Beruflich Dokumente

Kultur Dokumente

13

Hochgeladen von

iaetsdiaetsdCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

13

Hochgeladen von

iaetsdiaetsdCopyright:

Verfügbare Formate

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

ANALYTICAL STUDY OF GENERAL FAILURE IN

PROMINENT COMPONENTS

I.

Balaji V.R

Under Graduate Student

SSN College of Engineering

Kalavakkan,Tamilnadu,India

Amitesh Jain

Under Graduate Student

SSN College of Engineering

Kalavakkan,Tamilnadu,India

A.Kirthivasan

Under Graduate Student

SSN College of Engineering

Kalavakkan,Tamilnadu,India

D.Ananthapadmanaban

Associate Professor

Dept. of Mechanical Engg.

SSN College of Engineering,

Kalavakkam, Tamilnadu, India

Introduction

The defects in quality, design, process or part application are the

underlying cause of a failure. The human errors are considered, when

failure depends on the user of the product or process. The failure

analysis includes the area of creep, fatigue, structural resonance, crack

initiation, crack propagation, spalling and pitting, fretting and wear,

component failure. The components are subjected to failure analysis

before and after manufacturing. Even though the various tests are

conducted, failure happens at one stage.

The mechanism of failure can be attributed to multiple factors which

simultaneously plays an influential role. These include corrosion,

abnormal electric current welding of contacts, returns spring fatigue

failure, unintended failure, dust accumulation and blockage of

mechanism, etc.

The strategy for safety is to make various test before the product

comes into the usage. The investigation of failure is vividly illustrated

in the pioneering efforts of the consideration of physical evidence and

355

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

the use of engineering and scientific principles and analytical tools.

Often, the reason why one performs a failure analysis is to

characterize the causes of failure with the overall objective to avoid

repetition of similar failures. However, analysis of the physical

evidence alone may not be adequate to reach this goal. The scope of a

failure analysis can, but does not necessarily, lead to a correctable root

cause of failure. Many times, a failure analysis incorrectly ends at the

identification of the failure mechanism.

A material or component shows gradual deformation or creep when

subjected to sustained loading especially at elevated temperatures. It

occurs even if the applied stresses are below the proportional limit. It

occurs in both metals and non-metals.

Similarly when a component is subjected repeated continuous load, it

tends to gradually deteriorate resulting in fatigue failure. Fatigue

occurs in three stages namely crack initiation, crack propagation and

unstable rapid growth.

Fatigue failure may also occur due propagation of the cracks

originating from the surface of the component. They are of two types

namely spalling and pitting. It occurs due to sub surface tensile and

shear stresses that exceed materials fatigue limits. Gears and bearings

are usually subjected to such stresses. When surfaces of two

components mate each other they are subjected to normal pressure and

tangential oscillatory motion fretting failure occurs. The surface

undergoes failure due to fatigue, high normal forces or wear and failure

can be accelerated in the presence of chemical attack.

II.

Failure analysis-History and Inception

The importance and value of failure analysis to safety, reliability,

performance, and economy are well documented.

356

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

For example, the importance of investigating failures is vividly

illustrated in the pioneering efforts of the Wright Brothers in

developing self-propelled flight. In fact, while Wilbur was traveling in

France in 1908, Orville was conducting flight tests for the U.S. Army

Signal Corps and was injured when his Wright Flyer crashed (Fig. 1).

His passenger sustained fatal injuries [1]. Upon receiving word of the

mishap, Wilbur immediately ordered the delivery of the failed flyer to

France so that he could conduct a thorough investigation. This was

decades before the formal discipline called failure analysis was

introduced.

Unfortunately, there are many dramatic examples of catastrophic

failures that result in injury, loss of life, and damage to property. For

example, a molasses tank failed in Boston in 1919, and another

molasses tank failed in Bellview, NJ, in 1973 [2]. Were the causes

identified in 1919? Were lessons learned as a result of the accident?

Were corrective actions developed and implemented to prevent

recurrence?

Fig.1 Crash of the Wright Flyer, 1908. Courtesy of the National Air and

Space Museum,Smithsonian Institution Photo A-42555-A[1]

Conversely, failures can also lead to improvements in engineering

practices. The spectacular failures of the Liberty ships during World

War II were studied extensively in subsequent decades, and the

outcome of these efforts was a significantly more thorough

357

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

understanding of the phenomenon of fracture, culminating in part with

the development of the engineering discipline of fracture mechanics [3].

Through these and other efforts, insights into the cause and prevention

of failures continue to evolve.

Space shuttle, Columbia orbitter failed upon its re-entry

into the earths atmosphere. Earlier it was believed that failure was

caused by foam piece which got dislodged from external tank during

takeoff and struck the leading edge of the left wing. This damaged the

latter made of carbon-carbon composites thereby providing a breach in

the shuttle leading to catastrophic failure [4].

The foam tiles on analysis show signs of erosion due to high

temperatures exceeding 2000K during re-entry which is sufficient

enough to melt aluminium. Hence it is quite apparent that Aluminium

Sandwich Panel Skins below the tiles were protected during re-entry.

Hence an analysis was carried out on the Aluminium Sandwich Panel

Skin recovered from the debris field. They were 0.6mm thick sheets

made up of 2000-series Aluminium alloy.

A micrograph of sample taken few millimetres behind fracture

surface reveals that it was subjected to much higher temperatures than

area directly beneath the tile. From these images it is clear that second

phase particles present in the microstructure composed of copper,

manganese and iron melted and subsequently wetted the grain

boundaries upon exposure to high temperature causing significant

weakening of grain boundaries, ultimately resulting in intergranular

failure.

358

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

Fig.2 Light optical microscopy micrograph of panel skin section at

fracture surface. Notice that liquation isobserved across entire

micrograph. A crack along a grain boundary is also present. [4]

The Sandwich Panel was locally heated to cause liquation only near

the fracture surface whereas aluminium microstructure directly

beneath an insulating tile shows no sign of liquation. This lead to

formation of local hotspots where there was no thermal protection due

to loss of insulation resulting from the accident. These localised

hotspots lead to the failure of the aluminium sandwich panel and hence

failure of the space shuttle.

III.

Recent trends and advancements

Modern automobiles increasingly utilize high-strength low-weight

alloys for better fuel efficiency. Aluminium alloys seem to serve the

purpose owing to its high strength to weight ratio. Several major

automobile components such as engine blocks, pistons, intake manifold,

carburettors and brake parts make use of aluminium castings. Since

aluminium alloys such as Al-356 is extensively used, a study to realize

the reason for their mechanical failure is necessary.

S. Nasrazadani and L. Reyes investigated a clutch pedal lever made of

permanent mould cast Al 356-T6 aluminium by way of metallography,

SEM, hardness testing and visual inspection [5]. They concluded that the

parts in clutch assembly must be designed with thicker sections to

resist the applied stress. Fatigue and brittle failure occurs due to

359

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

presence of dendrite phases and micro-porosity and it can be avoided by

production of heat treated Al 356-T6.

Fig. 3 Image of the fractured part showing two visible cracks[5]

Y. Huang and Y. Zhu[6] metallurgically examined the section of a

fractured spindle from an axle housing of a truck. It was found that

after about 8,000 miles of service the axle fractured at the friction weld

interface. Metallographic and SEM examinations at the fractured site

revealed the existence of micro-porosity and formation of ferrite layer.

This had reduced the impact strength of the weld resulting in overload

fracture. Due to air exposure at the molten layer interface, a band of

oxides was formed and the solidification of liquid film leads to microshrinkage.

360

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

Fig. 5 The assembly fractured along the weld interface (a ferrite band

with oxides), etched, 2% natal[6]

A lap welded steel joint had failed when it was operated under very

high speeds[7]. This joint was fabricated by a laser beam welding using

high energy coherent optical source of heat at low pressure. The steel

sheets used for this purpose was 0.5 mm thick. The components of the

debris was put into failure analysis for metallurgical investigation. The

sheet and plate used to form this joint were analysed for their chemical

composition.

Fig.4 Oxidation product visible at the grain boundary (arrows) with

other oxidized grain boundaries (encircled) [7]

361

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

The results showed that both were made of the same steel grade

X2NiCoMo18-8-5. The samples were cut from both defected and nondefected regions and were analysed using optical microscopy. From the

analysis it was observed that welding bead had serious problems due to

the oxidation of the plate. The surface of metal plate was deposited by

oxidation products due to under machining of the plate, before welding.

Hence during welding, the oxidation products get entrapped within

weld bead or may appear on the surface of the weld. This weakens the

weld thereby causing failure.

IV.

Root-Cause Analysis

Failure analysis is considered to be the examination of the

characteristics and causes of equipment or component failure[8]. In most

cases this involves the consideration of physical evidence and the use of

engineering and scientific principles and analytical tools. Often, the

reason why one performs a failure analysis is to characterize the causes

of failure with the overall objective to avoid repeat of similar failures.

However, analysis of the physical evidence alone may not be adequate

to reach this goal. The scope of a failure analysis can, but does not

necessarily, lead to a correctable root cause of failure. Many times, a

failure analysis incorrectly ends at the identification of the failure

mechanism and perhaps causal influences. The principles of root-cause

analysis (RCA) may be applied to ensure that the root cause is

understood and appropriate corrective actions may be identified. An

RCA exercise may simply be a momentary mental exercise or an

extensive logistical charting analysis.

Many volumes have been written on the process and methods of RCA.

The concept of RCA does not apply to failures alone, but is applied in

response to an undesirable event or condition (Fig. 4). Root-cause

analysis is intended to identify the fundamental cause(s) that if

corrected will prevent recurrence.

362

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

Fig. 6 Root-cause analogy [8]

V.

Recent Case History

Building in Chennai under construction crashed recently (2014) when

there was rain for about 1 or 2 hours. Most probably the soil itself must

have been loose around that area, Chennai being home to clayey soil[9].

Another reason could be-lack of proper curing of foundation. In earlier

days, foundations used to be cured for close to 3 weeks. These days, it is

not certain whether proper procedures are followed. Most often, there

is a combination of factors involved each of which contributes to the

ultimate failure. So, it is suggested that at each stage, mandatory

checks be followed so that even if a structure fails, one can exactly

pinpoint what went wrong and at which stage it went wrong.

363

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

Fig.7 The Hindu 11 floor building collapse at Bai kadai junction

Moulivakkam,near Porur on Sunday.in Chennai-TN.India[9]

VI. Conclusions

Various procedures followed during failure analysis have been

documented in this paper. Root cause analysis has been discussed.

Starting from the history of failure analysis some case studies have

been presented. It can be concluded that failure analysis is a very vast

field of research and any analysis can give the possible cause of failure

only.Sometimes there may be a a combination of factors for a material

or component to fail.

References

1. P.L. Jakab, Visions of a Flying Machine: The Wright Brothers and

the Process of Invention, Smithsonian Institution, 1990, p 226

2. R.W. Hertzberg, Deformation and Fracture Mechanics

Engineering Materials, John Wiley & Sons, 1976, p 229230

of

3. D.J. Wulpi, Understanding How Components Fail, 2nd ed., ASM

International, 1999

4. Metals Handbook,American Society of Metals,Volume 5,Failure

Analysis and prevention.

364

INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY EDUCATIONAL RESEARCH

ISSN : 2277-7881; IMPACT FACTOR - 2.735; IC VALUE:5.16

VOLUME 3, ISSUE 9(2), SEPTEMBER 2014

5. S. Nasrazadani L. Reyes ,Failure Analysis of Al 356-T6 Clutch

Lever, Failure Analysis of Al 356-T6 Clutch Lever

6. Y. Huang and Y. Zhu, Failure Analysis of Friction Weld (FRW) in

Truck Axle Application, Submitted: 17 September 2007 / in revised

form: 16 November 2007 / Published online: 20 December 2007_

ASM International 2007

7. A. Nusair Khan W. Mohammad I. Salam..: Failure Analysis of

Laser Weld Joint of X2NiCoMo18-8-5 Steel.

8.

http://en.wikipedia.org/wiki/Root_cause_analysis

9. http://www.thehindu.com/news/cities/chennai/ap-cm-announcesexgratia-for-telugu-victims-in-chennai-buildingcollapse/article6159984.ece

365

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Sediment Classification Using Side Scan SONARDokument5 SeitenSediment Classification Using Side Scan SONARiaetsdiaetsdNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Slow Intelligence System Based Software TestingDokument6 SeitenSlow Intelligence System Based Software TestingiaetsdiaetsdNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- A Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditionDokument4 SeitenA Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditioniaetsdiaetsdNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- IOT Based Waste Management System For Smart CityDokument7 SeitenIOT Based Waste Management System For Smart Cityiaetsdiaetsd100% (2)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Survey - Data Security and Privacy Big DataDokument6 SeitenA Survey - Data Security and Privacy Big DataiaetsdiaetsdNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Design of Transformer Peripharals by Computer Aided Design Drafting (Cadd)Dokument8 SeitenDesign of Transformer Peripharals by Computer Aided Design Drafting (Cadd)iaetsdiaetsdNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Impact of Partition As Revealed in Bapsi Sidhwa's Ice Candy ManDokument9 SeitenThe Impact of Partition As Revealed in Bapsi Sidhwa's Ice Candy ManiaetsdiaetsdNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- MHD Flow With Silver (Ag) and Titanium (TiO2) Water Based Nano Fluid Over A Non-Linearly Stretching/strinking SheetDokument8 SeitenMHD Flow With Silver (Ag) and Titanium (TiO2) Water Based Nano Fluid Over A Non-Linearly Stretching/strinking SheetiaetsdiaetsdNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Mathematical Model For Marangoni Convection MHD Flow of Carbon Nanotubes Through A Porous MediumDokument7 SeitenMathematical Model For Marangoni Convection MHD Flow of Carbon Nanotubes Through A Porous MediumiaetsdiaetsdNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- In Vitro Propagation of Anisochilus Carnosus (LF.) Wallich - A Medicinal PlantDokument3 SeitenIn Vitro Propagation of Anisochilus Carnosus (LF.) Wallich - A Medicinal PlantiaetsdiaetsdNoch keine Bewertungen

- A Review Paper On Online Restaurant Management System - Http://iaetsdjaras - OrgDokument5 SeitenA Review Paper On Online Restaurant Management System - Http://iaetsdjaras - OrgiaetsdiaetsdNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- A Comparative Analysis of Income and Expenditure Pattern of Working and Non-Working Women in TamilnaduDokument8 SeitenA Comparative Analysis of Income and Expenditure Pattern of Working and Non-Working Women in TamilnaduiaetsdiaetsdNoch keine Bewertungen

- Retrofitting of Reinforced Column by Using Ferrocement JacketingDokument4 SeitenRetrofitting of Reinforced Column by Using Ferrocement JacketingiaetsdiaetsdNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- BN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesDokument13 SeitenBN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesGiftObionochieNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- PWHTDokument25 SeitenPWHTBruce leeNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Eawc201 en W Alni r05Dokument1 SeiteEawc201 en W Alni r05Anonymous nKOyHbNoch keine Bewertungen

- Advanced Ceramic Components - Materials, Fabrication, and Applications PDFDokument32 SeitenAdvanced Ceramic Components - Materials, Fabrication, and Applications PDFDaxel Val100% (1)

- 5 - Compression Failure Mechanisms in Unidirectional CompositesDokument45 Seiten5 - Compression Failure Mechanisms in Unidirectional CompositesMo 57sNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Smoke - Control ICB Handout PDFDokument42 SeitenSmoke - Control ICB Handout PDF185412Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Pipeline Integrity Management MSC (Penspen)Dokument7 SeitenPipeline Integrity Management MSC (Penspen)Majeed Rumani0% (2)

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDokument4 SeitenCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNoch keine Bewertungen

- Model Estimate For Construction of Concrete RoadDokument8 SeitenModel Estimate For Construction of Concrete RoadAria Beepamungkas100% (1)

- Uta Fall23 Designbuild Pointzero CdsDokument14 SeitenUta Fall23 Designbuild Pointzero CdsDerek MaynardNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Polyguard PEDokument2 SeitenPolyguard PEabcd1860100% (1)

- Vikings-Preaction FoamWater System Supplied by A Bladder TankDokument12 SeitenVikings-Preaction FoamWater System Supplied by A Bladder TankHenry WuNoch keine Bewertungen

- Luminarias Glamox para Areas DeportivasDokument2 SeitenLuminarias Glamox para Areas DeportivasAlberto PopushoyNoch keine Bewertungen

- Norton WeldingMetalFabCatalog 2011Dokument182 SeitenNorton WeldingMetalFabCatalog 2011RSR_2K5364Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Ölflex® Classic 110 LT: Product InformationDokument4 SeitenÖlflex® Classic 110 LT: Product InformationPhaniNoch keine Bewertungen

- A New Approach With Prepregs For ReinforcingDokument8 SeitenA New Approach With Prepregs For ReinforcingRajesh Kumar SNoch keine Bewertungen

- Compressive Strength of Concrete - Cube Test, Procedure, ResultsDokument6 SeitenCompressive Strength of Concrete - Cube Test, Procedure, ResultsAravindanNoch keine Bewertungen

- Bringing Power To Light: Company ProfileDokument32 SeitenBringing Power To Light: Company ProfileYu hongNoch keine Bewertungen

- In-Place Methods To Estimate Concrete Strength: Reported by ACI Committee 228Dokument41 SeitenIn-Place Methods To Estimate Concrete Strength: Reported by ACI Committee 228yusak santosoNoch keine Bewertungen

- International Journal of Mechanical Sciences: Hamad Ul Hassan, Heinrich Traphöner, Alper Güner, A. Erman TekkayaDokument13 SeitenInternational Journal of Mechanical Sciences: Hamad Ul Hassan, Heinrich Traphöner, Alper Güner, A. Erman TekkayaAnya CooperNoch keine Bewertungen

- ACI Committee 423 - Recommendations For Concrete Members Prestressed With Unbonded Tendons, ACI 423.3R-05Dokument21 SeitenACI Committee 423 - Recommendations For Concrete Members Prestressed With Unbonded Tendons, ACI 423.3R-05bournelinNoch keine Bewertungen

- Characterization of The Young's Modulus and Residual Stresses For A Sputtered SiliconDokument5 SeitenCharacterization of The Young's Modulus and Residual Stresses For A Sputtered Silicon夕何Noch keine Bewertungen

- Environmental Effects On Engineered Materials - Russell H. JonesDokument517 SeitenEnvironmental Effects On Engineered Materials - Russell H. JonesVictorNoch keine Bewertungen

- ATR Ata - 21 - Air - ConditioningDokument115 SeitenATR Ata - 21 - Air - ConditioningJesús Montalvo Fernández100% (5)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Materials Science and Engineering by Callister Chapter 1 ReviewerDokument3 SeitenMaterials Science and Engineering by Callister Chapter 1 ReviewerTy ztickNoch keine Bewertungen

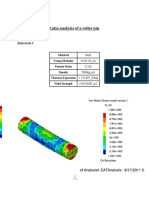

- Catia Analysis of A Roller PinDokument15 SeitenCatia Analysis of A Roller Pinanteneh tesfayeNoch keine Bewertungen

- Triton Cargo Worthy Standards - May2017 RevisionDokument57 SeitenTriton Cargo Worthy Standards - May2017 RevisionHoan VuNoch keine Bewertungen

- Presurizacion Controll System PDFDokument16 SeitenPresurizacion Controll System PDFVin PhearakNoch keine Bewertungen

- Buttress Dam AnalysisDokument8 SeitenButtress Dam AnalysisIzet Mehmetaj100% (1)

- Compressible FlowDokument11 SeitenCompressible FlowZain Abdul Malik NooraliNoch keine Bewertungen

- Colleen Hoover The Best Romance Books Complete Romance Read ListVon EverandColleen Hoover The Best Romance Books Complete Romance Read ListNoch keine Bewertungen