Beruflich Dokumente

Kultur Dokumente

Concrete Quality Is Improved With COFFOR

Hochgeladen von

Ionescu StefanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Concrete Quality Is Improved With COFFOR

Hochgeladen von

Ionescu StefanCopyright:

Verfügbare Formate

1

CONCRETE QUALITY IS IMPROVED WITH COFFOR

BECAUSE OF THE RAPID ELIMINATION OF EXCESS WATER

COFFOR eliminates naturally and rapidly the excess water. It is well known that excess

water has a negative impact on concrete quality. Excess water generates:

- bleeding or water rise, resulting in a less resistant concrete on surface and heterogeneous,

- water accumulation under the aggregates, resulting in bonding defects, micro fissures

between the paste and the aggregates, ice formation in case of frost,

- water accumulation under the rebars resulting in corrosion risk

- increase of shrinkage and creep,

- porosity increase resulting into less resistance against all external aggressions (frost,

aggressive water, possible corrosion of rebars due to rapid carbonation).

The elimination of excess water improves the intrinsic characteristics of concrete. Several

tests demonstrated that the COFFOR concrete quality* is greater than concrete poured in

traditional waterproof formwork.

* A maximum of 2% of concrete goes through the COFFOR grids during the pour. Tests

show that this has no negative effect on resistance of COFFOR.

SHRINKAGE TESTS

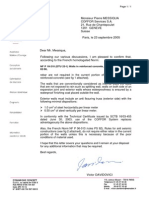

In June 1994, tests were made at CERAM (Centre d'Enseignement et de Rechercghe en

Analyse des Matriaux), the Research Center of Ecole Nationake des Ponts et Chausses,

Paris France, to control concrete shrinkage of COFFOR walls compared to walls poured with

traditional waterproof formwork.

The results are given in the following page.

The exhibit shows that immediate concrete shrinkage with COFFOR is less than 3 microns,

i.e. 20 times lower than with traditional waterproof formwork.

01.09.2010

IMMEDIATE CONCRETE SHRINKAGE

08/06/1994

-20

-25

Formwork vibrated

00/03:15

-15

00/03:04

-10

00/02:52

00/02/14

00/02/29

00/02/18

00/02:06

00/01:55

00:01:43

00:01:32

00/01:20

Traditional waterproof

COFFOR non vibrated

COFFOR vibrated

00/01:09

Time in days/hour:mm

-30

00/00:57

00/00:45

00/00:34

01.09.2010

00/00:23

00/00:11

00/00:11

00/00:00

00/00:00

-5

COMPRESSION TESTS

In February 1996, tests were made at CSTB (Centre Scientifique et Technique du Btiment),

Paris, France, to compare compression strength of COFFOR walls with walls poured with

traditional waterproof formwork.

Five samples were poured with the same concrete, 4 with COFFOR and 2 with traditional

waterproof formwork..

The results were as follows:

No

Nature of

tests

A

(mm2)

123 200

123 200

123 200

123 200

Load Fmax in

kN resulting in

breaking

3 170

2 200

2 250

2 480

Loading in

N/mm2 at

breaking point

25.7

17.9

18.3

20.1

Young

(elasticity)

module

-36 831

36 095

41 615

Type of

breakin

g

R1

R2

R2

R2

1

2

3

4

Compression

test on

COFFOR

Walls

5

6

Compression test

on tradtional

waterproof formwork

106 400

106 400

2000

1770

18.8

16.6

31 128

23 748

R3

R3

R1: concrete breaking in lower part

R2: concrete breaking in higher part

R3: concrete breaking in higher part

The results show that COFFOR walls have a compression strength 10% greater and a Young

(Elasticity) Module 30 % greater than concrete walls built with traditional waterproof

formworks.

DEFLEXION TESTS

1. In November 1999, a test was made at the Laboratoires d'Essai des Matriaux et Structures

of the Ecole des Ingnieurs de Genve, Geneva, Switzerland, to examine resistance under

deflexion of a COFFOR panel.

A 2900 cm x 73 cm x 15 cm COFFOR panel was used. A press with 2 points was applied

125 cm apart

Under deflexion, the COFFOR panel broke under a load of 35.5 kN (3.55 T)

2. In November 2002, a similar test was made at CSTB, Paris, France

01.09.2010

A 2000 cm x 122 cm x 15 cm COFFOR panel was used. A press with one point was applied

in the center

Under deflexion, the COFFOR panel broke under a load of 48 kN (4.8 T)

TRACTION TEST

In November 2002, traction tests were made to control the bonding of the COFFOR C profile

with concrete.

All tests made with C profile anchored in 30 cm concrete (or more) showed a 100% bonding,

as the C profile broke under traction.

On 5 tests made with C profiles anchored in 20 cm concrete (and without any support from

the zigzag COFFOR loop), 3 C profiles broke under traction, and 2 C profiles slided through

the concrete, but at their elasticity limit.

These tests show an excellent bonding of the C profile with concrete.

Complete report on these tests are available under request.

Additional tests are under way to determine an equivalence between steel content in COFFOR

and hard steel rebars.

.

01.09.2010

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- NA To Sls en 1992-1-2Dokument12 SeitenNA To Sls en 1992-1-2Shan Sandaruwan AbeywardeneNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Constructions - Pile Foundation DetailsDokument1 SeiteConstructions - Pile Foundation DetailsNikiNoch keine Bewertungen

- Blindside WaterproofingDokument4 SeitenBlindside WaterproofingPramod V PatilNoch keine Bewertungen

- ASD Tug Specification - PTBDokument29 SeitenASD Tug Specification - PTBNasrulSyahruddinNoch keine Bewertungen

- Dead Load ReferenceDokument3 SeitenDead Load ReferenceCheng Por Eng100% (2)

- Columbine Report Pgs 3501-3600Dokument100 SeitenColumbine Report Pgs 3501-3600columbinefamilyrequestNoch keine Bewertungen

- BS en 12063-1999Dokument58 SeitenBS en 12063-1999vinaysa18gmailcom100% (2)

- 4by4 HouseDokument8 Seiten4by4 HousePratik Patel100% (1)

- Pompeii and HerculaneumDokument21 SeitenPompeii and HerculaneumMark Royters100% (4)

- Vata de Sticla Pe ExteriorDokument6 SeitenVata de Sticla Pe ExteriorIonescu StefanNoch keine Bewertungen

- Plan Parter SC: 1:100Dokument9 SeitenPlan Parter SC: 1:100Ionescu Stefan100% (1)

- 2007 - 8PCEE - Peng Et Al - Response of RC Plastic HingeDokument9 Seiten2007 - 8PCEE - Peng Et Al - Response of RC Plastic HingeIonescu StefanNoch keine Bewertungen

- Coffor Constructive Instructions: December 2009 1Dokument13 SeitenCoffor Constructive Instructions: December 2009 1Ionescu StefanNoch keine Bewertungen

- Constructive Instruction For Crawl SpaceDokument16 SeitenConstructive Instruction For Crawl SpaceIonescu StefanNoch keine Bewertungen

- Deflection and Traction TestDokument20 SeitenDeflection and Traction TestIonescu StefanNoch keine Bewertungen

- Certificate VD EnglishDokument3 SeitenCertificate VD EnglishIonescu StefanNoch keine Bewertungen

- Coffor Constructive Instructions: December 2009 1Dokument13 SeitenCoffor Constructive Instructions: December 2009 1Ionescu StefanNoch keine Bewertungen

- LogDokument52 SeitenLogNey BwllNoch keine Bewertungen

- MSR 2011 053 060 EarthworkDokument8 SeitenMSR 2011 053 060 EarthworkThongam Bikel SinghNoch keine Bewertungen

- AWS Direct Connect: User Guide API Version 2013-10-22Dokument61 SeitenAWS Direct Connect: User Guide API Version 2013-10-22AshishNoch keine Bewertungen

- APPENDIXDokument100 SeitenAPPENDIXalyssa babylaiNoch keine Bewertungen

- DSLAM ConfigurationDokument82 SeitenDSLAM ConfigurationEhsan GhasisinNoch keine Bewertungen

- 1501ENG Review Questions 2011Dokument11 Seiten1501ENG Review Questions 2011Brendan BartelNoch keine Bewertungen

- Architecture (AR) III YearDokument17 SeitenArchitecture (AR) III YearFiroj AnsariNoch keine Bewertungen

- Standard Classroom Building - DPWH As of 021524 A1Dokument1 SeiteStandard Classroom Building - DPWH As of 021524 A1designers.starlightNoch keine Bewertungen

- Audio Coding ThesisDokument126 SeitenAudio Coding ThesisKhaqan TahirNoch keine Bewertungen

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, BhopalDokument1 SeiteRajiv Gandhi Proudyogiki Vishwavidyalaya, BhopalAbhijeet RaghuwanshiNoch keine Bewertungen

- Corvi BrochureDokument28 SeitenCorvi BrochureParas Sagarawat0% (1)

- Jurnal Konstruksi KayuDokument8 SeitenJurnal Konstruksi KayuEdo GustantoNoch keine Bewertungen

- AC500Dokument1.308 SeitenAC500Alexandro Montes AlvarezNoch keine Bewertungen

- Pic 16f877a MicrocontrollerDokument222 SeitenPic 16f877a MicrocontrollerVijay Raj PuniaNoch keine Bewertungen

- (Tenobooks - Com) The Lodge of The Lynx by Katherine Kurtz, Deborah Turner HarrisDokument191 Seiten(Tenobooks - Com) The Lodge of The Lynx by Katherine Kurtz, Deborah Turner HarrisCasandrescu Ion DanielNoch keine Bewertungen

- Microcontrollers Notes For IV Sem ECE StudentsDokument19 SeitenMicrocontrollers Notes For IV Sem ECE StudentsVigneshwar DhamodharanNoch keine Bewertungen

- Lebanese University: Zeinab NounDokument1 SeiteLebanese University: Zeinab NounZeina NounNoch keine Bewertungen

- Learning Multi FrameDokument61 SeitenLearning Multi FrameChainun Taidamrong0% (1)

- En Security Chp3 PTActA AAA StudentDokument4 SeitenEn Security Chp3 PTActA AAA StudentFnan KifluNoch keine Bewertungen

- An Enhanced Uplink Scheduling Algorithm Based On Voice Activity For Voip Services in Ieee 802.16D/E SystemDokument3 SeitenAn Enhanced Uplink Scheduling Algorithm Based On Voice Activity For Voip Services in Ieee 802.16D/E SystemTamal ChakrabortyNoch keine Bewertungen

- PVC Crust Foam Board Manufacture Process ControDokument1 SeitePVC Crust Foam Board Manufacture Process ControFrank ZhangNoch keine Bewertungen