Beruflich Dokumente

Kultur Dokumente

US State Emulsion Spec

Hochgeladen von

dj_peruvianOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

US State Emulsion Spec

Hochgeladen von

dj_peruvianCopyright:

Verfügbare Formate

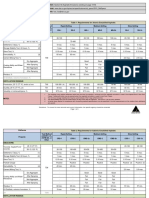

State: New Mexico

Materials: Re: Section 402-Bituminous Materials

Date: 7/29/13

Web Address: www.dot.state.nm.us

Contact: James Gallegos (Asphalt Manager)

Contact Info: James.Gallegos@state.nm.us

New Mexico

Table 1: Requirements for Anionic Emulsified Asphalts (1)

Test Method

AASHTO (T),

ASTM (D), or

Other

Property

Rapid-Setting

Medium-Setting

Slow-Setting

Quick-Setting

RS-1

RS-2

MS-1

MS-2

MS-2h

SS-1

SS-1h

QS-1H

25 C (77 F)

20-100

20-100

100 min.

100 min.

20-100

20-100

20-100

50 C (122 F)

75-400

1 max.

1 max.

1 max.

1 max.

1 max.

1 max.

1 max.

0.10max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

60 min.

60 min.

2.0 max.

2.0 max.

Dry Aggregate

Good

Good

Good

After Spraying

Fair

Fair

Fair

Wet Aggregate

Fair

Fair

Fair

After Spraying

Fair

Fair

Fair

55 min.

63 min.

55 min.

65 min.

65 min.

57 min.

57 min.

57 min.

EMULSIONS:

Viscosity, Saybolt Furol

seconds

Settlement, 5 days, %

Storage Stability Test, 24 hours, %

Sieve Test, %

(2)

(2,3)

Demulsibility, %

(4)

T59

Cement Mixing Test, %

Coating Ability and Water

Resistance

Residue, %

DISTILLATION RESIDUE:

Penetration, 25 C (77 F), tenths of mm

T49

100-200

100-200

100-200

100-200

40-90

100-200

40-90

40-90

Ductility, 25 C (77 F), cm

T51

40 min.

40 min.

40 min.

40 min.

40 min.

40 min.

40 min.

40 min.

Solubility in trichloroethylene or n-propyl

bromide, %

T44

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

NOTES:

1.

2.

3.

4.

Refer to R5 for typical applications.

This test requirement on representative samples is waived if successful application of the material has been achieved in the field.

A maximum percentage of 0.30 is acceptable for samples taken at the point of use.

The demulsibility test shall be performed within 30 days from the date of shipment. Use 35 ml, 0.02 N CaCl2 solution.

Disclaimer: To ensure the most accurate and current information, the specific agency should be contacted

Page 1 of 5

New Mexico

Table 2: Requirements for Cationic Emulsified Asphalts (1)

Test Method

AASHTO (T),

ASTM (D), or

Other

Property

Rapid-Setting

Medium-Setting

Slow-Setting

Quick-Setting

CRS-1

CRS-2

CMS-2

CMS-2h

CSS-1

CSS-1h

CQS-1h

25 C (77 F)

20-100

20-100

20-100

50 C (122 F)

20-100

100-400

50-450

50-450

EMULSIONS:

Viscosity, Saybolt Furol

seconds

Settlement, 5 days, %

Storage Stability Test, 24 hours, %

(2)

1 max.

1 max.

1 max.

1 max.

1 max.

1 max.

Sieve Test, %

(2)

0.10 max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

Positive

Positive

Positive

Positive

Positive

Positive

Positive

40 min.

40 min.

2.0 max.

2.0 max.

Dry Aggregate

Good

Good

After Spraying

Fair

Fair

Wet Aggregate

Fair

Fair

After Spraying

Fair

Fair

Residue, %

60 min.

65 min.

65 min.

65 min.

57 min.

57 min.

57 min.

Oil Distillate, volume of emulsion, %

3 max.

3 max.

12 max.

12 max.

T200

Penetration, 25 C (77 F), tenths of mm

T49

100-250

100-250

100-250

40-90

100-250

40-90

40-90

Ductility, 25 C (77 F), cm

T51

40 min.

40 min.

40 min.

40 min.

40 min.

40 min.

40 min.

Solubility in trichloroethylene, %

T44

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

Particle Charge

Demulsibility , %

(3)

T59

Cement Mixing Test, %

Coating Ability and Water

Resistance

pH

DISTILLATION RESIDUE:

NOTES:

1.

2.

3.

Refer to R5 for typical applications.

This test requirement on representative samples is waived if successful application of the material has been achieved in the field.

Use 35 ml of 0.8% sodium dioctyl sulfosuccinate solution.

Disclaimer: To ensure the most accurate and current information, the specific agency should be contacted

Page 2 of 5

New Mexico

Table 3: Requirements for High Float Emulsified Asphalt (1)

Test Method

AASHTO (T), ASTM (D), or

Other

Property

RapidSetting

Medium-Setting

HFRS-2

HFMS-1

HFMS-2

HFMS-2h HFMS-2s

HFE-60

HFE-90

HFE-150

HFE-300

25 C (77 F)

20-100

100 min.

100 min.

50 min.

50 C (122 F)

75-400

50 min.

50 min.

50 min.

50 min.

5 max.

5 max.

5 max.

5 max.

1 max.

1 max.

1 max.

1 max.

1 max.

1 max.

1 max.

1 max.

1 max.

EMULSIONS:

Viscosity, Saybolt Furol

seconds

Settlement, 5 days, %

Storage Stability Test, 24 hours, %

Sieve Test, %

(2)

0.10 max. 0.10 max. 0.10 max. 0.10 max. 0.10 max. 0.10 max. 0.10 max. 0.10 max. 0.10 max.

(2,3)

T59

Demulsibility , %

Coating Ability and

Water Resistance

60 min.

30 min.

30 min.

Dry Aggregate

Good

Good

Good

Good

After Spraying

Fair

Fair

Fair

Fair

Wet Aggregate

Fair

Fair

Fair

Fair

After Spraying

Fair

Fair

Fair

Fair

Grades,

Stones

coated

thoroughly

Grades,

Stones

coated

thoroughly

Grades,

Stones

coated

thoroughly

Grades,

Stones

coated

thoroughly

(4)

Coating Test, 3 minutes

Residue, %

63 min.

55 min.

65 min.

65 min.

65 min.

1-7

1 max.

3 max.

7 max.

7 max.

65 min. (5) 65 min. (5) 65 min. (5) 65 min. (5)

T59

Oil Distillate, volume of emulsion, %

DISTILLATION RESIDUE:

Penetration, 25 C (77 F), tenths of mm

T49

100-200

100-200

100-200

40-90

200 min.

60-90

90-150

150-300

300 min.

Ductility, 25 C (77 F), cm

T51

40 min.

40 min.

40 min.

40 min.

40 min.

T44

97.5 min.

97.5 min.

97.5 min.

97.5 min.

97.5 min.

T50

1200 min. 1200 min. 1200 min. 1200 min. 1200 min. 1200 min. 1200 min. 1200 min. 1200 min.

Solubility in trichloroethylene, %

(6)

Float Test at 60 C (140 F), seconds

NOTES:

1.

2.

3.

4.

5.

6.

Refer to R5 for typical applications.

This test requirement on representative samples is waived if successful application of the material has been achieved in the field.

A maximum percentage of 0.30 is acceptable for samples taken at the point of use.

The demulsibility test shall be performed within 30 days from the date of shipment. Use 35 ml 0.02 N CaCl2 solution for HFRS-2, and 1.2 fl. Oz.

0.10 N CaCl2 solution for HFE-60 and HFE-90.

Distillation to 500 F.

N-propyl bromide may also be used for HFRS-2.

Disclaimer: To ensure the most accurate and current information, the specific agency should be contacted

Page 3 of 5

New Mexico

Table 4: Requirements for Polymer-Modified High Float Emulsified Asphalt

Test Method

AASHTO (T), ASTM (D), or

Other

Property

Rapid-Setting

Medium-Setting

HFRS-2P

HFE-60P

HFE-150P

HFE-300P

25 C (77 F)

50 C (122 F)

100-400

50 min.

50 min.

50 min.

1 max.

1 max.

1 max.

0.10 max.

0.10 max.

0.10 max.

0.10 max.

40 min.

30 min.

Residue, %

65 min. (2)

65 min. (3)

65 min. (3)

65 min. (3)

Oil Distillate, volume of emulsion, %

3 max.

1 max.

7 max.

7 max.

90-150

60-90

150-300

300 min.

20 min.

40 min.

40 min.

25 min.

25 min.

58 min.

55 min.

1200 min.

1200 min.

1200 min.

1200 min.

EMULSIONS:

Viscosity, Saybolt Furol

seconds

Storage Stability Test, 24 hours, %

Sieve Test, %

T59

Demulsibility , %

(1)

DISTILLATION RESIDUE:

Penetration, 25 C (77 F), tenths of mm

T49

4 C (39.2 F)

Ductility, cm

T51

(4)

25 C (77 F)

4 C (39.2 F)

Elastic Recovery, %

T301

10 C (50 F)

Float Test at 60 C (140 F), seconds

NOTES:

T50

1.

2.

3.

4.

Use 1.2 fl. Oz. 0.02 N CaCl2 solution for HFRS-2P, and 1.2 fl. Oz. 0.10 N CaCl2 solution for HFE-60P and HFE-90P.

Distillation to 450 F.

Distillation 400 F.

Use 2 in/min. pull rate.

Disclaimer: To ensure the most accurate and current information, the specific agency should be contacted

Page 4 of 5

New Mexico

Table 4: Requirements for Asphalt Emulsified Prime (AE-P) and Penetrating Emulsified Prime (PE-P)

Test Method

AASHTO (T), ASTM (D), or

Other

AE-P

PE-P

25 C (77 F)

50 C (122 F)

15-150

75 max.

1 max.

0.10 max.

Residue, %

65 min.

38 min.

Oil Distillate, volume of emulsion, %

25 max.

0-4

97.5 min.

Property

EMULSIONS:

Viscosity, Saybolt Furol

Seconds

Settlement, 24 hr, %

T59

Sieve, %

(1)

DISTILLATION RESIDUE:

Solubility in trichloroethylene, %

NOTES:

T44

1.

Retained on 0.35 in. sieve.

Disclaimer: To ensure the most accurate and current information, the specific agency should be contacted

Page 5 of 5

Das könnte Ihnen auch gefallen

- California: State: Specification: Date: Web Address: Contact: Contact InfoDokument5 SeitenCalifornia: State: Specification: Date: Web Address: Contact: Contact InfoSamuel Ch. G.Noch keine Bewertungen

- New Mexico: State: Materials: Date: 9 Web Address: Materials Engineer: Contact InfoDokument6 SeitenNew Mexico: State: Materials: Date: 9 Web Address: Materials Engineer: Contact InfoSamuel Ch. G.Noch keine Bewertungen

- Brett Haggerty: TexasDokument8 SeitenBrett Haggerty: TexasSamuel Ch. G.Noch keine Bewertungen

- Viscosity-Graded Asphalt Cement: Standard Specification ForDokument4 SeitenViscosity-Graded Asphalt Cement: Standard Specification Formohammed karasnehNoch keine Bewertungen

- GRSP Presentation PDFDokument30 SeitenGRSP Presentation PDFChaitanyaNoch keine Bewertungen

- RN86638218Dokument10 SeitenRN86638218eli rezekiNoch keine Bewertungen

- Tests Astm Test Method Requirements Min. MaxDokument12 SeitenTests Astm Test Method Requirements Min. Maxhisham gawishNoch keine Bewertungen

- m20 PDF FreeDokument1 Seitem20 PDF FreeDede NurcahyadiNoch keine Bewertungen

- M20Dokument1 SeiteM20FRANZ RICHARD SARDINAS MALLCO75% (4)

- M82Dokument1 SeiteM82FRANZ RICHARD SARDINAS MALLCO100% (1)

- Cut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForDokument1 SeiteCut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForKaterin HernandezNoch keine Bewertungen

- Standard Specification For: ScopeDokument2 SeitenStandard Specification For: Scopedong ganNoch keine Bewertungen

- Medium Curing Cutback Asphalts Product Data Sheet: Description and Physical PropertiesDokument1 SeiteMedium Curing Cutback Asphalts Product Data Sheet: Description and Physical PropertiesEsrom AbebeNoch keine Bewertungen

- Shall Be Supplied by An Approved Supplier in Accordance With ITM 581. PerformanceDokument15 SeitenShall Be Supplied by An Approved Supplier in Accordance With ITM 581. PerformanceMog GomNoch keine Bewertungen

- NitrocelluloseDokument8 SeitenNitrocellulose6x7bx9kwknNoch keine Bewertungen

- SP 8888 PDFDokument6 SeitenSP 8888 PDFMohammad ShamimNoch keine Bewertungen

- D 977 - 98 Rdk3ny1sruqDokument4 SeitenD 977 - 98 Rdk3ny1sruqRufo CascoNoch keine Bewertungen

- B732 N1 Versus EPR TableDokument1 SeiteB732 N1 Versus EPR TableGuilioNoch keine Bewertungen

- SSC W FemaleDokument3 SeitenSSC W FemaleshyhuNoch keine Bewertungen

- International Standard ISO 8217: 1996 British Standard BS MA 100: 1996Dokument1 SeiteInternational Standard ISO 8217: 1996 British Standard BS MA 100: 1996Vilius BukysNoch keine Bewertungen

- Construction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailDokument84 SeitenConstruction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailMohd Ali100% (1)

- Mobil Aero HF Series (PDS)Dokument3 SeitenMobil Aero HF Series (PDS)Vikram SinghNoch keine Bewertungen

- Resumen SuperpaveDokument60 SeitenResumen SuperpaveFranklinNoch keine Bewertungen

- Loctite 594 1998Dokument5 SeitenLoctite 594 1998Boss_enqNoch keine Bewertungen

- The Rubber Formulary NRDokument47 SeitenThe Rubber Formulary NRCarla CorreiaNoch keine Bewertungen

- 2023 Trabalho EhsDokument6 Seiten2023 Trabalho Ehsfernandomanuelll29Noch keine Bewertungen

- NBR Catalogue Eng KKPCDokument2 SeitenNBR Catalogue Eng KKPCChandrasekar KrishnamurthyNoch keine Bewertungen

- Lubrifin TINDokument2 SeitenLubrifin TINPrecub Ioana AdrianaNoch keine Bewertungen

- Determinación Del Grado de MoliendabilidadDokument13 SeitenDeterminación Del Grado de Moliendabilidadbone cabero laoNoch keine Bewertungen

- Zytel ST 801 Ahs NC 010 PDFDokument2 SeitenZytel ST 801 Ahs NC 010 PDFAdam GordonNoch keine Bewertungen

- 3.4 Bituminous Materials: 3.4.1 DescriptionDokument5 Seiten3.4 Bituminous Materials: 3.4.1 DescriptionSujon AhmmedNoch keine Bewertungen

- Al Farabi University College ةيلك ةعماجلا يبارافلا: ASTM D88-99Dokument6 SeitenAl Farabi University College ةيلك ةعماجلا يبارافلا: ASTM D88-99Abbas sabbarNoch keine Bewertungen

- TDS Yd535lv - TH7253 - 8Dokument5 SeitenTDS Yd535lv - TH7253 - 8polypolyy100% (2)

- M 82-75 (2004) Cutback Asphalt (MC Type)Dokument2 SeitenM 82-75 (2004) Cutback Asphalt (MC Type)WalticoZegarraHerrera100% (1)

- PPC - MTCDokument1 SeitePPC - MTCNaresh KumarNoch keine Bewertungen

- M 20-70 (2004) Penetration-Graded Asphalt CementDokument2 SeitenM 20-70 (2004) Penetration-Graded Asphalt CementWalticoZegarraHerreraNoch keine Bewertungen

- AralditeDokument7 SeitenAralditeRohit RanaNoch keine Bewertungen

- Mix Design - m40 - Modified 28 Days CcsDokument23 SeitenMix Design - m40 - Modified 28 Days CcsKuldeep Chakerwarti100% (2)

- 60 (415) 65 (450) 70 (485) Grade: SA-515/SA-515MDokument1 Seite60 (415) 65 (450) 70 (485) Grade: SA-515/SA-515MganeshNoch keine Bewertungen

- Sintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)Dokument13 SeitenSintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)volkanNoch keine Bewertungen

- GSM Performance Report - 100 999 MallDokument7 SeitenGSM Performance Report - 100 999 MallBenjamin MedinaNoch keine Bewertungen

- Araldite LY556 - Aradur 917 - Accelarator DY 070 - TDSDokument6 SeitenAraldite LY556 - Aradur 917 - Accelarator DY 070 - TDSjbd170352Noch keine Bewertungen

- Acoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011Dokument84 SeitenAcoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011concord1103Noch keine Bewertungen

- Cloropreno WRT Sales SpecDokument2 SeitenCloropreno WRT Sales SpecCarlos Romero MuñozNoch keine Bewertungen

- Umts Performance ReportDokument18 SeitenUmts Performance ReportBenjamin MedinaNoch keine Bewertungen

- Sikafloor®-161: Product Data SheetDokument5 SeitenSikafloor®-161: Product Data SheetashayshaNoch keine Bewertungen

- Basic Properties of Refractories From FIMISCO GreeceDokument6 SeitenBasic Properties of Refractories From FIMISCO GreeceTsakalakis G. KonstantinosNoch keine Bewertungen

- Bitumen EmulsionDokument2 SeitenBitumen EmulsionSaurabh ShrivastavaNoch keine Bewertungen

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsVon EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsBewertung: 5 von 5 Sternen5/5 (1)

- The Science and Engineering of Thermal Spray CoatingsVon EverandThe Science and Engineering of Thermal Spray CoatingsNoch keine Bewertungen

- التجربة الثانية الانكسارDokument3 Seitenالتجربة الثانية الانكسارAymen AbdulrahmanNoch keine Bewertungen

- Article 1601456104Dokument3 SeitenArticle 1601456104VijayNoch keine Bewertungen

- BS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedDokument24 SeitenBS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedtienlamNoch keine Bewertungen

- LHB Coach (Mechnical Features)Dokument38 SeitenLHB Coach (Mechnical Features)gayathri12092002Noch keine Bewertungen

- Alloy 6201 Product Specification Rev.4Dokument3 SeitenAlloy 6201 Product Specification Rev.4Ly PhongNoch keine Bewertungen

- ETPDokument3 SeitenETPSanaNoch keine Bewertungen

- United States Patent: (21) Appl - No .: 16 / 120, 651Dokument6 SeitenUnited States Patent: (21) Appl - No .: 16 / 120, 651Treerat VacharanukrauhNoch keine Bewertungen

- Alkaline Ionised Water BookletDokument25 SeitenAlkaline Ionised Water Bookletmichelle_wong_6Noch keine Bewertungen

- Complex Systems in Finance and EconometricsDokument19 SeitenComplex Systems in Finance and EconometricsJuliana TessariNoch keine Bewertungen

- 1.TDS MIXO Plast D100Dokument2 Seiten1.TDS MIXO Plast D100mohamed ragabNoch keine Bewertungen

- Ce 8381 - Question PaperDokument2 SeitenCe 8381 - Question PaperculvertsNoch keine Bewertungen

- Production of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesDokument13 SeitenProduction of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesATWIJUKIRE DICKENSNoch keine Bewertungen

- CH 0 Cleaning Cross Refference Table DREW AMEROIDDokument36 SeitenCH 0 Cleaning Cross Refference Table DREW AMEROIDPavel ViktorNoch keine Bewertungen

- Notes On MRI - FinalDokument16 SeitenNotes On MRI - FinalAnju GuptaNoch keine Bewertungen

- EXPERIMENT 1 Introduction To Chemistry LabDokument6 SeitenEXPERIMENT 1 Introduction To Chemistry LabDulce DeNoch keine Bewertungen

- Precipitation TitrationDokument7 SeitenPrecipitation Titrationadnan nuravifNoch keine Bewertungen

- Lydia 1-S2.0-S0022391320301669-MainDokument9 SeitenLydia 1-S2.0-S0022391320301669-MainCherifNoch keine Bewertungen

- Chemistry: NO CHODokument12 SeitenChemistry: NO CHOPrasann KatiyarNoch keine Bewertungen

- Pharmaceutical Industry BR 9108227 en Us 2102 1Dokument12 SeitenPharmaceutical Industry BR 9108227 en Us 2102 1PhongNoch keine Bewertungen

- Physics Vol 1 Master The NCERTDokument450 SeitenPhysics Vol 1 Master The NCERTARYAN RANADIVE100% (1)

- Ionic and Covalent BondsDokument5 SeitenIonic and Covalent Bondsapi-233981890Noch keine Bewertungen

- Benzene: Training On The Hazards of Benzene in The WorkplaceDokument26 SeitenBenzene: Training On The Hazards of Benzene in The WorkplaceAgung RahmadaniNoch keine Bewertungen

- IOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeDokument187 SeitenIOGP S-616 - 2022 - Supp. Specification To API SPEC 5L & ISO 3183 Line PipeFerryNoch keine Bewertungen

- Separating Solids From LiquidsDokument4 SeitenSeparating Solids From LiquidsRizal RusydiNoch keine Bewertungen

- NAAMM EMMA 557-20 Standards For Expanded MetalDokument18 SeitenNAAMM EMMA 557-20 Standards For Expanded MetalScott NorrisNoch keine Bewertungen

- Q4 COT - Chemical ReactionsDokument3 SeitenQ4 COT - Chemical ReactionsGelli Jean Tortosa-LluparNoch keine Bewertungen

- Haloalkane Note NDokument109 SeitenHaloalkane Note NBichitra GautamNoch keine Bewertungen

- CY100 Engineering Chemistry Syllabus 2016Dokument2 SeitenCY100 Engineering Chemistry Syllabus 2016Siju N. AntonyNoch keine Bewertungen

- ChemistryDokument9 SeitenChemistryAbhey GuptaNoch keine Bewertungen

- Project Report On Marketing Strategy of NalcoDokument73 SeitenProject Report On Marketing Strategy of NalcoLAXMI KANTA GIRI100% (2)