Beruflich Dokumente

Kultur Dokumente

42crmo4astmen PDF

Hochgeladen von

Vijayakumar SamyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

42crmo4astmen PDF

Hochgeladen von

Vijayakumar SamyCopyright:

Verfügbare Formate

Quality

According to standards

Number

Chemical composition

C%

0,380,45

0.02

Si%

max

0,40

+ 0.03

Temperature C

Hotforming

1100850

Soft

annealing +A

720

air

(HB max 241)

42CrMo4

TECHNICAL CARD

GRUPPO LUCEFIN

REVISION 2012

ALL RIGHTS RESERVED

EN 10269 (AC: 2008)

1.7225

Mn%

P%

max

0,025

+ 0.005

0,600,90

0.04

Normalizing

+N

870

air

Isothermal

annealing +I

820 furnace cooling

to 670, then air

(HB 180240)

Quenching

+Q

860

oil or polymer

Spheroidizing

annealing +AC

730740

furnace cooling

(HB max 200)

S%

max

0,035

+ 0.005

Cr%

Mo%

0,901,20

0.05

0,150,30

0.03

Quenching

+Q

850

water

End quench

hardenability test

840

water

Product deviations are

allowed

Tempering

+T

540680

air

Preheating welding

300

AC1

745

Stressrelieving

+SR

50 under the

temperature of tempering

Stressrelieving

after welding

550 furnace cooling

MS

Mf

335

120

AC3

790

Mechanical properties

Hotrolled +QT EN 10269 (AC: 2008)

size mm

Kv and traction test at room temperature in longitudinal

R

Rp 0.2

A%

C%

from

to

N/mm2 .

N/mm2 min. min.

min.

60

8601060

730

14

50

+QT = quenched and tempered

Min. proof strength 0.2 % at high temperatures

d. max 60 mm

720

702

677

C

50

100

150

Plastic deformations and creep rupture resistance

1(1%) N/mm2

C

10.000 h

100.000 h

450

190

137

500

88

49

550

29

15

1 = permanent creep strain strength 1%

640

200

Kv +20 C

J min.

50

Kv 40 C

J min.

40

Rp 0.2 N/mm2 EN 10269: 2001

602

562

518

475

250

300

350

400

R N/mm2

10.000 h

320

137

29

R = creep rupture strength

Thermal Expansion

12.1

12.7

106 K1

Mod. of Elasticity long.

GPa

210

205

195

Mod. of Elasticity tang. GPa

80

78

75

Specific Heat Capacity J/(KgK)

460

Thermal Conductivity

W/(mK)

33.5

34.0

Density

Kg/dm3

7.85

Specific Electric Resist. Ohmmm2/m

0.19

Electrical Conductivity Siemensm/mm2

5.26

C

20

100

200

250

The symbol indicates temperature between 20 C and 100 C, 20 C and 200 C

13.2

185

70

Kv 100 C

J min.

27

420

450

375

500

550

100.000 h

240

96

15

13.6

175

67

14.0

14. 4

155

59

34.2

300

Kv and traction test at room temperature in longitudinal on hotrolled +QT material. Lucefin experience

Rp/R

diameter grain

R

Rp 0.2

A%

C%

mm

size

N/mm2

N/mm2

min.

min.

40

6

995

845

0,85

15,2

58

60

56

947

767

0,81

16.0

60

400

500

Kv +20 C

J min.

909092

847880

600

Kv 20 C

J min.

605858

505056

42CrMo4 1.7225

Data under fatigue +20 C

Cyclic yield strength, y

+N

328

N/mm2 low cycle number

716

+QT

0.12

Cyclic strength exponent, n

+N

low cycle number

0.10

+QT

673

Cyclic strength coefficient, K

+N

N/mm2 low cycle number

+QT

1367

Fatigue strength coefficient, f

+N

1000

N/mm2 low cycle number

+QT

1454

Fatigue strength exponent, b

+N

0.11

low cycle number

+QT

0.08

Fatigue ductility exponent, c

+N

1.00

low cycle number

+QT

0.72

+N = normalization +QT = quenching and tempering

EUROPE

ITALY

CHINA

GERMANY

42CrMo4

42CrMo4

ML42CrMo

42CrMo4

EN

UNI

GB

DIN

FRANCE

U.K.

RUSSIA

42CD4

708M40

42HM

AFNOR

B.S.

GOST

USA

AISI/SAE

4140

The data contained herein are intended as reference only and are subject to constant change. Lucefin s.P.A. Disclaims any and all liability for any consequences that may result from their use.

Das könnte Ihnen auch gefallen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Ck45 Mechanical PropertiesDokument3 SeitenCk45 Mechanical PropertiesDaniel CringusNoch keine Bewertungen

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- 42CrMo4 Datos Tecnicos PDFDokument2 Seiten42CrMo4 Datos Tecnicos PDFjlplazaolaNoch keine Bewertungen

- C55EDokument2 SeitenC55EniranjanbmazireNoch keine Bewertungen

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- CR Mo 4Dokument2 SeitenCR Mo 4Mohsen ParpinchiNoch keine Bewertungen

- Quality 42crmo4: Lucefin GroupDokument1 SeiteQuality 42crmo4: Lucefin GroupAnonymous Gbers2ENoch keine Bewertungen

- C45EDokument3 SeitenC45ETrương Định100% (1)

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionVon EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionBewertung: 5 von 5 Sternen5/5 (1)

- Technical Card Ck45 Mechanical PropertiesDokument3 SeitenTechnical Card Ck45 Mechanical PropertiesNuno Miguel TorcatoNoch keine Bewertungen

- Dynamometer: Theory and Application to Engine TestingVon EverandDynamometer: Theory and Application to Engine TestingNoch keine Bewertungen

- 1 8159-51CrV4Dokument2 Seiten1 8159-51CrV4black_absynthNoch keine Bewertungen

- Tempering Conditions For 30CrNiMo8Dokument2 SeitenTempering Conditions For 30CrNiMo8madyeNoch keine Bewertungen

- 30 CR Ni Mo 8Dokument2 Seiten30 CR Ni Mo 8Amy GriffinNoch keine Bewertungen

- 36NiCrMo16 PDFDokument2 Seiten36NiCrMo16 PDFAmy GriffinNoch keine Bewertungen

- Linear Positive Miniature Tempco ThermistorDokument3 SeitenLinear Positive Miniature Tempco ThermistorkpNoch keine Bewertungen

- 42 CR Mo 4Dokument2 Seiten42 CR Mo 4ElMacheteDelHuesoNoch keine Bewertungen

- TTF 103 ResistorDokument5 SeitenTTF 103 Resistorjackanddiane1Noch keine Bewertungen

- Polystyrene Capacitors Max.10nFDokument2 SeitenPolystyrene Capacitors Max.10nFsonic8659Noch keine Bewertungen

- Codificare Rezistente SMD 60A Are 412 Ohmi CF TabelDokument6 SeitenCodificare Rezistente SMD 60A Are 412 Ohmi CF Tabelromeo1966Noch keine Bewertungen

- 41 CR 4Dokument2 Seiten41 CR 4Jhon ChitNoch keine Bewertungen

- K48-50 Carbon Film ResistorsDokument3 SeitenK48-50 Carbon Film ResistorseminuscloudNoch keine Bewertungen

- 1 4571a316ti69Dokument2 Seiten1 4571a316ti69Admir TalicNoch keine Bewertungen

- En10083-2 - 1996 - C35eDokument3 SeitenEn10083-2 - 1996 - C35ealextentwentyNoch keine Bewertungen

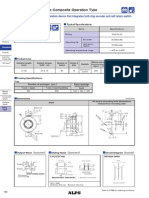

- 35mm Size Ring Type: A Low-Profile Unit With 4.5mm Height and Good Operation FeelDokument3 Seiten35mm Size Ring Type: A Low-Profile Unit With 4.5mm Height and Good Operation FeelshyhuNoch keine Bewertungen

- 40NiCrMo7 PDFDokument2 Seiten40NiCrMo7 PDFAmy GriffinNoch keine Bewertungen

- AISI304Dokument2 SeitenAISI304tony_abNoch keine Bewertungen

- 34 CR Mo 4Dokument2 Seiten34 CR Mo 4Stefan GhNoch keine Bewertungen

- TY616Dokument8 SeitenTY616Anupam AshokNoch keine Bewertungen

- CL05B104KO5NNNCDokument2 SeitenCL05B104KO5NNNCmarcosribeirobrNoch keine Bewertungen

- 1 2714Dokument1 Seite1 2714K Mohana PraneshNoch keine Bewertungen

- Specification: CL 31 B 104 K B C N N N CDokument2 SeitenSpecification: CL 31 B 104 K B C N N N Cfan1802Noch keine Bewertungen

- Material 1.2379 - X153CrMoV12Dokument2 SeitenMaterial 1.2379 - X153CrMoV12johnnydoe90Noch keine Bewertungen

- Multilayer Ceramic CapacitorsDokument12 SeitenMultilayer Ceramic CapacitorscostpopNoch keine Bewertungen

- Quality SAE 1018: Lucefin GroupDokument1 SeiteQuality SAE 1018: Lucefin GrouponeakshayNoch keine Bewertungen

- DMR 63PK PDFDokument11 SeitenDMR 63PK PDFFelipePerezNoch keine Bewertungen

- Thermistor DatasheetDokument8 SeitenThermistor DatasheetWeb BrowserNoch keine Bewertungen

- 41Cr4 Chemical PDFDokument2 Seiten41Cr4 Chemical PDFGayathriRajasekaranNoch keine Bewertungen

- 21mm Size Ring Type: Ring Encoder With 4mm Height Contribute To Space Saving and MultifunctioningDokument4 Seiten21mm Size Ring Type: Ring Encoder With 4mm Height Contribute To Space Saving and MultifunctioningshyhuNoch keine Bewertungen

- 34 CR Mo 4Dokument2 Seiten34 CR Mo 4ceca nikolicNoch keine Bewertungen

- 28mm Size Ring Type: A Low-Profile Unit With 4mm Height and Good Operation FeelDokument3 Seiten28mm Size Ring Type: A Low-Profile Unit With 4mm Height and Good Operation FeelshyhuNoch keine Bewertungen

- Cas02x 071 X0710T502Dokument2 SeitenCas02x 071 X0710T502Vu NguyenNoch keine Bewertungen

- 1 8550-34CrAlNi710Dokument2 Seiten1 8550-34CrAlNi710Michel PortalNoch keine Bewertungen

- Material 1.2738 - 40CrMnNiMo8-6-4Dokument1 SeiteMaterial 1.2738 - 40CrMnNiMo8-6-4johnnydoe90100% (1)

- 42 Crmo 4Dokument2 Seiten42 Crmo 4Shiva Kumar MNoch keine Bewertungen

- ThermistorDokument44 SeitenThermistorjuca_br2002Noch keine Bewertungen

- 35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchDokument3 Seiten35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchshyhuNoch keine Bewertungen

- UD2 - Hoja de Característica de CondensadoresDokument18 SeitenUD2 - Hoja de Característica de CondensadoresRaul Sanchez RoyNoch keine Bewertungen

- TTC 103 NTC ThermistorDokument7 SeitenTTC 103 NTC ThermistorBilly SilvaNoch keine Bewertungen

- 2CDC002157D0201Dokument7 Seiten2CDC002157D0201260380sdNoch keine Bewertungen

- Quality 1.4362 Chemical Composition: Technical CardDokument2 SeitenQuality 1.4362 Chemical Composition: Technical CardTeodor EzaruNoch keine Bewertungen

- Material 1.2312 - 40CrMnMoS8-6Dokument1 SeiteMaterial 1.2312 - 40CrMnMoS8-6johnnydoe90Noch keine Bewertungen

- DatasheetDokument9 SeitenDatasheetloisaomNoch keine Bewertungen

- PS2815-1, PS2815-4: PhotocouplerDokument14 SeitenPS2815-1, PS2815-4: PhotocouplerJuan Carlos H. SoriaNoch keine Bewertungen

- T1620-600W / 700W T1630-600W: Snubberless TriacDokument5 SeitenT1620-600W / 700W T1630-600W: Snubberless TriacLaercio NasctoNoch keine Bewertungen

- C606 C607 C752 753Dokument2 SeitenC606 C607 C752 753Sol De GabrielNoch keine Bewertungen

- Identifying and Correcting Paint DefectsDokument37 SeitenIdentifying and Correcting Paint Defectsismael barreraNoch keine Bewertungen

- Berger MIO Coating Brown.253140503Dokument2 SeitenBerger MIO Coating Brown.253140503Gaurav TripathiNoch keine Bewertungen

- Paint DefectsDokument129 SeitenPaint Defectsmohammad100% (6)

- Committee Calculator - Xls 1Dokument1 SeiteCommittee Calculator - Xls 1Vijayakumar SamyNoch keine Bewertungen

- Paint DefectsDokument129 SeitenPaint Defectsmohammad100% (6)

- Berger MIO Coating Brown.253140503Dokument2 SeitenBerger MIO Coating Brown.253140503Gaurav TripathiNoch keine Bewertungen

- Microsoft Word - Control Philosophy For Reclaimer PDFDokument7 SeitenMicrosoft Word - Control Philosophy For Reclaimer PDFVijayakumar SamyNoch keine Bewertungen

- Austenitic Manganese SteelsDokument3 SeitenAustenitic Manganese SteelsVijayakumar SamyNoch keine Bewertungen

- Identifying and Correcting Paint DefectsDokument37 SeitenIdentifying and Correcting Paint Defectsismael barreraNoch keine Bewertungen

- WJ 1995 05 s153 PDFDokument7 SeitenWJ 1995 05 s153 PDFVijayakumar SamyNoch keine Bewertungen

- Manganese 12 14%Dokument3 SeitenManganese 12 14%Sreedhar Rakesh VellankiNoch keine Bewertungen

- Sheet01 Rotary Plate Mounting Structure Rev2-ModelDokument1 SeiteSheet01 Rotary Plate Mounting Structure Rev2-ModelVijayakumar SamyNoch keine Bewertungen

- FLS - 32 - Shell Liner - MKP PDFDokument2 SeitenFLS - 32 - Shell Liner - MKP PDFVijayakumar SamyNoch keine Bewertungen

- ACS800 Catalogue REV E 171003 PDFDokument40 SeitenACS800 Catalogue REV E 171003 PDFVijayakumar SamyNoch keine Bewertungen

- PulleyDokument3 SeitenPulleyVijayakumar SamyNoch keine Bewertungen

- Anti Collision Scheme PDFDokument4 SeitenAnti Collision Scheme PDFVijayakumar SamyNoch keine Bewertungen

- CBB35 50 PDFDokument2 SeitenCBB35 50 PDFVijayakumar SamyNoch keine Bewertungen

- Quality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedDokument2 SeitenQuality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedVijayakumar SamyNoch keine Bewertungen

- Quality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedDokument2 SeitenQuality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedVijayakumar SamyNoch keine Bewertungen

- Low-Cycle Fatigue Properties of Steel 42crmo4: R. Kunc, I. PrebilDokument8 SeitenLow-Cycle Fatigue Properties of Steel 42crmo4: R. Kunc, I. PrebilVijayakumar SamyNoch keine Bewertungen

- Pulley 1Dokument4 SeitenPulley 1Vijayakumar SamyNoch keine Bewertungen

- Noise MeasurementDokument8 SeitenNoise MeasurementVijayakumar SamyNoch keine Bewertungen

- Bolt ToleranceDokument1 SeiteBolt ToleranceVijayakumar SamyNoch keine Bewertungen

- Revised TC PDFDokument2 SeitenRevised TC PDFVijayakumar SamyNoch keine Bewertungen

- Astm d413 1982Dokument7 SeitenAstm d413 1982dharlanuctcomNoch keine Bewertungen

- Material & WeldingDokument58 SeitenMaterial & WeldingVijayakumar SamyNoch keine Bewertungen

- 700 Steel InclusionRating ASTM-E45Dokument1 Seite700 Steel InclusionRating ASTM-E45ksathisNoch keine Bewertungen

- AWS - Welding SymbolsDokument1 SeiteAWS - Welding SymbolsAli Saifullizan IsmailNoch keine Bewertungen

- 6b - 2 Wri Course Calendar 2013-14Dokument20 Seiten6b - 2 Wri Course Calendar 2013-14Vijayakumar SamyNoch keine Bewertungen

- 1367 1Dokument6 Seiten1367 1Vijay Shankar TNoch keine Bewertungen