Beruflich Dokumente

Kultur Dokumente

SafetyLine Hazard Assessment Guide1

Hochgeladen von

vesna9840 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten7 SeitenHazard Assessment guide for Occupational safety Officers

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHazard Assessment guide for Occupational safety Officers

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten7 SeitenSafetyLine Hazard Assessment Guide1

Hochgeladen von

vesna984Hazard Assessment guide for Occupational safety Officers

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

Page 1

Hazard and Risk Assessment Guide

Safety legislation in Canada (Occupational Health & Safety Act, Sec. 25)

entails employers to do everything that is reasonable to ensure their

workers have a healthy and safe workplace. The first step to ensuring this

safe working environment includes a hazard assessment.

And although safety equipment and protocol is improving, in Canada

in 2012, the most recent year for official statistics from Association of

Workers Compensation Boards of Canada, there were 977 workplacerelated fatalities and 245,365 workplace injuries. These numbers indicate

that vigilant hazard assessment protocol remains as important than ever.

Follow the guide below to conduct hazard assessments of locations where employees will be working,

and to highlight methods that contain that risk with the most practicable solution taking into account

cost, time, and effort against the risk. Attached to this guideline is a worksheet for your own hazard

assessment.

Reference will be made to the worksheet within the steps in the guideline, so be sure to print these both

out before your hazard assessment!

How to Conduct a Hazard Assessment

Step 1: Gather a Team

Start out by gathering an assessment team comprised of people in different positions. This will help

avoid any blind spots in your assessment. This team should include your operational health and safety

officer, or a person in the organization with a blend of skills and experience in the work activities being

assessed.

Step 2: Organize Your Assessment by Geography or Position Rank

Once your team has been assembled, identify how you would like to organize your hazard assessment.

This is normally done by geography or worker position rank. If your workers normally only work in one or

two locations, organizing your assessment by rank is useful. If you have workers spread out over varied

locations, organizing your assessment by geography would probably be the most successful. Determine

this organization with your team, and keep to it during your whole assessment.

Print out a new hazard assessment worksheet for each location or worker position being assessed. Write

each location or position being assessed at the top of the worksheet.

HAZARD ASSESSMENT GUIDE

SAFETYLINELONEWORKER.COM

Page 2

Hazard and Risk Assessment Guide

Step 3: List Work Activity For Each Location or Worker Position

Assess your work site and determine all the activities that

may be happening on the location. Be sure to consider all

employees and contract workers. If your focus is position based,

be sure to consider all duties that particular worker may have including various locations they may go to during their shift. If a

particular work activity is complex, such as operating a piece of

machinery, it is best to break down the activity into smaller parts

(ex: operating a dump truck can be broken down into operating,

loading, unloading, backing up, and fueling).

List these activities in the first column of your worksheet.

Step 4: Identify the Hazards Associated With Each Work Activity

Hazards have the potential to cause injury, illness or harm, which include physical, chemical, biological,

and psychosocial factors. Hazards may be people, the environment, geographical areas, or weather

conditions.

There are 6 main classifications of workplace hazards: Safety Hazards, Biological Hazards, Physical

Hazards, Ergonomic Hazards, Chemical Hazards, and Work Organization Hazards.

Safety Hazards are unsafe working conditions, such as anything that can

cause slips, trips, or falls, like ice or cords across the ground. Biological

Hazards include exposure to harm or disease associated with working

with animals, people, or infectious plant materials. Physical hazards can

be any factors within the environment that can harm the body without

necessarily touching it. Ergonomic Hazards occur when the type of work,

body positions and working conditions put a strain on your body. Chemical

Hazards are present when a worker is exposed to any chemical preparation

in the workplace in any form (solid, liquid, or gas). Work Organization

Hazards are stressors that cause stress or strain in the workers overall

wellbeing. Go through each category and identify if there are any hazards

that the worker faces in each of these categories.

Some questions to help with your identification of hazards in each category are as follows:

HAZARD ASSESSMENT GUIDE

SAFETYLINELONEWORKER.COM

Page 3

Hazard and Risk Assessment Guide

Safety Hazards

What equipment or materials are involved in this activity and how may it contribute to hazards?

Are there any blind spots or poorly lit areas in the work space?

Are walking and driving paths clear and free of obstructions?

Biological Hazards

Are workers exposed to living things or substances produced by living things that can cause illness;

through inhalation, ingestion or absorption?

Is there proper disposal of biological hazards available?

Are all workers that are dealing with those substances trained or certified in handling?

Physical Hazards

Are there any temperature extremes that could affect workers, equipment, or materials?

Are workers exposed to any radiation?

Are workers working at times of day that could affect vision?

Ergonomic Hazards

Can injury or strain arise from the design and organization of a workers work space?

Are workers subjected to vibration of any kind?

Do workers have to lift or move heavy objects frequently?

Chemical Hazards

Are workers exposed to anything that can be inhaled, ingested or absorbed into the body?

Are all chemicals labeled and classified properly?

Are all workers that are dealing with chemicals trained or certified in handling those specific chemicals?

Stress or Work Organization Hazards

Are workers at risk from threats or violent attacks from the public?

Are individuals at risk from bullying or aggression from other employees within the company?

Are tasks evenly distributed to prevent one individual from experiencing work overload?

Write all hazards in the second column of the worksheet beside the associated work activity.

HAZARD ASSESSMENT GUIDE

SAFETYLINELONEWORKER.COM

Page 4

Hazard and Risk Assessment Guide

Step 5: Assess the Risk Associated with Each Hazard

Risk is the likelihood that a hazard will have an adverse outcome with a consideration of how bad the

outcome is likely to be. Risk should be assessed on scales of severity and likelihood.

Severity should be based on the most predictable consequence if the hazard were to occur. Severity can

be ranked on a scale of Low, Medium, High, and Very High.

Low = No or minor injury that may require some first aid

Med = Medical treatment with no lost time. Minor damage to equipment and/or property

High = Injury that requires significant lost work time for the worker, or significant equipment and/

or property damage

Very High = Permanent disability or fatality for the worker or major equipment and/or property damage

Likelihood is the probability of an event occurring. Wherever possible, base likelihood of hazards

upon frequency of previous occurrences. Likelihood can be ranked on a scale of Low, Medium, High, and

Very High.

Low = Exposure to the uncontrolled hazard is unlikely to occur

Med = Exposure to the uncontrolled hazard could occur

High = Exposure to the uncontrolled hazard may occur often

Very High = Exposure to the uncontrolled hazard will occur.

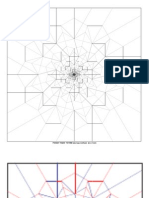

Once the Severity and Likelihood are determined, the overall Risk should be determined as Low, Medium,

High, or Very High. Please see the diagram below:

Very High

High

Med

Low

Severity

V High

Low

Likelihood

Med

High

HAZARD ASSESSMENT GUIDE

SAFETYLINELONEWORKER.COM

Page 5

Hazard and Risk Assessment Guide

Write the rank of severity, likelihood, and overall risk in the third column of your worksheet. Please

note, if the overall rank of the work activity is ranked as Very High, immediate action should be taken to

control that hazard before that work activity continues.

Step 6: Implement Appropriate Measures to Control Hazards

After identifying possible hazards and their associated risks to employees working alone in your

assessment area, it is time to identify appropriate measures to control those hazards.

It is a good practice to determine what the most practicable solution would be, taking into account cost,

time, and effort against the level of risk. Those risks determined to have high likelihood or high severity

would warrant more money, time, and effort to reduce those risks.

Some possible risk reduction controls could be:

Creating a detailed plan for staff routes

Using GPS tracking

Creating a system for flagging potentially aggressive clients if doing home visits

Educating staff on how to minimize risks (such as knowing how to put tires on cars in icy driving

conditions)

Create Your Own Hazard Assessment

Using the hazard assessment sheet provided, it is time to analyze the

hazards and risks for employees working alone in your company. With

your new hazard assessment team, decide on an organization method

for working through hazards. You may choose to analyze hazards

based on geography if you have multiple locations, or you may base

it on worker position. If you have many workers in multiple locations,

you may decide to instigate both methods - worker rank within each

location.

Following along the worksheet, assess each activity associated

with that location or worker position. Assess the hazards and risks

associated, and finally determine the corrective measures to put into place. Once you have done

this, you have succeeded in the first step towards a healthier and safer working environment for your

employees! Congratulations!

HAZARD ASSESSMENT GUIDE

SAFETYLINELONEWORKER.COM

Page 6

Hazard and Risk Assessment Guide

About SafetyLine Lone Worker

Effective 24/7 monitoring without manual procedures, call centers, or costly devices.

SafetyLine Lone Worker is a cloud based safety monitoring solution for your people working alone. We

work with you to develop a complete safety network using your existing equipment, so workers can checkin, and supervisors can monitor, locate and respond to workers, from any device, anywhere, at any time.

Workers will regularly check-in throughout their shifts using any of their current devices including

smartphone, satellite device, or pay-phone. If a worker is in distress or misses a check-in, SafetyLine will

start notifying their supervisors, who will get calls by phone, text messages and email.

Once the supervisor gets a call they will have access to

full information about the worker in distress, including:

Personal profile of worker

Worker check-in history

Voice messages left by worker

GPS location

Supervisors will also be prompted to follow each of

your companys Emergency Response Procedure

steps.

SafetyLine logs all events, and reports can be

created on demand online.

SafetyLines staff will consult with you to setup the most appropriate working alone program for your

needs, and your people will get training and ongoing support and thats just the bare bones.

Call SafetyLine to schedule a demo at 1-888-WRK-ALNE or email us at info@safetyline.ca

HAZARD ASSESSMENT GUIDE

SAFETYLINELONEWORKER.COM

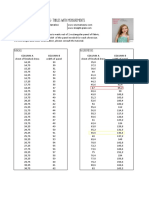

Hazard Assessment

Use this worksheet when conducting your hazard assessment of each

location or position of worker, and file with your written safety plan when

complete.

Company Name:

Date:

Location of Assessment:

Position Being Assessed:

Work Activity

Hazards

Risk Rating

Severity

Likelihood

Overall

Method to Control Hazard/Risk

Additional Notes: ________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

HAZARD ASSESSMENT GUIDE

SAFETYLINELONEWORKER.COM

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Honeycomb Dress TableDokument2 SeitenHoneycomb Dress Tablevesna984Noch keine Bewertungen

- Traditional Irish Soda Bread (Brown Bread)Dokument1 SeiteTraditional Irish Soda Bread (Brown Bread)vesna984Noch keine Bewertungen

- Reference 1 - HTML Tag ReferenceDokument4 SeitenReference 1 - HTML Tag ReferenceCarlos GarridoNoch keine Bewertungen

- SCLP Technical GuideDokument61 SeitenSCLP Technical Guidevesna984Noch keine Bewertungen

- Flower Tower 2 Purse MethodDokument3 SeitenFlower Tower 2 Purse Methodvesna984Noch keine Bewertungen

- Testing & Commissioning Procedure (Electrical)Dokument100 SeitenTesting & Commissioning Procedure (Electrical)Roland Nicolas100% (1)

- Stea CutieDokument1 SeiteStea CutieinstcrisNoch keine Bewertungen

- SafetyLine Hazard Assessment Guide1Dokument7 SeitenSafetyLine Hazard Assessment Guide1vesna984Noch keine Bewertungen

- WCB Ohs RegsDokument119 SeitenWCB Ohs Regsvesna984Noch keine Bewertungen

- How To Measure Light and Lux LevelsDokument2 SeitenHow To Measure Light and Lux Levelsgplese0Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Project Monitoring & EvaluationDokument26 SeitenProject Monitoring & EvaluationTewoflos TesfayeNoch keine Bewertungen

- Name: Nurul Atika Binti Zaini Matrix Number: 255326Dokument11 SeitenName: Nurul Atika Binti Zaini Matrix Number: 255326Muhd NurhaqimNoch keine Bewertungen

- Ugc Net-2018 (Brochure) PDFDokument76 SeitenUgc Net-2018 (Brochure) PDFsania2011Noch keine Bewertungen

- Chapter 7 Solutions Solution Manual Introductory Econometrics For FinanceDokument9 SeitenChapter 7 Solutions Solution Manual Introductory Econometrics For FinanceNazim Uddin Mahmud100% (1)

- EBS 341-Lab Briefing-19 Feb 2019Dokument71 SeitenEBS 341-Lab Briefing-19 Feb 2019NNadiah Isa100% (1)

- Strategising IT Service Management Through ITIL Implementation: Model and Empirical TestDokument29 SeitenStrategising IT Service Management Through ITIL Implementation: Model and Empirical TestcristhianNoch keine Bewertungen

- Thesis Chapter 1Dokument27 SeitenThesis Chapter 1Jefferson Ayubo BroncanoNoch keine Bewertungen

- StatisicsDokument2 SeitenStatisicsMary Joy Heraga PagadorNoch keine Bewertungen

- Essay Critical ThinkingDokument8 SeitenEssay Critical Thinkingafiboeolrhismk100% (2)

- Manuskrip Ana JihadDokument16 SeitenManuskrip Ana Jihadjihan islamiyahNoch keine Bewertungen

- Evaluation 3Dokument12 SeitenEvaluation 3api-456090970Noch keine Bewertungen

- The Perils of "Research Capitalism": Michael CottrellDokument4 SeitenThe Perils of "Research Capitalism": Michael CottrellLii EkiwatzinNoch keine Bewertungen

- 5E Model DescriptionDokument1 Seite5E Model Descriptionhouston deniseNoch keine Bewertungen

- Rainfall Analysis For Crop Planning in Ganjam District: Mintu Kumar Adak Adm No: 01AS/14Dokument84 SeitenRainfall Analysis For Crop Planning in Ganjam District: Mintu Kumar Adak Adm No: 01AS/14sivakumar656Noch keine Bewertungen

- Global Burden Disease Influenza ENGDokument22 SeitenGlobal Burden Disease Influenza ENGjeanNoch keine Bewertungen

- Core-Drilling Technique For In-Situ StressDokument6 SeitenCore-Drilling Technique For In-Situ StressAnshul JainNoch keine Bewertungen

- Epidemiology NursingDokument2 SeitenEpidemiology NursingDhAiRyA ArOrA100% (2)

- Top Engineering Colleges in West Bengal - All About EducationDokument6 SeitenTop Engineering Colleges in West Bengal - All About EducationAditya KrNoch keine Bewertungen

- Analysis of Handwritten Joint Characters in Gujarati LanguageDokument7 SeitenAnalysis of Handwritten Joint Characters in Gujarati LanguageIJRASETPublicationsNoch keine Bewertungen

- A Research On The Allowance and Budgeting of Grade 12 Students in ASIST Main CDokument23 SeitenA Research On The Allowance and Budgeting of Grade 12 Students in ASIST Main CCJ Daodaoen79% (48)

- The Myth of Mars and VenusDokument5 SeitenThe Myth of Mars and Venusaleenakarim4Noch keine Bewertungen

- Research Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewDokument19 SeitenResearch Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewAtul GargNoch keine Bewertungen

- Literature Review Institutional TheoryDokument8 SeitenLiterature Review Institutional Theorylixdpuvkg100% (1)

- Unit Assessment BDokument3 SeitenUnit Assessment BRitchie MiguelNoch keine Bewertungen

- Energy Vision 2013: Energy Transitions: Past and FutureDokument52 SeitenEnergy Vision 2013: Energy Transitions: Past and FutureJesus Black MillmanNoch keine Bewertungen

- WIPO Indicators 2012Dokument198 SeitenWIPO Indicators 2012Hemant GoyatNoch keine Bewertungen

- Internal and External Issues Worksheet SampleDokument3 SeitenInternal and External Issues Worksheet SampleMj Andres100% (2)

- Practical Handbook To Dissertation and Thesis Writing: February 2019Dokument9 SeitenPractical Handbook To Dissertation and Thesis Writing: February 2019Dr. Jamil AhmedNoch keine Bewertungen

- Synopsis of SandeepDokument9 SeitenSynopsis of SandeepsandeepchaurasiyaNoch keine Bewertungen

- Inteligencia de Negocios y Analítica de DatosDokument39 SeitenInteligencia de Negocios y Analítica de DatosfcojafetNoch keine Bewertungen