Beruflich Dokumente

Kultur Dokumente

V3i9 Ijertv3is090001 PDF

Hochgeladen von

Astri NgentOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

V3i9 Ijertv3is090001 PDF

Hochgeladen von

Astri NgentCopyright:

Verfügbare Formate

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 9, September- 2014

Hydraulic Transient Analysis of Kolar Water

Pipeline using Bentley Hammer

V8i A Case Study

Sadanand

Research Scholar

MANIT,Bhopal; India

Dr.T. S. Desmukh

Professor

MANIT,Bhopal; India

settings. variation in demands,sudden closure of valves and

pumping system performances affects the unsteady flow

.These all conditions effects the steady state nature of

flow(T.Tezcan,U.Gokkus and G.Sinir)[16].

Solution by Methods Of Characterstics(MOC):

Water hammer equations for elastic pipes produces a 1-d

partial equation and result of this one is found by Methods of

characterstics. this is the mathematical modeling of the

unsteady flow. To solve the momentum and conservation of

mass equation moc is used (wylie and streeter)[15]. These

equations are :

V 1 p

dz

f

g

V V 0 1.

t s

ds 2 D

IJE

RT

Abstract- The case study belongs to hydraulic transient

analysis with Bentley Hammer V8i software and

validating the results with manual calculations. Kolar

water pipeline has been taken for case study. For this the

result obtained from the PHE department, Bhopal were

used for comparison. The available results were for the

transient analysis with the surge protection devices in

position. However as no detail of the devices was available

the analysis with surge protection devices was not possible

in Bentley Hammer V8i. . Hence initially the transient

analysis for the Kolar pipeline was done manually (using

excel sheet) considering the location of air vessels for

validation. These results were found to match with the

PHE department results. Then manual analysis was done

without surge protection devices. After this the transient

analysis of the pipeline was performed using Bentley

Hammer V8i without surge protection devices. The

results so obtained matched fairly well with the manual

results for the same case. Bentley hammer v8i used for

analysis with condition without surge protection so that

the location for surge protection can be found out.

Keywords Hydraulic transients,

hammer v8i, surge .

MOC, bentley

INTRODUCTION-

a2

1 p

V

0 2.

s

t

Solution of the equations is:

C+ :

fx

a

(Q p Qi 1 ) ( H p H i 1 )

Q p Qi 1 0

2 gDA^ 2 .3.

gA

C-:

The hydraulic analysis in closed conduits is based on the

steady state flow conditions. by applying some governing

equations of conservation of mass and momentum and

extracting a general equation for the elastic pipe for solution.

That results into a method of solution called method of

characteristics(wylie and streeter)[15]. Methods of

characterstics(moc) is very popular method for studying

transients and water hammer effects. Avoiding the effects of

water hammer is big concerned in pipe technology. Design of

pipe on the basis of elastic theory of pipes and finding the

maximum

and

minimum

pressure

or

wave

oscillations(R.Wichowski)[14]. Methods of characterstics is

related to finite difference method as the equation is

discritized for different points. These points gives the

analysis values of pressure, discharge and velocity.

Transients of such systems are also depends upon the valave

IJERTV3IS090001

And

a

fx

(Qp Qi 1 ) ( H p Hi 1)

Qp Qi 1 0

gA

2 gDA^2

..4.

In the solution of equations; here velocity terms are converted

into discharge terms for our convenience( wylie and

streeter)[15]. Equation 1 and 2 are the quasi hyperbolic

equations and general method of solving is MOC in 3 and 4

equations.

For the solution there are many boundary solution is

considered requiring like reservoirs, pumps ,pipeline

branches, dead ends etc. but here we are using upstream

reservoir boundary conditions and pump conditions for

www.ijert.org

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 9, September- 2014

compatible MOC equation(A.Bergant, A.R.Simpson, E.

Sijamhodzic)[1].

The compatibility equation for c+ line Qi-1 has the known

value at the upstream section and Hi-1 also has the known

value at upstream section but for finding Qp at the starting

upstream section Hp is equal to Hr. similarly for c- line Qi+1 is

known and for Hp due to pump shut down considering initial

value is equal to zero. this approach at the downstream

section of pump outlet.

Problem statement and analysis: in the study of kolar water

scheme at Bhopal, MP; has two pumping main one raw water

main 7.2 km long and clear water pumping main 3.2 km long.

Here the data for the hydraulic transients

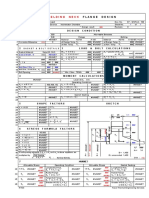

Table-Data of Kolar supply scheme

RAW WATER

PUMPING

MAIN

CLEAR

WATER

PUMPING

MAIN

Length of Pumping

Main

Material of Pipes

7200m.

3200m.

(1.)M.S. Pipes

with

cement

mortor inlining

and outcoating

fro 0 to 3210m.

(2.)PSC Pipes

from 3210m.to

7200m.

M.S. Pipes with

cement mortor

inlining

and

outcoating.

3.

Internal Diameter of

pipe line

1450mm.

for

Steel

Pipes

1500mm.

for

PSC Pipes.

1450mm. Steel

Pipe.

4.

5.

6.

Laying condition

Maximum flow rate

Pump

Discharge

Head

Pressure

wave

velocity

Under Ground

7152 cum/hr.

90.50m.

Under Ground

6740 cum/hr.

90m.

1016m/s upto

3210m.

and

904m/s for next

3990m. 7200m.

1016m/s.

pump velocity

Pump type

1000rpm.

Vertical Turbine

Type

980rpm.

Horizontal

1.

2.

7.

8.

9.

ITEMS

In above shown figures, those are the general data used for

elevation for the pipeline mains.

Analysis for pipeline mains with surge protection:

IJE

RT

SR.NO.

Fig.3. HGL vs length for raw water main with surge protection

As per the general solution of the MOC firstly calculated the

discharge term and then head term which is discussed earlier

after calculating all the values which gives the analysis of the

hydraulic transient for the case study.

Fig.1. Profile for raw water pipeline

IJERTV3IS090001

Fig.2. Profile for clean water pipeline.

Fig.4. HGLvs. length clear water main with surge protection

In both the pipeline mains results are matched quite well.

Following the same procedure for hydraulic transient analysis

with manual calculations for without surge protection

devices.

Benley Hammer V8i:

The transient analysis of the Kolar pipelines was done

through Bentley Hammer V8i software keeping the same

length of reaches as in case of manual solution. The given

profile of the Kolar pipeline was modeled in the software and

all its parameter specified. Then the pumps were defined for

both the pipelines. The analysis for raw water pipeline was

done initially using pump shut down time as the period

(2L/C) and then with the trial and error method weve

determined the total run duration time. The results shown

www.ijert.org

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 9, September- 2014

below is a comparison between manual calculation and

Bentley V8i Hammer V8i software.

Fig.5. Comparison of manual and software results without surge protection

raw water pipeline.

performing the transients analysis for a water supply pipeline

using the Bentley Hammer V8i software. For this the

solution obtained through the software has been validated

through manual solution of transient analysis for Kolar

Pipeline.

The locations are suggested for the surge protection devices

are very critical as pipe rupture conditions are high. Due to

air vapour pocket formation the problem of cavitation can

take place and hazardous effects can be happened.

Bentley Hammer V8i software is very efficient and user

defined for the study of this problem. A big advantage of the

Bentley Hammer V8i software is that it can introduce the air

vapour pocket itself in the model according to given

condition and reduces the trial and iterative work for

calculating the air vapour pressure in the system.

REFERENCES

1. A.Bergant, A.R.Simpson, E. Sijamhodzic (2012), Water

hammer analysis of pumping system for control of water in

underground mines, International mine water association,

2012.p.p.9 to 19.

2. A.G.Rasool, Z.Mustaffa (2012), Hydraulic Characteristics of

Energy Dissipation Systems, IEEE Colloquium on Humanities,

Science & Engineering Research, CHUSER, 2012.

3. Bergant and Tijsseling (2001), Affect of water hammer wave

attenuation, shape and timing.

4. Chaudhry, H.M. (1988), Applied Hydraulic Transients, Van

Nostrand Reinhold, New York

5. D. Stephenson, F.ASCE1 (2002), Simple guide for design of air

vessels for water hammer protection of pumping Lines, ASCE,

2002.p.p.792 to 797.

6. Fang Hong Qing, Shen Zu Yi (2005), Modeling and Simulation

of Hydraulic Transients for Hydropower Plants, IEEE/PES

Transmission and Distribution Conference & Exhibition: Asia

and Pacific Dalian, China, 2005.

7. Gilberto E. Urroz (2004), Hydraulic Pipe Transients by the

Method of Characteristics.

8. J.K.Roy, P.K.Roy, P.Basak (2005), Water Hammer Protection

in Water Supply System: A New Approach with Practical

Implementation.

9. K.Z.Wu Juan (2010), Study on Vibration Test System Excited

by Water Hammer, IEEE, 2010.p.p.338 to 341.

10. Kishore Sirvole (2007), Transient analysis in pipe network,

Blacksburg, Virginia, US, 2007.

11. Mosab Elbashir and Samuel Amoah (2007), Hydraulic

Transient in a Pipeline Using Computer Model to Calculate and

Simulate Transient, Malmo, Sweden, 2007.

12. O.H.Souza Jr., N.Barbieri, A.H.M. (1999), Santos Study of

Hydraulic Transients in Hydropower Plants Through Simulation

of Nonlinear Model of Penstock and Hydraulic Turbine Model,

IEEE Transactions on Power Systems, Vol. 14, No. 4, November

1999.p.p.1269 to 1272.

13. R.E.Wright,Willbros Butler Engg.Inc. Tulsa Oklahoma

(1993), Mitigating damage by hydraulic transients in liquid

pipeline system Material IEEE, Paper No. PCIC-93-16.p.p.147

to 159.

14. Roman Wichowski (2006), Gdansk University of Technology,

Faculty for Civil and Environmental Engineering, ul.

Narutowicza 11/12, 80-952 Gdansk, Poland.

15. Streeter, V.L. and E.B. Wylie (1967), Hydraulic Transients,

New York, NY, McGraw-Hill.

16. T.Tezcan, U.Gokkus and G.Sinir (1998), Analysis of Unsteady

Pipe Flow in Complex Pipe System by the Methods of

Characteristics. Association for scientific research.

17. V.V.Venkatesan, S.D.Harun, P.S.Karthikeyan (2005), Water

Hammer Elimination A Case Study, ESL IE.

18. Wood, Stephen L., "Modeling of Pipeline Transients: Modified

Method of Characteristics FIU Electronic Theses and

Dissertations, Paper 456.

IJE

RT

The study of the graph given above shows that the results

obtained both through manual as well as software give quite

comparable results. The nature of curve in maximum as well

as minimum piezometric head condition is similar. In case of

minimum HGL the deviation in two solutions is seen in the

reach between 3000m. to 6150. (Approximate). This is because

surges are expected in this reach and hence the software

automatically introduces air pocket in this region. Similarly the

introduction of air pocket in the maximum HGL is at 1250m

(Approximate).

Fig.6. Comparison of manual and software results without surge protection

in clean water pipeline

The study of the figures given above shows that the results

obtained both through manual as well as software calculation

are quite comparable. The nature of curves in maximum as

well as minimum hydraulic grade line is similar. In case of

minimum HGL the deviation between the two solutions is

seen between 2750m. to 3060m. (Approximately). This is

because surges are expected in this reach and hence the

software automatically introduces air pocket in this region.

Similarly the introduction of air pocket in the maximum HGL

is in the initial reach upto 750m. (Approximately).

CONCLUSION:

The analysis of both the raw water and clean water mains

revealed that hydraulic transients occur in the system. The

abrupt changes in pressures due to these transients are liable

to affect the performance and sustainability of the water

supply scheme. The present work shows the feasibility of

IJERTV3IS090001

www.ijert.org

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- D Value CalcDokument5 SeitenD Value CalcAstri NgentNoch keine Bewertungen

- Data Dial IndikatorDokument2 SeitenData Dial IndikatorAstri NgentNoch keine Bewertungen

- Mud Barge Sea ChestDokument1 SeiteMud Barge Sea ChestAstri NgentNoch keine Bewertungen

- Gantry Crane CalculatedDokument1 SeiteGantry Crane CalculatedAstri NgentNoch keine Bewertungen

- Plate and Box Girder DesignDokument60 SeitenPlate and Box Girder DesignKrishna ChandranNoch keine Bewertungen

- ZX 100 K-Truss Support PadDokument4 SeitenZX 100 K-Truss Support PadAstri NgentNoch keine Bewertungen

- Design of Welded ConnectionsDokument8 SeitenDesign of Welded ConnectionsAstri NgentNoch keine Bewertungen

- 10 11Dokument9 Seiten10 11PrashannaNoch keine Bewertungen

- Bekomat Produk DisplayDokument4 SeitenBekomat Produk DisplayAstri NgentNoch keine Bewertungen

- Beam Desain1Dokument2 SeitenBeam Desain1Astri NgentNoch keine Bewertungen

- Assy Joint Pipa Line 1Dokument1 SeiteAssy Joint Pipa Line 1Astri NgentNoch keine Bewertungen

- Slide Bearing PTFE Tes ReportDokument6 SeitenSlide Bearing PTFE Tes ReportAstri NgentNoch keine Bewertungen

- 26 Pressure Vessel.Dokument21 Seiten26 Pressure Vessel.mishtinil93% (14)

- Surge TankDokument4 SeitenSurge TankAstri NgentNoch keine Bewertungen

- Bearing Layout PDFDokument1 SeiteBearing Layout PDFAstri NgentNoch keine Bewertungen

- Weld Analysis-IC Method v1.1Dokument5 SeitenWeld Analysis-IC Method v1.1jefersonpimentelNoch keine Bewertungen

- Over Head Water Tank DesignDokument5 SeitenOver Head Water Tank DesignAstri Ngent100% (1)

- Flange Example CalcDokument14 SeitenFlange Example CalcAstri NgentNoch keine Bewertungen

- Spherical Roller Thrust Bearing PDFDokument16 SeitenSpherical Roller Thrust Bearing PDFAstri NgentNoch keine Bewertungen

- 6000 EN 00 04 Friction BearingDokument30 Seiten6000 EN 00 04 Friction BearingAstri NgentNoch keine Bewertungen

- Reinforced PadDokument3 SeitenReinforced PadAstri NgentNoch keine Bewertungen

- NTN Pillow BlockDokument54 SeitenNTN Pillow BlockteguheafNoch keine Bewertungen

- Calculating The Time Required To Empty A Vessel: ExamplesDokument1 SeiteCalculating The Time Required To Empty A Vessel: ExamplesKabir KhanNoch keine Bewertungen

- Plugin Bushes PDFDokument3 SeitenPlugin Bushes PDFAstri NgentNoch keine Bewertungen

- ValveDokument4 SeitenValveAstri NgentNoch keine Bewertungen

- Limit State DesignDokument26 SeitenLimit State DesignAstri NgentNoch keine Bewertungen

- Motor Selection, Inertia PDFDokument6 SeitenMotor Selection, Inertia PDFIswar Rauf Aboo 'AqilahNoch keine Bewertungen

- Hydroelectric Hydro Power 4 3 1 DesignDokument28 SeitenHydroelectric Hydro Power 4 3 1 DesignLouise UmaliNoch keine Bewertungen

- Hammer Product Data SheetDokument2 SeitenHammer Product Data SheetAstri NgentNoch keine Bewertungen

- Gang SawDokument55 SeitenGang SawAstri NgentNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Marine Pollution Using Remote Sensing PDFDokument26 SeitenMarine Pollution Using Remote Sensing PDFRoberto MoraNoch keine Bewertungen

- MRET Water Suppresses Tumor GrowthDokument18 SeitenMRET Water Suppresses Tumor GrowthtodosobrepedroNoch keine Bewertungen

- Abdirahiim Yousuf Barre-Full AssignmentDokument15 SeitenAbdirahiim Yousuf Barre-Full AssignmentMohamoud AbdulahiNoch keine Bewertungen

- 1204-Barge 2 Tech SpecsDokument13 Seiten1204-Barge 2 Tech SpecsmardiradNoch keine Bewertungen

- Accutek Product Guide 2011-2012Dokument78 SeitenAccutek Product Guide 2011-2012Ahmet MetinNoch keine Bewertungen

- Nursery ManagementDokument59 SeitenNursery Managementamol Akolkar ( amolpc86)50% (2)

- Method Statement of Pipeline WorksDokument13 SeitenMethod Statement of Pipeline Worksमनिसभेटुवाल86% (21)

- Monsoon Safety PDFDokument6 SeitenMonsoon Safety PDFparthaNoch keine Bewertungen

- The Dawn Wall SkillsDokument15 SeitenThe Dawn Wall Skillsenas salahNoch keine Bewertungen

- Flood RoutingDokument34 SeitenFlood RoutingDIPAK PRASADNoch keine Bewertungen

- Cherne Smoke Fluid MSDSDokument4 SeitenCherne Smoke Fluid MSDSPromagEnviro.comNoch keine Bewertungen

- Introduction To Civil Engineering PDFDokument6 SeitenIntroduction To Civil Engineering PDFBarun SarangthemNoch keine Bewertungen

- Safety Data Sheet for KLONOPIN Tablets (2.0 mgDokument8 SeitenSafety Data Sheet for KLONOPIN Tablets (2.0 mgSandro AlcobaçaNoch keine Bewertungen

- Ordinance No. 06 2016Dokument49 SeitenOrdinance No. 06 2016Lorna CandelariaNoch keine Bewertungen

- Bricks: Ingredients of Good Brick EarthDokument15 SeitenBricks: Ingredients of Good Brick Earthসামিউল হাসান শান্তNoch keine Bewertungen

- Pressure VesselDokument6 SeitenPressure VesselEshet ShumetNoch keine Bewertungen

- Jazeera Wood Elegance StainDokument2 SeitenJazeera Wood Elegance StainAhmad BougeisNoch keine Bewertungen

- 2631-RD Calc (MSMA II) - 19.10.25Dokument98 Seiten2631-RD Calc (MSMA II) - 19.10.25azwanNoch keine Bewertungen

- Irrigation Engineering PDFDokument676 SeitenIrrigation Engineering PDFDaniel Rockn-RollaNoch keine Bewertungen

- WärtsilÄ SSD Marine LowResDokument6 SeitenWärtsilÄ SSD Marine LowResEmanuel SemoNoch keine Bewertungen

- Fyrewashf 22021Dokument2 SeitenFyrewashf 22021noble.nwalozieNoch keine Bewertungen

- Systematic Study of The Phytoplankton Biodiversity of The Sidi Mhamed Benali Lake of Sidi Bel Abbes 8530Dokument6 SeitenSystematic Study of The Phytoplankton Biodiversity of The Sidi Mhamed Benali Lake of Sidi Bel Abbes 8530Chafik MhamdiaNoch keine Bewertungen

- Ahlstrom-Munksjo Disruptor®filter Media For Water PurificationDokument6 SeitenAhlstrom-Munksjo Disruptor®filter Media For Water PurificationmusNoch keine Bewertungen

- catalogue-BW SeriesDokument2 Seitencatalogue-BW SeriessugiantoNoch keine Bewertungen

- Coal Silo Fire ProtectionDokument20 SeitenCoal Silo Fire ProtectionKrishna N HNoch keine Bewertungen

- Chemicals Zetag DATA Powder Magnafloc 1011 - 0410Dokument2 SeitenChemicals Zetag DATA Powder Magnafloc 1011 - 0410PromagEnviro.com100% (1)

- Mishra Sir PDFDokument14 SeitenMishra Sir PDFSumit Kumar100% (1)

- SPE-190536-MS Shetland Gas Plant Waste Water Treatment Systems - Achieving Compliance in A Fragile EcosystemDokument18 SeitenSPE-190536-MS Shetland Gas Plant Waste Water Treatment Systems - Achieving Compliance in A Fragile Ecosystemantonio diego angelesNoch keine Bewertungen

- PRE-BOARD ESAS (No Solutions)Dokument112 SeitenPRE-BOARD ESAS (No Solutions)John Lloyd Santos100% (2)

- GREASE MsdsDokument6 SeitenGREASE Msdsazer AzerNoch keine Bewertungen