Beruflich Dokumente

Kultur Dokumente

ASA Couplings (4) Oldham's

Hochgeladen von

Ian DonovanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASA Couplings (4) Oldham's

Hochgeladen von

Ian DonovanCopyright:

Verfügbare Formate

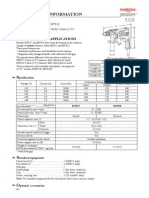

Oldham's couplings

Compact for the working toruque

Separatable on system assembling

hub

hub

slider

parallel

misalignment

Oldham s coupling absorbs mainly parallel misalignment through the slider sliding along its groove.(Refer to an

above gure.)So on condition that there is large parallel misalignment with load torque,abrasion will progress on

the slider s groove during each rotation.If you need to avoid the increase of backlashes caused by abrasion on

high-speed and adequate torque condition,you should adjust shafts to less misalignment.

Oldham s coupling is typically composed of metal hubs(e.g.,aluminum,steel,stainless steel)and a plastic

slider(e.g.,polyacetal,nylon,or thier reinforced resin)for good sliding characteristic.Since the slider is made of

weaker material,the part of slider caught between the drive and driven side projections is pushed outward and is

deformed when transmission torque is applied.When excessive load torque(shock/impact torque in many cases)is

applied,the slider is plastically deformed,and eventually ruptures in the deformation direction,as shown below.

Slider

Drive hub

Driven hub

Deformation of slider

Driven side projection

Drive side projection

A-A section

Features of Each Series

ASJ and ASJU Series

These products are composed of strong hubs,made of sintered stainless steel with resin impregnation,and sliders

molded with carbon ber-reinforced plastic for enhanced strength.Accordingly,these couplings oer high strength,

in addition to high transmission torque and high torsional rigidity.Furthermore,in order to support servo mechanism

at zero backlash,their hub and slider are assembled in light press-tting generally.

APJ and APJU Series

There are suitable for high-torque applications that would damage ASJ Series couplings.The sliders are made of

aluminum-bronze,and their destruction torque and torsional rigidity are more than three times greater than those

of the ASJ Series.(In the specications,the rated torque is limited to two times.)Since these products are made

completely of metal,the clearance of sliding surface is set to 0.02 to 0.04(mm)to prevent sticking,but this clearance

is lled with super-high viscosity grease to protect against sticking and to maintain zero backlash characteristics.

FJ and FJU Series

These are suitable for applications requiring larger couplings than ASJ Series,but their main feature is low cost.The

hub material is machined A2017 aluminum,while the slider,which is designed to be used at normal ambient

temperature,is made of machined polyacetal.Hubs and slider are assembled in light press-tting,so there is zero

backlash.If heat resistance is necessary,slider material options include MC nylon,GF reinforced PPS,and

aluminum-bronze.

FSPJ Series

These newly developed products are our strongest Oldham s couplings,and are suitable for applications requiring

lager couplings than those provided by APJ Series.The hubs are made of SUS303 stainless steel,while the sliders are

made of aluminum-bronze.These couplings oer our highest performance in term of transmission torque and

torsional rigidity.Super-high vicosity grease lls the clearance of the sliding surface,so there is zero backlash in

servo mechanism use.

20

ASJ

Oldham's

Set screw style

RoHS compatible

Features

Compact, powerful, and excellent durability

Wide product range enables selection of the ideal size

Combination of sintered stainless steel hubs and a carbon FRP

slider

Item No. designation

*Key groove processing

No entry: no processing

K3: 3mm key groove width

Conguration and materials

Slider: Carbon FRP

Key groove shape complies with new JIS standards. Special

key grooves should be shown in separate drawings.

For d1 and d2, orders for hole diameters other than the

standard values can be made.

Feel free to consult us about custom orders.

Combinations of set screw and clamp styles can also be

customized.

Hub: Sintered stainless steel

*Sintered metal that is Machined after resin

impregnation

*Superior to aluminum alloys in terms of

strength, frictional properties, and abrasion

resistance

Set screw M

Dimensions of key groove shape

Hole

diameter

6 8

Item No.

ASJ6

ASJ8

ASJ10

ASJ12

ASJ15

ASJ17

ASJ20

ASJ26

ASJ30

ASJ34

ASJ38

2 3

12

16.8

30

34

6.2

2.4

5.4

8.4

1.5

6.6

10.2

1.8

3.7

M2

2.7

5.4

M3

3.5

5.8

12

7.0

15

4.4

38

4.0

5.0

7.2

17.5

8.2

21

12.0

27

10 12 14

31

10 12 14 15 16 18 20

41

10 12 14 15 16

6 6

L1

6.2

13.0

14.0

35

16.0

9.6

9.2

14.2

13

19.8

10.8

16

5.2

M3

25.6

4.2

M4

34

5.5

32.5

26

2.6

M1.6

M4

20.9

22.2

3.5

6.7

21.4

17.6

1.7

3.3

14.4

40

5 5

2.8

3.4

3 3

4 4

2.3

15

6 6.35 8 9.53 10 12 14

26

0.0150

2 2

+0.1

12.5

6 6.35 8 9.53 10 12

20

1.8

d3

10.2

4 5 6 6.35 8

5 6 6.35 8

14.5

Nominal

dimension

of keys

1.0

1.4

DS

8.2

2 3 4

3 4 5

10

17 20

0.0125

12 17

1 1.5 2

10 12

Standard hole diameters (d1,d 2H8)

8 10

Dimensions

Basic

Basic

Tolerance

Tolerance

dimension

dimension

M4

M4

13

M5

M5

Fastening

torque

(Nm)

0.15

0.15

0.3

0.7

0.7

1.7

1.7

1.7

1.7

4.0

4.0

Specications

Item No.

ASJ

6

8

10

Transmission torque

(Nm)

Allowable misalignment

angular

Parallel

Rated torque Maximum torque misalignment

(mm) misalignment ( )

0.3

0.8

0.3

2

0.3

1.2

0.5

2

0.3

2

0.8

1.5

12

1.0

17

2.2

26

15

1.6

20

3.2

30

15

0.4

0.5

10

0.5

22

45

0.5

0.6

0.7

Torsional rigidity

(Nm/rad)

Maximum

rotating speed

(rpm)

Moment

of inertia

(kg)

12,000

5.9 10

-9

21

12,000

5.2 10

-8

90

10,000

3.5 10

-7

1.5

340

8,000

1.7 10

-6

1.5

1,200

6,200

1.4 10

-5

1.5

1.5

1.5

1.5

13

12,000

44

12,000

250

10,000

420

6,500

2.1 10

-8

1.5 10

-7

7.8 10

-7

61 10

-6

Mass

(g)

1.5

2.5

4

8

11

18

29

65

105

0.7

60

16

150

2.4 10 -5

6,000

1.5

2,400

0.7

85

28

230

4.3 10 -5

5,800

1.5

3,500

38

Heat resistance (ambient temperature): -30 to 80

When the hole diameter exceeds dimension d 3, characteristics such as the rated torque may deteriorate.

Usability at the rated torque cannot be determined solely by the maximum allowable misalignment. The magnitudes of the parallel and angular

misalignments can inuence the wear of a coupling in synergy with the working torque and rotational speed.

34

21

ASJU

Oldham 's

Clamp style

RoHS compatible

Features

Compact, powerful, and excellent durability

Wide product range enables selection of the ideal size and shape

Combination of sintered stainless steel hubs and a carbon FRP slider

Item No. designation

Conguration and materials

Slider: Carbon FRP

Key groove shape complies with new JIS standards. Special

key grooves should be shown in separate drawings.

For d1 and d2, orders for hole diameters other than the

standard values can be made.

Feel free to consult us about custom orders.

Combinations of set screw and clamp styles can also be

customized.

Hub: Sintered stainless steel

*Sintered metal that is Machined

after resin impregnation

*Superior to aluminum alloys in terms

of strength, frictional properties, and

abrasion resistance

Hexagon socket head cap screw M

Dimensions of key groove shape

Hole

diameter

6 8

10 12

12 17

Item No.

ASJU15

14.5

ASJU20

20

ASJU17

16.8

ASJU26

26

ASJU30

30

ASJU34

34

5

5

Basic

Basic

Tolerance

Tolerance

dimension

dimension

8 10

17 20

Dimensions

*Key groove processing

No entry: no processing

K3: 3mm key groove width

0.0125

0.0150

+0.1

1.8

1.0

1.4

2.3

Nominal

dimension

of keys

2 2

3 3

4 4

5 5

6 6

2.8

Standard hole diameters (d 1, d 2 H8)

DS

d3

L1

Fastening

torque

16

5.0

12.0

18.8

3.3

6.6

M2.5

1.0

8.2

18.2

4.5

10

M3

6

6

6

6.35

6.35

6.35

8

8

8

9.53

9.53

7.2

16.4

28

12.0

20.4

32.5

13.0

20.5

37

14.0

21.2

19

10

10

10

10

22

12

12

12

14

14

15

16

38

41

10 12 14 15 16 18 20

ASJU38

16.0

The clamp bolt for ASJU 34 with a hole diameter of 17 to 20 is M4.

The dimension Ds is the circumference of the clamp bolt head.

*The clamp bolt fastening torque for ASJU34 is 5.4 (Nm) when the hole diameters (d1, d2) are 16.

26.0

9.0

M3

5.0

11.5

M4

32.5

6.0

12

34

6.0

13

24.5

27.4

30.4

40

4.2

7.0

M5

M4

M5

M5

15

(Nm)

1.8

1.8

4.5

8.0

4.5

8.0

8.0

Specications

Item No.

ASJU

15

17

20

26

30

34

Transmission torque

(Nm)

Allowable misalignment

Parallel

angular

Rated torque Maximum torque misalignment (mm) misalignment ( )

0.4

1.5

5

1.6

0.4

1.5

7

2.2

3.2

10

0.5

15

45

0.7

6.0

16

22

0.6

60

0.7

Maximum

Torsional rigidity rotating

speed

(Nm/rad)

(rpm)

90

10,000

1.5

340

8,000

1.5

1,200

1.5

1.5

250

420

2,400

10,000

6,500

6,200

6,000

Moment

of inertia

(kg)

4.1 10

-7

2.0 10

-6

1.4 10

-5

1.0 10

-6

7.3 10

-6

2.4 10

-5

Mass

(g)

15

28

40

85

100

140

215

5,800

3,500

0.7

4.3 10 -5

1.5

85

38

28

Heat resistance (ambient temperature): -30 to 80

When the hole diameter exceeds dimension d3, characteristics such as the rated torque may deteriorate.

Usability at the rated torque cannot be determined solely by the maximum allowable misalignment. The magnitudes of the parallel and angular

misalignments can inuence the wear of a coupling in synergy with the working torque and rotational speed.

22

APJ

Oldham's

Set screw style

RoHS compatible

Features

Compact, more powerful and excellent durability

Rated torque is approximately twice compared with ASJ series

Item No. designation

*Key groove processing

No entry: no processing

K3: 3mm key groove width

Conguration and materials

Slider: Aluminum bronze

Key groove shape complies with new JIS standards.Special

key grooves should be shown in separate drawings.

For d1 and d2, orders for hole diameters other than the

standard values can be made. Feel free to consult us about

custom orders.

Combinations of set screw and clamp styles can also be

customized.

Hub: Sintered stainless steel

*Sintered metal that is Machined after

resin impregnation

*Superior to aluminum alloys in terms

of strength, frictional properties, and

abrasion resistance

Dimensions of key groove shape

Hole

diameter

6 8

8 10

10 12

12 17

Dimensions

Item No.

APJ12

APJ15

APJ17

APJ20

APJ26

APJ30

APJ34

APJ38

Standard hole diameters (d 1, d 2 H8)

D

12

14.5

4

4

16.8

20

5

5

5

6.35

6.35

6

6

26

17 20

6.35

6.35

30

9.53

10

12

10

12

10

10

34

10

38

12

14

12

14

12

14

14

15

16

20

1.8

0.0150

+0.1

0

2.3

2 2

3 3

4 4

5 5

6 6

2.8

L1

Fastening

torque

12

6.2

9.2

14.4

2.6

5.2

M3

0.7

17.5

8.2

13

20.2

3.3

6.7

M4

1.7

9.0

M4

13

M5

31

18

1.0

1.4

27

16

0.0125

d3

21

15

Nominal

dimension

of keys

DS

15

9.53

Basic

Basic

Tolerance

Tolerance

dimension

dimension

35

39

7.2

10.8

16.4

9.0

14.4

21.4

20.9

32.5

26

39.5

12

13

14

17

M3

2.7

5.4

3.5

7.0

M4

12

M4

15

M5

17.6

25.6

4.2

22.2

34

5.5

5.8

7.0

(Nm)

0.7

1.7

1.7

1.7

4.0

4.0

Specications

Item No.

APJ

12

15

17

20

26

30

Transmission torque

angular

Parallel

Rated torque Maximum torque misalignment

(mm) misalignment ( )

2.5

11

0.3

5.0

20

0.3

10

40

3.0

15

7.0

30

24

80

Maximum

Torsional rigidity rotating speed

Allowable misalignment

(Nm)

0.3

0.4

0.5

0.6

0.6

0.6

(Nm/rad)

(rpm)

0.1

250

10,000

0.1

1,000

7,000

4,000

5,000

End play (mm)

0.1

0.6

0.6

0.1

0.6

0.2

0.6

0.2

Moment of

inertia

(kg)

2.0 10

-7

1.0 10

-6

7.5 10

-6

800

8,000

4.5 10

-7

2,200

6,000

2.2 10

-6

5,500

5,000

1.7 10

-5

Mass

(g)

8.5

15

25

37

79

122

0.6

0.6

2.8 10 -5

4,000

0.2

173

6,000

0.6

0.6

5.2 10 -5

4,000

0.3

170

260

9,000

50

38

Heat resistance (ambient temperature): -30 to 100

When the hole diameter exceeds dimension d3, characteristics such as the rated torque may deteriorate.

Usability at the rated torque cannot be determined solely by the maximum allowable misalignment. The magnitudes of the parallel and angular

misalignments can inuence the wear of a coupling in synergy with the working torque and rotational speed.

Maximum rotational speed corresponds to no parallel misalignment (that is less than 1/10 of allowable value).

There is a possibility of slip occurring when a high transmission torque is loaded. For this reason, it may be necessary to process the key groove.

34

32

120

23

APJU

Oldham's

Clamp style

RoHS compatible

Features

Compact, more powerful and excellent durability

Rated torque is approximately twice compared with ASJU series

Item No. designation

Conguration and materials

*Key groove processing

No entry: no processing

K3: 3mm key groove width

Slider: Aluminum bronze

Hub: Sintered stainless steel

*Sintered metal that is Machined after

resin impregnation

*Superior to aluminum alloys in terms

of strength, frictional properties, and

abrasion resistance

Hexagon socket

head cap screw M

Key groove shape complies with new JIS standards. Special

key grooves should be shown in separate drawings.

For d1 and d2, orders for hole diameters other than the

standard values can be made. Feel free to consult us about

custom orders.

Combinations of set screw and clamp styles can also be

customized.

Dimensions of key groove shape

Hole

diameter

6 8

8 10

10 12

12 17

Dimensions

Item No.

APJU15

14.5

APJU17

APJU20

APJU26

APJU30

16.8

17 20

Standard hole diameters (d 1, d 2 H8)

4

5

5

20

26

6

6

6.35

6.35

6.35

8

8

8

30

9.53

9.53

10

10

10

12

14

3

4

5

0.0125

4

5

1.0

1.4

+0.1

1.8

0.0150

2.3

2 2

3 3

4 4

5 5

6 6

2.8

d3

L1

Fastening

torque

16

7.2

12

18.8

3.3

6.6

M2.5

1.0

22

4.5

10

8.7

16.4

28

12

20.4

32.5

13

20.5

18.2

21.2

14

37

10 12 14 15 16

34

26

APJU38 38

17

38

10 12 14 15 16 18 20

The dimension Ds is the circumference of the clamp bolt head.

The clamp bolt for APJU 34 with a hole diameter of 17 over is M4.

*The clamp bolt fastening torque for ASJU34 is 5.4 (Nm) when the hole diameters (d1, d2) are 16.

APJU34

Nominal

dimension

of keys

DS

19

12

Basic

Basic

Tolerance

Tolerance

dimension

dimension

9.0

24.5

4.2

30.4

5.0

11.5

32.5

6.0

12

34

6.0

13

27.4

39.5

7.0

15

(Nm)

M3

1.8

M4

4.5

M4

4.5

M5

8.0

M3

M5

M5

1.8

8.0

8.0

Specications

Item No.

APJU

15

17

20

26

Transmission torque

angular

Parallel

Rated torque Maximum torque misalignment

(mm) misalignment ( )

15

0.3

0.6

30

0.4

0.6

5

10

30

24

38

50

34

Allowable misalignment

(Nm)

32

20

40

80

120

170

0.3

0.5

0.6

0.6

0.6

0.6

0.6

0.6

0.6

0.6

End play (mm)

0.1

0.1

0.1

0.2

0.2

0.2

0.3

Maximum

Torsional rigidity rotating

speed

(Nm/rad)

(rpm)

800

8,000

2,200

6,000

5,500

5,000

1,000

7,000

4,000

5,000

6,000

4,000

9,000

4,000

Moment of

inertia

(kg)

5.1 10

-7

2.6 10

-6

1.7 10

-5

5.2 10

-5

1.2 10

-6

8.7 10

-6

2.8 10

-5

Mass

(g)

17

30

48

90

117

165

250

Heat resistance (ambient temperature): -30 to 100

When the hole diameter exceeds dimension d3, characteristics such as the rated torque may deteriorate.

Usability at the rated torque cannot be determined solely by the maximum allowable misalignment. The magnitudes of the parallel and angular

misalignments can inuence the wear of a coupling in synergy with the working torque and rotational speed.

Maximum rotational speed corresponds to no parallel misalignment (that is less than 1/10 of allowable value).

There is a possibility of slip occurring when a high transmission torque is loaded. For this reason, it may be necessary to process the key groove.

24

FJ

Oldham's with larger size

Set screw style

RoHS compatible

Features

Combination of aluminum hubs and a polyacetal slider to handle shaft diameters up to 38

High-precision slider groove for light press-tting and zero backlash, enabling servo operation

Sliders can also be made of chemical-resistant or heat-resistant materials

Conguration and materials

Item No. designation

*Key groove processing

No entry: no processing

K: mm key groove width

Slider: Polyacetal

Hub: Aluminum

Key groove shape complies with new JIS standards. Special

key grooves should be shown in separate drawings.

For d1 and d2, orders for hole diameters other than the

standard values can be made. Feel free to consult us about

custom orders.

Combinations of set screw and clamp styles can also be

customized.

Dimensions of key groove shape

Hole

diameter

Nominal

dimension

of keys

Basic

Basic

dimension Tolerance dimension Tolerance

14 17

17 22

22 30

30 38

10

10

0.0150

0.0180

2.3

5 5

+0.1

0

2.8

6 6

8 7

+0.2

0

3.3

10 8

Dimensions

Item No.

FJ44

44

FJ55

FJ70

Standard hole diameters d 1, d 2 H8

(left/right can be freely combined)

14 15 16 18 20 22

18 20 22 25 26

22 25

28 30 35 38

55

69

d3

L1

22.5

46

15

7.5

39

77

25

12.5

10

28

19

57

9.5

Fastening

torque

(Nm)

7.0

15.0

30.0

Specications

Item No.

FJ44

FJ55

FJ70

Rated torque

(Nm)

30

45

80

Maximum

rotating speed

(rpm)

12,000

10,000

8,000

Torsional rigidity Allowable parallel Allowable angular

misalignment

misalignment

(Nm/rad)

1,500

(mm)

0.7

1

2,800

1.2

4,800

Heat resistance (ambient temperature): -25 to 80 (rated torque should be 1/2 in 80)

25

( )

1.5

1.5

1.5

Moment of

inertia

(kg)

Mass

(g)

4 10 -5

140

40 10 -5

450

11 10 -5

260

FJU

Oldham's with larger size

Clamp style

RoHS compatible

Features

Combination of aluminum hubs and a polyacetal slider to handle shaft diameters up to 35

High-precision slider groove for light press-tting and zero backlash, enabling servo operation

Sliders can also be made of chemical-resistant and heat-resistant materials

Conguration and materials

Item No. designation

Slider: Polyacetal

*Key groove processing

No entry: no processing

K: mm key groove width

Hub: Aluminum

Key groove shape complies with new JIS standards. Special

key grooves should be shown in separate drawings.

For d1 and d2, orders for hole diameters other than the

standard values can be made. Feel free to consult us about

custom orders.

Combinations of set screw and clamp styles can also be

customized.

Dimensions of key groove shape

Hole

diameter

Basic

Basic

dimension Tolerance dimension Tolerance

14 17

17 22

22 30

30 35

10

10

d3

L1

22.5

46

15

7.5

14.5

0.0150

0.0180

2.3

5 5

+0.1

0

2.8

3.3

Nominal

dimension

of keys

+0.2

0

6 6

8 7

10 8

Dimensions

Item No.

FJU44

44

FJU55

55

Standard hole diameters d 1, d 2 H8

(left/right can be freely combined)

14

15

16

18

18

20

20

22

57

28

25

9.5

19

17

FJU70

24

12.5

25

77

39

69

22 25 28 30 35

For small hole diameters, it is necessary to fasten the clamp bolt to higher torque than the listed value to prevent slip.

The listed fastening torque is intended only as an approximate guide.

6

8

Fastening

torque

(Nm)

8.4

14.4

30

Specications

Item No.

FJU44

FJU55

FJU70

Allowable parallel Allowable angular

misalignment

misalignment

Maximum

rotating speed

Torsional rigidity

(rpm)

(Nm/rad)

(mm)

( )

26

10,000

1,500

0.7

1.5

72

6,000

4,800

1.2

1.5

Rated torque

(Nm)

40

8,000

2,800

Heat resistance (ambient temperature): -25 to 80 (rated torque should be 1/2 in 80)

26

1.5

Moment of

inertia

Mass

4 10 -5

140

40 10 -5

450

(kg)

11 10 -5

(g)

260

FSPJ

Oldham's

Set screw style

RoHS compatible

Features

Strongest Oldham's coupling

Combination of stainless steel hubs and aluminum-bronze slider: all-metal Oldham's coupling

The minimized clearance of the sliding surface is lled with super-high viscosity grease, for both anti-sticking

and zero backlash

Item No. designation

Conguration and materials

*Key groove processing

No entry: no processing

K: mm key groove width

Slider: Aluminum bronze

Hub: Stainless steel

Key groove shape complies with new JIS standards.

Special key grooves should be shown in separate drawings.

Dimensions of key groove shape

Hole

diameter

Basic

Basic

dimension Tolerance dimension Tolerance

15 17

17 22

22 30

30 35

10

10

0.0150

0.0180

2.3

+0.1

0

2.8

+0.2

0

3.3

Nominal

dimension

of keys

5 5

6 6

8 7

10 8

Dimensions

Standard hole diameters d1, d 2 H8

(left/right can be freely combined)

Item No.

FSPJ45

45

FSPJ55

55

15

18

18

20

20

22

22

25

28

70

FSPJ70

20 22 25 28 30 32

Cautions

Processing of key groove is necessary for FSPJ coupling

Make sure to specify hole diameter and key groove dimensions

d3

L1

Clearance

of the sliding

surface

Fastening

torque

22.5

43.6

15

7.5

0.01 0.025

M5

3.6

0.01 0.035

M8

14

29

36

35

49.4

57

17

20

8.5

10

M6

0.01 0.03

(Nm)

Specications

Item No.

Rated torque

(Nm)

FSPJ45

60

FSPJ70

160

FSPJ55

90

Allowable parallel Allowable angular

Maximum

rotating speed

misalignment

misalignment

(rpm)

(mm)

( )

10,000

0.6

1.6

0.6

10,000

10,000

1.2

0.6

27

Allowable

end play

Torsional rigidity

(mm)

(Nm/rad)

0.5

65,000

0.6

0.8

100,000

180,000

Moment of

inertia

(kg)

1.7 10

-4

1.1 10

-3

3.3 10

-4

Mass

(g)

380

750

1,300

Das könnte Ihnen auch gefallen

- Bosch Motronic ME7 DescriptionDokument12 SeitenBosch Motronic ME7 Descriptionmatt_peacock100% (10)

- Bolt Torque Table For All Type of Class 8.8,10.9Dokument12 SeitenBolt Torque Table For All Type of Class 8.8,10.91410200180% (5)

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- 65K-950JR HAWKJAW JR MANUAL Rev CDokument153 Seiten65K-950JR HAWKJAW JR MANUAL Rev CNestor MorenoNoch keine Bewertungen

- Calculus-Based Physics 1 MQ2-MIDTERM EXAMDokument27 SeitenCalculus-Based Physics 1 MQ2-MIDTERM EXAMVendaver AlzateNoch keine Bewertungen

- Fluro CatalogueDokument56 SeitenFluro CatalogueachinvanshNoch keine Bewertungen

- 3012en PDFDokument560 Seiten3012en PDFmgualdiNoch keine Bewertungen

- Festening Elements EN PDFDokument14 SeitenFestening Elements EN PDFmymail0808Noch keine Bewertungen

- FLURO Motor Sport Cataloque EnglishDokument16 SeitenFLURO Motor Sport Cataloque EnglishRMCsportNoch keine Bewertungen

- BLM 3 Nisan 2010 KTLDokument14 SeitenBLM 3 Nisan 2010 KTLsertackcdgNoch keine Bewertungen

- Mitsubishi Frézy APX3000Dokument16 SeitenMitsubishi Frézy APX3000Jan MolekNoch keine Bewertungen

- Plummer Block DskatkasndfmDokument30 SeitenPlummer Block DskatkasndfmVivek AradhyaNoch keine Bewertungen

- Pulleys TechDokument8 SeitenPulleys TechashkansoheylNoch keine Bewertungen

- WTI UK Screw Thread Inserts and Kits CatalogueDokument16 SeitenWTI UK Screw Thread Inserts and Kits CatalogueThor InternationalNoch keine Bewertungen

- SD II PDF - OCRDokument18 SeitenSD II PDF - OCRSuraj KumarNoch keine Bewertungen

- IKO Shell Needle RollerDokument25 SeitenIKO Shell Needle RollermandosasdNoch keine Bewertungen

- Plummer Blocks: Tightening Bolt Oil Fill PlugDokument30 SeitenPlummer Blocks: Tightening Bolt Oil Fill Plugmanoj983@gmail.comNoch keine Bewertungen

- Plummer en 03-32Dokument30 SeitenPlummer en 03-32refeiNoch keine Bewertungen

- PHNCDokument6 SeitenPHNCAmit MangaonkarNoch keine Bewertungen

- Kubler - Bellows CouplingsDokument2 SeitenKubler - Bellows CouplingsSayak BoseNoch keine Bewertungen

- Sheet Metal FastenersDokument15 SeitenSheet Metal FastenersSudath KularathnaNoch keine Bewertungen

- Self Locking Ring ElementsDokument44 SeitenSelf Locking Ring ElementsRolffoTelloNoch keine Bewertungen

- Plummer Block Housings: FeaturesDokument3 SeitenPlummer Block Housings: FeaturesrefeiNoch keine Bewertungen

- TTM Post TensioningDokument103 SeitenTTM Post Tensioninghorea67100% (2)

- Rod EndsDokument17 SeitenRod EndsAlberto LeónNoch keine Bewertungen

- FL6003 PDFDokument4 SeitenFL6003 PDFMauricio Barrios CastellanosNoch keine Bewertungen

- O-Ring (Metric Size)Dokument63 SeitenO-Ring (Metric Size)Kamlesh DalavadiNoch keine Bewertungen

- PEM Self Clinching Flush FastenersDokument4 SeitenPEM Self Clinching Flush FastenersAce Industrial SuppliesNoch keine Bewertungen

- Dichta CatalogueDokument62 SeitenDichta CataloguemaxatadesignNoch keine Bewertungen

- Needle Cages and Roller Cages: ConstructionDokument12 SeitenNeedle Cages and Roller Cages: ConstructionMohan Kumar MathrubaiNoch keine Bewertungen

- Grease Nipples From UMETA Catalogue GK84-E 04-2012-2Dokument46 SeitenGrease Nipples From UMETA Catalogue GK84-E 04-2012-2FranzKafkaNoch keine Bewertungen

- Ring JointDokument2 SeitenRing JointarianaseriNoch keine Bewertungen

- Anchor Bolt FAZ IIDokument4 SeitenAnchor Bolt FAZ IImmaleniNoch keine Bewertungen

- Thomson Roundrail 1NC SpecsheetDokument2 SeitenThomson Roundrail 1NC SpecsheetElectromateNoch keine Bewertungen

- Chapter 7Dokument61 SeitenChapter 7PacoNoch keine Bewertungen

- No.13 PRT2 Timing Belt Rings 01 UK PDFDokument4 SeitenNo.13 PRT2 Timing Belt Rings 01 UK PDFhepcomotionNoch keine Bewertungen

- RULAND ZupcasteDokument6 SeitenRULAND Zupcasteduxi1981Noch keine Bewertungen

- NSK CAT E1102m B4-45Dokument21 SeitenNSK CAT E1102m B4-45nvkjayanthNoch keine Bewertungen

- Ringlok RingfederDokument5 SeitenRinglok RingfederHector MaldonadoNoch keine Bewertungen

- Catalogo NSKDokument0 SeitenCatalogo NSKPedro Henrique SilverioNoch keine Bewertungen

- Notes On Ball BearingsDokument10 SeitenNotes On Ball BearingsSumit SinhaNoch keine Bewertungen

- 10Z 3Dokument95 Seiten10Z 3ZMCONTROLNoch keine Bewertungen

- Piston Uring FTL Seal TechnologyDokument3 SeitenPiston Uring FTL Seal Technologycristobal_tl2277100% (1)

- Manual Da Furadeira MakitaDokument10 SeitenManual Da Furadeira Makitaani_matrixx4733Noch keine Bewertungen

- DEFNUT - Nituri TubulareDokument28 SeitenDEFNUT - Nituri Tubularepaula09Noch keine Bewertungen

- PEM Self Clinching Self Locking FastenersDokument4 SeitenPEM Self Clinching Self Locking FastenersAce Industrial SuppliesNoch keine Bewertungen

- Material PropertiesDokument16 SeitenMaterial PropertiesMadan Kulkarni100% (1)

- Apex and Ma Gnus StrappingDokument3 SeitenApex and Ma Gnus StrappingRose MadderNoch keine Bewertungen

- Technical Characteristics: Upon RequestDokument7 SeitenTechnical Characteristics: Upon RequestMoin AftabNoch keine Bewertungen

- TC 12303Dokument12 SeitenTC 12303prasen10Noch keine Bewertungen

- Direct-Acting Pressure Reducing Valve For Air: ModelDokument2 SeitenDirect-Acting Pressure Reducing Valve For Air: ModelAmerico WaxNoch keine Bewertungen

- ARNOLD - Thread Forming ScrewDokument4 SeitenARNOLD - Thread Forming ScrewgirishawantiNoch keine Bewertungen

- Acople Grilla Love JoyDokument1 SeiteAcople Grilla Love JoyClaudia C. DiazNoch keine Bewertungen

- KVC 01Dokument35 SeitenKVC 01hamidreza_m85Noch keine Bewertungen

- TSN PrimeWall Catalog May09Dokument22 SeitenTSN PrimeWall Catalog May09Anonymous PjmE9RJcghNoch keine Bewertungen

- PRA/182000/M PRA/182000, ISO Cylinder Magnetic & Non-Magnetic Piston, Double ActingDokument19 SeitenPRA/182000/M PRA/182000, ISO Cylinder Magnetic & Non-Magnetic Piston, Double Actingyouri59490Noch keine Bewertungen

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersVon EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsVon EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsBewertung: 4 von 5 Sternen4/5 (1)

- Electromagnetic Induction and Damping - Quantitative Experiments Using PC InterfaceDokument5 SeitenElectromagnetic Induction and Damping - Quantitative Experiments Using PC InterfaceRaman BhullarNoch keine Bewertungen

- Class: XI Topic: Moment of Inertia & Torque Sub: PhysicsDokument8 SeitenClass: XI Topic: Moment of Inertia & Torque Sub: PhysicsSudharsan Gupta SudhirNoch keine Bewertungen

- Ahmed Daoud Motors - 50HzDokument14 SeitenAhmed Daoud Motors - 50Hzمحمد عبدالدايمNoch keine Bewertungen

- 006 Kinematics and Dynamics of Rotation PDFDokument34 Seiten006 Kinematics and Dynamics of Rotation PDFNIEVA LOU ORBOCNoch keine Bewertungen

- Class2 Moment of InertiaDokument45 SeitenClass2 Moment of Inertiadccadar100% (1)

- Week1 Introduction PDFDokument33 SeitenWeek1 Introduction PDFMohammad A AlawneNoch keine Bewertungen

- WSC 1st Sem NSQF FinalDokument118 SeitenWSC 1st Sem NSQF FinalGowtham Nagarajan100% (1)

- 2005-26-037 3W Brakes by TVSDokument10 Seiten2005-26-037 3W Brakes by TVSSiva ReddyNoch keine Bewertungen

- My ML WY RMS: SeriesDokument44 SeitenMy ML WY RMS: Serieshai hoangNoch keine Bewertungen

- Department of Mechanical Engineering: Er. Nipesh RegmiDokument30 SeitenDepartment of Mechanical Engineering: Er. Nipesh RegmiRosina AdhikariNoch keine Bewertungen

- Expt 2 Transfer Function 1Dokument6 SeitenExpt 2 Transfer Function 1JHUSTINE CAÑETENoch keine Bewertungen

- Is500 PDFDokument298 SeitenIs500 PDFShekhar Srivass50% (4)

- Physics Cheat Sheet Master PDFDokument6 SeitenPhysics Cheat Sheet Master PDFCha GabrielNoch keine Bewertungen

- Power Calculations: Design ParametersDokument4 SeitenPower Calculations: Design ParametersDhirender KapoorNoch keine Bewertungen

- Unit 1 Force Systems PDFDokument17 SeitenUnit 1 Force Systems PDFpeter vanderNoch keine Bewertungen

- Manual Hyd CSG TongDokument48 SeitenManual Hyd CSG TongpaonemechNoch keine Bewertungen

- Auma Acexc01.2Dokument96 SeitenAuma Acexc01.2Khang TrangNoch keine Bewertungen

- Universal Gravitational Constant: EquipmentDokument13 SeitenUniversal Gravitational Constant: EquipmentTraitor OneNoch keine Bewertungen

- Static and Dynamic Ergonomic Corrects of Torque Controlled in Bicycle ErgometerDokument5 SeitenStatic and Dynamic Ergonomic Corrects of Torque Controlled in Bicycle ErgometerSantiago Bonilla RiveraNoch keine Bewertungen

- 11.1. Rotational Dynamics QPDokument27 Seiten11.1. Rotational Dynamics QPxasollaNoch keine Bewertungen

- Advanced Pattern Cumalative Test 2 Paper 2Dokument27 SeitenAdvanced Pattern Cumalative Test 2 Paper 2AAVANINoch keine Bewertungen

- Machine Design Final ReportDokument23 SeitenMachine Design Final ReportAvk Sanjeevan100% (2)

- Cross Flow DesignDokument7 SeitenCross Flow DesignarielbankiNoch keine Bewertungen

- GyroscopeDokument16 SeitenGyroscopem_er100Noch keine Bewertungen