Beruflich Dokumente

Kultur Dokumente

Tabulasi Copper Smelter

Hochgeladen von

Anifah100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

79 Ansichten2 SeitenThe document summarizes the control and instrumentation of various equipment in a copper smelter plant. It lists the process equipment, controlled parameters, controlling parameters, controllers, functions, and control procedures. Key pieces of equipment include belt conveyors, electrolitic cells, rolling machines, electric furnaces, slag cleaning furnaces, converting furnaces, and anode furnances. The controlled parameters include temperature, flow, weight, level, and composition. Controllers include temperature indicators, flow controllers, weight controllers, level controllers, and composition indicators. The control procedures describe how controllers provide signals to valves and alarms to regulate parameters and keep the smelting processes running optimally.

Originalbeschreibung:

chdhg

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document summarizes the control and instrumentation of various equipment in a copper smelter plant. It lists the process equipment, controlled parameters, controlling parameters, controllers, functions, and control procedures. Key pieces of equipment include belt conveyors, electrolitic cells, rolling machines, electric furnaces, slag cleaning furnaces, converting furnaces, and anode furnances. The controlled parameters include temperature, flow, weight, level, and composition. Controllers include temperature indicators, flow controllers, weight controllers, level controllers, and composition indicators. The control procedures describe how controllers provide signals to valves and alarms to regulate parameters and keep the smelting processes running optimally.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

79 Ansichten2 SeitenTabulasi Copper Smelter

Hochgeladen von

AnifahThe document summarizes the control and instrumentation of various equipment in a copper smelter plant. It lists the process equipment, controlled parameters, controlling parameters, controllers, functions, and control procedures. Key pieces of equipment include belt conveyors, electrolitic cells, rolling machines, electric furnaces, slag cleaning furnaces, converting furnaces, and anode furnances. The controlled parameters include temperature, flow, weight, level, and composition. Controllers include temperature indicators, flow controllers, weight controllers, level controllers, and composition indicators. The control procedures describe how controllers provide signals to valves and alarms to regulate parameters and keep the smelting processes running optimally.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Table 1.

The control and instrumentation in Copper Smelter Plant

Process

Equipment

Valve ()

Controll

ed

Paramet

er

Temper

atur

Outlet

Belt

Conveyor

(C-202, C- Analit

203)

Outlet

Flow on

the

valve in

Electrolitic

the

Cell (P-201, stream

P-202)

before

Rolling

Machine

(PM-202)

and Casting

Machine (P203)

Electric

Furnance

The

amount

of

product

outlet

Analit

Outlet

Controllin

g

Parameter

Flow O

Controller

Temperatu

r Control

Alarm

The

Analit

weight of Indikator

analit

Control

The level

of

electrolyt Level

e liquid

Control

The rate

of

machine

The

weight of

Analit

control

Analit

Indikator

Function

Control Procedure

When the outlet temperatur is undesired, the

temperature transmiter will give a electric signal

Controlling temperatur of TIC, then, TIC will give a pneumatic signal for

smelting furnance to keep cooling air control valve. This valve will set the

process running in optimum best opening to make the outlet reachesthe

condition.

desired temperature.

Contolling the analit of the

solid raw materials is

purposed to keep the

process in smelting furnace

is produced a certain desired

capacity and reach the

optimum condiion.

Controlling the amount of

electrolite liquid to keep the

optimum condition for the

electrolysis so can be

produced the product with

our desired specs.

When the amount of solid raw material is in

undesired condition, transmiter will give a electric

signal AIC, so the alarm will ring and give

notification that the product doesnt suitable with

our spec

When the level is in undesired condition, the

temperature transmiter will give an electric signal

LIC, then, LIC will give a pneumatic signal for

electrolic cell control valve. This valve will set the

best opening to make the outlet reachesthe

desired level.

Controlling the amount of

product is related with the

storage room or storage

place that we have, this is

also realted with schedulling.

Controlling the composition

of the outlet product is

When the amount of solid raw material is in

undesired condition, transmiter will give a electric

signal AIC, so the alarm will ring and give

notification that the product doesnt suitable with

our spec.

When the amount of solid raw material is in

undesired condition, transmiter will give a electric

(B-205)

analit

Control

Slag

Cleaning

Furnance

(B-202)

The

composi

tion of

matte

Analit

Indikator

Control

Converting

Furnance,

Anode

Furnance(B203 , B-204)

Temper

ature

Inlet

Temperatu

r Indicator

Control

v

Temperat

ure

necessary to cover the

operation condition of next

stage process.

Controlling the composition

of the outlet product is

necessary to cover the

operation condition of next

stage process.

signal AIC, so the alarm will ring and give

notification that the product doesnt suitable with

our spec.

When the composition of matte in the outlet

doesn't reach17 %, the alarm will ring and give

notification that the product doesnt suitable with

our spec

When the outlet temperatur is undesired, the

temperature transmiter will give a electric signal

Controlling temperatur of TIC, then, TIC will give a pneumatic signal for

smelting furnance to keep cooling air control valve. This valve will set the

process running in optimum best opening to make the outlet reachesthe

condition.

desired temperature.

Das könnte Ihnen auch gefallen

- Strange Christmas TraditionsDokument2 SeitenStrange Christmas TraditionsZsofia ZsofiaNoch keine Bewertungen

- HAZID Assignment 5Dokument6 SeitenHAZID Assignment 5AnifahNoch keine Bewertungen

- Astm D974-97Dokument7 SeitenAstm D974-97QcHeNoch keine Bewertungen

- LINEAR INDUCTION MOTOR 6981660.ppsxDokument56 SeitenLINEAR INDUCTION MOTOR 6981660.ppsxFalley FasterNoch keine Bewertungen

- 65 ActsDokument178 Seiten65 ActsComprachosNoch keine Bewertungen

- PDFDokument6 SeitenPDFNina100% (1)

- Chemical Properties of Acetic AcidDokument3 SeitenChemical Properties of Acetic Acidmeimeiliu100% (1)

- Boundary ScanDokument61 SeitenBoundary ScanGéza HorváthNoch keine Bewertungen

- Wate Treatment Gold RefineryDokument11 SeitenWate Treatment Gold RefineryYorman Zambrano SilvaNoch keine Bewertungen

- NREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFDokument35 SeitenNREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFJosePPMolinaNoch keine Bewertungen

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDokument25 SeitenWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsIben Abdallah ZouhourNoch keine Bewertungen

- Frequency Converter English ManualDokument33 SeitenFrequency Converter English Manualproduccion multipack100% (2)

- Melting Point of MetalsDokument3 SeitenMelting Point of MetalsrhapknexxNoch keine Bewertungen

- Piping and Instrumentation DiagramsTutorials IDokument3 SeitenPiping and Instrumentation DiagramsTutorials Inishant9999100% (1)

- Good Practices in Tray DesignDokument7 SeitenGood Practices in Tray Designmehul10941100% (2)

- Oasis AirlineDokument5 SeitenOasis AirlineRd Indra AdikaNoch keine Bewertungen

- Library: Astrology and WisdomDokument13 SeitenLibrary: Astrology and Wisdomalimuhammedkhan2115Noch keine Bewertungen

- MM202 - 3 Process Metallurgy - Manish - Mass - BalanceDokument18 SeitenMM202 - 3 Process Metallurgy - Manish - Mass - BalanceSammy SinghaniaNoch keine Bewertungen

- Properties of Sea WaterDokument30 SeitenProperties of Sea WaterHalima akterNoch keine Bewertungen

- CYANEX ® 272 ExtractantDokument16 SeitenCYANEX ® 272 ExtractantEnis SevimNoch keine Bewertungen

- Literature Survey of Oxalic Acid ProductionDokument8 SeitenLiterature Survey of Oxalic Acid Productionvarun singhNoch keine Bewertungen

- Molten Salt by HousecroftDokument7 SeitenMolten Salt by HousecroftWwJd HeavenNoch keine Bewertungen

- Iodine Clock ReactionDokument2 SeitenIodine Clock ReactionDina Mohd HalidiNoch keine Bewertungen

- Hydrothermal Synthesis of Hydroxy Sodalite Zeolite Membrane SeparationDokument8 SeitenHydrothermal Synthesis of Hydroxy Sodalite Zeolite Membrane Separationcelcenu100% (1)

- Hand Panning: Vincent T. Cui Mete 128: Mineral Processing LaboratoryDokument3 SeitenHand Panning: Vincent T. Cui Mete 128: Mineral Processing LaboratoryVincent Tayanes Cui100% (1)

- Penggunaan Ferro Sulfat Dalam Proses Pengolahan Limbah Cair Yang Mengandung Logam Dengan Proses FlotasiDokument7 SeitenPenggunaan Ferro Sulfat Dalam Proses Pengolahan Limbah Cair Yang Mengandung Logam Dengan Proses Flotasiruslysmg0% (1)

- Tabel Komoditi Mineral Non LogamDokument4 SeitenTabel Komoditi Mineral Non LogamA A Ichsan CrNoch keine Bewertungen

- Madon 1958Dokument4 SeitenMadon 1958Nasrul ZA ST MTNoch keine Bewertungen

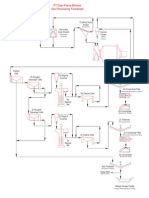

- PT. Dairi Prima Mineral Ore Processing FlowsheetDokument1 SeitePT. Dairi Prima Mineral Ore Processing Flowsheetharrison_sNoch keine Bewertungen

- Gold Dore BarsDokument2 SeitenGold Dore BarsdaelingNoch keine Bewertungen

- CH-440 NanotechnologyDokument22 SeitenCH-440 NanotechnologyAndrew SionNoch keine Bewertungen

- GDokument3 SeitenGGabrielNoch keine Bewertungen

- Co2 Gas MSDSDokument7 SeitenCo2 Gas MSDSK SubramaniNoch keine Bewertungen

- Standard Test Methods For Flow Rate of Metal Powders Using The Hall Flow Meter FunnelDokument6 SeitenStandard Test Methods For Flow Rate of Metal Powders Using The Hall Flow Meter FunnelAlex GonzálezNoch keine Bewertungen

- Ejercicios de Ingeniería EconómicaDokument2 SeitenEjercicios de Ingeniería EconómicaDiego MoralesNoch keine Bewertungen

- Laporan Praktikum Kimia Organik: Oleh: H-10 Nailal Mudliatunnur (110114452)Dokument16 SeitenLaporan Praktikum Kimia Organik: Oleh: H-10 Nailal Mudliatunnur (110114452)SenopatiNoch keine Bewertungen

- Neraca Massa Energi Reaktor SlakerDokument9 SeitenNeraca Massa Energi Reaktor Slakeroshin sinar hati siahaanNoch keine Bewertungen

- Precipitation Titrimetry-221Dokument11 SeitenPrecipitation Titrimetry-221HudzaifiNoch keine Bewertungen

- Artikel PenelitianDokument10 SeitenArtikel PenelitianAuni Fitri HumaerahNoch keine Bewertungen

- Stoikiometri (Stoichiometry) : Perhitungan Kimia (Chemical Calculation)Dokument12 SeitenStoikiometri (Stoichiometry) : Perhitungan Kimia (Chemical Calculation)Bakhitah NurulNoch keine Bewertungen

- SN Octoate - Dow PDFDokument6 SeitenSN Octoate - Dow PDFAngga Tri PrasetyoNoch keine Bewertungen

- The Smelting Process: (Transported by Ship and Railcars Via Quebec City)Dokument1 SeiteThe Smelting Process: (Transported by Ship and Railcars Via Quebec City)fostbarrNoch keine Bewertungen

- Nutrient Agar and Broth PreparationDokument1 SeiteNutrient Agar and Broth PreparationKal BuenaflorNoch keine Bewertungen

- Waste Management: Muammer KayaDokument27 SeitenWaste Management: Muammer KayaNgoni MhondeNoch keine Bewertungen

- Ayırma İşlemleri SorularDokument9 SeitenAyırma İşlemleri SorularElif Yaren Öztürk0% (1)

- Aquamatic Stager Valves: Model Number Body Material Number of Ports Typical ApplicationsDokument3 SeitenAquamatic Stager Valves: Model Number Body Material Number of Ports Typical ApplicationskaduxaNoch keine Bewertungen

- Contoh Mineral Gambar Simbol InternasionalDokument2 SeitenContoh Mineral Gambar Simbol InternasionalapapaNoch keine Bewertungen

- 3 Tin and Its AlloyDokument22 Seiten3 Tin and Its AlloymohansaiNoch keine Bewertungen

- ElektrolisisDokument48 SeitenElektrolisisrofiqaasriNoch keine Bewertungen

- Ocw Chapter 4Dokument48 SeitenOcw Chapter 4Agam HanasichulaNoch keine Bewertungen

- Kuliah NMR 6Dokument20 SeitenKuliah NMR 6Leni LismayantiNoch keine Bewertungen

- JIS ChlorideDokument2 SeitenJIS ChlorideAndhikaAgraWisesaNoch keine Bewertungen

- Lead Smelting Equipments - Aswathi Industries LimitedDokument1 SeiteLead Smelting Equipments - Aswathi Industries LimitedmOHITNoch keine Bewertungen

- History of The Stibnite Mining Area, Valley County, IdahoDokument180 SeitenHistory of The Stibnite Mining Area, Valley County, IdahoRussell Hartill100% (3)

- Presentation Lumped Parameter Model, Conservation of Mass, Reaction (Group 6) FixDokument16 SeitenPresentation Lumped Parameter Model, Conservation of Mass, Reaction (Group 6) FixPrayogo KuntoroNoch keine Bewertungen

- Extrapone ArnicaDokument1 SeiteExtrapone ArnicaAnonymous 9UW4rEVNoch keine Bewertungen

- Sphalerite Leaching With H2SO4 and NaNO3Dokument11 SeitenSphalerite Leaching With H2SO4 and NaNO3Ade SatriaNoch keine Bewertungen

- Sodium Bicarbonate - Wikipedia, The Free EncyclopediaDokument12 SeitenSodium Bicarbonate - Wikipedia, The Free EncyclopediaJoekkkNoch keine Bewertungen

- UTS OPM I Bukit 2017Dokument1 SeiteUTS OPM I Bukit 2017Muhammad Fikri PratamaNoch keine Bewertungen

- Determination of Iron in Ore by Redox TitrationDokument5 SeitenDetermination of Iron in Ore by Redox TitrationVinayakNoch keine Bewertungen

- UreaDokument1 SeiteUreaHarsha100% (2)

- PFD HCL NewDokument2 SeitenPFD HCL NewroxetteNoch keine Bewertungen

- Bahasa Inggris Teknik - Controlling The Plant InstrumentationDokument15 SeitenBahasa Inggris Teknik - Controlling The Plant InstrumentationIka Mustika WatiNoch keine Bewertungen

- Kinetics Aspects Inorganic ChemistryDokument28 SeitenKinetics Aspects Inorganic ChemistryFirda SafitriNoch keine Bewertungen

- Jurnal Destilasi PDFDokument9 SeitenJurnal Destilasi PDFIlhamNoch keine Bewertungen

- Sodium Nitrate and Nitrite PDFDokument22 SeitenSodium Nitrate and Nitrite PDFAbu Izzan Al BunyNoch keine Bewertungen

- As 3988-1991 Copper Lead Zinc Gold and Silver Ores - Guide To Sample Preparation For The Determination of GolDokument6 SeitenAs 3988-1991 Copper Lead Zinc Gold and Silver Ores - Guide To Sample Preparation For The Determination of GolSAI Global - APACNoch keine Bewertungen

- Preparative Methods in Solid State ChemistryVon EverandPreparative Methods in Solid State ChemistryPaul HagenmullerNoch keine Bewertungen

- Chlorine: International Thermodynamic Tables of the Fluid StateVon EverandChlorine: International Thermodynamic Tables of the Fluid StateNoch keine Bewertungen

- AnswersDokument22 SeitenAnswersVAIBHAV KESHAV MANGARNoch keine Bewertungen

- Jadwal Shalat & PJ Ifthar Ramadhan 1442 HDokument1 SeiteJadwal Shalat & PJ Ifthar Ramadhan 1442 HAnifahNoch keine Bewertungen

- WFH Rules & PlanningDokument3 SeitenWFH Rules & PlanningAnifahNoch keine Bewertungen

- Guideline PSG - Zoning Convention Regional 2Dokument20 SeitenGuideline PSG - Zoning Convention Regional 2AnifahNoch keine Bewertungen

- Working Towards An Energy Efficient and Sustainable FutureDokument10 SeitenWorking Towards An Energy Efficient and Sustainable FutureAnifahNoch keine Bewertungen

- Total F 0.1Dokument17 SeitenTotal F 0.1AnifahNoch keine Bewertungen

- Technical Design of The Bukwimba Open Pit Final 12042017Dokument31 SeitenTechnical Design of The Bukwimba Open Pit Final 12042017Rozalia PengoNoch keine Bewertungen

- 4MA0 4H MSC 20140306Dokument14 Seiten4MA0 4H MSC 20140306HaiqaPervezNoch keine Bewertungen

- Neuropsychological Performance in Neurofibromatosis Type 1: Original ArticleDokument5 SeitenNeuropsychological Performance in Neurofibromatosis Type 1: Original ArticleRaquel DuarteNoch keine Bewertungen

- Ield Methods: A Typical Field Mapping Camp in The 1950sDokument4 SeitenIeld Methods: A Typical Field Mapping Camp in The 1950sshivam soniNoch keine Bewertungen

- Foldable HelmetDokument16 SeitenFoldable Helmetharsha kotewarNoch keine Bewertungen

- Book 2 - Koning (COMPLETO)Dokument100 SeitenBook 2 - Koning (COMPLETO)Kevin VianaNoch keine Bewertungen

- Biasing Opamps Into Class ADokument11 SeitenBiasing Opamps Into Class AsddfsdcascNoch keine Bewertungen

- Water Vapor Permeability of Polypropylene: Fusion Science and TechnologyDokument5 SeitenWater Vapor Permeability of Polypropylene: Fusion Science and TechnologyBobNoch keine Bewertungen

- Spina 2002Dokument10 SeitenSpina 2002hasantapNoch keine Bewertungen

- Pantalla Anterior Bienvenido: Cr080vbesDokument3 SeitenPantalla Anterior Bienvenido: Cr080vbesJuan Pablo Virreyra TriguerosNoch keine Bewertungen

- Moldex Realty, Inc. (Linda Agustin) 2.0 (With Sound)Dokument111 SeitenMoldex Realty, Inc. (Linda Agustin) 2.0 (With Sound)Arwin AgustinNoch keine Bewertungen

- TXN Alarms 18022014Dokument12 SeitenTXN Alarms 18022014Sid GrgNoch keine Bewertungen

- Unit-1 Infancy: S.Dharaneeshwari. 1MSC - Home Science-Food &nutritionDokument16 SeitenUnit-1 Infancy: S.Dharaneeshwari. 1MSC - Home Science-Food &nutritionDharaneeshwari Siva-F&NNoch keine Bewertungen

- Hyundai Forklift Catalog PTASDokument15 SeitenHyundai Forklift Catalog PTASjack comboNoch keine Bewertungen

- Nitofloor NDokument3 SeitenNitofloor Nkiranmisale7Noch keine Bewertungen

- Cho Gsas - Harvard 0084L 11462Dokument503 SeitenCho Gsas - Harvard 0084L 11462Claudemiro costaNoch keine Bewertungen

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesDokument65 SeitenIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaNoch keine Bewertungen

- 33 Mpact - of - The - Great - Earthquake-2015 - On - Hospitality PDFDokument30 Seiten33 Mpact - of - The - Great - Earthquake-2015 - On - Hospitality PDFJoannabelNoch keine Bewertungen

- Mechanism Design: A SeriesDokument3 SeitenMechanism Design: A Seriesamirmasood kholojiniNoch keine Bewertungen

- EU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Dokument60 SeitenEU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Kram NawkNoch keine Bewertungen