Beruflich Dokumente

Kultur Dokumente

High-Rise Buildings in The Netherlands

Hochgeladen von

akielarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

High-Rise Buildings in The Netherlands

Hochgeladen von

akielarCopyright:

Verfügbare Formate

High-Rise Buildings in the Netherlands: Hybrid Structures and

Precast Concrete

J.N.J.A. Vambersky

Delft University of Technology,

Corsmit Consulting Engineers, The Netherlands

Abstract

The emergence of new building materials and new construction technologies has changed the face of the building

industry. Structural steel, reinforced and precast concrete are now easily accessible and compete in the construction

market. However, joining forces, seeking synergy rather than confrontation, is the emergent trend. The result of this

trend is a growing number of hybrid structures in use in everyday building practice. Hybrid or mixed construction with

precast concrete means combined use with other structural materials, such as steel, timber, cast-in-situ concrete and

glass, for the benefit of the building process at large. In the Netherlands two recent examples of this development are

the "Malietoren" office tower, constructed over the motorway entering the city of The Hague, and the 100 m high

sloping "Belvedere" office tower in Rotterdam, where the aim of the architect Renzo Piano to create appealing but

competitively priced buildings was realised through hybrid construction. The planned concepts, alternatives, final

solutions and detailing of these two architecturally appealing buildings are discussed in this paper, to illustrate this new

development. A development in which, especially in the Netherlands, precast concrete is playing an important role.

1. Advantagess of hybrid construction - Currently hybrid construction is being used in more

than 50 % of new multi-storey buildings, once the

Hybrid construction maximises the structural and traditional domain of cast-in-situ concrete and

architectural advantages of combining components made structural steelwork. Precast concrete is ideally suited

of different materials. To achieve this, it is vital to have to hybrid construction as it may be readily combined

good cooperation between the architect the structural with other materials, such as steel, timber, cast-in-situ

engineer, services engineer, manufacturer, supplier and concrete, masonry and glass, for the benefit of the

the contractor. Hybrid or mixed construction must be building process at large.

distinguished from "composite" construction where - By using precast concrete as the dominant material in

different materials are constructed to act as one structural hybrid construction, on-site operations are consi-

unit. derably reduced because there is less wet concrete to

In hybrid construction the different materials may place, fewer loose reinforcing bars to fix and fewer

work together or independently, but will always provide structural components and formwork to erect. There is

advantages over the use of a single material. Today in also less construction noise and disturbance to local

engineering practice, builders and users are discovering communities. This results in a safer working

that hybrid construction is essential to meet architectural environment. Prefabricated components also provide

requirements, providing high surface finishes, minimising working platforms for workers, and this eases the

structural floor depths, achieving better sustainability and construction process and improves safety.

ensuring rapid construction, all of which translate into - Various case studies claim that hybrid construction

substantial savings and better quality of the end-product. when compared with traditional systems can save

Hybrid construction methods vary considerably with the between 10% and 20% construction time.

type of construction and building function. These reflect - Hybrid construction is, by definition, cost effective

local trends, environmental and physical conditions, because it maximises the beneficial structural and

relative material and labour costs and local expertise. The architectural advantages of using components made of

fib-commission 6 -Prefabrication, Working group on different materials. The technique requires the

Mixed Construction[1] reports the following. cooperation of architects, consulting engineers, manu-

facturers, suppliers and contractors.

- In some cases client and architectural demands can be

Contact author: Prof.dipl.-ing. J.N.J.A. Vambersky, Delft satisfied only by using mixed construction techniques.

University of Technology, Dept. of Civil Engineering and

geosciences 2. The “Malietoren” office tower, The Hague

P.O. Box 5048, 2600 GA Delft, the Netherlands

Tel. + 31 15 2785488 Fax + 31 15 2781560 The growth human population and its demands for

e-mail: j.n.j.a.vambersky@citg.tudelft.nl increased living and working space are often in direct

conflict with our desire to conserve grasslands, forests

136 CTBUH 2004 October 10~13, Seoul, Korea

and natural resources. Multiple use of space for our

building activities is one answer to this dilemma.

The “Malietoren” office tower (Figure 1) is a case in

point. It is situated over the “Utrechtse Baan” motorway

entering the city of The Hague. The building is almost

square in plan, 40 m long and 32.2 m wide (Figure 2).

The ground floor is designed as an entry and reception

area (Figure 3). Above are five car parking floors reached

by a spiral ramp cantilevering half way over the

motorway on the north face of the building. The sixth and

seventh floors are conference facilities while the

remaining 13 floors are designed as offices. The building

services are concentrated on the top floor of the building,

bringing the total height to 74 m. (See the appendix for

the construction details).

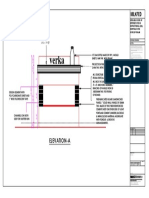

Figure 2. Elevation of truss and plan of building

(dimensions in mm)

The optimum solution was to adopt a composite

concrete truss transfer structure (Figure 2) with a height

of 8.2 m and a span of 32.2 m at the entrance level.

This also satisfied the architectural perception in terms

of structural demands and economy. The 2m-deep precast,

prestressed and post-tensioned lower chord of the truss

was designed to function at the erection stage as a simply

supported beam to carry the weight of the ground floor

acting as a working area. Being prefabricated, the beams

and working floor were placed very quickly (in a single

night) (Figure 4). Diagonals and the upper chord were

then added in in situ concrete B65. The upper floors are

precast hollow-core slabs on precast prestressed concrete

beams, which are very economical and fast to erect.

(Figure 2)

Figure 1. The Malietoren office block

3. The structure

Building over an existing motorway is never easy. The

motorway – effectively a watertight reinforced concrete

trough sunk into the ground – cannot be closed without

causing severe disruption to the life of the city. As a

result, it had to be bridged over to prevent any

disturbance, including additional loads or penetrations to Figure 3. Entrance and reception area

the trough.

CTBUH 2004 October 10~13, Seoul, Korea 137

5. The “Bélvèdere” sloping tower Rotterdam

The old harbours in the centre of Rotterdam have lain

idle for a number of years. Today these areas are prime

locations for urban development. Wilhelmina pier, the

site from which over the past two centuries many

European emigrants have boarded ships on their way to

America, is one such a location. Situated on the River

Maas, it is connected to the city centre by the well-known

Figure 4. Erection of precast beams Erasmus bridge, “the Swan bridge”. Development of

high-quality buildings on this location is the aim of the

Municipality of Rotterdam and of the designers involved.

4. Innovation

For the high-strength (B85) two-storey precast

concrete columns, an innovative, but simple and cheap,

connection (Figure 5) was developed using steel plates

and epoxy resin injection resulting in an enhanced speed

of erection and a minimum column cross-section area

(8% reinforcement). Composite precast concrete façade

frames in system lines A and D and structural steel

bracings in system lines 1 and 6 (Figure 2) were

connected by in-situ concrete corner columns (Figure 6)

to form a stabilising façade tube. The result is a high

quality environmentally and ecologically friendly

building at a very competitive price.

Figure 7. Artist’s impression

Figure 5. Column-column connection 6. The building

(dimensions in mm)

The architect Renzo Piano was commissioned by the

Real Estate Developer William Properties BV to produce

the architectural design. His inspiration was the Erasmus

bridge immediately adjacent to the location of the

building site. The 100m tall building follows the

inclination of the cable stays of the Erasmus Bridge

(Figure 7 + 8). The building contains approximately

20000 m2 of office space, 5000 m2 of retail and

commercial space and two levels of underground car

parking for approximately 250 cars.

7. The inclination

The 6o inclination of the building, or rather of its

eastern façade close to the Erasmus bridge, was the first

challenge faced by the structural engineer. The position

Figure 6. Connection of steel bracing to corner

of the columns (vertical supports), in relation to the

column (dimensions in mm)

inclined side of the building, influences the horizontal

forces acting upon of this inclination; that is to say, the

138 CTBUH 2004 October 10~13, Seoul, Korea

Figure 9. Architect’s sketch

Structural scheme A (see Figure 10) shows a design

which has floors spanning from one inclined façade to

another. The effect of this is that the total weight Q of the

Figure 8. Model of the building whole grid will generate horizontal forces as a function of

the inclination of the columns supporting the floors.

bigger the span, the bigger the vertical floor support These horizontal forces in turn will cause moments in the

reaction to be carried by the inclined side and the bigger stabilising elements such as cores and shear walls as well

the horizontal load caused by this inclination on the as in their foundations. The total moment, which has to

stabilising structure (Figure 13). However, even with the be resisted, is

optimum position of the columns in the given archi-

tectural design, this horizontal force was still too great to Ma.= ¼Qa = ½ qah2 (1)

be borne by conventional structural means like cores or

shear walls only. Being an excellent architect, Renzo

Piano was instinctively aware of this problem, and even

his first sketches on the back of his cigar box include a

reversely inclined compression strut to compensate and

support the leaning side of the building (Figure 9).

This synergy of form and structure, combined with

Piano’s understanding of the different disciplines

involved, had huge potential as a powerful architectural

and structural concept for this building.

8. Inclined buildings: general concept

Before discussing the structural design of the

Belvédère tower it may be interesting to look first at the

phenomenon of inclined buildings and the impact of the

inclination on the price of the building, depending on the

structural scheme which has been chosen.

The following static schemes A, B and C (see fig. 10,

11 & 12) for an inclined building with the top of the

building being one-half of the base width "a" out of

plumb.

In all three schemes the column-floor connections are

hinge connections. The diaphragm action of the floors

together with the stabilising elements (cores and/or shear

walls) provides the stability of the whole.

Figure 10. Structural scheme A

CTBUH 2004 October 10~13, Seoul, Korea 139

Structural scheme B (see Figure 11) shows a scenario gives more freedom to the architect and more

where two vertical inner columns have been introduced column-free space at ground floor level.

as close to the façade as possible in order to reduce the

reactions of the floors supported by the inclined façades.

The smaller the reactions on the inclined façades will be,

the smaller the horizontal components of these reactions

which in turn will have to be resisted by the stabilising

elements. In the given example shown, this results in a

considerably reduced moment Mb=¼Ma, which again has

to be resisted by the stabilising elements as well as by

their foundations.

Figure 12. Structural scheme C

It is clear that there will be a significant price variation

between a building under scheme A and a building under

scheme C, despite the fact that the buildings and their

inclination are the same.

9. The static scheme

Figure 11. Structural scheme B

The reversely inclined strut, depending on its angle of

Scheme C (see Figure 12) shows a situation which is inclination, the magnitude of the vertical load assigned to

exactly the same as scheme B, except for the foundation it, the place where it is attached to the building and the

support of the left-hand side façade which is omitted here. way in which it is designed and detailed to function in the

The façade is designed as a hanger which transfers the total structural scheme can:

gravity forces first to the top of the building where they - Compensate for (counterbalance) the horizontal

meet the vertical column which in turn takes these forces forces caused by inclination of the building

to the foundation. This static scheme has the following (Figure 13)

consequences: - Form part of (and function as) an outrigger

- Perform both functions (1) and (2)

- The moment Mc due to inclination which has simultaneously.

to be taken by the stabilising elements, is only

1/16Ma. An analysis of different structural schemes revealed

that the most economical solution was the counter

- This moment has to be resisted by the balancing scheme, in combination with structural core for

stabilising elements and not by their foundations overall stability (Figure 15).

as the moment in this scheme at the foundation

level is zero. For counter balancing, the central column in the

inclined façade does not continue to the foundation but

- As the gravity forces at the left-hand façade stops at the level +10.5 m above ground level (Figure 16).

are hung up, there is no need of supports. This The total force in this column is transferred to the strut

140 CTBUH 2004 October 10~13, Seoul, Korea

and together with the tuned angle of the strut, it 10. The structure

counterbalances from level +46.55m the influence of the

slope of the building. Once established, this static concept appeared to be a

very strong one. Various alternatives with different

structural technologies could be realised. From these

alternatives two economically equal scenarios were

considered and maintained up to the tender stage. Both

alternatives were alternatives were hybrid structures:

- Alternative 1

The vertical section of the building with cast-in-situ

core, load bearing façade and precast prestressed

hollow core slabs. The inclined part of the building

being made of structural steel with composite steel

concrete floors.

- Alternative 2

The vertical section of the building with cast-in-situ

core, load bearing façade and precast prestressed

hollow core slabs. The inclined part of the building

being made with two-storey-high precast concrete

columns and composite precast concrete beams

bearing precast prestressed hollow core slabs.

Figure 13. Horizontal forces

Figure 15. Typical floor plan (dimensions in mm)

In both alternatives the compression strut was designed

as a steel/concrete composite member with structural

steel tube diameter 800mm at the ends (2000mm in the

middle). Due to the required fire resistance, at both ends

the strut was filled with concrete over a length of 5 m.

The floor at level +46.55m where the horizontal

balancing force from the strut is transferred to the

structure is designed as a massive 260mm thick cast-in-

situ concrete floor.

In the end there appeared to be no difference in price

between these two alternatives. However, based on the

contractor’s experience and preference, alternative 2 was

finally chosen (Figures 15 and 16).

Figure 14. The inclined strut

CTBUH 2004 October 10~13, Seoul, Korea 141

shows the building under construction and the appendix

gives construction details.

Figure 16. Section (dimensions in mm)

Concrete wall

d=350 mm, B65

Reïnforcement

welded to the steel blok

Figure 18. Column detail

steel block 350x800x1750 mm

massive steel column cap

steel plate

Column Ø 800 – B90

Figure 17. Steel transfer block

In the required architectural design the emphasis was

on the strut as an important element, therefore it was very

important for the architect that the remaining columns

under the building should be visually almost unobtrusive.

This was especially so at the top of these columns where

the high-rise part of the building transfers its gravity

forces to these columns. The solution was a hybrid

construction in which columns of diameter 800mm were

executed in high-strength concrete grade B90 and

provided with massive steel caps, effectively reducing the

diameter of the column to only 300mm there, where it

meets the upper structure. To transfer the full column

force to the 350mm thick grade B65 concrete wall

situated above this considerably reduced column section,

a massive steel transfer block was introduced into the

wall to spread the concentrated force over a sufficient

length of the wall (see Figures 17 and 18). Figure 19 Figure 19. Building under construction

142 CTBUH 2004 October 10~13, Seoul, Korea

Appendix. Construction details for the two buildings the Netherlands

Malietoren office tower, The Hague Architect: Renzo Piano,

Genova Italy / Paris France

Client: Multivastgoed (Real Estate) Structural Engineer: Corsmit Consulting Engineers

Development Gouda, the Rijswijk, the Netherlands

Netherlands

Contractor: Wilma Bouw The Hague,

the Netherlands References

Architect: Benthem Crouwel Architecten

Amsterdam, The 1)Elliot, Kim S.: "Precast Concrete in Mixed

Netherlands Construction”, The Second International Symposium on

Structural Engineer: Corsmit Consulting Engineers Prefabrication, 17-19 May 2000, Helsinki, Finland.

Rijswijk, The Netherlands

In cooperation with Ove Arup & Partners, London 2) Font Freide, J.J.M. and P. Peters: “Een hoogwaardige

constructie, het VNO-kantoor boven de Utrechtsebaan in

Den Haag”. Cement, 12/1995

"Belvedere" sloping tower, Rotterdam

3) Vambersky, J.N.J.A.: “Mortar joints loaded in

Client: William Properties BV, compression”, proceedings of the International Seminar

Rotterdam, the Netherlands Prefabrication of Concrete Structures, Delft, the

Contractor: HBG Rijswijk (ZH), Netherlands, October 25-26, 1990.

CTBUH 2004 October 10~13, Seoul, Korea 143

Das könnte Ihnen auch gefallen

- 1702 High Rise Buildings in The Netherlands Hybrid Structures and Precast Concrete PDFDokument9 Seiten1702 High Rise Buildings in The Netherlands Hybrid Structures and Precast Concrete PDFNithiya SmileeNoch keine Bewertungen

- List of AbbreviationsDokument29 SeitenList of Abbreviationsdhaval2culNoch keine Bewertungen

- 4361-01.213-220 (Rob Verhaegh)Dokument8 Seiten4361-01.213-220 (Rob Verhaegh)Củ HànhNoch keine Bewertungen

- Paper 2Dokument16 SeitenPaper 2VicenteNoch keine Bewertungen

- Steel Modular Construction and Its Applicability To The Building Industry in ChinaDokument8 SeitenSteel Modular Construction and Its Applicability To The Building Industry in ChinaKris LeeNoch keine Bewertungen

- The Vienna Donau City TowerDokument9 SeitenThe Vienna Donau City TowerSakisNoch keine Bewertungen

- MB Concrete Tall Buildings Feb18 PDFDokument20 SeitenMB Concrete Tall Buildings Feb18 PDFAlparslan GureNoch keine Bewertungen

- Design and Construction of Skyscraper: Fig 1. Burj KhalifaDokument19 SeitenDesign and Construction of Skyscraper: Fig 1. Burj Khalifaವಿನಯ್ ಎಮ್. ಆರ್100% (1)

- Exzenterhaus BochumDokument7 SeitenExzenterhaus BochumGonzalo NavarroNoch keine Bewertungen

- Cable-stayed Cantilever Structures for Seismic AreasDokument12 SeitenCable-stayed Cantilever Structures for Seismic AreasArtjom SamsonovNoch keine Bewertungen

- Design and Construction of SkyscraperDokument19 SeitenDesign and Construction of Skyscraperವಿನಯ್ ಎಮ್. ಆರ್100% (1)

- PM WEB19355Dokument13 SeitenPM WEB19355hesham alhelaleeNoch keine Bewertungen

- Hoi - Thao T11-03 LuuDokument22 SeitenHoi - Thao T11-03 LuuvuhachauNoch keine Bewertungen

- Building Construction Is The Engineering Deals With The Construction of Building Such AsDokument36 SeitenBuilding Construction Is The Engineering Deals With The Construction of Building Such AsMichaelNoch keine Bewertungen

- Lloret2015 PDFDokument10 SeitenLloret2015 PDFKelensantNoch keine Bewertungen

- "Hybrid" Light Steel Panel and Modular Systems PDFDokument11 Seiten"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozNoch keine Bewertungen

- Concrete Light - Possibilities and VisionsDokument2 SeitenConcrete Light - Possibilities and VisionsHau NguyenNoch keine Bewertungen

- Buildings 11 00533 v2Dokument21 SeitenBuildings 11 00533 v2Júlio CésarNoch keine Bewertungen

- Advance construction techniques summaryDokument12 SeitenAdvance construction techniques summaryMoïsës TavarexNoch keine Bewertungen

- A Comparative Study On Structural Analysis of High-Rise BuildingsDokument13 SeitenA Comparative Study On Structural Analysis of High-Rise Buildingsdwi latifaNoch keine Bewertungen

- Precast Concrete and Prefabricated TechnologyDokument45 SeitenPrecast Concrete and Prefabricated TechnologyAzrina MadihiNoch keine Bewertungen

- Report (Print Whole)Dokument22 SeitenReport (Print Whole)rounit prashantNoch keine Bewertungen

- A Study On Composite Structures - A Solution For High Rise Structures in IndiaDokument5 SeitenA Study On Composite Structures - A Solution For High Rise Structures in IndiaHealer AVNoch keine Bewertungen

- BesterN2013 Concreteforhigh Risebuildings PerformancerequirementsmixdesignandconstructionconsiderationsDokument5 SeitenBesterN2013 Concreteforhigh Risebuildings PerformancerequirementsmixdesignandconstructionconsiderationsSiti Aisyah NurjannahNoch keine Bewertungen

- PSG College Report on Modern Prefabrication TechniquesDokument6 SeitenPSG College Report on Modern Prefabrication TechniquesMASILAMANI TNoch keine Bewertungen

- Analysis and Design of A Multi Storied Residential Building of (Ung-2+G+10) by Using Most Economical Column MethodDokument8 SeitenAnalysis and Design of A Multi Storied Residential Building of (Ung-2+G+10) by Using Most Economical Column MethoddhanashekarVNoch keine Bewertungen

- The Open Construction & Building Technology JournalDokument16 SeitenThe Open Construction & Building Technology Journalgreat2008Noch keine Bewertungen

- DISCUSSION 1 3advance Construction MethodsDokument6 SeitenDISCUSSION 1 3advance Construction Methodsted burningtonNoch keine Bewertungen

- Design and Analysis of Prefabricated Structure Using E TABDokument12 SeitenDesign and Analysis of Prefabricated Structure Using E TABInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Peb 2Dokument6 SeitenPeb 2Ayush GargNoch keine Bewertungen

- IABSE SEI 1 2007 Stress Ribbon Roof StructuresDokument6 SeitenIABSE SEI 1 2007 Stress Ribbon Roof StructuresAarti ChandrasekharNoch keine Bewertungen

- Defination of High Rise BuildingDokument14 SeitenDefination of High Rise BuildingankitaNoch keine Bewertungen

- Module TitleDokument5 SeitenModule TitleShah ZaibNoch keine Bewertungen

- E3sconf Icemee2021 03020Dokument4 SeitenE3sconf Icemee2021 03020Akanksha PendharkarNoch keine Bewertungen

- Composite ConstructionDokument2 SeitenComposite Constructionkapilsharma404Noch keine Bewertungen

- Cantilever Structure in Modern Construction: XXVI R-S-P Seminar 2017, Theoretical Foundation of Civil EngineeringDokument7 SeitenCantilever Structure in Modern Construction: XXVI R-S-P Seminar 2017, Theoretical Foundation of Civil Engineeringgayatri parkarNoch keine Bewertungen

- A Project Report On Analysis and DesignDokument14 SeitenA Project Report On Analysis and Designyoyo 9585873163100% (1)

- The Structural Behavior of Low Medium Hi1Dokument8 SeitenThe Structural Behavior of Low Medium Hi1DEPARTMENT OF CIVIL ENGINEERINGNoch keine Bewertungen

- High Rise BuildingDokument4 SeitenHigh Rise BuildingMel FNoch keine Bewertungen

- Design of Commercial Building (G+3)Dokument68 SeitenDesign of Commercial Building (G+3)avnishNoch keine Bewertungen

- Services in High Rise Buildings: Origin: ScopeDokument1 SeiteServices in High Rise Buildings: Origin: ScopeIndrajit GaikwadNoch keine Bewertungen

- Factors Affecting Duration of High-Rise ConstructionDokument10 SeitenFactors Affecting Duration of High-Rise ConstructionAtef RagabNoch keine Bewertungen

- Applsci 13 09014Dokument17 SeitenApplsci 13 09014Evelin AlvaradoNoch keine Bewertungen

- Hybrid' Light Steel Panel and Modular SystemsDokument11 SeitenHybrid' Light Steel Panel and Modular SystemsIr AyenNoch keine Bewertungen

- The Structural Behavior of Low Medium Hi PDFDokument7 SeitenThe Structural Behavior of Low Medium Hi PDFabdul khaderNoch keine Bewertungen

- Structures: Huu-Tai Thai, Tuan Ngo, Brian UyDokument26 SeitenStructures: Huu-Tai Thai, Tuan Ngo, Brian UyHit PopatNoch keine Bewertungen

- Group 5 - Construction Methods and Operations-1Dokument6 SeitenGroup 5 - Construction Methods and Operations-1Donna Cece MelgarNoch keine Bewertungen

- 3D Printing of Reinforced Concrete Elements Technology and DesignDokument14 Seiten3D Printing of Reinforced Concrete Elements Technology and DesignSharifah Intan Amira Binti Sayed Mustaffa KamalNoch keine Bewertungen

- Construction Procedure of A Straw Bale Walled Building - A RevewDokument9 SeitenConstruction Procedure of A Straw Bale Walled Building - A RevewJan Roycan DamanikNoch keine Bewertungen

- Mivan TechnologyDokument24 SeitenMivan TechnologyArjun MNoch keine Bewertungen

- Sustainable Prefabricated Modular Buildings Cut Construction WasteDokument8 SeitenSustainable Prefabricated Modular Buildings Cut Construction WasteAnselm FernandesNoch keine Bewertungen

- 14 Case Study Shanghai World Financial CenterDokument6 Seiten14 Case Study Shanghai World Financial CenterElvin Michaels100% (1)

- Affordable House 2010Dokument23 SeitenAffordable House 2010Ionut SavaNoch keine Bewertungen

- Define ConstructionaaaaaDokument1 SeiteDefine ConstructionaaaaaidlydumpfvckNoch keine Bewertungen

- Slenderness Ratio InfluenceDokument8 SeitenSlenderness Ratio InfluenceBaguma Grace GariyoNoch keine Bewertungen

- Prefabricated Construction in Hong KongDokument142 SeitenPrefabricated Construction in Hong Kongsolano21Noch keine Bewertungen

- Space Efficiency in Contemporary Supertall Residential BuildingsDokument13 SeitenSpace Efficiency in Contemporary Supertall Residential BuildingsEmre ILGINNoch keine Bewertungen

- Prgstalleretal ForcesbehindthesceneDokument9 SeitenPrgstalleretal ForcesbehindthescenecelsoNoch keine Bewertungen

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresVon EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNoch keine Bewertungen

- Jason Anthony ResumeDokument2 SeitenJason Anthony ResumeaialosangelesNoch keine Bewertungen

- UPVC Windows Benefits Over Wood, Steel and AluminiumDokument2 SeitenUPVC Windows Benefits Over Wood, Steel and Aluminiumnaresh kumarNoch keine Bewertungen

- LRFD Accelerated Bridge ConstructionDokument21 SeitenLRFD Accelerated Bridge ConstructionJhon Escobar0% (1)

- 6 Cladding (A2) - Layout1 PDFDokument1 Seite6 Cladding (A2) - Layout1 PDFHarshit Gupta100% (1)

- FibracousticDokument2 SeitenFibracousticPratik ThakkarNoch keine Bewertungen

- Strength Design of Structural Masonry - 2017 10 12Dokument70 SeitenStrength Design of Structural Masonry - 2017 10 12Ricardo Muñiz DelgadoNoch keine Bewertungen

- NSC Feb 2015Dokument34 SeitenNSC Feb 2015onurumanNoch keine Bewertungen

- Bill of Quantities (Boq) For Labor WorkDokument7 SeitenBill of Quantities (Boq) For Labor WorkSiddiqur RahmanNoch keine Bewertungen

- Academic Zone - Detailed Area ProgramDokument6 SeitenAcademic Zone - Detailed Area ProgramAshwin AdveNoch keine Bewertungen

- Services Integration With Concrete Buildings Guidance For A Defect Free Interface (Sample)Dokument7 SeitenServices Integration With Concrete Buildings Guidance For A Defect Free Interface (Sample)AndRew YNoch keine Bewertungen

- JEWELLERY CASE STUDY Final SONALDokument33 SeitenJEWELLERY CASE STUDY Final SONALsonal guptaNoch keine Bewertungen

- The Architect and The LawDokument9 SeitenThe Architect and The LawKenneth Williams100% (2)

- Sandwich 3D Panel System: Construction Practices and Experimental InvestigationsDokument11 SeitenSandwich 3D Panel System: Construction Practices and Experimental InvestigationsVirat DesaiNoch keine Bewertungen

- Estimtiation of KUNAR Cold StorageDokument6 SeitenEstimtiation of KUNAR Cold StorageMilad Ahmad MST100% (1)

- 2 Concrete Works CompuDokument14 Seiten2 Concrete Works CompuALFONSO RAPHAEL SIANoch keine Bewertungen

- Scope of Work Material Unit I. Facilities: Group MembersDokument5 SeitenScope of Work Material Unit I. Facilities: Group MembersAganon AristotleNoch keine Bewertungen

- DRG 02Dokument1 SeiteDRG 02Palak BhatiaNoch keine Bewertungen

- Technical Drawing GuideDokument26 SeitenTechnical Drawing GuideB.i. Shahed0% (1)

- Sample Field ReportDokument6 SeitenSample Field ReportIsabellaPeriginaNoch keine Bewertungen

- 2018 STD Plns For Web A11y PDFDokument601 Seiten2018 STD Plns For Web A11y PDFchuaycharNoch keine Bewertungen

- Revised Drawings For Courtyard MarriottDokument20 SeitenRevised Drawings For Courtyard MarriottNews10NBCNoch keine Bewertungen

- ompadmin,+MOMOWO 01 LOPEZ RODERO LOCK PDFDokument8 Seitenompadmin,+MOMOWO 01 LOPEZ RODERO LOCK PDFRaquel SantosNoch keine Bewertungen

- Herbert Jacobs House Casestudy P2-CompressedDokument19 SeitenHerbert Jacobs House Casestudy P2-CompressedFiorella Isabel Benitez QuiñonezNoch keine Bewertungen

- Japanese GardensDokument13 SeitenJapanese GardensAshok Nirman100% (1)

- Koflan Catalogue Accessories 2022 New Stock PDFDokument40 SeitenKoflan Catalogue Accessories 2022 New Stock PDFBenjamin ngilaNoch keine Bewertungen

- Ceramic Stone and Waterproofing Systems and Work Method StatementsDokument65 SeitenCeramic Stone and Waterproofing Systems and Work Method StatementsumitNoch keine Bewertungen

- Case StudyDokument1 SeiteCase StudyShirya EvaNoch keine Bewertungen

- Expandable House: For Disaster Relief and Flexible DwellingDokument77 SeitenExpandable House: For Disaster Relief and Flexible DwellingkimNoch keine Bewertungen

- Architecture Thesis Topics List PhilippinesDokument4 SeitenArchitecture Thesis Topics List Philippinesjessicatannershreveport100% (2)