Beruflich Dokumente

Kultur Dokumente

Evaluation of Current Design Practices On Estimation of PDF

Hochgeladen von

yousef1369Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Evaluation of Current Design Practices On Estimation of PDF

Hochgeladen von

yousef1369Copyright:

Verfügbare Formate

Sep. 2013, Volume 7, No. 9 (Serial No. 70), pp.

1080-1091

Journal of Civil Engineering and Architecture, ISSN 1934-7359, USA

DAVID

PUBLISHING

Evaluation of Current Design Practices on Estimation of

Axial Capacity of Concrete Encased Steel Composite

Stub Columns: A Review

Amiya Kumar Samanta1 and Amit Paul2

1. Department of Civil Engineering, National Institute of Technology, Durgapur 713209, India

2. Durgapur Projects Ltd., Durgapur 713201, India

Abstract: This paper presents the design assessment of concrete encased I-sections composite column based approaches given in

Eurocode, ACI Code, BS Code and AISC-LRFD. This study includes comparison of various design parameters and evaluation of

design strength based on the procedures predicted in the various codes of practices. A practical example has been assumed and

calculation has been shown to evaluate their potentiality in understanding in predicting the potentiality of various procedures. The

obtained results based on the methods varies widely, because of the different design considerations adopted by the different codes. As

such, they have hardly considered the effect of confinement of the concrete due to the presence of longitudinal reinforcements as well as

lateral ties. The study has attempted to throw light on critical review and their potentiality in assessing the strength of such concrete

encased composite column under purely axial loads.

Key words: Concrete encased, structural steel, composite column, design philosophy.

1. Introduction

A composite column is a compression member

which may either be made up of a structural steel

sections encased by concrete or concrete filled in

hollow circular/rectangular steel tube. A few such

cross-sections are shown in Fig. 1. These compression

members are extensively used in the construction of tall

building under a specified time frame in the developing

countries over the last few decades. It has got a few

advantages over the conventional reinforced concrete

construction: (1) due to its higher strength and stiffness,

cross-sectional area reduces; (2) reduces material

consumption and project execution time; (3) inherent

ductility resulting in suitability for earthquake loading;

and (4) provides good fire resistance. As a result, it is

becoming increasingly popular in the construction

industry particularly in foreign countries, those having

Corresponding author: Amiya Kumar Samanta, M.Tech.,

Ph.D., research field: structural engineering. E-mail:

aksnitd@gmail.com.

a definite design guideline based on their individual

codes of practice and advanced construction

techniques/equipments. But in India, it is still not

adopted, in general, in spite of the efforts from various

ends due its lack of design guideline or code of practice.

This study presents a critical review of knowledge base

on concrete encased steel I-section composite columns.

The discussion is mainly focused on the behavior of

stub columns based on various codes of practice and a

comparison.

Several commonly used methods, which are

available at present for designing such composite

columns, include Eurocode 4 (EC4): Part 1.1, BS 5400:

Part 5, ACI 318 and AISC-LRFD specifications. The

objective of this presentation is to assess the suitability

of current design methods as per the mentioned codes

of practice for evaluating the ultimate compressive

strength of concrete encased steel I-section composite

column and to recommend design guidelines in Indian

perspective. The differences in the design capacities

following the above codes of practice are highlighted

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

Fully encased Partially encased

RHS

Circular

(a) Concrete encased sections (b) Concrete filled hollow

sections

Fig. 1

Typical composite column sections.

and compared. Design calculations are carried out for

typical cross-section(s) to mention their similarities

and differences. An attempt has also been made to

include other parameters which are not yet included in

those procedures for better understanding and

prediction of its behavior in the conclusion.

2. Past Researches

Past works have been carried out both

experimentally as well as numerically to study the

ultimate strength of concrete encased steel composite

column. Furlong [1] and Lundberg and Galambos [2]

described AISC-LRFD and ACI Code method for

encased composite column design with example

calculation and highlighted some of the differences in

their design philosophies. LRFD procedure is easier to

apply because it employs specific formulas for strength

values compared to ACI method. Although ACI Code

procedure requires tedious computations, but it is

applicable to cross sections of any shape and it appears

to be unnecessarily conservative for slender composite

columns. The LRFD procedure offers the most

appropriate method for designing concentrically

loaded slender composite columns.

The study reported in Mirza [3] investigated the

effects of different variables on the variability of the

ultimate strength of steelconcrete composite

columns in which steel shapes are encased in concrete.

The ultimate strength of a number of typical composite

columns was studied in terms of the ratio of

theoretical strength based on an accurate description

of strength and probability distributions of variables

affecting the strength to a nominal strength based on

1081

design expressions of the ACI Code. This was done to

non-dimensionalization of strength and to simplify the

comparison of strength for different columns. The

major conclusions drawn from the analysis of results

reported in this study are: (1) The residual stresses play

an appreciable role in the strength of composite

columns; (2) The concrete confinement provided by

the lateral ties produces a beneficial effect on the

strength of composite columns; (3) The specified

concrete strength, end eccentricity ratio and

slenderness ratio are the major parameters affecting the

variability of composite column strength.

Tawil et al. [4] had produced an interactive computer

program COSBIAN (composite section blaxial

ananlysis) for modeling biaxial bending of encased

composite steel-concrete columns to analytically

investigate the inelastic behavior based on the fiber

element method. The nominal uniaxial and biaxial

bending strengths were calculated according to

ACI-318 and LRFD specifications and compared with

fiber element analysis results. ACI-318 nor the LRFD

provisions explicitly consider any increase in the

strength or ductility of concrete due to transverse ties,

confinement effects were not included in the fiber

analyses. It was concluded that: (1) Overall, the

ACI-318 design method models the behavior more

realistic than the LRFD method; (2) For both short and

slender columns the ACI-318 strengths were slightly

unconservative (up to 8% and 10%, respectively)

compared to the fiber element results; (3) For short

columns, the LRFD strengths were up to 41%

conservative compared to the fiber results, but for

slender columns with large steel ratios (L/r = 40 and

As/Ag = 16%) the LRFD and fiber strengths were fairly

close.

Muoz and Hsu [5] proposed a set of unified design

equations and moment interaction curves to predict the

ultimate load capacity of short and slender

concrete-encased composite columns under purely

axial load as well as uniaxial/biaxial bending, which

utilizes the design parameters of both ACI and

1082

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

AISC-LRFD methods. They have carried a calculation

based on modified radius of gyration, modified

modulus of elasticity, modified allowable stress and

modified critical stress of the composite section, which

takes care of the presence of concrete and rebars while

assessing the strength of the whole section. The authors

concluded that it evaluates very accurate results in

regard to the assessment of encased composite columns

when compared with experimental results by the

different researchers.

Tawil and Deierlein [6] has reviewed design criteria

for concrete encased composite columns with emphasis

on seismic behavior and the use of high-strength

concrete. Strength and ductility of composite columns

have been studied using a fiber analysis technique that

accounts for the inelastic stress-strain response of steel

and concrete. The change in composite column

behavior as a function of the ratio of structural steel to

gross column area, the nominal compression strength

of concrete and concrete confinement by reinforcing

bar ties have also been studied. The author has limited

the discussion to short columns where slenderness

effects are not considered. The author has shown large

differences in the nominal strengths for combined axial

compression and bending calculated according to the

ACI and the AISC-LRFD specifications for concrete

encased composite columns, and this discrepancy

increases as the concrete strength increases.

Wang [7] carried out tests to calibrate EC4 against

BS 5400 for slender composite columns and assess the

accuracy of a new design method for composite

columns, based on BS 5950. In the new method, two

equations are satisfied: a local capacity check and a

global buckling check. Max and May are the reduced

column maximum buckling moments, in the presence

of the axial load N, about the major and minor axis,

respectively. The author has made comparisons

between three different methods using concrete of

grade M25/30 and low strength steel of grade Fe275

and predicted column strengths with test result and

concluded that all the codes were conservative and

have similar overall accuracy.

Narayanan and Usha [8] in their lecture note

highlighted that a composite column may be designed

for ultimate limit state for the most unfavorable load

combination. It is said that although local bucking of

steel section reduces, overall bucking must be allowed

for together with second order effects in slender

columns. A reduction in flexural stiffness due to

cracking of the concrete in the tension area should also

be considered. They proposed a design method based

on EC4 and European bucking curves, of course using

the design/material parameters from relevant Indian

code of practice.

Saw and Liew [9] presented the design assessment of

encased I-sections and CFT columns based on the

approaches given in Eurocode 4: Part 1.1, BS 5400:

Part 5 and AISC-LRFD which includes studies on the

design parameters, comparison of the nominal strength

predicted by the three codes and comparison of the

predicted strengths with the available test results.

Shanmugam and Lakshmi [10] presented the state of

art review on steel-concrete composite columns

including the behavior of short and slender composite

columns. A detailed discussion on the effect of local

buckling, bond strength, confinement of concrete,

seismic behavior and secondary stresses on composite

columns were presented. Neither the ACI-318 nor the

AISC-LRFD

provisions

explicitly

consider

confinement effects on strength or ductility of member.

ACI provisions for calculating the strength interaction

between axial and flexural effects are essentially the

same as those for reinforced concrete column, whereas

AISC-LRFD are based on the bilinear interaction

formulae which have the same form as those of steel

columns. In the above design methods, flexural

stiffness is underestimated and confining effect of the

steel tube on the concrete core is ignored. Code

provisions in BS 5400 are based on limit state design

with loading factors and material safety factors. The

ultimate moment is calculated from plastic stress

distribution over the cross-section, and an

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

approximation for the interaction curve for axial load

and moment is used. This method is applicable to

symmetrical sections only and restricted to the range of

sections catered for in the European buckling curves.

Zhong and Chen [11] presented a new simplified

superposition design method for concrete encased

composite columns subjected to biaxial bending

recommended

by

the

Chinese

YB9082-97

Specification along with the design examples.

Comparisons made between the two methods in the

determination of load carrying capacities of rectangular

cross sections with symmetrically placed H-shaped and

box-shaped structural steel indicate that the simplified

method appears to be conservative on all

cross-sectional cases studied, but display different

overall accuracies on cross sections with different

structural steel shapes and different load eccentricities.

Weng and Yen [12] calculated design strength of

concrete-encased composite column based on the

design provisions of ACI-318 (1999) and AISC-LRFD

(1993) and investigated the difference between these

two approaches. The study indicates that the predicted

The work of Mirza and Lacroix [14] compares the

strengths of 150 physical tests from the published

literature for rectangular encased composite columns in

the published literature with the strengths calculated

from selected computational procedures and also

compares computational procedures with ACI 318-02,

AISC-LRFD and EC4. The columns were braced and

pinned at both ends and subjected to short-term loads,

producing pure axial force, axial force combined with

symmetrical single-curvature bending, or pure bending.

An improvement over the procedure of ACI 318-02

was also suggested.

Chen and Lin [15] analytically investigated concrete

encased steel stub columns for predicting axial

compressive capacity considering unconfined concrete,

partially and highly confined concrete by the

longitudinal rebar, lateral ties and structural steel

section in the composite cross section including

post-peak strength. Compressive strength of partially

confined concrete is given by Eq. (1) and highly

confined concrete by Eq. (2):

'

(1)

f cp K p f

co

capacities based on the ACI-318 approach are about

8%-25% closer to the test results than those based on

the AISC-LRFD approach. It is concluded that in

general, as compared with the test results, the ACI-318

approach is found to be more accurate than the

AISC-LRFD approach in predicting the capacities of

encased composite columns. For concrete-encased

composite columns with steel ratio ranging from 2% to

12%, this comparative study reveals that the ACI-318

approach shows better strength predictions than that of

the AISC-LRFD.

Tikka and Mirza [13] have examined around 12,000

isolated square composite columns and assessed EI

value provided by ACI building code used for the

design of steel encased concrete composite columns. A

new nonlinear equation for EI has been developed for

use in design of slender composite columns subjected

bending and it has been proposed as an alternative to

the existing ACI EI equations.

1083

f ch K

'

(2)

co

whereas compressive strength of unconfined concrete

same as the concrete compressive strength

measured from the cylinder test. Kp and Kh are defined

as confinement factors for partially and highly

confined concrete. On the basis of strain compatibility

and constitutive relationships, they suggested

expression for the estimation of analytical axial load

and a simplified squash load (without considering

confinement effect) to predict the axial compressive

capacity for a stub column, but without considering the

length factor or the slenderness effect.

A generic fiber model algorithm has been presented

by Charalampakis and Koumousis [16] for the efficient

analysis of arbitrary composite sections under biaxial

bending and axial load. The geometry of the cross

section has been described by multi-nested curvilinear

polygons. The proposed method addressed towards

construction

of

moment-curvature

diagrams,

1084

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

calculation of the ultimate strength and determination

of the deformed state of the cross section under given

external loads.

Ellobody and Young [17] presented a nonlinear 3D

FE (finite element) model in Abaqus for pin-ended

axially loaded concrete encased steel composite

columns with an objective to understand the structural

response and modes of failure of the columns and to

assess the composite column strengths against current

design codes. The details of nonlinear material model

have been presented exclusively. The study covered

slender, non-slender, stub and long concrete encased

steel composite columns for concrete strength 20-110

MPa and steel yield stresses 275-690 MPa. It has been

shown that the increase in structural steel strength has a

small effect on the composite column strength for the

columns having higher relative slenderness ratios due

to the flexural buckling failure mode. The composite

column strengths obtained from the FE analysis was

compared with the design strengths calculated using

the AISC and EC4 for composite columns. Generally,

it is shown that the EC4 accurately predicted the design

strength for the concrete encased steel composite

columns having a concrete cylinder strength of 30 MPa

and structural steel yield stresses of 275 MPa and 460

MPa, which are in the limits of the code, which

otherwise, was generally conservative.

Ellobody and Young [18] investigated a nonlinear

3D FE model for concrete encased steel composite

columns with pin-ends and eccentric load acting along

the major axis. The columns were pin-ended subjected

to an eccentric load acting along the major axis (e =

0.125-0.375 D). The model was prepared in Abaqus

and it considered material non-linearity of structural

steel, concrete, longitudinal and transverse

reinforcement bars including the concrete confinement

effect and bond/interaction behavior. It has been shown

that the effect on the composite column strength due to

the increase in structural steel yield stress is significant

for eccentrically loaded columns with small

eccentricity of 0.125 D. On the other hand, for columns

with higher eccentricity 0.375 D, the effect on the

composite column strength due to the increase in

structural steel yield stress is significant for columns

with concrete strengths lower than 70 MPa. The

strength of composite columns calculated on the basis

of FE analysis was also compared with the design

strengths calculated using the EC4 & AISC Code for

composite columns.

Narayanan and Kayanraman [19] had compiled the

INSDAG (Institute of Steel Development and Growth)

guide for the structural use of steelworks I buildings.

The guide book is based on limit state of design which

has been derived from BS 5950, EC4 and IS800-2007.

This book includes method of design of concrete

encased steel composite, concrete filled steel tubes

about which IS 800 is absolutely silent and in a sense it

is most useful in Indian context, too. It uses some of

stipulations from foreign codes which is being

modified with some new set of values of partial safety

factors. That is why the authors have chosen a model

described in the next section and wishes to compare the

design strength values as described by the previous

investigators and codes of practice.

3. Model Description

A 150 mm wide 200 mm deep and 1,250 mm long

model section has been proposed for calculation. The

details of the section are shown in Fig. 2. The structural

steel I-shape section is a fabricated one made up of

flange plate 50 mm 8 mm and web plate 84 mm 5

mm encased by concrete and additionally reinforced

with four longitudinal steel corner bars as well as

lateral ties. The said cross-section has been chosen with

a view that its axial capacity does not exceed 100 t. The

experimental set-up existing in the department is

limited to 100 t.

The grade of concrete mix, structural steel and

reinforcements are M25, Fe410 and Fe415,

respectively. The slenderness ratio is 8.34, which is a

short column. Four 10 mm diameters steel bars are

provided for longitudinal covering (1.047%) and 8 mm

1085

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

diameter stirrups are given at maximum 150 mm

spacing. The material and geometrical properties are

shown in Table 1, which has been used in the

calculation unless and until specified in particular.

In most of the cases/codes, calculations have been

which defined as

done using the concrete strength

compressive strength obtained from the standard 150

mm diameter by 300 mm high cylinder tests. In general,

the author derives the concrete compressive strength

Eq. (3) from the 150 mm cube tests:

(3)

Hence to calculate the concrete compressive

cylinder strength from the concrete compressive cube

strength [14], the following Eq. (4), in this case, for Eq.

(5) has been used:

0.76

25,

0.2 log

0.78

0.8f

(4)

(5)

Fig. 2

Sectional properties of concrete encased composite column.

Table 1 Geometrical and material properties used.

Item description

Gross section

Concrete grade M25

Structural steel

grade Fe410

Rebar

grade Fe415

Property

Overall section

Gross c/s area

Minimum M.I.

Notation

bdL

Ag (mm2)

Ig (mm4)

Net area of concrete

Ac (mm2)

Minimum M.I.

Comp. cube strength

Comp. cylinder strength

Modulus of elasticity

Area of structural steel

Minimum M.I.

Ratio of structural steel

Modulus of elasticity

Yield stress

Area of rebar

Minimum M.I.

Rebar ratio

Modulus of elasticity

Yield stress

Ic (mm4)

fck (MPa)

fc (MPa)

Ec (MPa)

Ass (mm2)

Iss (mm4)

ss (%)

Ess (MPa)

fys (MPa)

Ars (mm2)

Irs (mm4)

rs (%)

Ers (MPa)

fyr (MPa)

Magnitude

Remarks

150 200 1,250 L = 1,250

30,000

5.625 107

Unconfined concrete (Acu) = 19,908

28,466

Partially confined (Acp) = 6,057

Highly confined (Ach) = 2,501

5.544 107

25

fck = fcu

20

0.8

25,000

Ec = 5,000

1,220

Flange 50 8, Web 84 5

167,542

4.07

2 105

250

fu = 410

314

10-4nos.

638,136

1.05

2 105

360

fu = 415

1086

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

4. Review of Design Methodology

4.1 Approach by Chen and Lin [15]

The analytical axial load Eq. (6):

(6)

where, f and A stands for stress and area, subscript s

and r stands for structural steel and rebar, u, p and h

stands for unconfined, partially confined and highly

confined concrete, respectively. Choosing the material

properties as described in Table 1 and assuming

confinement factors Kp = 1.2, Kh = 1.4 for concrete

grade M25, stress of the partially confined concrete

Eq. (7), stress of the highly confined concrete Eq. (8):

1.2 20 = 24.0 MPa

(7)

1.4

20 = 28.0 MPa

(8)

Hence,

= (250 1,220+ 360 314 + 20 19,908 +24

6,057 + 28 2,501)N = 1,032 kN

(9)

The squash load was derived as Eq. (10):

0.85

(10)

where, fys is the yield strength of the structural steel, fys

is the yield strength of the longitudinal bar, Ac is the

total area of the concrete. Choosing the same materials,

having yield stress in structural steel Eq. (11), yield

stress of the longitudinal bars Eq. (12), characteristic

stress in concrete Eq. (13):

fys = 250 MPa

(11)

(12)

fyr = 0.87 fy = 360 MPa

(13)

fc = 0.8 25 = 20 MPa

Psquash = 0.85 (0.8 25) 28,466 + 250 1,220

+ 360 314 = 902 kN

(14)

It may be noted that the Panalysis is dependent on

confinement factors, which is again dependent on

details, spacing of lateral ties and both Panalysis as well

as Psquash are factored/ultimate loads. Hence based on

the expressions, design axial working load may be

derived using a factor (= 1.5) as 902/1.5 = 601 kN.

4.2 Approach by Mirza and Lacroix [14]

Mirza and Lacroix [14] calculated strength of

composite columns in pure axial compression using

three international standards: (1) ACI318-02; (2)

AISC-LRFD; (3) Eurocode 4 and compared them with

published experimental results. In all cased pin ended

column has been considered with minor axis bucking in

the following applications of various codes.

4.2.1 ACI318-02

It specifies maximum axial load (upper limit Pn) =

.

with = 0.85 and Eq. (15):

0.85

(15)

where, Ag is gross area of column cross section, Ass and

Ars are the area of structural steel and rebars, fc is the

cylinder strength of concrete, fyss and fyrs are the yield

strength of structural steel and rebars, respectively. The

authors get Eqs. (16) and (17):

Po = 0.85 20 28,466 + 250 1,220 +

360 314 = 902 kN

(16)

(17)

It also specifies maximum axial load for pin ended

column (lower limit Pc) = 2EI/l2 with minimum EI =

(0.2 EcIg + EsIss) where modulus of elasticity of

concrete Eq. (18):

P0 = 0.85 902 = 767 kN

Ec= 57,000

Hence:

ksi = 4,733

Mpa = 31,167

(18)

EI = 0.2 21,167 5.625 107 +

2 105 167,542 = 2.72 1,011

(19)

Pc = 2.72 10 /1,250 N = 1,716 kN (20)

2

11

for short-term loading. If cracking and nonlinearity is

taken into account in the calculation of EI as per

Mirza-Tikka (1999), then the authors get Eq. (21):

0.3

0.3

0.2

0.2

0

0.8

21,167

5.625

10

167,542

4.85 10

0.8 2 10 167,542 638,136

(21)

However, considering the lower EI design axial

capacity will be the lesser of Pn and Pc, i.e., 767 kN.

4.2.2 AISC-LRFD

It procedures uses axial capacity for pin ended

column Eqs. (22) and (23):

0.658

for

1.5

(22)

.

for

1.5

(23)

where, Eq. (24) with modified modulus of elasticity Eq.

(25), modified yield strength Eq. (26):

.

(24)

1087

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

0.2

(25)

/

0.7

0.6

(26)

and modified radius of gyration rm = 0.3 times least

lateral dimension of composite section. With rm = 0.3

150 = 45 mm and other equations:

Em = 2 105 + 0.2 21,677 28,466/1,220 = 301,110 MPa (27)

fmy = 250 + 0.7 360

+ 0.6 20

,

,

0.393

(29)

(30)

The composite column slenderness parameter Eq. (49)

with Eq. (50):

and for:

1.5

1,220

595

680 kN

and modified critical stress for composite section is

calculated as Eq. (45) or Eq. (46):

0.658

for

1.5

(45)

(46)

with modified allowable stress of composite section by

LRFD as Eq. (47), modified modulus of elasticity for

composite section Eq. (48):

/

/

/

(47)

/

/

/

(48)

= 595 MPa (28)

ACI and AISC-LRFD methods, the design axial

capacity (without bending moments) of a composite

. , where nominal axial

column is given by

.

,

being gross sectional area

strength

0.877/

for

1.5

4.2.3 Eurocode 4

(49)

It defines the resistance of the column under pure

.

where reduction

axial compression as

/ .

coefficient:

(31)

(32)

1/

0.5 1

0.2

0.49 and nondimensional

imperfection factor

slenderness ratio:

(33)

as modified radius of gyration for composite section

satisfying

0.3 , where b = least dimension of

column cross section, k1 = 0.60, k2 = 0.80, k3 = 0.80,

4,733

and k4 = 1.5. With

the properties of Table 1:

0.85

767 kN

20

28,848 5.625

10 167,542

1.44

Pc =

28,848 MPa

10

167,542

63,8136

0.49 0.29

1/ 0.564

1.44

10

0.29

0.2

0.564

0.953

0.29

0.29

767

0.6

0.564

0.953

731 kN

(41)

(42)

(43)

(44)

4.3 Approach by Muoz and Hsu [5]

Approach by based on the design parameters of both

33.83

20

,

,

250

(51)

45

1,220

28,466 /30,000

(36)

(37)

(38)

(39)

(40)

150

10 314

1.5

41,065 MPa

0.8

,

360

22.53 MPa

638,136

10 /1,250 N = 9,128 kN

7679,128

0.5 1

(35)

0.8

9,500

0.3

With the equations in the following:

9,500

21,167 MPa and

(34)

Pc =

0.8

(50)

/ .

0.275

21,667

(52)

0.8

(53)

(54)

for:

1.5,

22.53 0.658

30,000

0.85

21.83

655

21.83 MPa (55)

655 kN

557 kN

(56)

4.4 Approach by Tikka and Mirza [13]

Tikka and Mirza [13] used ACI building code

procedures along with an projection of ultimate axial

capacity of concrete encased steel column using a new

1088

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

equation for EI as an alternative to the existing ACI EI

equation. Assuming minor axis post-buckling failure

criteria and from an extensive regression analysis they

proposed the short-term effective flexural stiffness Eq.

(57), Where dimensionless reduction factor for

concrete Eq. (58):

(57)

0.47

3.5

30 ,

eccentricity ratio , slenderness ratio

reinforcement ratio

1% , structural steel ratio

4%, dimensionless reduction factor for structural

steel

= dimensionless reduction factor for

longitudinal rebar

= 0.8. With minimum

0.1,

1,250 150 8.33, the authors get Eq.

(59) and with with modulus of elasticity of concrete

Eqs. (60) and (61):

0.47

3.5

0.003

1

0.1

1 9.5 0.1

8.33 0.315

4,733

0.315

21,167

(59)

(60)

21,167 MPa

28,848 5.625

10

167,542

(61)

Considering the smaller one, the design capacity

becomes 767 kN.

0.8

10 167,542

386,808

1.08

10

4.5 Approach by Ellobody and Young [17]

Ellobody and Young [17] calculated strength of

composite columns in pure axial compression using

two international standards: (1) AISC-LRFD; (2)

Eurocode 4 and compared them with 3D FE model in

ABAQUS:

(1) The unfactored design strengths (PAISC) for

axially loaded concrete encased steel composite

columns calculated based on column slenderness as Eq.

(62) for Eq. (63) and Eq. (64) for Eq. (65):

0.658

(62)

(63)

(64)

(65)

0.44

0.877

0.44

where, the authors get:

0.85

0.1

(66)

0.3

(67)

(68)

(69)

where, A = respective area (mm ), E = modulus of

elasticity (MPa), I = MI (mm4) and f = respective

cylinder/yield stress (MPa). With the material

properties from the equations:

(58)

0.003

0.5

0.1

2

10 167,542

21,167

5.625

3.128

10

250

0.85

638,136

3.128

/ 1,250

1,220

20

0.5

10

0.44

0.181

(71)

(72)

10

1,976

360

28,466

(70)

0.181

314

(73)

(74)

(75)

902 kN

902

397

0.658

745 kN

(2) On the other hand, as per EC4 the unfactored

design strengths (PEC4) for axially loaded concrete

encased steel composite columns was calculated using

the simplified method of design, based on the relative

slenderness () as Eq.(76):

.

(76)

where, Eq. (77) with Eq. (78) and relative slenderness

Eq. (79):

.

1

(77)

0.5 1 0.49

0.2

(78)

.

(79)

where, Ecm is the secant modulus of elasticity of

concrete in MPa for short-term loading, Le is the

effective length of the composite column. With:

9,500

0.85

,

(81)

.

,

,

,

0.356

0.5 1

0.49 0.356

0.2

0.356

0.602

0.356 .

250

360

1,220

314

1.1

1.15

698 kN

28,846 0.85 .

0.602

(80)

28,848 MPa

(82)

0.602 (83)

0.92 (84)

(85)

1089

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

0.92

698

(86)

642 kN

As per their proposed method, based on Eurocode 4

and relevant IS Code of practice, the following partial

safety factors are assumed. Partial safety factors for

structural steel a, reinforcement s, concrete c and

Concrete for determination of effective stiffness c* are

1.15, 1.15, 1.5 and 1.35, respectively. For concrete

grade M25, concrete modulus of elasticity Eq. (87):

Ecm= 5,00025 = 25,000 MPa

(87)

For short term loading, effective flexural stiffness of

composite column Eq. (88), where Ecd = Ecm/c*.

0.8

(88)

The elastic critical buckling load Eq. (89), and

plastic resistance of the encased section Eq. (90):

/

(89)

0.85

(90)

Plastic resistance of the cross-section to compression

(with a = c= s= 1.0) is the following Eq. (91). Non

dimensionalized slenderness parameter computed in

the plane of buckling is , Eq. (92):

(91)

=

/

(92)

Assuming imperfection factor for buckling about

minor axis is the following Eq. (93), reduction factor

for column buckling is the following Eq. (94):

y = 0.34, = 0.5 1

0.2

(93)

/

(94)

Buckling load of a column under pure axial

compression:

(95)

103 MPa

Ecd = 25,000/1.35 = 19.23

= 2.0

10 167,542

10

5.54

/ =

1,220

10 = 9.83

9.83

250

1.15

250

28,466

0.8

10

11

(96)

19.23

(97)

10 /1,250 = 621 kN (98)

28,466

314

1,220

638,136

0.85

= 701 kN

20

314

(101)

Assuming imperfection factor for buckling about

minor axis is Eqs. (102) and (103), reduction factor is

Eq. (104), axial capacity is Eq. (105):

y = 0.34

(102)

= 0.5

1 0.34

0.385 0.2

0.385 = 0.605 (103)

=

4.6 Approach by Narayanan and Usha [8]

Slenderness parameter Eq. (101):

20

1.5

0.605

= 919621 = 0.385

0.605

0.385

0.932

As per the INSDAG guide authored by Narayanan

and Kayanraman [19], the plastic resistance of an

encased steel section, i.e., so called squash load is

given by Eq. (106) and its example Eq. (107):

(106)

.

(107)

and

stand for cross sectional area of

where, ,

steel section, the concrete and reinforcing steel

,

and

are the yield

respectively;

strength of the steel section, the characteristic

compressive strength(cylinder) of the concrete and

yield strength of reinforcing steel respectively; (fck)cu is

the characteristic compressive strength (cube) of the

concrete;

is the strength co-efficient for concrete

and is equal to 0.85 for fully or partially restrained

concrete encased steel section. For fully encased

section, local buckling of steel section check is not

required provided cover to the flange is neither less

than 40 mm nor one sixed of the least lateral dimension.

The buckling resistance of a column is derived from

non-dimensionalised column buckling curve (which

also takes care of both residual stress and geometric

.

imperfection) as

, where the reduction factor

( ) is derived on the basis of non-dimensionalised

slenderness ratio:

.

415 = 919 kN

(100)

(105)

4.7 Approach by Narayanan and Kayanraman [19]

(99)

= 0.932 (104)

701 = 653 kN

(108)

which is limited to 0.8 for non-sway column and 0.5 for

sway column. For short term loading, effective flexural

stiffness of composite column is given by:

1090

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

(109)

0.8

Ecm/c*

where, Ecd =

(The factor 0.8 is an empirical

multiplier). This method also uses IS 800-2007 for the

estimation of axial capacity of composite column.

Using the properties of materials as in Table 1, the

authors have Eq. (110), The elastic critical buckling

load Pcr (Eq. (110)):

= 2.0

10

2.0

10

10

167,542

3.078

5.544

.

11

638,136 = 3.078

/ =

0.8

10 N-mm

10 /1,250

(111)

10 N

=1.944

(110)

Plastic resistance of the encased section:

0.85

284,66

=

0.85

1,220

314

= 873,810 1.944

= 686 kN (112)

10

= 0.67 (113)

With y = 0.49, the authors have Eq. (114):

= 0.5 1

0.670

0.2

0.2

0.670

= 0.5

= 0.8396

0.49

(114)

Reduction factor:

0.8396

0.8396

0.670

= 0.743 (115)

Buckling load of a column (member) under pure

axial compression:

= 0.743 686 510 kN

(116)

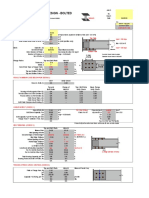

5. Comparison of Axial Capacity

Chen and Lin [15] evaluated the factored capacity of

concrete encased steel column and is purely based on

Table 2

analytical method considering force-deformation

relationship of all the individual components. It also

takes care of confinement effect of concrete which

needs experimental verification. Hence the said

capacity can not be assumed to be safe for the purpose

of design. Tikka and Mirza [13] assumes the upper

bound value of ACI building code as the capacity of the

column. Mirza and Lacroix [14] and Ellobody and

Young [17] derived the values. A comprehensive list of

design capacities derived as above have been enlisted

in Table 2, purely on the basis of AISC and EC4 codes

and the estimated capacity is unfactored ones. Muoz

and Hsu [5] although described a new method using

equivalent sectional properties and stress parameters, it

evaluated the capacity much on conservative end.

Narayanan and Usha [8] used EC4 provision

extensively and justifies the capacity using limit state

concept by incorporating the partial safety factors for

all the components and plastic resistance of the

section indirectly. In this connection, this method

seems to be comparative in Indian context, which

incorporates latest revisions in relevant code of

practice for steel construction practices. Narayanan

and Kayanraman [19] has described the same method

following EC4 as previous one but incorporates an

empirical factor c* = 7.55 to derive effective elastic

flexural strength.

Comparison of Paxial.

Sl. No. Reference

1

Chen and Lin [15]

Mirza and Lacroix [14]

Muoz and Hsu [5]

Tikka and Mirza [13]

Ellobody and Young [17]

6

7

Narayanan and Usha [8]

Narayanan and Kayanraman [19]

Notation

Remarks

Magnitude (kN)

1,032

902

767

680

729

2.02

1.77

1.50

1.33

1.43

557

1.09

767

745

642

653

510

1.50

1.46

1.26

1.28

1.00

Factored capacity

Unfactored capacity

New method based on ACI &

AISC-LRFD

Using modified EI value

New method based on EC4

INSDAG guide 2003 & IS800-2007

Evaluation of Current Design Practices on Estimation of Axial Capacity of

Concrete Encased Steel Composite Stub Columns: A Review

6. Conclusions

This paper presents a review on methods of design

based on approaches given in the current version of

Eurocode, ACI Code and AISC-LRFD and their

assessment for concrete encased composite column

under subjected to only axial load. It includes

comparison of various design process/parameters and

evaluation of design strength based on the procedures

predicted in the various codes of practices. A practical

I-section has been assumed and calculation has been

shown using the methods discussed to evaluate their

potentiality in understanding and predicting the

strength of fully encased composite column section. It

has been found that the evaluated strength varies

widely and their acceptability in Indian context is also

difficult. As per the INSDAG procedure, which is

again based on the foreign code EC4, seems to derive

the axial capacity of composite column much oan

conservative side. Also the limits in slenderness ratio

for which axial capacities are derived varying widely.

Hence there is a need for analytical as well as

experimental verification of similar models including

various parametric studies so that a rational and

practical approach may be adopted in Indian codes of

practice.

References

[1]

[2]

[3]

[4]

[5]

R.W. Furlong, Column rules of ACI, SSLC and LRFD

compared, Journal of Structural Engineering 110 (11)

(1984) 2820-2823.

J.E. Lundberg, T.V. Galambos, Load and resistance factor

design of composite columns, Structural Safety 18 (2-3)

(1996) 169-177.

S.A. Mirza, Parametric study of composite column

strength variability, Journal of Constructional Steel

Research 14 (2) (1989) 121-137.

S.E. Tawil, C.F. Sanz-Picn, G.G. Deierlein, Evaluation

of ACI 318 and AISC (LRFD) strength provisions for

composite beam-columns, Journal of Constructional Steel

Research 34 (1) (1995) 103-123.

P.R.

Muoz, C.T.T.

Hsu, Biaxially loaded

concrete-encased composite columns: Design equation, J.

Struct. Engrg. 123 (12) (1997) 1576-1585.

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

1091

S.E. Tawil, G.G. Deierlein, Strength and ductility of

concrete encased composite column, Journal of Structural

Engineering 132 (10) (1999) 1590-1602.

Y.C. Wang, Tests on slender composite columns, Journal

of Constructional Steel Research 49 (1) (1999) 25-41.

R. Narayanan, P. Usha, Steel-Concrete Composite

Columns, Refresher Course on Composite Construction

Using Structural Steel (Jan. 17-21, 2000) at Jadavpur

University, Kolkata Organized by Institute for Steel

Development & Growth (INSDAG), India, 2000.

H.S. Saw, J.Y.R. Liew, Assessment of current methods for

the design of composite columns in buildings, Journal of

Constructional Steel Research 53 (2) (2000) 121-147.

N.E. Shanmugam, B. Lakshmi, State of the art report on

steel-concrete

composite

columns,

Journal

of

Constructional Steel Research 57 (10) (2001) 1041-1080.

J.H. Zhong, S.F. Chen, Evaluation of simplified

superposition design method for composite columns, in:

The Third International Conference on Advances in

Steel Structures (ICASS02), Hong Kong, 2002, pp.

559-566.

C.C. Weng, S.I. Yen, Comparisons of concrete-encased

composite column strength provisions of ACI code and

AISC specification, Engineering Structures 24 (1) (2002)

59-72.

T.K. Tikka, S.A. Mirza, Nonlinear EI equation for slender

composite columns bending about the minor axis,

Journal of Structural Engineering 132 (10) (2006)

1590-1602.

S.A. Mirza, E.A. Lacroix, Comparative strength analyses

of concrete-encased steel composite columns, J. Struct.

Engrg. 130 (12) (2004) 1941-1953.

C.C. Chen, N.J. Lin, Analytical model for predicting axial

capacity and behavior of concrete encased steel composite

stub columns, Journal of Constructional Steel Research 62

(5) (2006) 424-433.

A.E. Charalampakis, V.K. Koumousis, Ultimate strength

analysis of composite sections under biaxial bending and

axial load, Advances in Engineering Software 39 (11)

(2008) 923-936.

E. Ellobody, B. Young, Numerical simulation of concrete

encased steel composite columns, Journal of

Constructional Steel Research 67 (2) (2011) 211-222.

E. Ellobody, B. Young, Eccentrically loaded concrete

encased steel composite columns, Thin-Walled Structures

49 (1) (2011) 53-65.

R. Narayanan, V. Kalyanraman, The Structural Use of

Steel Works in Buildings, Indian Institute of Technology

Madras and Institute of Steel Development and Growth

(INSDAG), India, 2003.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ETAG 007: Guideline For European Technical Approval ofDokument46 SeitenETAG 007: Guideline For European Technical Approval ofMatt MacDonaghNoch keine Bewertungen

- CraneDokument27 SeitenCranemsk7182Noch keine Bewertungen

- Mathcad - Pipe Gusset PlateDokument4 SeitenMathcad - Pipe Gusset PlatePradeep ChitluriNoch keine Bewertungen

- SOM Question Bank For RevisionDokument11 SeitenSOM Question Bank For RevisiongoldencometNoch keine Bewertungen

- NS18steeldesign 3 PDFDokument51 SeitenNS18steeldesign 3 PDFLemark R.Noch keine Bewertungen

- Extended End Plate Moment Connections PDFDokument47 SeitenExtended End Plate Moment Connections PDFManvitha Reddy100% (1)

- AISC LRFD Moment Connections BoltedDokument531 SeitenAISC LRFD Moment Connections BoltedManoj JaiswalNoch keine Bewertungen

- Design of Steel Beams - TablesDokument4 SeitenDesign of Steel Beams - TablesPonnada MarkandeyarajuNoch keine Bewertungen

- Proracun - Example Cold Formed SteelDokument10 SeitenProracun - Example Cold Formed SteelpedjaNoch keine Bewertungen

- Civil EngineeringDokument16 SeitenCivil EngineeringYashpal GangeshwarNoch keine Bewertungen

- Composites Fundamentals Questions and AnswersDokument16 SeitenComposites Fundamentals Questions and AnswersAdrian ArasuNoch keine Bewertungen

- Spaghetti Bridge Construction HintsDokument22 SeitenSpaghetti Bridge Construction Hintsjorgefernando98100% (1)

- DRS-007 Design Report For Walkway Support SystemDokument4 SeitenDRS-007 Design Report For Walkway Support SystemcmthebossNoch keine Bewertungen

- Compartment Masonry Walls in Fire SituationsDokument22 SeitenCompartment Masonry Walls in Fire SituationsnaidademNoch keine Bewertungen

- AISC-Design of Structural Connections-Hogan and Thomas-4th ED-1994-OCRDokument338 SeitenAISC-Design of Structural Connections-Hogan and Thomas-4th ED-1994-OCRBarrasons Engineers TeamNoch keine Bewertungen

- End Plate DesignDokument26 SeitenEnd Plate DesignNitesh SinghNoch keine Bewertungen

- Adam Christopulos Thesis (BRB Reference-BRB04)Dokument331 SeitenAdam Christopulos Thesis (BRB Reference-BRB04)Anant ParghiNoch keine Bewertungen

- Structural Behavior of Steel-Concrete Composite BeamDokument12 SeitenStructural Behavior of Steel-Concrete Composite BeamJaime Morales BazalduaNoch keine Bewertungen

- Design The Midship Section and Calculate Von-Misses Stress.: Pathak PharindraDokument31 SeitenDesign The Midship Section and Calculate Von-Misses Stress.: Pathak PharindraPharindra PathakNoch keine Bewertungen

- Tire A PartDokument12 SeitenTire A PartmilosarNoch keine Bewertungen

- Static Metallic Manual - Mts004Dokument656 SeitenStatic Metallic Manual - Mts004ROUSSMAT83% (6)

- 22) Composite Beams - IIDokument47 Seiten22) Composite Beams - IIPrabhumk07100% (2)

- Crane Girder Beam Design - ExampleDokument6 SeitenCrane Girder Beam Design - Exampledinesh100% (3)

- Dynamic Stability of Thin-Walled Structures: A Semi-AnalyticalDokument244 SeitenDynamic Stability of Thin-Walled Structures: A Semi-Analyticalnjm00175% (4)

- 1) EM 1110 345 413 Design of Structures To Resist The Effects of Atomic WeaponsDokument166 Seiten1) EM 1110 345 413 Design of Structures To Resist The Effects of Atomic WeaponsLeonichevNoch keine Bewertungen

- Buckling: From Wikipedia, The Free EncyclopediaDokument10 SeitenBuckling: From Wikipedia, The Free EncyclopediaSherif GebalyNoch keine Bewertungen

- Refresher. Roales 3. 2022 09 28Dokument27 SeitenRefresher. Roales 3. 2022 09 28reneotejrboardexamNoch keine Bewertungen

- Flare Header Failure-AnalysisDokument5 SeitenFlare Header Failure-AnalysisChem.EnggNoch keine Bewertungen

- Indian Standard: Code of Practice For General Construction, in SteelDokument144 SeitenIndian Standard: Code of Practice For General Construction, in Steelrvmehta18Noch keine Bewertungen

- ATH2017 Upgrade enDokument2 SeitenATH2017 Upgrade enFatih AvdovicNoch keine Bewertungen