Beruflich Dokumente

Kultur Dokumente

Precast Sewerage System Guide

Hochgeladen von

ArdiPratomoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Precast Sewerage System Guide

Hochgeladen von

ArdiPratomoCopyright:

Verfügbare Formate

CONCRETE SEWER PIPES

MANHOLE COMPONENT

JACKING PIPES

PIPE FITTINGS

INLET SYTEM

SEPTIC TANK

Pt. Dantosan Precon Perkasa

PRECON SEWERAGE SYSTEM

Introduction

Due to rapid growth in urban area, most of the metropolitan city in Indonesia urgently required

integrated waste water management system. The systems can cover limited area i.e. residential

estate, industrial estate, commercial area or large area of city.

The system includes sewer pipelines to convey waste water collecting from the source to The

Treatment Installation Plant.

The sewerage system is designed to withstand aggressive effluents condition and no leakage

along the system.

Precon has been developing concrete sewer pipes, manholes, and other products to match these

conditions. It is more efficient to use concrete pipes other than PVC or HDPE pipe for size larger

than 300mm diameter, beside the concrete material is stronger and can be protected by wide

range method depend on the condition of effluent.

Page 2/10

Pt. Dantosan Precon Perkasa

Precast Sewerage Products

Concrete Sewer Pipes

All precon pipes are produced from hard dense impermeable concrete and supplied with a

flexible rubber ring joint. Standard pipes will accept hydrostatic test head of 120kPa, but higher

head are available on request. All pipes has concrete cover minimum of 25mm thickness.

Available in various type of protection that is Type-S (Sulfate Resisting Cement + FA Protection),

Type-C (Calcareous Aggregate Protection), Type-SC (Combination A & B Protections)

Jacking Pipes

When the pipes are installed beneath

the existing surface facilities which must

not be disrupted, jacking method will

be applied. The pipes are designed to

have high axial load and collar joint

with rubber ring to adopt deflection at

joint during applying jacking force.

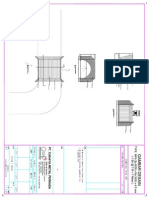

Pipe Fitting

Pipe Bend is allowed the designer to

make curvature pipeline. Pipe Bend

have maximum angle of 45o and 30o for

small and large diameter respectively.

Tee Junction and Y-Junction are

designed to make joint between two

pipes which have different alignment

and size.

Page 3/10

Pt. Dantosan Precon Perkasa

Manholes System (Access Chamber)

Precons Manhole System is designed in standard

components

allows

you

to

complete

manhole

construction in any depth required. The construction will

be very easy, simple, without formwork, fewer operation

skills and less supervision.

The system consists of:

Top Components

Circular/rectangular cover & frame, Cast Iron

Concrete Cover. It is designed to withstand fast

moving vehicle load

Middle Component

Make-up Ring, Straight Back Taper, Conversion

slab. Make-up Ring is available in any height to

adjust the elevation while for adjusting the upper

and lower opening Straight Back Taper or

Conversion Slab is introduced.

Bottom Component

Manhole Shaft and Manhole Base, completed with

step ladder, Bitumen Sealant Strips is apply

between joint of the component to ensure water

tightness.

Sewerage Associated Products

Precon also develop products and accessories related to sewerage system. The products

include inlet system, interceptor, Oil/Grease Separator, Filter Tank and Septic Tank

Page 4/10

Pt. Dantosan Precon Perkasa

Concrete Sewer Pipes

STANDARD REFFERENCE

Australian Standard AS 4058-1992

Japanese Industrial Standard

JIS.A.5303-1990

PIPE DESIGN

Coef. of Manning n = 0.011-0.013

Flexible Joint System Socket-Spigot

Joint with Rubber Ring.

Test Pressure 120 kPa

Concrete Absorption < 6.5%

Concrete Strength 600 kg/cm2

Concrete cover of 25mm (minimum

Requirement)

Cementitious Content 450kg/m3

DEISGN LOAD

Live Load SNI -02-2005 ( Axle Load of

225 kN)

Depth of Back Fill 0.3 ~ 6.0 m

Inside

Dia.

Thickness

300

55,

-/+3

60,

-/+3

500

80,

-/+5

600

90,-/+5

700

95,-/+5

800

Socket

Dia.

Effective

Length

Class-4 : AS-4058 (kN/m)

Crack Load

Ult. Load

Weight

2500,

-/+10

30 kN/m

45 kN/m

382 kg

2500,

-/+10

36 kN/m

54 kN/m

543 kg

800

2500,

-/+10

44 kN/m

66 kN/m

859 kg

925

2500,-/+10

52 kN/m

78 kN/m

1195 kg

1065

2500,-/+10

60 kN/m

90 kN/m

1476 kg

-/+5

1185

2500,

-/+15

67 kN/m

101 kN/m

1752 kg

900

105,-/+7

1291

2500,-/+15

74 kN/m

111 kN/m

2206 kg

1000

112,

-/+7

1410

2500,

-/+15

81 kN/m

121 kN/m

2588 kg

1100

115,

-/+7

1560

2500,

-/+15

87 kN/m

130 kN/m

2924 kg

1200

130,-/+7

1685

2500,-/+15

92 kN/m

138 kN/m

3557 kg

1300

135,

-/+7

1800

2500,

-/+15

96 kN/m

144 kN/m

4008 kg

145,

-/+7

2500,

-/+15

104 kN/m

156 kN/m

4613 kg

400

1400

PRODUCTION SYSTEM

Roller Compaction Bidirectional

Radial Press, fully conform to the

requirement of JIS 5303-1990.

95,

510

630

1920

Rubber Ring Profile

Joint Details

TYPE OF PROTECTION RELATED TO THE AGGRERSIVE CONDITION OF EFFLUENT

TYPE

Type S

Type C

Type SC

DESCRIPTION

Sulfate Resisting Cement (T-V)

Cement + Fly Ash

Using Calcareous Aggregate in

Concrete

Calcareous Aggregate + Sulfate

Resisting Cement + Fly Ash

RECOMMENDATION

Slightly aggressive conditions, where calculated

corrosion factor c < 0.3mm/year

Mildly aggressive condition, where calculated corrosion

factor c < 1.0mm/year

Aggressive condition, Corrosion factor c > 0.5mm/year

Notes :

All Concrete Sewer Pipes are to have internal cover to reinforcement of 25mm and Pipe Wall Thickness of

50mm.

All Concrete Sewer Pipes have minimum concrete strength of 600 kg/cm2

Corrosion Factor s affected by the following data :

- Biological Oxygen Demand

- Hydraulic gradient of pipeline

- pH and Temperature of sewage

- Wetted Perimeter of pipe, Acid Reaction Efficiency, and etc.

Page 5/10

Pt. Dantosan Precon Perkasa

Jacking Pipes

DIMENSION :

PROPERTIES :

Inside

Dia.

Thickness

Outside

Diameter

(mm)

(mm)

(mm)

Effective

Length

Collar

Thickness

Collar

Length

Collar

Diameter

Crack

Load

Ultimate

Load

Jacking

Force (*)

Pipe

Weight

Collar

Weight

(mm)

(mm)

(mm)

(mm)

(kg/m)

(kg/m)

(Ton)

(kg)

(kg)

584

2430,-/+10

575

4300

6500

107

642

19

730

2430,

-/+10

721

4700

7100

133

819

24

850

2430,

-/+10

841

4900

7400

187

1096

28

960

2430,-/+10

951

7200

10800

230

1331

31

1080

2430,

-/+10

1071

7800

11700

299

1681

35

2430,

-/+10

1191

8400

12600

377

2068

39

1310

2430,

-/+15

1301

8700

13000

438

2428

42

1430

2430,-/+15

1421

9000

13500

531

2843

46

1500

140,

-/+7

1780

2430,

-/+15

1768

9600

14400

794

4357

74

1650

150,-/+7

1950

2430,-/+15

1938

10800

16200

945

5125

81

1800

160,

-/+7

2120

2430,

-/+15

2108

11400

17100

1109

5918

91

175,

-/+7

2430,

-/+15

2338

12000

18900

1364

7180

101

205,

-/+7

2430,

-/+15

13200

19800

1897

10038

186

450

67,-/+3

600

65,

-/+3

700

75,

-/+3

800

80,-/+5

900

90,

-/+5

100,

-/+5

1100

105,

-/+5

1200

115,-/+7

1000

2000

2400

1200

2350

2810

4.5mm

6.0mm

9.0mm

260mm

260mm

300mm

2792

(*) Maximum Jacking Force at NO-deflection along pileline, while for 2o

deflection at any point in the whole pipeline Jacking force is limited to 30%.

Further analysis will be provides upon request to Precons Engineering

LEfective

Do

OD

Steel Collar

Rubber Ring

Lc

Ring Wire

Packer

Rubber Ring Profile

Type GJS-24

STANDARD REFFERENCE

Japanese Sewerage Water Work

Association Standard JS WAS A-2

1991 and JS WAS A-6 1989.

DEISGN LOAD

Live Load SNI -02-2005 ( Axle Load of

225 kN)

High Axial Force During Jacking

llation

Excavation Depth 2.0m ~ 20.0m

PRODUCTION SYSTEM

Automatic Roller Compaction

Bidirectional Radial Press,

PIPE DESIGN

Flexible Joint for Heavy Duty Application. The System includes PreEmbedded Steel Collar with Rubber Ring.

Test Pressure > 120kPa, With Low permeability < 6.5% Absorption

Test.

Concrete Strength K-600, High Cementitious Content > 450kg/m3.

W/C Content < 0.35

Rubber Ring : Vulcanized Rubber Ethyl Propyl Diene Monomer,

Tensile Strength > 8.5MPa, Hardness 45-55, Sulfate Resistance

Rubber.

Steel Collar : ST-37 , SS-41 Steel, Protected by Hot Dip Galvanized

or Zincromate Coating.

Packer thickness is defined based on load analysis during jacking

installation which is affected by Soil Condition, Section Length,

deflection, jacking force, and etc

Page 6/10

Pt. Dantosan Precon Perkasa

Jacking Pipes

INSTALLATION METHOD:

Concrete Pipe Jacking is method of Installing Pipelines without disruption existing surface facilities or activities.

Concrete pipes is installed by apply jacking force to push the concrete pipes into the cavity excavated ahead of

the progressing pipelines.

Trust Block

Hydraulic Jack

Trusting Ring

Jacking Pipe

Jacking Shield

Lead Pipe

Laser Light

Horizontal excavation is usually carried out by using Tunnel Boring

Machine. In case the size of pipes is larger than 1200mm, the

excavation may be carried out by manually digging.

The Hydraulic Jacks capacity is depend on the pipe size, section

length and the soil condition. Typically two or four hydraulic jacks

are used for pushing and steering the pipe, and stroke up to 1.2m.

Trust block is installed in the main pit to resist jacking force which is

applied to the pipes through Steel Trusting Ring.

The Steel Cutting Shield fitted to the Lead Pipe gives protection to

the workers and allows steering and alignment adjustment. The

shield and lead pipe are pushed into receiving pit and removed for

reuse.

Intermediate jacking stations may be required in the long section line ( > 120m) and stiff ground conditions.

Alternatively Bentonite injection may be applied to reduce friction between pipe and soil.

Generally, the work method is consisting of repetitive sequence works of excavation at the face, pushing the

pipe in to the excavated cavity and removing the soils by using muck cart on rails or slurry pipes wither the

machine capable to break excavated soil to the slurry material.

Slurry Pipe &

Drained Pipe

Trust Block

Ring block

Concrete Jacking

Pipe

Removing Jacking Sheld

and Lead Pipe

Concrete

Deadman

Laser Light

Main Pit (Driving Pit)

Receiving Pit

Jacking Direction

Hydraulic Jack

Trusting Ring

Packer Wood /Chipboard

Concrete Jacking Pipe

Pipeline alignment is continually monitored and adjusted during jacking by laser light from the jacking pit to

the target fixed to the inside crown of the lead pipe or shield. Gradual adjustments are continuously made to

avoid over-stressing to the concrete pipe. In the alignment adjustment process, deflection between

concrete pipes is limited up to 2o, otherwise concrete may be cracks.

Generally, pipe jacking is carried during two daily shifts of 8-10 hours per shift and progress, dependent on

pipe size and ground conditions, can vary from 1-6 pipes per shift.

Page 7/10

Pt. Dantosan Precon Perkasa

Manhole Access Chamber

Precons Access Chambers are designed as integral components which can be assembled to variety depth to

suit the project requirements. The Construction will be very simple and ease. Manhole can be finished not more

than 30 minutes.

THE COMPONENTS:

DIMENSION

COMPONENT

t

MH-Cover

t

H

MH-Surround

Make-Up Ring

t

Converter Slab I

MH-Cover Light Duty (LD)

80

MH-Cover Heavy Duty (HD)

125

MH-Surround Light Duty (LD)

150

150

100

Converter Slab-II (1000/1500)

150

82

200

95

100

155

150

232

225

349

180

366

300

255

600

510

900

765

1200

1020

1500

1275

180

801

1200

2258

1500

2822

1800

3387

625

1000

1000

1500

t

Base Manhole

140

1500

Converter Slab II

Base Manhole

76

625

MH Shaft

MH-Shaft

(kg)

-

H

Converter Slab-I (625/1000)

715

MH-Surround Heavy Duty (HD)

Make-Up Ring

WEIGHT

111

Base Slab 1000

1000

120

342

Base Slab 1500

1500

150

924

Bitumen Impregnanted

Sealant Strip (PCRA)

t

Lifting Eye / Anchorage

Cap 1,3 ~2.5Ton

H

Base Slab

JOINT DETAIL

MANHOLE DESIGN:

LIFTING CLUTH

Designed in conformance with Australian Standard AS 4198-1994.

Water tights Joint and Impermeable Wall, Test Pressure > 120kPa,

With Low permeability < 6.5% Absorption Test.

High Sulfate Resistance with Sulfate Resisting Cement + Fly Ash and

High Cementitious Content > 450kg/m3.

Manhole can be installed up to 25.0m depth, since lateral forces

act equally around the periphery, which places the section pure

compression

Lifting anchorage system, to provide safe and ease handling.

Two alternative design loads, Heavy Duty to withstand Heavy

Vehicle Load and Light Duty for Light Vehicle or Pedestrian usage.

MATERIAL SPECIFICATION

Concrete Strength : K-400

Steel Wire : Hard Drawn Deformed

Wire, fy 500MPa.

Joint Material : Bitumen

Impregnanted Sealant Strip.

Step Ladder : Hot Dip Galvanized

Ladder of 16mm diameter rebar.

LOAD CAPACITTY :

Crack

Load Class

Load

Light Duty

40kN

Heavy Duty

105kN

Ultimate

Load

80 kN

210kN

Page 8/10

Pt. Dantosan Precon Perkasa

Sewerage Associated Products

Interceptor / Inlet System

Interceptor / inlet system is to collect wastewater directly from kitchen sink, toilets, lavatory and

waste full and carrying to the Manhole System.

This pipe size is 4~6inchi diameter of PVC. While for main pipeline is Concrete Sewer Pipes of

300mm or greater.

Stink Pipe

From Urinoir

From Lavatory

PVC Pipe

From Kitchen Sink

PVC Pipe

To Secondary Pipe

((To Concrete Sewer Pipe)

Oil Separator, Filter Tank, Septic Tank

Oil separator is designed to separate oil/grease from water, which is collect from kitchen or

other source containing grease/oil.

Filter tank is used to avoid blocked in the sewer pipeline due to inorganic coarse material.

Filter Tank

SEPTIC TANK

Oil Separator

Septic tank is

individually

sewerage

treatment

plant which

only cater for

single house or

a few house

not more than

20 people.

Aeration Tank

(Aerobe Process)

Decomposition Tank

(Anaerobe Process)

Page 9/10

Pt. Dantosan Precon Perkasa

Project Reference

Sewerage Pipeline System , PLP Yogyakarta, Package 5

Project includes Constructions of Reinforced Concrete Pipes 600mm Diameter, more than 1000m

length and construction of Manhole Access chamber.

Sulfate Resisting Cement and Fly Ash are used to protect the pipe from aggressive condition on

sewerage pipelines.

Precon is able to quick response to meet very tight schedule which the project need be

accomplished within 3 months.

BSD City Jacking Pipe Design

Construction of Large Pipes 1650mm, 1800mm and 2000mm diameter. The Pipes are designed in

conformance with Specification of Jacking Pipes - JS WAS A-2 1991, the installation method is

open excavation trench which is buried more than 6m depth.

Jati Gede Pipe Siphon

Project includes Installation of Twin Siphon Pipes of 1200mm Diameter. High Load Strength of

pipe is required to withstand high load which have cover depth > 25m.

Pipe Bends are designed with angle of 120o 170o , and working pressure of 120 kPa.

Page 10/10

Das könnte Ihnen auch gefallen

- Trenchless TechnologyDokument41 SeitenTrenchless TechnologyESAM ALHASHEDINoch keine Bewertungen

- Rocla Jacking Pipe BrochureDokument2 SeitenRocla Jacking Pipe BrochureAndres ArguedasNoch keine Bewertungen

- Brosur Concrete PipeDokument20 SeitenBrosur Concrete PipegneissetiagrahaNoch keine Bewertungen

- Hot Dip Galvanizing corrosion categoriesDokument2 SeitenHot Dip Galvanizing corrosion categoriesJpolyPolyNoch keine Bewertungen

- Hume Pipe JackingDokument1 SeiteHume Pipe JackingLau Meng YongNoch keine Bewertungen

- SFRC Jacking Pipe Design: Numerical Modelling and Factory TrialsDokument34 SeitenSFRC Jacking Pipe Design: Numerical Modelling and Factory Trialsjuan carlos silva ospinaNoch keine Bewertungen

- L2. Closure To Effect of Bentonite Slurry Pressure On Interface Friction of Pipe Jacking by Mucahit Namli and Erol GulerDokument4 SeitenL2. Closure To Effect of Bentonite Slurry Pressure On Interface Friction of Pipe Jacking by Mucahit Namli and Erol GulerAna Maria Garcia EscandonNoch keine Bewertungen

- Service Life DesignDokument16 SeitenService Life Designapi-3766593Noch keine Bewertungen

- 1.2 Pipe JackingDokument11 Seiten1.2 Pipe JackingKandasamy AsohanNoch keine Bewertungen

- Box Culvert Joint SealantDokument6 SeitenBox Culvert Joint SealantgemotorresNoch keine Bewertungen

- HOBAS Gravity Pipe SystemsDokument42 SeitenHOBAS Gravity Pipe SystemsMarkoNoch keine Bewertungen

- Tolerances On Plate Thickness AS PER IS:1852: Min. Max. 12.50% Plate THKDokument1 SeiteTolerances On Plate Thickness AS PER IS:1852: Min. Max. 12.50% Plate THKArvindNoch keine Bewertungen

- Cracks and Repairs R.C.C. Structures: Tool Kit For EngineersDokument23 SeitenCracks and Repairs R.C.C. Structures: Tool Kit For EngineersAndhra Waterproofing AndhraNoch keine Bewertungen

- Catálogo de Gaviones Tejidos PRODAC (Inglés) PDFDokument9 SeitenCatálogo de Gaviones Tejidos PRODAC (Inglés) PDFpapolamNoch keine Bewertungen

- Nilex Fabriform BrochureDokument4 SeitenNilex Fabriform BrochureApurba haldarNoch keine Bewertungen

- Inspection Manual For Precast Concrete Pipe and StructuresDokument63 SeitenInspection Manual For Precast Concrete Pipe and StructuresMukeshNoch keine Bewertungen

- Shotcrete A Basic OverviewDokument12 SeitenShotcrete A Basic OverviewDes Vlietstra100% (1)

- FP McCann Precast Concrete Headwalls InstallationDokument4 SeitenFP McCann Precast Concrete Headwalls InstallationgemotorresNoch keine Bewertungen

- Geotextil TencateDokument2 SeitenGeotextil TencateHugo HiddNoch keine Bewertungen

- Fibre Reinforced ConcreteDokument6 SeitenFibre Reinforced ConcreteFranklyn GenoveNoch keine Bewertungen

- (Paper) Jack Down Construction MethodDokument6 Seiten(Paper) Jack Down Construction MethodShaileshRastogiNoch keine Bewertungen

- Concepts of Shotcrete Technology PDFDokument8 SeitenConcepts of Shotcrete Technology PDFSritam Swapnadarshi100% (1)

- Pozos Equipos de PerforacionDokument9 SeitenPozos Equipos de Perforacionpetroco15Noch keine Bewertungen

- Avn1200tb Avn1800tb PJ DB GB 14-06-30 HK2052Dokument2 SeitenAvn1200tb Avn1800tb PJ DB GB 14-06-30 HK2052Enri05Noch keine Bewertungen

- Maccaferri IG UK Green Terramesh Apr07Dokument2 SeitenMaccaferri IG UK Green Terramesh Apr07John SmithNoch keine Bewertungen

- Micro Pile SpecificationsDokument3 SeitenMicro Pile SpecificationsAnonymous 5VwQ0KC3Noch keine Bewertungen

- Functions of GeosyntheticsDokument24 SeitenFunctions of GeosyntheticsAzaz AhmedNoch keine Bewertungen

- Presentation Pipe Jacking Rev03Dokument47 SeitenPresentation Pipe Jacking Rev03Jasmine ENoch keine Bewertungen

- TTC - Segment Accessories BrochureDokument8 SeitenTTC - Segment Accessories Brochurefivehours5Noch keine Bewertungen

- Rammed Aggregate Pier Subgrade Reinforcement: Geopier Foundation Company, IncDokument41 SeitenRammed Aggregate Pier Subgrade Reinforcement: Geopier Foundation Company, IncDeepakNoch keine Bewertungen

- Excel Pipes Jacking PipesDokument4 SeitenExcel Pipes Jacking PipesAli ZarehNoch keine Bewertungen

- MEP post-tender training BOQ analysisDokument2 SeitenMEP post-tender training BOQ analysisMohamedNoch keine Bewertungen

- Specifications For The Steel Fibers Reinforced ConcreteDokument1 SeiteSpecifications For The Steel Fibers Reinforced ConcretecoolkaisyNoch keine Bewertungen

- Deep Excavation and Earth RetentionDokument71 SeitenDeep Excavation and Earth RetentionESAM ALHASHEDINoch keine Bewertungen

- Techcell For Slope ProtectionDokument6 SeitenTechcell For Slope ProtectionN GANESAMOORTHYNoch keine Bewertungen

- Avnd2300ah Avnd4000ah DB SL GB 14-07-02 HK2052 01Dokument1 SeiteAvnd2300ah Avnd4000ah DB SL GB 14-07-02 HK2052 01MinaSaeedNoch keine Bewertungen

- Tunnel Full Paper Id Number 306Dokument10 SeitenTunnel Full Paper Id Number 306Bosko SarenacNoch keine Bewertungen

- Vibropipe CatalougeDokument4 SeitenVibropipe CatalougeRavishankar GowdaNoch keine Bewertungen

- Rules of Thumb Microtunneling Part 1Dokument1 SeiteRules of Thumb Microtunneling Part 1mahaprakash0% (1)

- SETTING TIME OF CONCRETEDokument2 SeitenSETTING TIME OF CONCRETEraja qammarNoch keine Bewertungen

- What Are The Requirements of BentoniteDokument1 SeiteWhat Are The Requirements of BentonitesuryakantameNoch keine Bewertungen

- 01 PTE Unbonded System 02 070909Dokument9 Seiten01 PTE Unbonded System 02 070909Aizaz ShaikhNoch keine Bewertungen

- Fosroc GeotexDokument3 SeitenFosroc GeotexBalasubramanian AnanthNoch keine Bewertungen

- Sheet PileDokument22 SeitenSheet PileMuhammad HasifNoch keine Bewertungen

- Slopes & Channels: Installation GuideDokument11 SeitenSlopes & Channels: Installation GuideAlejandra GomezNoch keine Bewertungen

- Avn1200tc Avn1800tc PJ DB GB 14-06-30 HK2052Dokument2 SeitenAvn1200tc Avn1800tc PJ DB GB 14-06-30 HK2052francis0511Noch keine Bewertungen

- Ewhtp Direct Pipe Sup Sup c751bf9f00Dokument4 SeitenEwhtp Direct Pipe Sup Sup c751bf9f00Ayman ElMawardyNoch keine Bewertungen

- 1604 - Expert Report - Presentation To MSPC, MITI (Ministry of Trde & Industry, Malaysia)Dokument17 Seiten1604 - Expert Report - Presentation To MSPC, MITI (Ministry of Trde & Industry, Malaysia)chengkhNoch keine Bewertungen

- Ultrasonic Drilling Monitor SpecificationsDokument2 SeitenUltrasonic Drilling Monitor SpecificationsDaniel MarínNoch keine Bewertungen

- Ground Engineering Systems - 10 - Spin-Lock AnchorsDokument10 SeitenGround Engineering Systems - 10 - Spin-Lock AnchorsTimothy McmillanNoch keine Bewertungen

- Gannon - Primary Firm Secant Pile Concrete Specification - April 2016Dokument11 SeitenGannon - Primary Firm Secant Pile Concrete Specification - April 2016muhammad ismailNoch keine Bewertungen

- Rockfall Mitigation NH-22 Case StudyDokument4 SeitenRockfall Mitigation NH-22 Case StudyRaghavNoch keine Bewertungen

- Design and Installation Guidelines for Erosion ControlDokument15 SeitenDesign and Installation Guidelines for Erosion Controlmike DonNoch keine Bewertungen

- PC PilesDokument12 SeitenPC PilesBobby SetiawanNoch keine Bewertungen

- 8 Plastering PDFDokument26 Seiten8 Plastering PDFZayedur RahmanNoch keine Bewertungen

- Pipe Jacking Trial Mix Concrete Test ResultsDokument1 SeitePipe Jacking Trial Mix Concrete Test ResultsNA SleeperNoch keine Bewertungen

- During Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkDokument2 SeitenDuring Tremie Concreting The Following Precautions Are To Be Taken While Doing The WorkRaghavendraNoch keine Bewertungen

- PreconSewerageSystem PDFDokument10 SeitenPreconSewerageSystem PDFArdiPratomoNoch keine Bewertungen

- Culvert SlipliningDokument8 SeitenCulvert SlipliningbetopagoadaNoch keine Bewertungen

- Poly Pipe Rural 2aDokument2 SeitenPoly Pipe Rural 2aSarah DeanNoch keine Bewertungen

- Dynamic Cone PenetrometerDokument3 SeitenDynamic Cone Penetrometerme-elormNoch keine Bewertungen

- Stanley Market / Stanley Main Street 14 Pennington Street Causeway BayDokument1 SeiteStanley Market / Stanley Main Street 14 Pennington Street Causeway BayArdiPratomoNoch keine Bewertungen

- Ideal Paver Guide PDFDokument24 SeitenIdeal Paver Guide PDFArdiPratomoNoch keine Bewertungen

- Pola KertamuktiDokument1 SeitePola KertamuktiArdiPratomoNoch keine Bewertungen

- Oceanpark To Stanley 6aDokument1 SeiteOceanpark To Stanley 6aArdiPratomoNoch keine Bewertungen

- Handout - 6900 - CI6900-L Handout Civil ViewDokument18 SeitenHandout - 6900 - CI6900-L Handout Civil ViewMartin GuerreroNoch keine Bewertungen

- Typical Section Interstate - 0705Dokument1 SeiteTypical Section Interstate - 0705ArdiPratomoNoch keine Bewertungen

- Utm ZoneDokument11 SeitenUtm ZoneArdiPratomoNoch keine Bewertungen

- PreconSewerageSystem PDFDokument10 SeitenPreconSewerageSystem PDFArdiPratomoNoch keine Bewertungen

- Typical Cross Sections - 0704Dokument1 SeiteTypical Cross Sections - 0704ArdiPratomoNoch keine Bewertungen

- Ts Trimble Operation Hand OutDokument8 SeitenTs Trimble Operation Hand OutArdiPratomoNoch keine Bewertungen

- MDOT-Vertical Curve Calcs 120887 7Dokument2 SeitenMDOT-Vertical Curve Calcs 120887 7ArdiPratomoNoch keine Bewertungen

- OFFICE LayoutDokument1 SeiteOFFICE LayoutArdiPratomoNoch keine Bewertungen

- Data Elevation Surface To Use in Civil3dDokument1 SeiteData Elevation Surface To Use in Civil3dArdiPratomoNoch keine Bewertungen

- Halal Food HKDokument7 SeitenHalal Food HKArdi Yoga PratomoNoch keine Bewertungen

- LBR 2 Legenda ModelDokument1 SeiteLBR 2 Legenda ModelArdiPratomoNoch keine Bewertungen

- Design of 6 Storey Building in EtabsDokument51 SeitenDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- S. MasjidDokument1 SeiteS. MasjidArdiPratomoNoch keine Bewertungen

- Presentation Subheading Goes HereDokument2 SeitenPresentation Subheading Goes HereArdiPratomoNoch keine Bewertungen

- New Features For 2004Dokument9 SeitenNew Features For 2004dmotwaniNoch keine Bewertungen

- Earthwork Volume Calculation Methods ExplainedDokument1 SeiteEarthwork Volume Calculation Methods ExplainedArdiPratomoNoch keine Bewertungen

- METODE Volume CalculationDokument2 SeitenMETODE Volume CalculationArdiPratomoNoch keine Bewertungen

- Volume CalculationDokument2 SeitenVolume CalculationArdiPratomoNoch keine Bewertungen

- Volume CalculationDokument2 SeitenVolume CalculationArdiPratomoNoch keine Bewertungen

- Radioactive Waste Disposal MethodsDokument23 SeitenRadioactive Waste Disposal MethodsCarlos WilliamsonNoch keine Bewertungen

- EPA Guidline For Concrete Wash OutDokument5 SeitenEPA Guidline For Concrete Wash OutJoe PlanteNoch keine Bewertungen

- Worm Infestations 1Dokument18 SeitenWorm Infestations 1Beta UserNoch keine Bewertungen

- Caso 1 - Clase - Procter y Gamble - W28608-Pdf-Eng PDFDokument7 SeitenCaso 1 - Clase - Procter y Gamble - W28608-Pdf-Eng PDFMaria Fernanda FloresNoch keine Bewertungen

- 어법실전문제 리카수니 분석전문 블로그Dokument12 Seiten어법실전문제 리카수니 분석전문 블로그Byungjoon MoonNoch keine Bewertungen

- Heat RecoveryDokument8 SeitenHeat RecoveryPrashantNoch keine Bewertungen

- ThinnerDokument13 SeitenThinnerhgfsdeNoch keine Bewertungen

- Corporate Projects Project Management Manual Hse Inspection/Audit Checklist Contract: Date Inspected: NWC Representatives: Areas InspectedDokument11 SeitenCorporate Projects Project Management Manual Hse Inspection/Audit Checklist Contract: Date Inspected: NWC Representatives: Areas InspectedAbdul RafeequeNoch keine Bewertungen

- Waste Water Management PlanDokument4 SeitenWaste Water Management Planzhou wangchaoNoch keine Bewertungen

- PLUMBING TERMINOLOGY GUIDEDokument15 SeitenPLUMBING TERMINOLOGY GUIDEGels GenovaNoch keine Bewertungen

- Effect of Nanoparticles On Crops and Soil Microbial CommunitiesDokument9 SeitenEffect of Nanoparticles On Crops and Soil Microbial CommunitiesPragyan RoyNoch keine Bewertungen

- Propose GulayanDokument6 SeitenPropose GulayanJorald Tuvilla88% (8)

- Hierarchy of Solid Waste ManagementDokument6 SeitenHierarchy of Solid Waste ManagementJustine joy EstoqueNoch keine Bewertungen

- GMPDokument93 SeitenGMPPhạm Thanh Vấn100% (1)

- Chapter VDokument32 SeitenChapter VDino SiopongcoNoch keine Bewertungen

- Appendix L - TBBSR Engineering Investigations and Cost Estimates PDFDokument185 SeitenAppendix L - TBBSR Engineering Investigations and Cost Estimates PDFnanesculNoch keine Bewertungen

- Project Description of LPG PlantDokument8 SeitenProject Description of LPG PlantEnoch TwumasiNoch keine Bewertungen

- Wolayita Sodo Hospital Waste Water EvaluationDokument9 SeitenWolayita Sodo Hospital Waste Water EvaluationFasil GeberemeskelNoch keine Bewertungen

- May 10, 2013Dokument20 SeitenMay 10, 2013Maxine AndresNoch keine Bewertungen

- Powerengineering201307 1 DLDokument93 SeitenPowerengineering201307 1 DLNinh Quoc TrungNoch keine Bewertungen

- Health Care Waste Management Policy and GuidelinesDokument55 SeitenHealth Care Waste Management Policy and GuidelinesAlvin RamirezNoch keine Bewertungen

- Oasis Water Friendly Solution - Water Drinking FountainsDokument23 SeitenOasis Water Friendly Solution - Water Drinking FountainsPankaj SinhaNoch keine Bewertungen

- Greenberry Hotel and Resorts-Monorail Track Layout PlanDokument1 SeiteGreenberry Hotel and Resorts-Monorail Track Layout PlanRanjit S KashyapNoch keine Bewertungen

- F Y S W M P: Unding OUR Olid Aste Anagement RogramDokument0 SeitenF Y S W M P: Unding OUR Olid Aste Anagement RogramIacomus BugsNoch keine Bewertungen

- Action PlanDokument2 SeitenAction PlanJULIET PIZARRONoch keine Bewertungen

- Asda Stores LTD Is A British Super Market ChainDokument10 SeitenAsda Stores LTD Is A British Super Market ChainSazzad Shahriar100% (1)

- US4744965 Process For Producing DapDokument7 SeitenUS4744965 Process For Producing DapVictor VazquezNoch keine Bewertungen

- Project Proposal Group2 FinalDokument14 SeitenProject Proposal Group2 FinalKeanna Marie TorresNoch keine Bewertungen

- Heat Fence Inorganic MineralsDokument3 SeitenHeat Fence Inorganic MineralsmeNoch keine Bewertungen

- 370 PDFDokument2 Seiten370 PDFA MahmoodNoch keine Bewertungen

- University of Chicago Press Fall 2009 CatalogueVon EverandUniversity of Chicago Press Fall 2009 CatalogueBewertung: 5 von 5 Sternen5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesVon EverandUniversity of Chicago Press Fall 2009 Distributed TitlesBewertung: 1 von 5 Sternen1/5 (1)