Beruflich Dokumente

Kultur Dokumente

DANS An DAN Optimizing The Operation of Legacy Online Gcs by Retrofitting Controllers

Hochgeladen von

Mukesh VadaliaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DANS An DAN Optimizing The Operation of Legacy Online Gcs by Retrofitting Controllers

Hochgeladen von

Mukesh VadaliaCopyright:

Verfügbare Formate

Optimizing

the Operation

of Legacy

DANIEL

MEASUREMENT

AND CONTROL

WHITEOnline

PAPERSGas Chromatographs by Retrofitting Controllers

page 1

Optimizing the Operation of Legacy Online Gas Chromatographs by Retrofitting Controllers

www.daniel.com

ABSTRACT

Gas chromatographs (GCs) are frequently used in pipelines for

Manufacturers typically specify instrument repeatability rather

custody transfer measurement of the energy content in natural

than accuracy. Various operational procedures that determine

gas. Accuracy is determined by calibration-gas quality and

accuracy include:

how well the technician is able to diagnose and troubleshoot

Quality of the calibration gas

the operation of the GC over long periods of time. A general

Installation of the calibration gas

trend in industry away from specialization has made it difficult

Set-up and operation of the gas chromatograph

for technicians to reach a high competency level in any one

basis.

CHROMATOGRAPHY IN CUSTOMER TRANSFER

APPLICATIONS

Advanced software tools are available to assist and train the

usually in mole % units. It does not directly measure physical

area. Chromatography is a difficult field to master on a part-time

technician in how to look beyond the basic functions and fully

optimize GC operations. Training is enhanced and accuracy can

be improved substantially on legacy-model gas chromatographs.

Properly utilized, the potential exists to improve accuracy and

A gas chromatograph measures the composition of natural gas,

properties like heating value or relative density. Frequently, a

review of heating values by a pipeline technician will include

minimal attention to the reported component concentrations.

However, the gas chromatograph calculates physical properties

extend equipment life.

from component concentrations. Therefore, improvements in

INTRODUCTION

concentration measurement.

When a new Emerson Process Management gas chromatograph

is initially delivered for field installation, it has passed a series of

quality checks at the factory to optimize performance to within

+/-.25 BTU repeatability. If the technician installs a primary

calibration standard, gravimetrically measured by weights

traceable to NIST (National Institute of Standards Technology),

operational error can be minimized. If this gas chromatograph

is installed and operated correctly, accuracy can approach the

same inherent +/-.25 BTU performance level. The longer a

gas chromatograph is in operation, the further it can drift from

accuracy can be achieved only from optimizing component-

The primary natural-gas-pipeline measurement provided by a

chromatograph is energy content (BTU or MJ) or relative density

(specific gravity) derived from quantification of component

concentrations. The latter may be used by a flow computer for

AGA-8 compressibility calculations which are used to determine

a corrected volumetric flow rate.

CHROMATOGRAPH DIAGNOSTICS

A chromatogram graphically depicts the gas chromatograph

factory settings.

detector signal. It contains most of the information required

Emerson Process Managements 2350A Gas Chromatograph

chromatogram is analyzed along with raw data to compare

Controller and complementary MON software were designed to

give users a field upgrade so a technician can enhance gas

chromatograph performance. Emerson Process Management

provides columns, valves, detectors, and other wetted

parts from stainless steel for operation in a non-corrosive

environment where mechanical or chemical wear is minimal.

Solenoids, filters, and valve diaphragms may require periodic

maintenance. In natural gas service, older gas chromatographs

have the potential to operate as well as new GCs once the

electronics (controller) have been updated with the newer, more

user-friendly software that optimizes performance.

to optimize the gas chromatograph performance. When the

against the original operational parameters, a wealth of

information is available about the internal workings of the

chromatograph. The problem that many technicians face is

that they dont know what to look for in a chromatogram, nor

do they understand how to relate that to a specific problem.

Furthermore, historical data in the form of paper is not usually

filed in the proper order. Frequently, raw data, chromatograms,

analyzer results, configuration reports, and calibration reports

are often hard to recover and correlate to each other over time.

In short, paper tends to get lost.

DANIEL MEASUREMENT AND CONTROL WHITE PAPER

page 2

MOUNTING

Electronic storage of data allows the technician to keep all

There are three options for mounting the controller:

the information pertinent to a given gas chromatograph on a

Rack mount

disk, hard drive, or in the gas chromatograph controller itself.

NEMA 4 X-proof (Class I, Division I, Group C & D)

Chromatograms, raw data, and results can be stored as one file

Panel mount /Retrofit (no keypad)

and compared against previous data to simplify troubleshooting.

By referring to these chromatograms and the associated

The panel mount version fits a conventional 19 free-standing

user description, which offers subtle, site-specific information

cabinet. A keypad and display are optional. It is designed to

contained within the chromatogram, the technician can begin

fit into the same panel cuttout as the older controller with less

to understand what to look for in a chromatogram. Overlay and

depth behind the panel. Physical space requirements behind

zoom functions allow direct comparisons of historical and current

the panel (width and height) are increased to accommodate a

chromatograms. This can help supervisors and team members

plug-in rack and a minimum of five plug-in boards.

to collaborate in examining trends and troubleshooting problems

associated with columns, valve timing, helium and calibration

COMMUNICATIONS

gas quality, and changes in carrier gas pressure.

Four serial communications ports independently support a total

of four different field-configurable versions of Modbus protocol.

Gradual changes usually occur over time with a corresponding

The 32-bit (IEEE floating point) version originally used by Daniel

effect on accuracy. The most frequent revision of software allows

in the 2251 is still supported in the original ASCII format now

the user to save a chromatogram and raw data from any run

referred to as SIM 2251.

during an alarm. This can be very valuable in troubleshooting

intermittent problems if the alarms are configured properly.

Register assignments have been kept the same as in the older

2350 and 2251 controllers to simplify host communications;

Auto-calibration is often considered a fix-all solution for these

additional user configured registers have simply been added.

types of instrument changes. Although calibration can adjust

The 8-bit binary RTU Modbus format is now supported as well.

for gradual changes in detector sensitivity and some changes

SIM 2251 allows users to poll a single Modbus register for 32-

in carrier pressure by tracking new retention times, it can also

bit floating points or integers. The newer version, User Modbus,

cover up problems that are not related to calibration at all. GCs

refers to the original 16-bit implementation commonly used by

can operate in custody transfer installations for years with

control system manufacturers. This version requires two Modbus

optimal accuracy if chromatograms and raw data are properly

registers to pass a single 32-bit variable (the 32-bit value is split

used.

into two16-bit values). Both versions are field-configurable in

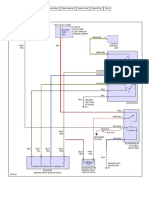

WIRING

ASCII or RTU format with flexible register assignments.

Interconnect wiring between the gas chromatograph and the

One of the most difficult communications problems with older

2350A controller is the same as for the older 2350 and 2251

controllers is the limitation in trying to output gas chromatograph

controllers. Thirteen wires carry four analog (4-20) signals plus

data to several Modbus masters through one serial port. Serial

a common wire from the GC pre-amp board. Timed events are

port multiplexers and port-sharing devices have been used

executed with BCD logic utilizing five VDC levels carried over

successfully in the past to pass data to multiple masters such

four wires plus a common from the gas chromatograph decoder

as flow computers, RTUs, and off-site hosts. The additional

board. An additional 5 VDC signal is periodically referenced to

serial ports in the controller allow for easy communications to

ground to perform an auto zero once every analysis; this requires

multiple Modbus masters by assigning one master for each

an additional wire . Two wires are dedicated to a low-pressure

serial port. Each serial port is interrupt-driven and will operate

helium alarm from a discrete N/C contact on a pressure switch

independently at speeds up to 19.2 kBaud. A fifth parallel port is

located at the gas chromatograph. This makes a total of 13 wires.

dedicated to hardcopy printed reports.

Additional wires are required to carry optional analog inputs

to the gas chromatograph, usually from other analyzers and

DATA STORAGE

back to the controller. Removable quick-connect terminations

Extensive data storage/retrieval capability assists measurement

simplify maintenance by allowing the user to easily disconnect

accounting personnel as well as measurement technicians and

field wiring from the termination board without removing existing

operators. Major features include:

wire terminals.

Archive storage of the most recent 1200 cycles (over

three days of four-minute cycles) with the ability to

Optimizing the Operation of Legacy Online Gas Chromatographs by Retrofitting Controllers

trend all calculated results.

subtracted from any legitimate overlapping peak found during

Archive results from the last 400 calibrations (typically

normal calibration and analysis runs to improve accuracy.

over a year of analyses).

page 3

Average 64 components and retain results of the

SUMMARY

last 64 time units. (For example, 64 units equals a

Several factors can affect gas chromatograph performance

24-hour average for four streams of N to 2 C6+ with

and reduce measurement accuracy over time. Retrofitting gas

BTU, SG, compressibility, and un-normalized total.)

chromatograph controllers can initiate a program to improve

Daily average results from the last 64 days for all 16

accuracy. But this must be followed by extensive use of available

components are stored.

software tools for each gas chromatograph in order to monitor

trends and know what remedial action to take and when.

if

The newer diagnostic capability, with a number of example

communications or other recordkeeping breaks down, valuable

chromatograms to initiate the process, can greatly assist

results will nevertheless be available. ASCII files of all calculated

technicians in learning the finer points of chromatography.

values can be created and exported in the format commonly

The end result can be improved measurement accuracy and

used by most companies. Extensive paper files can be replaced

extended equipment life.

This

data

storage/retrieval

capability

ensures

that

by compact, convenient electronic storage.

Trends can be set up from archive data to display measurement

results. A more creative use of trend information as a quality

check is to trend response factors for components such as C6+

or retention times for ethane. The use of trending as a tool in

diagnosing gas chromatograph problems is almost unlimited, as

the data storage capability in the 2350A is very large.

CALIBRATION

Repeatability is even more important when a gas chromatograph

is in calibration mode. Generally 3-4 consecutive runs are

required with an average value for each new response factor

that does not exceed 10% deviation from the previous one.

When all response factors and retention times have been

updated, particular attention should be given to the response

factor deviations on C6+, as well as the component splits

between columns. On a Daniel portable GC with a four-minute

analysis time, these column splits occur between ethane /

propane and normal pentane and C6+. Any deviations in

response factors on these components may require small

changes in the valve timing for V-2 and V-3 off-times.

A baseline check can be performed periodically to ensure that

the GC is operating correctly. A baseline check is simply an

analysis run performed without the sample turned on. Peaks will

be integrated and stored in raw data, without sample injection.

However, the chromatogram should not produce any peaks. Any

peaks that do occur will decrease with subsequent analysis runs

if they are a result of carry-over from a previous analysis. If a

single repeatable peak occurs immediately after the backflush, it

may indicate wet off-spec helium is being used. Dry UHP (ultrahigh purity) grade helium is required for GC analysis.

This raw area from peaks found during a baseline check can be

Emerson Process Management

Daniel Measurement and Control, Inc.

www.daniel.com

North America / Latin America:

Headquarters

USA - Houston, Texas

T +1.713.467.6000

F +1.713.827.3880

USA Toll Free 1.888.FLOW.001

Europe: Stirling, Scotland, UK

T +44.1786.433400

F +44.1786.433401

Middle East, Africa: Dubai, UAE

T +971.4.811.8100

F +971.4.886.5465

Asia Pacific: Singapore

T +65.6777.8211

F +65.6777.0947 / 0743

Daniel Measurement and Control, Inc. is a wholly owned subsidiary of Emerson Electric Co., and a

division of Emerson Process Management. The Daniel name and logo are registered trademarks

of Daniel Industries, Inc. The Emerson logo is a registered trademark and service mark of

Emerson Electric Co. All other trademarks are the property of their respective companies. The

contents of this publication are presented for informational purposes only, and while every

effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, expressed or implied, regarding the products or services described herein or their use

or applicability. All sales are governed by Daniels terms and conditions, which are available upon

request. We reserve the right to modify or improve the designs or specifications of such products

at any time. Daniel does not assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any Daniel product remains

solely with the purchaser and end-user.

2010 Daniel Measurement and Control, Inc. All Rights Reserved. Unauthorized duplication in whole or in part is prohibited. Printed in the USA.

DAN-TECHNOLOGIES-OPTIMIZING-THE-OPERATION-OF-LEGACY-ONLINE-GAS-CHROMATOGRAPHS-BY-RETROFITTING-CONTROLLERS

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Indian Classical MusicDokument87 SeitenIndian Classical Musicsudipto917100% (10)

- Heat Rate Calc in ExcelDokument13 SeitenHeat Rate Calc in ExcelMukesh VadaliaNoch keine Bewertungen

- Heat Rate Calc in ExcelDokument13 SeitenHeat Rate Calc in ExcelMukesh VadaliaNoch keine Bewertungen

- Technical Specification For 20 MVA Transformer PDFDokument21 SeitenTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- Literature Case Study On Design CollegeDokument21 SeitenLiterature Case Study On Design CollegeSophia Chin100% (1)

- Jenbacher Type 9 Flextra Engine 2 PDFDokument8 SeitenJenbacher Type 9 Flextra Engine 2 PDFChristian Celeste100% (1)

- C5-21B B777 CapabilitiesDokument8 SeitenC5-21B B777 CapabilitiesPablo Restrepo OssaNoch keine Bewertungen

- Reid Vapor PressureDokument5 SeitenReid Vapor Pressurefumerojr5164100% (1)

- 61R Compact Raise Borer Technical Specification WorksheetDokument4 Seiten61R Compact Raise Borer Technical Specification WorksheetRoiNoch keine Bewertungen

- Type of Input No. of Channels/P Oints Input/Output Type/Range OthersDokument2 SeitenType of Input No. of Channels/P Oints Input/Output Type/Range OthersMukesh VadaliaNoch keine Bewertungen

- Type of Input No. of Channels/P Oints Input/Output Type/Range OthersDokument2 SeitenType of Input No. of Channels/P Oints Input/Output Type/Range OthersMukesh VadaliaNoch keine Bewertungen

- DroopDokument1 SeiteDroopMukesh VadaliaNoch keine Bewertungen

- Calculation of Pay-Back For Opting Diesel Vehicle Over Petrol VehicleDokument2 SeitenCalculation of Pay-Back For Opting Diesel Vehicle Over Petrol VehicleMukesh VadaliaNoch keine Bewertungen

- Presentation On Process-AutomationDokument27 SeitenPresentation On Process-AutomationMukesh VadaliaNoch keine Bewertungen

- SSUP InstructionsDokument2 SeitenSSUP InstructionsMukesh VadaliaNoch keine Bewertungen

- Pur Vs HireDokument7 SeitenPur Vs HireMukesh VadaliaNoch keine Bewertungen

- 3.7 Cooling TowersDokument6 Seiten3.7 Cooling TowersSaurabh VijNoch keine Bewertungen

- Basic Electronics - BookDokument486 SeitenBasic Electronics - BookulahannanNoch keine Bewertungen

- Six SigmaDokument5 SeitenSix SigmaMukesh VadaliaNoch keine Bewertungen

- Newtb 141Dokument7 SeitenNewtb 141proxywarNoch keine Bewertungen

- S11.0 Seismic Restraint SpacingDokument12 SeitenS11.0 Seismic Restraint SpacingAndrew WaddingtonNoch keine Bewertungen

- CIE IGCSE Forces Hookes Law OnlyDokument22 SeitenCIE IGCSE Forces Hookes Law Onlyh aNoch keine Bewertungen

- Rame ProfileDokument6 SeitenRame Profiletri_purwadiNoch keine Bewertungen

- GT Load Effect On HRSGDokument3 SeitenGT Load Effect On HRSGsatishchemeng100% (1)

- Outotec: Managing Talent Globally With Successfactors® SolutionsDokument3 SeitenOutotec: Managing Talent Globally With Successfactors® SolutionsxandaniNoch keine Bewertungen

- Report On Tripping of Delta I Relay On Running of Wag12 LocosDokument3 SeitenReport On Tripping of Delta I Relay On Running of Wag12 LocosrdkrdsoNoch keine Bewertungen

- Dams: Parts, PakistanDokument22 SeitenDams: Parts, PakistanEnigmatic Yousafzai100% (1)

- Rencana Power Energize 11 Feb 21 Rev.2Dokument11 SeitenRencana Power Energize 11 Feb 21 Rev.2Ari Puji HidayatullahNoch keine Bewertungen

- CHE412 Process Dynamics Control BSC Engg 7th SemesterDokument17 SeitenCHE412 Process Dynamics Control BSC Engg 7th SemesterwreckiebNoch keine Bewertungen

- Calefaccion Mazda 3 2006 - 2010Dokument2 SeitenCalefaccion Mazda 3 2006 - 2010Jhon ConnorNoch keine Bewertungen

- Quantitative Determination OF AND: Vitamin A Vitamin EDokument20 SeitenQuantitative Determination OF AND: Vitamin A Vitamin EAras RafiqNoch keine Bewertungen

- Pastite For Pipe Connection System Bul 4300 PTPDokument6 SeitenPastite For Pipe Connection System Bul 4300 PTPanoop9079Noch keine Bewertungen

- EJ200 Turbofan Engine: The Innovative PowerDokument2 SeitenEJ200 Turbofan Engine: The Innovative PowerufcNoch keine Bewertungen

- Viscosity of Blueberry and Raspberry Juices For Processing ApplicationsDokument8 SeitenViscosity of Blueberry and Raspberry Juices For Processing ApplicationsAmparitoxNoch keine Bewertungen

- HYSYS Upstream GuideDokument188 SeitenHYSYS Upstream GuideJahangir Malik100% (1)

- Whirlpool Awm 4120Dokument16 SeitenWhirlpool Awm 4120Zoran ProkicNoch keine Bewertungen

- Checklist 519 Insulation Resistance Test: Equipment NameDokument2 SeitenChecklist 519 Insulation Resistance Test: Equipment NameBhalsingh Jangra100% (1)

- Woodward GovernorDokument4 SeitenWoodward GovernorAbhijit Manna100% (1)

- Daytona 350Dokument48 SeitenDaytona 350coco FadhNoch keine Bewertungen

- Motion in A Plane PDFDokument38 SeitenMotion in A Plane PDFaman btechNoch keine Bewertungen

- Eng Sicor Catalogue GearlessDokument52 SeitenEng Sicor Catalogue GearlessEmeka Pius OramunwaNoch keine Bewertungen

- Chemistry MSCDokument17 SeitenChemistry MSCRajesh ShahiNoch keine Bewertungen

- Assembly Features: Removable Terminal BlueDokument3 SeitenAssembly Features: Removable Terminal BlueJagadesh C S NadarNoch keine Bewertungen

- Cylinder Cover Assembly KG170-02000: Fuel Oil System KG170-09000Dokument1 SeiteCylinder Cover Assembly KG170-02000: Fuel Oil System KG170-09000Александр ЩеблыкинNoch keine Bewertungen