Beruflich Dokumente

Kultur Dokumente

Simple Joints Jaspart

Hochgeladen von

Sargunam SankaravadivelCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Simple Joints Jaspart

Hochgeladen von

Sargunam SankaravadivelCopyright:

Verfügbare Formate

International Seminar on Joints

Oslo, April 20, 2005

EUROPEAN RECOMMENDATIONS

FOR THE DESIGN OF SIMPLE

JOINTS IN STEEL STRUCTURES

Assoc. Prof. J.P. JASPART

Lige University, Belgium

Simple joints in steel structures

Braced structure

Simple joints in steel structures

V0

M=0

Available design rules

Few design rules provided by Eurocode 3

Part 1-8

National design codes:

z

z

z

z

- UK : BS5950 and BCSA-SCI provisions

- NL : NEN 6770

- DE : Ringbuch

-

European recommendations

On the basis of:

z

z

Eurocode 3 Part 1-8

Available European design codes and others

ECCS European recommendations

European Convention for Constructional

Steelwork

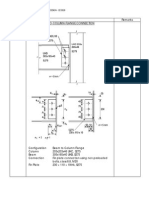

Different joint configurations

Single-sided beam-to-column joints

Minor axis joint

Major axis joint

Different joint configurations

Double-sided beam-to-column joints

Minor axis joint

Major axis joint

Different joint configurations

Beam-to-beam joints

Uncoped

supported beam

Single-coped

supported beam

Double-coped

supported beam

Different joint configurations

Beam splices

_

joint

position

_

_

_

_

+

Different types of profiles

Different connection types

Partial depth enplate connections

ACTUAL PINNED CONNECTIONS

Different connection types

Fin plate connections

ACTUAL PINNED CONNECTIONS

Different connection types

Web cleats connections

ACTUAL PINNED CONNECTIONS

Different connection types

But also flush endplate connections

USUALLY CONSIDERED AS ACTUAL PINNED CONNECTIONS

Classification and modelling

Actual pinned joints:

Sj.ini <<

Mj

Rigid

Semi-rigid

Pinned

Stiffness classification boundaries

Initial joint stiffness

Classification and modelling

Joints considered as pinned :

Mj

Rigid

Semi-rigid

Pinned

Stiffness classification boundaries

Initial joint stiffness

Sj.ini

Classification and modelling

As an alternative to semi-continuous

modelling, is it safe to design a joint as

pinned when it is known to exhibit a semirigid behaviour?

Semi-rigid

Sj.ini > 0,5EIb/Lb

Partial strength

Mj.Rd > 0,25 Mfull-strength

??

Nominally pinned

Sj.ini = 0

Nominally pinned

Mj.Rd = 0

Classification and modelling

Yes, it is as long as the joint possesses:

a sufficient rotation capacity

ability of the joint

to rotate

M

a sufficient ductility

actual yield criterion

MRd

ability of the joint

actual load path

to follow the actual

load path in a

assumed load path

ductile way

V

VRd

Design requirements

Simple modelling adopted

FRAME ANALYSIS

EUROPEAN

RECOMMENDATIONS

shear force VSd

shear resistance VRd

required rotation required

available rotation available

combined with ductility requirements

Extra design requirement

Sufficient tying resistance for robustness

Partial depth endplates

Constitutive components

bolts in shear

header plate in bearing

gross section of the header

plate in shear

net section of the header plate

in shear

shear block of the header plate

header plate in bending

beam web in shear

weld in shear

----------------column flange in bearing

Partial depth endplates

Rotation requirement

Bending

moment

Tension

forces in the

bolts

Bending

moment

Compression

force

Contact between

the supported beam

and the supporting

element

Rotation

available

Partial depth endplates

Rotation requirement

available

db hb

hp

hp < db

he

tp

available =

tp

he

Partial depth endplates

Ductility requirement

z

Avoid premature bolt failure

Avoid premature weld failure

under unavoidable joint bending moments

Partial depth endplates

Ductility requirement

z

Avoid premature bolt failure

d

2,8

tp

f yp

d

2,8

tp

f ycf

f ub

f ub

for the header plate

for a supporting column flange

d and fub : diameter and ultimate strength of the bolt

plate yields before bolt fails in tension

Partial depth endplates

Ductility requirement

z

Avoid premature weld failure

Full-strength welds required

beam web yields before welds

Partial depth endplates

Resistance requirement

z

Application of the component method to

derive VRd

derivation of the resistance

of all the components

assembly of the components

Partial depth endplates

Resistance requirement

Analytical evaluation of

the shear resistance VRd

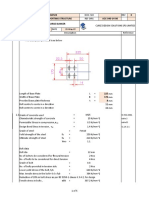

Partial depth endplates

Bolts in shear

VRd 1 = 0,8 n Fv,Rd

with:

Fv ,Rd =

v f ub A

M2

A = As (shear trough the threated bolt portion)

v = 0,6 (4.6, 5.6 or 8.8 bolts)

= 0,5 (4.8, 5.8, 6.8, 10.9 bolts)

A = A (shear trough the unthreated bolt portion)

v = 0,6 (4.6, 5.6 or 8.8 bolts)

n = number of sheared bolts

reduction factor 0,8 because of bending effects

Partial depth endplates

Header plate in bearing

p 2'

e2S

p2 '

e1

e1

p1

p1

p1

e1

p1

e1

mp e2

p2 e2S

mp

e2

Partial depth endplates

Header plate in bearing

VRd 2 = n Fb,Rd

with:

Fb , Rd =

k1 b f up d t p

= min (

M2

e1

p

1 f

; 1 ; ub

3 d 0 3 d 0 4 f up

ou 1,0

p2

e2

k1 = min ( 2,8 1,7 ; 1,4 1,7 ; 2,5 )

d0

d0

d0 = bolt hole diameter

Partial depth endplates

Gross section of header plate in shear

p 2'

e2S

p2 '

e1

e1

p1

p1

p1

e1

p1

e1

mp e2

p2 e2S

mp

e2

Partial depth endplates

Gross section of header plate in shear

VRd 4 =

2 hp t p

f yp

1,27

3 M0

reduction factor 1,27 because of bending effects

Partial depth endplates

Net section of header plate in shear

p 2'

e2S

p2 '

e1

e1

p1

p1

p1

e1

p1

e1

mp e2

p2 e2S

mp

e2

Partial depth endplates

Net section of header plate in shear

VRd 5 = 2A v.net

with:

f up

3 M2

Av,net = tp ( hp n1 d0)

n1 = number of horizontal bolt rows

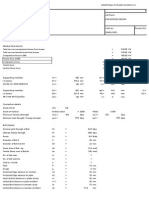

Partial depth endplates

Header plate in shear: shear block

p 2'

e2S

p2 '

e1

e1

p1

p1

p1

e1

p1

e1

mp e2

p2 e2S

mp

e2

Partial depth endplates

Header plate in shear: shear block

VRd 6 = 2 Feff,Rd

if hp < 1,36 p22 and n1 > 1 :

Feff,Rd = Feff , 2, Rd =

0,5

M2

Anv

1

+

f yp

M0

3

bending effects

else :

Feff,Rd = Feff ,1, Rd =

f up Ant

f up Ant

M2

Anv

1

+

f yp

M0

3

no bending effects

Partial depth endplates

Header plate in shear: shear block

P22

P22

e1

e2

no bending effects

bending effects

Ant = tp ( e2 0,5 d0 )

Anv = tp ( hp e1 (n1 0,5) d0 )

Partial depth endplates

Header plate in bending

p 2'

e2S

p2 '

e1

e1

p1

p1

p1

e1

p1

e1

mp e2

p2 e2S

mp

e2

Partial depth endplates

Header plate in bending

VRd 7 =

if hp 1,36 p22

else :

f yp

2 Wel

VRd 7 =

( p22 t w ) M

0

2

t p h p2

where: Wel =

6

Partial depth endplates

Beam web in shear

VRd 8 = tbw h p

f ybw

Partial depth endplates

Design shear resistance of the connection

Assembly of the components*:

VRd = min VRdi

i =1

* - component 3: supporting member in bearing

- full strength welds

Partial depth endplates

Resistance requirement

Analytical evaluation of

the tying resistance Nu

Partial depth endplates

Bolts in tension

Nu 1 = n Bt,u

with :

Bt,u = f ub As / u

As

Partial depth endplates

Header plate in bending

p 2'

e2S

p2 '

e1

e1

p1

p1

p1

e1

p1

e1

mp e2

p2 e2S

mp

e2

Partial depth endplates

Bolts in tension

Nu 2 = min ( Fhp,u,1 ; Fhp,u,2 )

with:

Fhp,u,1 =

Fhp,u,2 =

(8 n p 2 ew ) leff . p.t ,1 mu . p

2 m p n p ew ( m p + n p )

2 leff . p.t , 2 mu . p + n Bt .u n p

mp + np

where: np = min ( e2 ; 1,25 mp )

mu.p =

t 2p f up 4 u

leff.pt1 = leff.pt2 = hp

Partial depth endplates

Beam web in tension

Nu 4 = tw hp f ubw / u

Partial depth endplates

Tying resistance of the connection

Assembly of the components*:

4

N u = min N u i

i =1

* - component 3: supporting member in bending

- full strength welds

Partial depth endplates

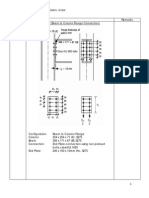

Worked example

M20

HEA200

IPE300

International Seminar on Joints

Oslo, April 20, 2005

THANKS FOR YOUR ATTENTION

Das könnte Ihnen auch gefallen

- 04 Acciaio Connection DesignDokument62 Seiten04 Acciaio Connection DesignSultano78Noch keine Bewertungen

- Mathcad V1 BDokument11 SeitenMathcad V1 BDoğan ArslanNoch keine Bewertungen

- Engelhardt Steel Notes VI - ConnectionsDokument29 SeitenEngelhardt Steel Notes VI - ConnectionsJorge SanchezNoch keine Bewertungen

- ConnectionsDokument205 SeitenConnectionsbsitler100% (1)

- SN017 (NCCI - Shear Resistance of A Fin Plate Connection)Dokument13 SeitenSN017 (NCCI - Shear Resistance of A Fin Plate Connection)Hamati Rami100% (2)

- SKILLS M02E Moment Connections Part1Dokument90 SeitenSKILLS M02E Moment Connections Part1ELMSSALINoch keine Bewertungen

- Steel Connection DesignDokument11 SeitenSteel Connection DesignSam A.Noch keine Bewertungen

- UB Fin Plate DesignDokument8 SeitenUB Fin Plate DesignWin ThanNoch keine Bewertungen

- End-Plate - Beam to Beam Connection Design 3Dokument8 SeitenEnd-Plate - Beam to Beam Connection Design 3gianniorlatiNoch keine Bewertungen

- Design bolt connection between IPE beam and HEA columnDokument5 SeitenDesign bolt connection between IPE beam and HEA columna.b.a.c.u.sNoch keine Bewertungen

- Design of Bolted ConnectionsDokument205 SeitenDesign of Bolted ConnectionsbsitlerNoch keine Bewertungen

- Tying Resistance of A Fin Plate ConnectionDokument9 SeitenTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- FLANGE DN800 PN40Dokument35 SeitenFLANGE DN800 PN40fsalminNoch keine Bewertungen

- MOMENT EndplateDokument8 SeitenMOMENT Endplatemoseslugtu6324Noch keine Bewertungen

- Structural ConnectionsDokument26 SeitenStructural ConnectionsAlemtsehay ShiferawNoch keine Bewertungen

- Design of A Notched Section at The End of A BeamDokument5 SeitenDesign of A Notched Section at The End of A BeamBobaru MariusNoch keine Bewertungen

- Beam/Column to End plate Design ChecksDokument3 SeitenBeam/Column to End plate Design ChecksASKOKONoch keine Bewertungen

- Fin Plate Beam-To-column-flange Connection (GB)Dokument16 SeitenFin Plate Beam-To-column-flange Connection (GB)Vlad MosNoch keine Bewertungen

- Anker Vrska KompletDokument4 SeitenAnker Vrska KompletstojanovalidijaNoch keine Bewertungen

- Orifice Plate - Monobloc: DatasheetDokument8 SeitenOrifice Plate - Monobloc: Datasheetbiomed systechNoch keine Bewertungen

- End Plate Design As Per-Ec3Dokument18 SeitenEnd Plate Design As Per-Ec36j7100% (1)

- Splice - Rev - 02Dokument22 SeitenSplice - Rev - 02raghav abudhabiNoch keine Bewertungen

- KKKH3353 - Structural Steel Design - Joints 2Dokument26 SeitenKKKH3353 - Structural Steel Design - Joints 2Zeyad Tareq Al SaroriNoch keine Bewertungen

- Body Flange Design-Appx-2Dokument4 SeitenBody Flange Design-Appx-2Matthieu100% (1)

- Column Design - EURO CODEDokument8 SeitenColumn Design - EURO CODEsopnanairNoch keine Bewertungen

- Flux Cored WireDokument38 SeitenFlux Cored WireKentDemeterioNoch keine Bewertungen

- Beam-Column Using Double Angle CleatDokument7 SeitenBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Catalogue MetalweldDokument17 SeitenCatalogue MetalweldRadivojevic SasaNoch keine Bewertungen

- Steel Joint Design (Fin Plate)Dokument8 SeitenSteel Joint Design (Fin Plate)Wazini D. IzaniNoch keine Bewertungen

- Connection Surge Bin Supp Beam1Dokument5 SeitenConnection Surge Bin Supp Beam1Venkatesh HebbarNoch keine Bewertungen

- Connections in Steel Structures PDFDokument54 SeitenConnections in Steel Structures PDFsmmsajediNoch keine Bewertungen

- FTM '12 DBZ Wedge AnchorDokument4 SeitenFTM '12 DBZ Wedge AnchorshankerNoch keine Bewertungen

- End Plate DesignDokument4 SeitenEnd Plate DesignAgnon Fung100% (4)

- TEDDS calculation summaryDokument5 SeitenTEDDS calculation summaryIvan DimitrovNoch keine Bewertungen

- Connection DesignDokument30 SeitenConnection DesignAdil Rasheed KhanNoch keine Bewertungen

- Framing Connections Continued: Bolted and Welded AlternativesDokument106 SeitenFraming Connections Continued: Bolted and Welded AlternativesAnonymous mcHqIfbnV1Noch keine Bewertungen

- Fin Plate Connection DesignDokument10 SeitenFin Plate Connection DesigncklconNoch keine Bewertungen

- Design CaculationsDokument29 SeitenDesign Caculationsg4goharNoch keine Bewertungen

- Steel Joint Design (Flexible End Plate)Dokument6 SeitenSteel Joint Design (Flexible End Plate)Wazini D. IzaniNoch keine Bewertungen

- Application for Design of Members in Tension and BendingDokument48 SeitenApplication for Design of Members in Tension and BendingVictor TvvNoch keine Bewertungen

- Structural Steel Beam to Column Connection DesignDokument7 SeitenStructural Steel Beam to Column Connection DesignWazini D. IzaniNoch keine Bewertungen

- Sn018a en EuDokument9 SeitenSn018a en EuNguyễn TrườngNoch keine Bewertungen

- Din 11851 Edited VersionDokument22 SeitenDin 11851 Edited VersionSenthilKumarShanmughamNoch keine Bewertungen

- Beam-Column Connection CalculationsDokument8 SeitenBeam-Column Connection Calculationsdubin strukturNoch keine Bewertungen

- 26 Induction Motor DesignDokument21 Seiten26 Induction Motor DesignLatisha CarterNoch keine Bewertungen

- End Plate-Splice ConnectionDokument76 SeitenEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- MP1 Design (EN1993)Dokument6 SeitenMP1 Design (EN1993)blerandNoch keine Bewertungen

- 851 Series: Applications DescriptionDokument26 Seiten851 Series: Applications Descriptionantono1971Noch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesVon EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesBewertung: 4.5 von 5 Sternen4.5/5 (7)

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Materials Data for Cyclic Loading: Cast and Welded MetalsVon EverandMaterials Data for Cyclic Loading: Cast and Welded MetalsNoch keine Bewertungen

- Isogen InfoDokument34 SeitenIsogen InfoNagarajan100% (1)

- AutoCAD 2017 TipsnTricksDokument23 SeitenAutoCAD 2017 TipsnTricksDeepak SavantNoch keine Bewertungen

- Python Notes For ProfessionalsDokument814 SeitenPython Notes For ProfessionalsNemani100% (11)

- SPECON Reference ManualDokument67 SeitenSPECON Reference ManualNewuman MonteroNoch keine Bewertungen

- C#Dokument338 SeitenC#bebikash011100% (3)

- Microsoft SQ L Server Notes For ProfessionalsDokument286 SeitenMicrosoft SQ L Server Notes For ProfessionalsEribertMarquezNoch keine Bewertungen

- Using OpenSTAAD Application ObjectDokument7 SeitenUsing OpenSTAAD Application ObjectRobert RayNoch keine Bewertungen

- Finite Element Analysis of The Fatigue Strength of A Big End BoltDokument136 SeitenFinite Element Analysis of The Fatigue Strength of A Big End BoltSargunam SankaravadivelNoch keine Bewertungen

- Acoustically Induced Piping Vibration in PDFDokument13 SeitenAcoustically Induced Piping Vibration in PDFSargunam Sankaravadivel100% (1)

- Yield StressDokument2 SeitenYield StressSargunam SankaravadivelNoch keine Bewertungen

- Nima Thesis-Last VersionDokument110 SeitenNima Thesis-Last VersionSargunam SankaravadivelNoch keine Bewertungen

- Fatigue Life EstimationDokument7 SeitenFatigue Life EstimationJomer J SimpsonNoch keine Bewertungen

- Documents For Export ImportDokument1 SeiteDocuments For Export ImportSargunam SankaravadivelNoch keine Bewertungen

- FEA Failure TheoryDokument3 SeitenFEA Failure TheoryRamesh BammankattiNoch keine Bewertungen

- Pdmstocaesarii PDFDokument0 SeitenPdmstocaesarii PDFshaffetiNoch keine Bewertungen

- Fatigue Analysis GuideDokument12 SeitenFatigue Analysis GuideSargunam SankaravadivelNoch keine Bewertungen

- Flow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFDokument12 SeitenFlow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFSargunam SankaravadivelNoch keine Bewertungen

- Initiate A Stress-Intensity Factors CalculationDokument9 SeitenInitiate A Stress-Intensity Factors CalculationSargunam SankaravadivelNoch keine Bewertungen

- Three Layer Architecture in C#Dokument11 SeitenThree Layer Architecture in C#Sargunam SankaravadivelNoch keine Bewertungen

- Bolt Length Calculation For Standard Flange-Gasket-Flange - PDMS MacroDokument1 SeiteBolt Length Calculation For Standard Flange-Gasket-Flange - PDMS MacroSargunam SankaravadivelNoch keine Bewertungen

- Creating Optical Character Recognition (OCR) Applications Using Neural Networks - CodeProjectDokument7 SeitenCreating Optical Character Recognition (OCR) Applications Using Neural Networks - CodeProjectSargunam SankaravadivelNoch keine Bewertungen

- Requirement of Flexibility in Piping Design - An Overview - What Is Piping PDFDokument8 SeitenRequirement of Flexibility in Piping Design - An Overview - What Is Piping PDFSargunam SankaravadivelNoch keine Bewertungen

- Windows OOPS Principles (SOLID Principles) Sample in C# For Visual Studio 2010Dokument7 SeitenWindows OOPS Principles (SOLID Principles) Sample in C# For Visual Studio 2010Sargunam SankaravadivelNoch keine Bewertungen

- Budstikka - Dette Er Våre Vanskeligste KryssDokument10 SeitenBudstikka - Dette Er Våre Vanskeligste KryssSargunam SankaravadivelNoch keine Bewertungen

- What Is Poisson Ratio - What's It Application - QuoraDokument2 SeitenWhat Is Poisson Ratio - What's It Application - QuoraSargunam SankaravadivelNoch keine Bewertungen

- C# ProgramingDokument117 SeitenC# ProgramingSargunam SankaravadivelNoch keine Bewertungen

- Edge Detection-Shetty PrajwalDokument63 SeitenEdge Detection-Shetty PrajwalSargunam SankaravadivelNoch keine Bewertungen

- How Does The Material Properties Affect Stress Results in FEA - QuoraDokument3 SeitenHow Does The Material Properties Affect Stress Results in FEA - QuoraSargunam SankaravadivelNoch keine Bewertungen

- Array Collection and Appending - Page 2Dokument4 SeitenArray Collection and Appending - Page 2Sargunam SankaravadivelNoch keine Bewertungen

- FEA Failure TheoryDokument3 SeitenFEA Failure TheoryRamesh BammankattiNoch keine Bewertungen

- Possible solution to past CM exam question on new city centre office block designDokument33 SeitenPossible solution to past CM exam question on new city centre office block designMartinNoch keine Bewertungen

- Direct Stiffness35Dokument38 SeitenDirect Stiffness35N TNoch keine Bewertungen

- Eurocode 2: Design of Concrete Structures: @seismicisolationDokument72 SeitenEurocode 2: Design of Concrete Structures: @seismicisolationAbdullah NajjarNoch keine Bewertungen

- CE6603-Design of Steel StructuresDokument15 SeitenCE6603-Design of Steel StructuresVasim Jaman SNoch keine Bewertungen

- Ejma 8TDokument3 SeitenEjma 8TpiziyuNoch keine Bewertungen

- Shear Strength of Continuous Fiber-Reinforced Advanced Ceramics at Ambient TemperaturesDokument8 SeitenShear Strength of Continuous Fiber-Reinforced Advanced Ceramics at Ambient TemperaturessenthilNoch keine Bewertungen

- SA Important Questions 16-03-22Dokument13 SeitenSA Important Questions 16-03-22siva 17Noch keine Bewertungen

- Biomechanics of Bone-Fracture Fixation by Stiffness-Graded Plates in Comparison With Stainless-Steel PlatesDokument16 SeitenBiomechanics of Bone-Fracture Fixation by Stiffness-Graded Plates in Comparison With Stainless-Steel PlatesRENATO ALONSO PACHECO ROSALESNoch keine Bewertungen

- Lateral-Torsional Buckling of Beams and The Southwell PlotDokument15 SeitenLateral-Torsional Buckling of Beams and The Southwell PlotPablo Augusto Krahl0% (1)

- Rectangular Expansion Joint: Description Section PDF Symbol NotesDokument3 SeitenRectangular Expansion Joint: Description Section PDF Symbol NotesRufus D SNoch keine Bewertungen

- L07 Compatibility Mode 1645956007946Dokument97 SeitenL07 Compatibility Mode 1645956007946Saini boyNoch keine Bewertungen

- B.tech-Syllabus (6th To 8th Semester)Dokument25 SeitenB.tech-Syllabus (6th To 8th Semester)Pratyush KumarNoch keine Bewertungen

- Fundamental Loadings: Prismatic BarDokument7 SeitenFundamental Loadings: Prismatic BarAGEGTAMNoch keine Bewertungen

- Applsci 12 01273 v2Dokument16 SeitenApplsci 12 01273 v2Anandlal RNoch keine Bewertungen

- Chapter 5 Design For Earthquake Resistance Ductility of RC JointsDokument110 SeitenChapter 5 Design For Earthquake Resistance Ductility of RC JointsMisganaw YeshiwasNoch keine Bewertungen

- In-House Training Done at Kyambogo UniversityDokument25 SeitenIn-House Training Done at Kyambogo UniversityOrtega IanNoch keine Bewertungen

- Shear Performance Analysis Tapered Beam-Resal PDFDokument11 SeitenShear Performance Analysis Tapered Beam-Resal PDFp rNoch keine Bewertungen

- Silt Gravel Removal GateDokument16 SeitenSilt Gravel Removal GateRaja SinghNoch keine Bewertungen

- Evaluation of Ultimate Ship Hull Strength: Po@.-Collapse Loss F10@Dokument16 SeitenEvaluation of Ultimate Ship Hull Strength: Po@.-Collapse Loss F10@maaathanNoch keine Bewertungen

- Structure White Paper - Crane Girder - FinalDokument61 SeitenStructure White Paper - Crane Girder - Finalclam2014Noch keine Bewertungen

- Design Model For Bolted Moment End Plate With RhsDokument63 SeitenDesign Model For Bolted Moment End Plate With Rhsfirter100% (1)

- Structurally Determinate Beams and Frames AnalysisDokument44 SeitenStructurally Determinate Beams and Frames AnalysisMah MoodNoch keine Bewertungen

- Bridge RulesDokument21 SeitenBridge Rulesraghuveer11Noch keine Bewertungen

- CH-2-Analysis of Statically Determinate StructuresDokument18 SeitenCH-2-Analysis of Statically Determinate StructuresyareqNoch keine Bewertungen

- Shear Strength of Steel FibresDokument29 SeitenShear Strength of Steel FibresHarish T S GowdaNoch keine Bewertungen

- Plates and Shells: Instructor's Solutions ManualDokument3 SeitenPlates and Shells: Instructor's Solutions Manualehab elsawyNoch keine Bewertungen

- Worksheet Beams (Student)Dokument5 SeitenWorksheet Beams (Student)ClmNoch keine Bewertungen

- Web5160, MODELS FOR DYNAMIC ANALYSIS OR RAILWAY BRIDGES PDFDokument90 SeitenWeb5160, MODELS FOR DYNAMIC ANALYSIS OR RAILWAY BRIDGES PDFJuan Carlos Torres HernándezNoch keine Bewertungen

- Syllabus of BCECE.Dokument281 SeitenSyllabus of BCECE.Rohit SinghNoch keine Bewertungen

- Rock Bolts Increase Shear Resistance of JointsDokument29 SeitenRock Bolts Increase Shear Resistance of JointsgianniorlatiNoch keine Bewertungen