE PDFHRroofingNoch keine Bewertungen

- GTS-PP-120: 3 LayerDokument2 SeitenGTS-PP-120: 3 Layershoaib1985100% (1)

- 10-D1-VHightech (Very High Density Foam)Dokument1 Seite10-D1-VHightech (Very High Density Foam)GPNoch keine Bewertungen

- Polyken 934 TapeDokument2 SeitenPolyken 934 TapeKyaw Kyaw AungNoch keine Bewertungen

- 3170Dokument2 Seiten3170Mohammed Satti100% (1)

- Polyken YGIII Coating SystemDokument2 SeitenPolyken YGIII Coating SystemKyaw Kyaw AungNoch keine Bewertungen

- Wrapid BondDokument2 SeitenWrapid BondgrtunaNoch keine Bewertungen

- Polyken 2000 High TempDokument2 SeitenPolyken 2000 High TempKyaw Kyaw AungNoch keine Bewertungen

- Polyken 4000 PrimerlessDokument2 SeitenPolyken 4000 PrimerlessKyaw Kyaw AungNoch keine Bewertungen

- CamisaDokument2 SeitenCamisaJuan Roberto López BetanzosNoch keine Bewertungen

- Proofex EngageDokument4 SeitenProofex EngagekalidindivenkatarajuNoch keine Bewertungen

- Curaflex EngDokument6 SeitenCuraflex EngStefanNoch keine Bewertungen

- Afico Faceed InsulationDokument4 SeitenAfico Faceed Insulationhello1230Noch keine Bewertungen

- DPW Series Profile Wrapping Application HeadDokument2 SeitenDPW Series Profile Wrapping Application HeadNordson Adhesive Dispensing SystemsNoch keine Bewertungen

- ESD Tape ApplicationsDokument6 SeitenESD Tape Applicationslordycarlos8588Noch keine Bewertungen

- Duct Liner (AFICO)Dokument4 SeitenDuct Liner (AFICO)hshoooma65Noch keine Bewertungen

- Proflex 200 Ha: E Xpansion C Ontrol S Ystem S InternationalDokument2 SeitenProflex 200 Ha: E Xpansion C Ontrol S Ystem S InternationalIkhsanRamadhanNoch keine Bewertungen

- TDS FlexiClad 70Dokument2 SeitenTDS FlexiClad 70DuongNoch keine Bewertungen

- Chapter 3 Datasheets Roof PanelsDokument16 SeitenChapter 3 Datasheets Roof PanelsMladen BilincNoch keine Bewertungen

- DP490Dokument6 SeitenDP490transervuk2013Noch keine Bewertungen

- Sealfl Ex: Description Method of UseDokument4 SeitenSealfl Ex: Description Method of UseramiNoch keine Bewertungen

- Pikotek Vcs Tech SpecsDokument2 SeitenPikotek Vcs Tech SpecsBaskar KannaiahNoch keine Bewertungen

- Client: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEDokument2 SeitenClient: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEShakil AkhterNoch keine Bewertungen

- HBR XL - Crosslink Closed Cell PDSDokument2 SeitenHBR XL - Crosslink Closed Cell PDSHuy ThaiNoch keine Bewertungen

- Marine-Offshore Cable & Pipe Penetration DossierDokument39 SeitenMarine-Offshore Cable & Pipe Penetration DossierHonka VoxNoch keine Bewertungen

- Seal Link - Psi - Catalogue - 2016-04-09 PDFDokument8 SeitenSeal Link - Psi - Catalogue - 2016-04-09 PDFAnonymous xxrkd4aNoch keine Bewertungen

- The Complete Guide To Pressure and Vacuum Sealing AssembliesDokument22 SeitenThe Complete Guide To Pressure and Vacuum Sealing AssembliesLuiz Carlos Vidal100% (1)

- Wavistrong Installation ManualDokument63 SeitenWavistrong Installation ManualRenganathan Prabunath0% (1)

- DS Flex Rev7 0309 PDFDokument2 SeitenDS Flex Rev7 0309 PDFDavid GonzaloNoch keine Bewertungen

- Suggested Specifications For X-PLUG-GreenstreakDokument3 SeitenSuggested Specifications For X-PLUG-GreenstreakAlsayed DiabNoch keine Bewertungen

- Tricosal KatalogasDokument32 SeitenTricosal KatalogaschaubeyskcNoch keine Bewertungen

- Heat Shrink Sleeve FinalDokument11 SeitenHeat Shrink Sleeve FinalpepeNoch keine Bewertungen

- Polyken Utility Tape 900 910 908 911 920Dokument2 SeitenPolyken Utility Tape 900 910 908 911 920Tracy EvansNoch keine Bewertungen

- PeDokument9 SeitenPeMekhmanNoch keine Bewertungen

- Stage Gate PDFDokument16 SeitenStage Gate PDFjay2kay5793100% (1)

- Exm Notes PMPDokument29 SeitenExm Notes PMPjay2kay5793100% (1)

- Radiograph Interpretation (RT Film Interpretation)Dokument10 SeitenRadiograph Interpretation (RT Film Interpretation)Abu HurairaNoch keine Bewertungen

- Radiograph Interpretation (RT Film Interpretation)Dokument10 SeitenRadiograph Interpretation (RT Film Interpretation)Abu HurairaNoch keine Bewertungen

- Quality Gates Concept PDFDokument38 SeitenQuality Gates Concept PDFjay2kay5793Noch keine Bewertungen

- PT PDFDokument22 SeitenPT PDFmohamedNoch keine Bewertungen

- API 510 Final Model Exam-Open Book Page 1 of 6Dokument6 SeitenAPI 510 Final Model Exam-Open Book Page 1 of 6jay2kay5793Noch keine Bewertungen

- 04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTADokument4 Seiten04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTAjay2kay5793Noch keine Bewertungen

- Inspection Test Report (ITR) : Steel Reinforcement ChecklistDokument1 SeiteInspection Test Report (ITR) : Steel Reinforcement Checklistjay2kay5793Noch keine Bewertungen

- 04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTADokument5 Seiten04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAjay2kay5793Noch keine Bewertungen

- Calculation: B02 11-Jan-15 5 LC AS US Issued For Company ApprovalDokument5 SeitenCalculation: B02 11-Jan-15 5 LC AS US Issued For Company Approvaljay2kay5793Noch keine Bewertungen

- Mangalore Zonal RegulationsDokument56 SeitenMangalore Zonal RegulationsChethan100% (1)

- Description: Inspection Test Report (ITR)Dokument2 SeitenDescription: Inspection Test Report (ITR)jay2kay5793Noch keine Bewertungen

- 04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTADokument5 Seiten04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAjay2kay5793Noch keine Bewertungen

- The Effect of Social Media Marketing On Online Consumer BehaviorDokument14 SeitenThe Effect of Social Media Marketing On Online Consumer Behaviordindo_waeNoch keine Bewertungen

- Parameters of SAWDokument9 SeitenParameters of SAWcanakyuzNoch keine Bewertungen

- Allowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No ReferenceDokument209 SeitenAllowed To Use The ASME Codes and The API Books On The First Portion of The Test Only. No Referencejay2kay5793Noch keine Bewertungen

- Product MappingDokument27 SeitenProduct Mappingjay2kay5793Noch keine Bewertungen

- Austenitic Stainless SteelsDokument4 SeitenAustenitic Stainless Steelsandy1036Noch keine Bewertungen

- Pnacy789 PDFDokument310 SeitenPnacy789 PDFdarkwolfbrNoch keine Bewertungen

- FitnessDokument1 SeiteFitnessjay2kay5793Noch keine Bewertungen

- Stage BookDokument24 SeitenStage BookraksnghNoch keine Bewertungen

- Msa BookletDokument39 SeitenMsa BookletAli HafeezNoch keine Bewertungen

- Pnacy789 PDFDokument310 SeitenPnacy789 PDFdarkwolfbrNoch keine Bewertungen

- Marketing: The Key To Organizational EffectivenessDokument3 SeitenMarketing: The Key To Organizational Effectivenessjay2kay5793Noch keine Bewertungen

- Risk Based InspectionDokument10 SeitenRisk Based Inspectionjay2kay5793100% (1)

- Sample Rti Application FormDokument1 SeiteSample Rti Application Formmganesan6767Noch keine Bewertungen

- SMPV PDFDokument54 SeitenSMPV PDFAnonymous BbZceWkVnNoch keine Bewertungen

- ISO - GuideDokument10 SeitenISO - Guidejay2kay5793Noch keine Bewertungen

- 2-Introduction Drilling Sans Stats14sDokument14 Seiten2-Introduction Drilling Sans Stats14sjay2kay5793Noch keine Bewertungen