Beruflich Dokumente

Kultur Dokumente

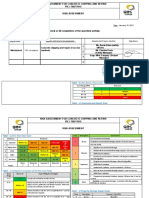

Motor Vehicle Mechanical Repair Workshop: Example Risk Assessment For A

Hochgeladen von

selvavishnuOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Motor Vehicle Mechanical Repair Workshop: Example Risk Assessment For A

Hochgeladen von

selvavishnuCopyright:

Verfügbare Formate

Health and Safety

Executive

Example risk assessment for a motor vehicle mechanical repair workshop

Setting the scene

The garage manager did the risk assessment. The

business employed 12 mechanics, including two

apprentices who carried out mechanical repairs.

How was the risk assessment done?

The garage manager first looked at relevant guidance on

the HSE website, including:

The health and safety toolbox: How to control risks

at work (www.hse.gov.uk/toolbox/index.htm)

Health and safety in the motor vehicle repair (MVR)

industry (www.hse.gov.uk/mvr/index.htm)

COSHH essentials sheets for repair workshops

(www.hse.gov.uk/coshh/index.htm)

about health and safety issues. He confirmed what

training had been provided and asked that they

consider particular requirements the two young

apprentices may need

phoning the licensed disposal contractor to discuss

the arrangements for waste disposal

looking at the accident book to learn what had

previously resulted in accidents or near misses.

As he identified the hazards he also thought about who

could be harmed and how. He noted what he was already

doing to control the risks and considered whether he

needed to do anything more. He then recorded any

further actions required.

He also read the manufacturers instructions for chemicals

and equipment.

Putting the risk assessment into practice, the manager set

out what actions needed to be taken. Who would do

them and by when. He placed a copy of the risk

assessment where all workers could see it.

He then identified the hazards in the garage. He did this

by:

The findings of the risk assessment were discussed by the

supervisors and their teams of mechanics.

walking around the repair workshop and noting things

The manager decided to review the risk assessment

whenever there were any significant changes such as new

work equipment, work activities or workers.

that may cause harm

talking to workers to learn from their knowledge and

experience and listen to their concerns and opinions

Example risk assessment: Motor vehicle mechanical repair workshop

How to use this example

This example risk assessment shows a wide range of

hazards that might be present in this type of small

business. It can be used as a guide to help you think

through some of the hazards in your business and the

steps you need to take to control the risks.

However, this is not a generic risk assessment. Every

business is different. To satisfy the law you must

identify and assess the hazards your business poses,

think through the controls required to provide effective

protection to people who may be affected by them, and

record the significant findings from your risk

assessment of your business.

1 of 5 pages

Health and Safety

Executive

Company name: PQR Motor Vehicle Repair shop (mechanical repairs only)

Date of risk assessment: 01/05/2012

What are the hazards?

Who might be harmed and how?

What are you already doing?

Do you need to do anything else to

control this risk?

Action

Action by Done

by who? when?

Hazardous substances

Skin contact over a long period can lead to

Contact with used engine severe dermatitis and skin cancer.

oil etc during servicing

Nitrile gloves supplied and used

Garage overalls supplied and used

Contract for regular cleaning of overalls

Workers informed to clean hands thoroughly and use skin

creams provided after contact with hazardous substances

Supervisor to start keeping a check that JB

gloves are being used

10/03/12

09/03/12

Risks from dermatitis and skin cancer to JB

be explained to workers

10/03/12

09/03/12

Car engine running

inside, toxic exhaust

fumes, eg carbon

monoxide

The fumes may cause eye irritation and

breathing difficulties.

Car exhaust attached to extractor system when

engine is running

Extractor system maintained and tested to prevent leaks

No further action required

Fire

Petrol and LPG fires

If trapped workers and customers could

suffer fatal injuries from smoke inhalation/

burns.

Fire alarms maintained and tested by manufacturer

Extinguishers provided and inspected under contract

Special fire exits not needed as all work areas have

immediate access to outside

Fuel retriever used to empty vehicle fuel tanks outside

Spillages cleared immediately

Component cleaning in re-circulating paraffin system, not

petrol

LPG fuelled vehicles ported in safe places

Workers trained in hazards of LPG

Fire risk assessment has been done, and any necessary

action taken, see www.gov.uk/workplace-fire-safety-yourresponsibilities

Manager to arrange training on use of

extinguishers for all workers

SP

1/7/12

Annual fire drill to be carried out

RB

11/11/12

Brief workers on safe working with

RB

petrol. Refer to HSEs Safe use of petrol

in garages (INDG331).

02/07/12

Brief workers on safe working with LPG. RB

Refer to HSEs LPG-fuelled motor

vehicles (INDG387)

02/07/12

Proprietary charger, installed by electrician, is used in

accordance with instructions

Acid-resistant gloves and goggles supplied and used

No further action required

Battery charging

Workers could suffer burns from contact

with battery acid while charging,

particularly if battery is overcharged and

explodes.

Example risk assessment: Motor vehicle mechanical repair workshop

2 of 5 pages

Health and Safety

Executive

What are the hazards?

Who might be harmed and how?

What are you already doing?

Electrical equipment

Portable appliances, eg

hand lamps.

Workers could get electrical shocks or

burns from faulty electrical equipment or

on installation.

Electrical faults can also lead to fires.

Low voltage 24 V hand lamps used

Residual current device (RCD) built into main switchboard.

A few 240 V tools are used. All have industrial plugs and

leads

Testing carried out annually on all portable 240 V tools

and workers are trained to carry out pre-use visual

checks and report defects

Safety checks of the electrical equipment and installations

are carried out to ensure that equipment continues to be

safe. Where necessary this is done by a competent

electrician

Manager to assess suitability of

replacing 240 V tools with air-powered

or 110 V alternatives

All mechanical equipment checked before use and faults

reported to supervisor

Equipment not to be left running unattended

Guarding provided

Ear defenders and safety goggles provided and worn.

Grinding wheels changed by trained person

No further action required

No further action required

Car lifts and jacks serviced by supplier and inspected by

insurers every 6 months

Jacks only used where ground conditions are firm, stable

and level. Once vehicle lifted, axle stands used

Axle stands regularly maintained and inspected

Safe working loads not exceeded

Workers are trained in correct procedures

Brief workers on safe working with airconditioning systems (from HSEs Safe

working with vehicle air-conditioning

systems INDG349).

Mechanical equipment

Use of grinding

equipment

Workers may suffer serious injury from

unguarded moving parts of machinery.

Workers can also get cut on sharp edges

or scald themselves on hot parts.

Falling objects

Failure of a car lift, jack or other lifting

Car lift failure or car jack equipment may cause severe crush injuries

failure

to an employee.

Work involving air

conditioning systems

Workers could suffer:

frostbite through skin or eye contact

with refrigerant liquid or gas

asphyxiation if sufficient quantities of

gas escape into confined space

exposure to harmful gases through

thermal decomposition of refrigerant if

exposed to a naked flame.

Example risk assessment: Motor vehicle mechanical repair workshop

Do you need to do anything else to

control this risk?

Action

Action by Done

by who? when?

SP

15/06/12

RB

05/11/12

3 of 5 pages

Health and Safety

Executive

What are the hazards?

Who might be harmed and how?

What are you already doing?

Compressed air

Explosion of equipment

tyres

Workers could suffer blast injuries from

tyre or equipment explosion. Workers could

suffer damage to internal organs if air is

introduced into the body.

Do you need to do anything else to

control this risk?

Action

Action by Done

by who? when?

No further action required

All workers trained in safe working procedures and

dangers of horseplay

Airline has deadmans handle

System inspected and serviced every year by insurers

Handling vehicle air bags Air bags could explode when not fitted,

causing injury.

Units are stored in suitable cabinet of their own

Workers are trained in correct handling and fitting

Faulty units are returned to supplier for disposal

Brief workers on safe handling of air

bags (from HSEs A guide to the

handling and storage of airbags and

seat belt pretensioners at garages and

motor vehicle repair workshops

(INDG280)

RB

02/07/12

Manual handling

Movement of

components

Workers are trained in safe manual handling and to

ensure contractors follow safe manual handling

techniques

Manual handling aids are available, eg lift truck

Manager to arrange manual handling

training for the workers in the store.

SP

10/07/12

15/05/12

Brief workers on handling tyres, refer to RB

HSE publication Collection and delivery

of tyres - Tackling the risk of manual

handling injuries: a practical guide

15/05/12

15/05/12

A detailed assessment to be done using JB

HSE publication Manual handling

assessment charts (INDG383)

15/08/12

15/05/12

No further action required

18/05/12

20/05/12

Workers risk injuries or back pain or pain

elsewhere from handling heavy and/or

bulky objects.

Vehicle movements

Workers and customers risk potentially

serious injury if struck by a moving vehicle

Example risk assessment: Motor vehicle mechanical repair workshop

Safe parking provided for customers without need for

reversing

Marked walkways for pedestrians

Vehicles driven slowly around premises

Workers ensure that cars being manually pushed always

have a person seated at the wheel, to keep the vehicle

under control

JB

4 of 5 pages

Health and Safety

Executive

What are the hazards?

Who might be harmed and how?

What are you already doing?

Slips and trips

Doorways (rain),

spillages, uneven

surfaces

Workers and customers may be injured if

they trip over objects or slip on spillages,

eg oil or water.

Working at height

Falls from any height can cause bruising

and fractures and potentially serious

injuries.

Public access to

workshop

Customers could suffer various injuries if

they wander into the workshop.

Do you need to do anything else to

control this risk?

Action

Action by Done

by who? when?

Good housekeeping standards maintained through

training and monitoring

Floors degreased weekly

Absorbent granules and sawdust put on spills as soon as

possible

Entrances and exits maintained

Walkways and storage areas to be

designated by yellow lines

JB

09/06/12

07/06/12

Weekly housekeeping check to be

started

JB

09/05/12

12/05/12

Appropriate access equipment is provided for work on

trailers and tops of commercial vehicles

Handrails fitted at edges of raised storage areas and

access stairway provided

Workers are competent to use ladders where appropriate

Vehicle inspection pits clearly marked and covered when

not in use

Supervisor to monitor use of portable

JB

ladders, access equipment for working

on vehicles, and safety at inspection pits

03/06/12

03/06/12

Signs banning customers from the workshop and viewing

window provided in reception

Workers to be reminded to challenge

anyone entering the workshop without

permission

15/07/12

SP

Assessment review date: 01/04/13

Example risk assessment: Motor vehicle mechanical repair workshop

Published by the Health and Safety Executive

04/13

5 of 5 pages

Das könnte Ihnen auch gefallen

- Behavior-based safety A Clear and Concise ReferenceVon EverandBehavior-based safety A Clear and Concise ReferenceNoch keine Bewertungen

- Heat Stress Toolbox TopicsDokument6 SeitenHeat Stress Toolbox TopicsSammie WilliamsNoch keine Bewertungen

- Installation & Safety Guide for Waste Compactors & Recycling SystemsDokument21 SeitenInstallation & Safety Guide for Waste Compactors & Recycling SystemsVuong BuiNoch keine Bewertungen

- Journey Management ReviewDokument3 SeitenJourney Management Reviewhamid123456789Noch keine Bewertungen

- Hearing Conservation Training: Environmental Health and Safety University of TennesseeDokument54 SeitenHearing Conservation Training: Environmental Health and Safety University of TennesseeMG NandanNoch keine Bewertungen

- SOP - Motor Bike SafetyDokument4 SeitenSOP - Motor Bike SafetyTafadzwaNoch keine Bewertungen

- Noise and Hearing Conservation TrainingDokument1 SeiteNoise and Hearing Conservation TrainingRabialtu SulihahNoch keine Bewertungen

- Training Program: By: Rahul AhujaDokument17 SeitenTraining Program: By: Rahul Ahujakei HoinaNoch keine Bewertungen

- Health Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacDokument2 SeitenHealth Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacFabianGregoryWomacNoch keine Bewertungen

- Haulage TruckDokument52 SeitenHaulage TruckPrimelift Safety Resources LimitedNoch keine Bewertungen

- Manual Handling TechniquesDokument142 SeitenManual Handling TechniquesVARUN SHARMANoch keine Bewertungen

- Hse Plan 3Dokument14 SeitenHse Plan 3YcRij SeYerNoch keine Bewertungen

- Slip Trip Fall PreventionDokument9 SeitenSlip Trip Fall Preventionmuhammadarifh4486Noch keine Bewertungen

- Occupational health and safety A Complete Guide - 2019 EditionVon EverandOccupational health and safety A Complete Guide - 2019 EditionNoch keine Bewertungen

- Personal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationDokument4 SeitenPersonal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationAnge JuanNoch keine Bewertungen

- Forklift Safety GuideDokument10 SeitenForklift Safety GuidebanguliekNoch keine Bewertungen

- Safety Ambassador SpeechDokument9 SeitenSafety Ambassador SpeechPraks SaxenaNoch keine Bewertungen

- Forklift Safety TrainingDokument22 SeitenForklift Safety TrainingSteve DonardNoch keine Bewertungen

- Flagman TrainingDokument58 SeitenFlagman TrainingIndermohan MehtaNoch keine Bewertungen

- AP Work Height SWPDokument30 SeitenAP Work Height SWPfuazNoch keine Bewertungen

- Water blasting SWMSDokument5 SeitenWater blasting SWMSjohney2Noch keine Bewertungen

- Pallet Jack Safety: Wear Personal Protective EquipmentDokument2 SeitenPallet Jack Safety: Wear Personal Protective EquipmentRadhaKrishnan R100% (1)

- Standard Operating Procedure For The Greenbelt Farms (LTD) WorkshopDokument4 SeitenStandard Operating Procedure For The Greenbelt Farms (LTD) WorkshopJames100% (1)

- Initial & Re-CertificationDokument107 SeitenInitial & Re-CertificationSatya PrabhatNoch keine Bewertungen

- Safety - Mast ClimbingDokument78 SeitenSafety - Mast ClimbingparadigmanNoch keine Bewertungen

- TOPIC: Personal Protective Equipment ChecklistDokument1 SeiteTOPIC: Personal Protective Equipment ChecklistMd ShNoch keine Bewertungen

- Risk Management or Environmental Health and Safety or Safety ManDokument3 SeitenRisk Management or Environmental Health and Safety or Safety Manapi-121419389Noch keine Bewertungen

- New Safety Initiative Ideas To Improve Workplace SafetyDokument3 SeitenNew Safety Initiative Ideas To Improve Workplace SafetyvipinNoch keine Bewertungen

- Forklift Policy HandbookDokument48 SeitenForklift Policy Handbooknezla100% (1)

- Hsps03 Working at HeightDDokument25 SeitenHsps03 Working at HeightDZeinfahmi Dwireski WibawaNoch keine Bewertungen

- Halliburton: Job Safety AnalysisDokument2 SeitenHalliburton: Job Safety Analysisaneshse100% (1)

- TiremanDokument6 SeitenTiremanKent Charles Monreal NotarioNoch keine Bewertungen

- Chapter 1 - Safety and Health Manager (Ferrer and Rellores)Dokument3 SeitenChapter 1 - Safety and Health Manager (Ferrer and Rellores)Evan Charl Moraleda100% (1)

- Hot Work Quiz for EmployeesDokument1 SeiteHot Work Quiz for EmployeesAmeenudeenNoch keine Bewertungen

- Safe vehicle operation hazard analysisDokument3 SeitenSafe vehicle operation hazard analysisamitNoch keine Bewertungen

- Confined Spaces ProcedureDokument10 SeitenConfined Spaces Procedurezam110Noch keine Bewertungen

- Training Needs AssessmentDokument5 SeitenTraining Needs AssessmentahmadNoch keine Bewertungen

- Aerial Lift Inspection FormsDokument15 SeitenAerial Lift Inspection FormsianNoch keine Bewertungen

- JSA for Mobilization and Installation of Process Area SpoolsDokument8 SeitenJSA for Mobilization and Installation of Process Area SpoolsMohammed MinhajNoch keine Bewertungen

- Basic Safety AwarenessDokument12 SeitenBasic Safety AwarenessAkuabataNoch keine Bewertungen

- Safe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofDokument22 SeitenSafe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofIvan BaracNoch keine Bewertungen

- Hand and Powertool Safety PDFDokument8 SeitenHand and Powertool Safety PDFJamal Uddin100% (1)

- Safety Resume Without Certificate PDFDokument4 SeitenSafety Resume Without Certificate PDFSAFETY RNoch keine Bewertungen

- Safe Work Practice: Title General Application Protective MechanismsDokument1 SeiteSafe Work Practice: Title General Application Protective Mechanismssriset100% (1)

- 52tips For Safety TrainersDokument22 Seiten52tips For Safety TrainersVicki LibreightNoch keine Bewertungen

- Planned Safety Inspection GuideDokument104 SeitenPlanned Safety Inspection GuideKirstie Lou Sales100% (1)

- Ramapo College Vehicle Fueling SOPDokument1 SeiteRamapo College Vehicle Fueling SOPAnees EkNoch keine Bewertungen

- Riddor: Health and Safety Advice For StonemasonsDokument12 SeitenRiddor: Health and Safety Advice For StonemasonsMohammed IlliasuddinNoch keine Bewertungen

- Operate A Cab Controlled Overhead CraneDokument222 SeitenOperate A Cab Controlled Overhead CraneGerard DurasamiNoch keine Bewertungen

- Plant Safety and Employee Well-BeingDokument26 SeitenPlant Safety and Employee Well-BeingCheenie Quinsay LawisNoch keine Bewertungen

- Metal Chop Saw SopDokument2 SeitenMetal Chop Saw SopkylealamangoNoch keine Bewertungen

- culture of safety A Complete Guide - 2019 EditionVon Everandculture of safety A Complete Guide - 2019 EditionBewertung: 5 von 5 Sternen5/5 (1)

- 4.2 Unit GC2: Controlling Workplace Hazards: Learning OutcomesDokument18 Seiten4.2 Unit GC2: Controlling Workplace Hazards: Learning Outcomesnavin100% (2)

- Electrical Safety Hazards and PreventionDokument38 SeitenElectrical Safety Hazards and PreventionYvonne TohNoch keine Bewertungen

- Module GuideDokument10 SeitenModule GuideselvavishnuNoch keine Bewertungen

- Company Law (Corse Outline)Dokument142 SeitenCompany Law (Corse Outline)selvavishnuNoch keine Bewertungen

- Enhancing Your Career With ReflectionDokument19 SeitenEnhancing Your Career With ReflectionselvavishnuNoch keine Bewertungen

- Ppe AssessmentDokument49 SeitenPpe AssessmentbhushansalunkeNoch keine Bewertungen

- Directors DutiesDokument24 SeitenDirectors DutiesselvavishnuNoch keine Bewertungen

- Unit 1 Communication BarriersDokument4 SeitenUnit 1 Communication BarriersselvavishnuNoch keine Bewertungen

- 5BUS1085 Team Assignment BriefingDokument11 Seiten5BUS1085 Team Assignment BriefingselvavishnuNoch keine Bewertungen

- Law 3222Dokument2 SeitenLaw 3222selvavishnuNoch keine Bewertungen

- Creativity and Innovation Tutorial StudentDokument7 SeitenCreativity and Innovation Tutorial StudentselvavishnuNoch keine Bewertungen

- Communication Skills Tutorial - StudentDokument9 SeitenCommunication Skills Tutorial - StudentselvavishnuNoch keine Bewertungen

- 5BUS1085 - Lecture 4 - Career Report Assignment RequirementsDokument17 Seiten5BUS1085 - Lecture 4 - Career Report Assignment RequirementsselvavishnuNoch keine Bewertungen

- Communication Skills Tutorial - StudentDokument9 SeitenCommunication Skills Tutorial - StudentselvavishnuNoch keine Bewertungen

- Slides (Cor)Dokument11 SeitenSlides (Cor)selvavishnuNoch keine Bewertungen

- Communication and Employability Skills For IT: Attempted? Checked? Achieved?Dokument1 SeiteCommunication and Employability Skills For IT: Attempted? Checked? Achieved?selvavishnuNoch keine Bewertungen

- 154 - Managing PeopleDokument4 Seiten154 - Managing PeopleselvavishnuNoch keine Bewertungen

- Co Law (Malaysia)Dokument60 SeitenCo Law (Malaysia)selvavishnuNoch keine Bewertungen

- Managing Absenteeism - SlidesDokument17 SeitenManaging Absenteeism - SlidesselvavishnuNoch keine Bewertungen

- Com Law MTDokument6 SeitenCom Law MTselvavishnuNoch keine Bewertungen

- Employer 1Dokument4 SeitenEmployer 1selvavishnuNoch keine Bewertungen

- Managing Absenteeism - SlidesDokument17 SeitenManaging Absenteeism - SlidesselvavishnuNoch keine Bewertungen

- Managing Absenteeism - SlidesDokument17 SeitenManaging Absenteeism - SlidesselvavishnuNoch keine Bewertungen

- Employer 1Dokument4 SeitenEmployer 1selvavishnuNoch keine Bewertungen

- AssignDokument8 SeitenAssignselvavishnuNoch keine Bewertungen

- So With Monday Being Officially TheDokument20 SeitenSo With Monday Being Officially TheselvavishnuNoch keine Bewertungen

- So With Monday Being Officially TheDokument20 SeitenSo With Monday Being Officially TheselvavishnuNoch keine Bewertungen

- Internal Verification of Sampling Assessment Decision SheetDokument1 SeiteInternal Verification of Sampling Assessment Decision SheetselvavishnuNoch keine Bewertungen

- So With Monday Being Officially TheDokument20 SeitenSo With Monday Being Officially TheselvavishnuNoch keine Bewertungen

- 104-01-F03-InT Internal Verification of Sampling Assessment Decision Pec 1033 Nov 12 Assignmnet Itp Special SuppDokument4 Seiten104-01-F03-InT Internal Verification of Sampling Assessment Decision Pec 1033 Nov 12 Assignmnet Itp Special SuppselvavishnuNoch keine Bewertungen

- Internal Verification of Sampling Assessment Decision SheetDokument1 SeiteInternal Verification of Sampling Assessment Decision SheetselvavishnuNoch keine Bewertungen

- High Court Dismisses Bid To Declare Command Council UnconstitutionalDokument84 SeitenHigh Court Dismisses Bid To Declare Command Council UnconstitutionalNokukhanya MntamboNoch keine Bewertungen

- Caries Activity TestDokument19 SeitenCaries Activity TestArizona GreyNoch keine Bewertungen

- Importance of Proper Employee InductionDokument1 SeiteImportance of Proper Employee InductionRaynus ArhinNoch keine Bewertungen

- Risk Assessment Guide For PetroleumDokument69 SeitenRisk Assessment Guide For PetroleumSri KanthNoch keine Bewertungen

- UG RA 007 - Asphalt Cutting Using Roto MillDokument5 SeitenUG RA 007 - Asphalt Cutting Using Roto MillshamshuddinNoch keine Bewertungen

- Risk-Proportionate Clinical Trial Monitoring: An Example Approach From A Non-Commercial Trials UnitDokument10 SeitenRisk-Proportionate Clinical Trial Monitoring: An Example Approach From A Non-Commercial Trials UnitAnton ChernetsovNoch keine Bewertungen

- Ra Concrete Chipping 7514Dokument5 SeitenRa Concrete Chipping 7514Charles DoriaNoch keine Bewertungen

- Position Statements: BRC Global Standard For Food Safety Issue 6Dokument9 SeitenPosition Statements: BRC Global Standard For Food Safety Issue 6Isabella GonçalvesNoch keine Bewertungen

- Avaliação de Risco USEPA 2009 IIDokument68 SeitenAvaliação de Risco USEPA 2009 IINayaraFeitosaNoch keine Bewertungen

- Permit To Work FormsDokument8 SeitenPermit To Work FormsMarc Vincent SeñorinNoch keine Bewertungen

- Ac4 Preliminary Planning Procedures - Client InvolvementDokument4 SeitenAc4 Preliminary Planning Procedures - Client InvolvementAndrew PanganibanNoch keine Bewertungen

- Risk Management in MinesDokument50 SeitenRisk Management in Minestridev kant tripathiNoch keine Bewertungen

- Md. Shahid Uz Zaman Dept. of CSE, RUETDokument18 SeitenMd. Shahid Uz Zaman Dept. of CSE, RUETJarir AhmedNoch keine Bewertungen

- Taj in Der SinghDokument7 SeitenTaj in Der SinghHarkamal singhNoch keine Bewertungen

- Guidelines For Process Safety Hazard Assessment Based On Process InformationDokument19 SeitenGuidelines For Process Safety Hazard Assessment Based On Process InformationtyoNoch keine Bewertungen

- Assessment Task 2 Cover Sheet: Student DeclarationDokument35 SeitenAssessment Task 2 Cover Sheet: Student DeclarationNitin80% (5)

- Defeat Safety Critical Systems ProcedureDokument16 SeitenDefeat Safety Critical Systems ProcedureNikhil DangariyaNoch keine Bewertungen

- Implementing an Effective Safety Management SystemDokument20 SeitenImplementing an Effective Safety Management SystemSherief ArafatNoch keine Bewertungen

- Risk Assessment in Online Banking SystemDokument7 SeitenRisk Assessment in Online Banking SystemseventhsensegroupNoch keine Bewertungen

- Seker Sikunim InstructionsDokument347 SeitenSeker Sikunim InstructionsAnonymous yDrLHxP9Noch keine Bewertungen

- EXECUTIVE SUMMARY European Climate Risk Assessment TH-AL-24-001-EN-NDokument40 SeitenEXECUTIVE SUMMARY European Climate Risk Assessment TH-AL-24-001-EN-NrauljuganaruNoch keine Bewertungen

- Risk-Based Maintenance (RBM) A Quantitative Approach ForDokument13 SeitenRisk-Based Maintenance (RBM) A Quantitative Approach ForJuan Carlos RiveraNoch keine Bewertungen

- Case QRA Oil and Gas IndustryDokument35 SeitenCase QRA Oil and Gas IndustryRama Alpha Yuri MargaretaNoch keine Bewertungen

- Risk Management - Event Management Plan For Open and Club EventsDokument24 SeitenRisk Management - Event Management Plan For Open and Club EventsMazlenashahNoch keine Bewertungen

- Corporate Responsibility Report 2008Dokument28 SeitenCorporate Responsibility Report 2008Raytheon Company100% (1)

- GROUP RISK ASSESSMENTDokument3 SeitenGROUP RISK ASSESSMENTJacob ChirayilNoch keine Bewertungen

- SANS 3000-2!1!2008 - Railway Safety RegulatorDokument16 SeitenSANS 3000-2!1!2008 - Railway Safety RegulatorBertus ChristiaanNoch keine Bewertungen

- Risk Assessment - Masonry WorksDokument4 SeitenRisk Assessment - Masonry Worksmahmoud nadaNoch keine Bewertungen

- Mooring Integrity Management: Guidance Notes OnDokument26 SeitenMooring Integrity Management: Guidance Notes OnArdy MansNoch keine Bewertungen

- BCSA - 36 04 Secure PDFDokument50 SeitenBCSA - 36 04 Secure PDFWilliam CaballeroNoch keine Bewertungen