Beruflich Dokumente

Kultur Dokumente

CAM

Hochgeladen von

Jay JoshiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CAM

Hochgeladen von

Jay JoshiCopyright:

Verfügbare Formate

Computer aided manufacturing

3361901

GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, GUJARAT

COURSE CURRICULUM

COURSE TITLE: COMPUTER AIDED MANUFACTURING (CAM)

(COURSE CODE:3361901)

Diploma Programme in which this course is offered

MECHANICAL ENGINEERING

Semester in which offered

SIXTH

1. RATIONALE.

The era of conventional machines are being limited. Evolution of information

technology, variety manufacturing concepts with zero lead time demand and

quality consciousness have supported fast adaption of computerized numerical

control (CNC) machines. CNC programming has more importance along with

selection and use of CNC tooling. An attempt has been made to focus exclusively

on CNC machines and advance development. CNC machines normally are not

only limited to machine tools but in real its use has widened in almost all areas of

manufacturing, processes and support activities.

2. COMPETENCY.

The course content should be taught and implemented with the aim to develop

different types of skills so that students are able: to acquire following

competencies.

Select required operating parameters, appropriate tools, tool holders,

accessories and consumables for manufacturing a given job on CNC.

Manufacture simple jobs using CNC part program

3. COURSE OUTCOMES.

Students will be able to

i.

ii.

iii.

iv.

Identify different axes, machine zero, home position, controls and

features of CNC machines.

Select, mount and set cutting tools and tool holders on CNC.

Prepare part programmes using ISO format for given simple components

with and without use of MACRO, CANNED CYCLE and

SUBROUTINE using ISO format.

Interface software application for auto part programming.

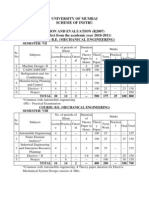

4. TEACHING AND EXAMINATION SCHEME.

Total

Examination Scheme

Teaching Scheme

Credits

Practical

(In Hours)

(L+T+P Theory Marks

Marks

)

L

ESE

PA

ESE

PA

70

30

20

30

Total

Marks

150

GTU/ NITTTR Bhopal/14-1

Gujarat State

1

Computer aided manufacturing

3361901

Legends: L-Lecture; T Tutorial/Teacher Guided Theory Practice; P -Practical; C

Credit, ESE -End Semester Examination; PA - Progressive Assessment.

5. COURSE DETAILS.

Unit

Unit I.

Fundamentals

of CAM.

Unit- II

Constructional

features

of

CNC

machines.

Major Learning

Outcomes

(in cognitive

domain)

1a. Differentiate

between

NC,

CNC and DNC.

1b. Identify

parameters

governing

for

selection of CNC

machines.

2a. Classify

CNC

machines.

2b. Identify role of

main elements of

CNC machines.

2c. Identify

CNC

axes.

2d. Preset tool on

CNC machines.

2e. Use

qualified

tools and tool

holders on CNC

machines.

Topics and Sub-topics

1.1

1.2

1.3

1.4

2.1

2.2

2.3

2.4

2.5

2.6

3.1

Unit III

CNC

machines.

3a. List features of

specified CNC

turning

centre

and

CNC

machining

centre.

3b. Identify various

work holding and

tool

holding

devices.

GTU/ NITTTR Bhopal/14-1

3.2

CAM - concept and definition.

NC

(Numerical

Control),

CNC

(Computerized Numerical Control) and

DNC (Direct Numerical Control) concept, features and differences.

Advantages and limitations of CNC.

Selection criteria for CNC machines.

CNC machines: Types, classification,

working and constructional features.

Spindle drives and axes drives on CNC

machines.

Machine structure- Requirements and

reasons.

Elements of CNC machines - Types,

sketch, working and importance of:

i. Slide ways.

ii. Re-circulating ball screw.

iii. Feedback devices (transducers,

encoders).

iv. Automatic tool changer (ATC).

v. Automatic pallet changer (APC).

CNC axes and motion nomenclature.

CNC tooling :

i. Tool presetting-concept and

importance.

ii. Qualified tools-definition need

and advantages.

iii. Tool

holderstypes

and

applications.

CNC turning centres:

i. Types.

ii. Features.

iii. Axes nomenclature.

iv. Specification.

v. Work holding devices -types,

working and applications.

vi. Tool holding and changing

devices - types, working and

applications.

CNC machining centres:

Gujarat State

2

Computer aided manufacturing

Unit

3361901

Major Learning

Outcomes

(in cognitive

domain)

3c. Select

suitable

CAD/CAM

interfacing

standard.

Topics and Sub-topics

i.

ii.

iii.

iv.

v.

3.3

Unit IV

CNC part

programming.

4a. Interpret and use

ISO format of

CNC

part

programming.

4b. Use important G

and M codes in

CNC

part

programming.

4c. Set

various

compensations

on CNC.

4d. Prepare simple

part programme.

4e. Prepare

a job

using advanced

CNC

part

programming

features

like

canned cycle, do

loop, subroutine

etc.,

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

GTU/ NITTTR Bhopal/14-1

B Types.

Features.

Axes nomenclature.

Specification.

Work holding devices-types,

working and applications.

vi. Tool holding and changing

devices- types, working and

applications.

Types and applications of CAD/CAM

interfacing standards.

Definition and importance of various

positions like machine zero, home

position, work piece zero and

programme zero.

CNC part programming: programming

format and structure of part programme.

ISO G and M codes for turning and

milling-meaning and applications of

important codes.

Model and non-model G and M codes.

Need and importance of various

compensations:

i. Tool length compensation.

ii. Pitch error compensation.

iii. Tool radius compensation.

iv. Tool offset.

Simple part programming for turning

using ISO format having straight

turning,

taper

turning

(linear

interpolation)

and

convex/concave

turning (circular interpolation).

Simple part programming for milling

using ISO format.

Importance, types, applications and

format for:

i. Canned cycles.

ii. Macro.

iii. Do loops.

iv. Subroutine.

CNC turning and milling part

programming using canned cycles, Do

loops and Subroutine.

Gujarat State

3

Computer aided manufacturing

3361901

Unit

Unit V

Recent trends

in CAM.

Major Learning

Outcomes

(in cognitive

domain)

5a. List source of

variability

for

adaptive control.

5b. Interpret

different

FMS

layouts.

5c. Correlate areas

of CIM.

5d. Identify

types

and elements of

robots.

5e. Describe concept

of

Rapid

prototyping.

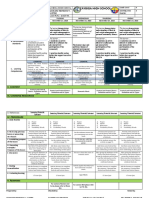

6. SUGGESTED

SPECIFICATION

TABLE

Topics and Sub-topics

5.1

5.2

5.3

5.4

5.5

Adaptive control- definition, meaning,

block diagram, sources of variability and

applications.

Flexible Manufacturing System (FMS) concept, evaluation, main elements and

their functions, layout and its

importance, applications.

Computer Integrated Manufacturing

(CIM) - Concept, definition, areas

covered, benefits.

Roboticsdefinition,

terminology,

classification and types, elements and

applications.

Rapid prototyping - Concept and

application

WITH

HOURS

AND

MARKS

(THEORY).

Unit

No.

Teaching

Hours

Unit Title

Distribution of Theory Marks

R

U

A

Total

Level Level Level Marks

Fundamentals of Computer Aided

4

4

6

0

Manufacturing

II

Constructional Features of CNC

5

6

4

4

machines

III

CNC machines.

4

2

5

2

IV

CNC part programming.

10

4

7

14

V

Recent trends in CAM.

5

4

8

0

Total

28

20

30

20

Legends: R = Remember U= Understand; A= Apply and above levels (Blooms revised

taxonomy).

Note: This specification table shall be treated as a general guideline for students and

teachers. The actual distribution of marks in the question paper may vary slightly from

above table.

General Notes:

a. If mid-sem test is part of continuous evaluation, unit numbers I, II and III are to

be considered.

b. Ask the questions from each topic as per marks weight age. Numerical

questions are to be asked only if it is specified. Optional questions must be

asked from the same topic.

GTU/ NITTTR Bhopal/14-1

Gujarat State

4

10

14

9

25

12

70

Computer aided manufacturing

7.

3361901

SUGGESTED LIST OF EXERCISES/PRACTICALS.

The practical/exercises should be properly designed and implemented with an attempt

to develop different types of skills (outcomes in psychomotor and affective domain)

so that students are able to acquire the competencies/programme outcomes. Following

is the list of practical exercises for guidance.

Note: Here only outcomes in psychomotor domain are listed as practical/exercises.

However, if these practical/exercises are completed appropriately, they would also

lead to development of certain outcomes in affective domain which would in turn lead

to development of Course Outcomes related to affective domain. Thus over all

development of Programme Outcomes (as given in a common list at the beginning of

curriculum document for this programme) would be assured.

Faculty should refer to that common list and should ensure that students also acquire

outcomes in affective domain which are required for overall achievement of

Programme Outcomes/Course Outcomes.

Sr.

No.

Unit

No.

II

IV

IV

Practical Exercises

(outcomes in Psychomotor Domain)

Approx.

Hours.

required

Demonstration of constructional features of CNC:

a. Demonstrate CNC machines and operations.

b. List major parts of CNC.

c. Write specification of CNC taken for demonstration.

d. Sketch important tool holders.

e. Tabulate sensors / feedback devices with type,

specification and purposes used on CNC taken for

demonstration.

f. Sketch display console. Also sketch symbols used on

display console with meaning of each.

g. State interfacing standards used.

CNC turning part programming:

Teacher will assign part drawings. Minimum five drawings

having following details are to be assigned. This include

parts- (i) Simple turning with steps, (ii) Turning with tapers,

(iii) Turning with circular (concave / convex shape)

interpolation, (iv) Turning using canned cycle - with

threading or drilling or other and (v)Turning with use of

subroutine or macro or do-loop.

a. Sketch each part with dimensions.

b. Prepare CNC part programme using G and M codes

with ISO format.

c. Show various zeros and tool path on part sketch with

color codes and dimensions.

d. Simulate the prepared part programmes using

available simulation softwares.

e. Prepare the parts on CNC.

CNC machining centre part programming:

Teacher will assign part drawings. Minimum three drawings

having following details are to be assigned. This include

parts- (i) Simple contour milling (ii) Contour milling with

GTU/ NITTTR Bhopal/14-1

Gujarat State

5

06

10

08

Computer aided manufacturing

III

ALL

3361901

(convex / concave) circular interpolation and (iii) contour

milling with drilling / tapping.

a. Sketch each part with dimensions.

b. Prepare CNC part programme using G and M codes

with ISO format.

c. Show various zeros and tool path on part sketch with

color codes and dimensions.

d. Simulate the prepared part programmes using

available simulation softwares.

e. Prepare the parts on CNC.

Demonstration of CAD/CAM integration:

a. Demonstrate CAD / CAM integration.

b. List interfacing standards.

Industrial visit:

Visit nearby industry having CNC machines. List and state

important features of them with detail specifications and

name of manufacturers.

Total Hours

02

02

28

Notes:

a. It is compulsory to prepare log book of exercises. It is also required to get each

exercise recorded in logbook, checked and duly dated signed by teacher.PA

component of practical marks is dependent on continuous and timely

evaluation and submission of exercises.

b. Term work report must not include any photocopy / ies, printed manual/pages,

litho, etc. It must be hand written / hand drawn by student only.

c. Mini project and presentation topic/area has to be assigned to the group of

specified students in the beginning of the term by batch teacher, if applicable.

d. For practical ESE part, students are to be assessed for competencies achieved.

They should be given experience/part of experience to perform as under.

i. B

8. SUGGESTED LIST OF STUDENT ACTIVITIES.

SR.NO.

1

2

3

4

ACTIVITY

Visit nearby industry having CNC machines. List and state important features of

them.

Prepare specifications of various types of CNC machines with images and names

of manufacturers.

Download images and videos of CNC machines and its parts. Prepare one

VCD/DVD in a a batch and submit to batch teacher.

Download free simulation softwares available on website and practice for part

programming.

GTU/ NITTTR Bhopal/14-1

Gujarat State

6

Computer aided manufacturing

9.

3361901

SPECIAL INSTRUCTIONAL STRATEGIES (if any).

Sr.

No.

1

Unit

Unit Name

Strategies

Introduction.

Constructional Features

of CNC machines

CNC machines.

Videos, Presentations, Demonstration.

Videos,

Presentations,

Industrial

Visits,

Demonstration,

Videos,

Presentations,

Industrial

Visits,

Demonstration,

Simulation softwares, actual practice on CNC

machines, Demonstration,

Videos, Presentations, Industrial Visits,

II

III

IV

CNC part programming.

Recent trends in CAM.

10. SUGGESTED LEARNING RESOURCES.

A.

List of Books:

S.

No.

1.

Title of Book

Author

CNC Machines.

Computer Numerical ControlTurning and Machining centers.

CAD/CAM.

Introduction

to

NC/CNC

Machines.

2.

3.

4.

5.

Computer Aided Manufacturing.

6.

CAD/CAM: computer aided

design and manufacturing.

Publication

Pabla B.S., Adithan M.

New

Age

International, New

Delhi,2014(reprint).

Quesada Robert

Prentice Hall 2014.

Sareen Kuldeep

S.Chand 2012.

S.K.Kataria

&

Sons. 2012.

Tata McGraw Hill

2014.

Vishal S.

Rao P N, Tiwari N K,

Kundra T

Groover

Mikell

P,

Zimmered W Emory

Prentice Hall 2011.

B) List of Major Equipment/ Instruments with Broad Specifications:

Sr. No.

1

Resource with brief specification.

CNC Turning Centre (Tutor or Productive)Minimum diameter 25 mm, Length 120 mm with ATC. (Approximate)

CNC Machining Centre (Tutor or Productive)X axis travel - 225 mm, Y axis travel - 150 mm, Z axis travel - 115 mm, With ATC.

(Approximate)

Simulation software likes: CNC Simulator Pro, Swansoft CNC, etc.

Latest version of CAD/CAM integration software like MASTER CAM, NX CAM.

etc.

GTU/ NITTTR Bhopal/14-1

Gujarat State

7

Computer aided manufacturing

3361901

C. List of Software/Learning Websites.

i.

ii.

iii.

iv.

v.

vi.

vii.

11.

http://www.nptel.ac.in

http://www.youtube.com/watch?v=M3eX2PKM1RI

http://www.youtube.com/watch?v=EHQ4QIDqENI&list=PLBkq

kLQO2nAt5MNLoaeUhvkFS9M0p8y_1

http://www.youtube.com/watch?v=hJFLcvtiNQI

http://www.youtube.com/watch?v=BIM1AyxfYkw.

http://www.mtabindia.com

http://www.swansoftcncsimulator.com

COURSE CURRICULUM DEVELOPMENT COMMITTEE

Faculty Members from Polytechnics.

Prof K.P. Patel, H.O.D, Mechanical Department, B.S.Patel Polytechnic,

Kherva.

Prof J.B.Patel, Sr. Lecturer, Mechanical Department, R.C.Technical Institute,

Ahmedabad

Prof R.A, Prajapati, Sr. Lecturer, Mechanical Department, R.C.Technical

Institute, Ahmedabad

Coordinator and Faculty Members from NITTTR Bhopal.

Dr. K.K. Jain, Professor, Department of Mechanical Engineering, NITTTR,

Bhopal

GTU/ NITTTR Bhopal/14-1

Gujarat State

8

Computer aided manufacturing

3361901

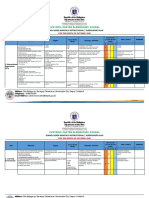

SUGGESTED QUESTION PAPER FORMAT

Q.NO.

SUB

Q.NO.

QUESTION

14

I

I

I

II

III

IV

IV

IV

V

V

2

2

2

2

2

2

2

2

2

2

a.

UNIT

Answer ANY seven from following.

i.

ii.

iii.

iv.

v.

vi.

vii.

viii.

ix.

x.

MARKS

DISTRIBUTION

6

4

I

II

OR

a.

b.

OR

b.

c.

4

4

II

II

II

OR

c.

3

a.

II

OR

a.

b.

6

4

II

V

4

4

V

V

OR

b.

c.

OR

c.

4

a.

a.

b.

c.

a.

Given the simple part drawing of milling contour with circular

interpolation, prepare the CNC part programme using G and M

codes with ISO format.

OR

Given the simple part drawing of milling contour with circular

interpolation, prepare the CNC part programme using G and M

codes with ISO format.

IV

IV

4

3

Given the simple part drawing, prepare the CNC turning part

programme using G and M codes with ISO format. Include circular

interpolation.

b.

c.

7

4

3

GTU/ NITTTR Bhopal/14-1

IV

IV

IV

III

III

Gujarat State

9

Das könnte Ihnen auch gefallen

- PDFDokument5 SeitenPDFNamdev dhanawdeNoch keine Bewertungen

- PDFDokument10 SeitenPDFvishallchhayaNoch keine Bewertungen

- SyllabusDokument3 SeitenSyllabusAnonymous 4h9p1EIQYSNoch keine Bewertungen

- Engineering Applications: A Project Resource BookVon EverandEngineering Applications: A Project Resource BookBewertung: 2.5 von 5 Sternen2.5/5 (1)

- Advanced Manufacturing Process 9094Dokument5 SeitenAdvanced Manufacturing Process 9094Raja VenkateshNoch keine Bewertungen

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Von EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Bewertung: 5 von 5 Sternen5/5 (1)

- CAD CAM AutomationDokument4 SeitenCAD CAM AutomationTiago LopesNoch keine Bewertungen

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successVon EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Computer Aided Manufacturing - 2 Marks - All 5 UnitsDokument18 SeitenComputer Aided Manufacturing - 2 Marks - All 5 UnitsMohan Prasad.M67% (6)

- CAD CAM Micro SyllabusDokument2 SeitenCAD CAM Micro Syllabusrajya lakshmiNoch keine Bewertungen

- Pec IvDokument6 SeitenPec Iv3111hruthvikNoch keine Bewertungen

- CNC LAB Manual PDFDokument33 SeitenCNC LAB Manual PDFrajee10133% (3)

- Mechanical - VI. Sem Syllabus GtuDokument115 SeitenMechanical - VI. Sem Syllabus GtukishormechNoch keine Bewertungen

- 06mel77 - Cim - AutoDokument79 Seiten06mel77 - Cim - AutoPraveen KumarNoch keine Bewertungen

- Computer Aided Manufacturing 2 Marks All 5 UnitsDokument18 SeitenComputer Aided Manufacturing 2 Marks All 5 UnitsMehul MunshiNoch keine Bewertungen

- Question Bank Introduction To CAM: Noble Group of Institutions, JunagadhDokument5 SeitenQuestion Bank Introduction To CAM: Noble Group of Institutions, JunagadhjanakNoch keine Bewertungen

- Cim Automation Lab Manual 10me78Dokument57 SeitenCim Automation Lab Manual 10me78chandrashekar mNoch keine Bewertungen

- Gujarat Technological University: Semester - II Subject Name: Computer Aided ManufacturingDokument3 SeitenGujarat Technological University: Semester - II Subject Name: Computer Aided ManufacturingBamania ChiragNoch keine Bewertungen

- CADCAMDokument50 SeitenCADCAMPrem Chander100% (5)

- CNC Lab Manual 2023 Med 3102Dokument66 SeitenCNC Lab Manual 2023 Med 3102G. RajeshNoch keine Bewertungen

- Assignment-1 Computer Aided Manufacturing ME-418Dokument21 SeitenAssignment-1 Computer Aided Manufacturing ME-418Prateek Kharbanda 79Noch keine Bewertungen

- CADCAM MinDokument91 SeitenCADCAM MinBandi KumarreddyNoch keine Bewertungen

- PDFDokument11 SeitenPDFjaniirNoch keine Bewertungen

- Cadcam 2 Marks PDFDokument18 SeitenCadcam 2 Marks PDFPct TejNoch keine Bewertungen

- Cam 25062016 030053amDokument4 SeitenCam 25062016 030053amRemi KwetchaNoch keine Bewertungen

- Computer Integrated Manufacturing Lab Manual: Subject Supervisor: Lab InchargeDokument53 SeitenComputer Integrated Manufacturing Lab Manual: Subject Supervisor: Lab InchargePuneet G-man KoliNoch keine Bewertungen

- Wsc2011 Td06 CNC TurningDokument12 SeitenWsc2011 Td06 CNC Turningelectro3ergenNoch keine Bewertungen

- MP403 ComputerintegratedmanufacturingDokument3 SeitenMP403 ComputerintegratedmanufacturingAbhay SajeevNoch keine Bewertungen

- Manufacturing Engineering-II Course Code: 4341904: Page 1 of 11Dokument11 SeitenManufacturing Engineering-II Course Code: 4341904: Page 1 of 11Gest Account 08Noch keine Bewertungen

- Computer Integrated ManufacturingDokument2 SeitenComputer Integrated ManufacturingDhiren Patel100% (1)

- CNC Lab ManualDokument24 SeitenCNC Lab ManualyuvasujanNoch keine Bewertungen

- Mechanical Engg 19Dokument115 SeitenMechanical Engg 19Harshul BrahmbhattNoch keine Bewertungen

- SEP Course Book PDFDokument36 SeitenSEP Course Book PDFfandhiejavanov2009Noch keine Bewertungen

- The Aim of The Subject Is To Provide Knowledge in Computer Integrated ManufacturingDokument7 SeitenThe Aim of The Subject Is To Provide Knowledge in Computer Integrated ManufacturingKeerthe VaasanNoch keine Bewertungen

- Minnesota State College - Southeast Technical CPMT 2665: Advanced CAD/CAM IIDokument2 SeitenMinnesota State College - Southeast Technical CPMT 2665: Advanced CAD/CAM IIayariseifallahNoch keine Bewertungen

- Zaverecna PraceDokument45 SeitenZaverecna Pracevijay kumarNoch keine Bewertungen

- Amp MicroprojectDokument16 SeitenAmp MicroprojectishantNoch keine Bewertungen

- CNC Milling MachineDokument15 SeitenCNC Milling Machinenajieyuya91% (11)

- Computer Integrated Manufacturing NotesDokument49 SeitenComputer Integrated Manufacturing NotesGovind Ashokkumar100% (1)

- Lecture01 - CAD CAM - CAE - Introduction of The CourseDokument21 SeitenLecture01 - CAD CAM - CAE - Introduction of The CourseSameer shaikhNoch keine Bewertungen

- MAC 121 Introduction To CNCDokument2 SeitenMAC 121 Introduction To CNCayariseifallahNoch keine Bewertungen

- 4 CNC LatheDokument28 Seiten4 CNC LatheAmiruddinMohktarNoch keine Bewertungen

- Training at GTTC Hassan. by Shivaraj KDokument13 SeitenTraining at GTTC Hassan. by Shivaraj KSHASHANKA B SNoch keine Bewertungen

- CAM - Training (CNC Simulator)Dokument110 SeitenCAM - Training (CNC Simulator)farid_a_dzNoch keine Bewertungen

- CAD&MDokument2 SeitenCAD&MVarun ANoch keine Bewertungen

- Wk1 D1 9introduction To CNC Machines)Dokument62 SeitenWk1 D1 9introduction To CNC Machines)Mel ParasNoch keine Bewertungen

- Tech Ascend CNC Student ManualDokument42 SeitenTech Ascend CNC Student ManualabyzenNoch keine Bewertungen

- ME3310 CNC Technology L T P C 3 0 0 3Dokument1 SeiteME3310 CNC Technology L T P C 3 0 0 3sivaeinfoNoch keine Bewertungen

- MCNC 75C CNC Lathes & Horizontal Machining Centers Programming & Operation, 4th Rotary Axis, Fixture Design 4 1/2 Unit(s)Dokument4 SeitenMCNC 75C CNC Lathes & Horizontal Machining Centers Programming & Operation, 4th Rotary Axis, Fixture Design 4 1/2 Unit(s)taher ncirNoch keine Bewertungen

- Computer Aided Design 2 Mark Questions With AnswersDokument18 SeitenComputer Aided Design 2 Mark Questions With AnswersM.Thirunavukkarasu100% (4)

- Jit, Jimma University: Computer Aided Engineering AssignmentDokument8 SeitenJit, Jimma University: Computer Aided Engineering AssignmentGooftilaaAniJiraachuunkooYesusiinNoch keine Bewertungen

- Development of Canned Cycle For CNC Milling Machine: AbstractDokument9 SeitenDevelopment of Canned Cycle For CNC Milling Machine: AbstractandreNoch keine Bewertungen

- 1.cim Text BookDokument18 Seiten1.cim Text BookVinayakNoch keine Bewertungen

- NC Programming Lahe Course by TruongDokument2 SeitenNC Programming Lahe Course by TruongTrần Văn TrườngNoch keine Bewertungen

- Instructional Module 520Dokument8 SeitenInstructional Module 520api-274441692Noch keine Bewertungen

- BE Mechanical-Mumbai UniversityDokument82 SeitenBE Mechanical-Mumbai UniversityJayesh NavareNoch keine Bewertungen

- Guidelines Macro Teaching Evaluation Form Ef5 2009Dokument4 SeitenGuidelines Macro Teaching Evaluation Form Ef5 2009Shahril Affandi Mat YusofNoch keine Bewertungen

- Repairing Education Through TruthDokument9 SeitenRepairing Education Through Truthapi-259381516Noch keine Bewertungen

- 10 - Final ResumeDokument2 Seiten10 - Final Resumeapi-314251476Noch keine Bewertungen

- RPMS PPST Roll Out Action Plan TemplateDokument4 SeitenRPMS PPST Roll Out Action Plan TemplateDenward Pacia100% (5)

- Measurement Lesson Plan - Gallon ManDokument4 SeitenMeasurement Lesson Plan - Gallon Manapi-252918385100% (3)

- Interactive Learner Guide: Cambridge IGCSE History 0470Dokument62 SeitenInteractive Learner Guide: Cambridge IGCSE History 0470Aman Singh100% (1)

- SSC Regions As Per SSC NotificationDokument13 SeitenSSC Regions As Per SSC Notificationjethin.aNoch keine Bewertungen

- t1 I Advantages and Disadvantages of Using Instructional Materials in Teaching EslDokument2 Seitent1 I Advantages and Disadvantages of Using Instructional Materials in Teaching EslchiewjungNoch keine Bewertungen

- MAPEH DLL 3RD Grading 2018-2019 Week 25Dokument2 SeitenMAPEH DLL 3RD Grading 2018-2019 Week 25KingRem LustreNoch keine Bewertungen

- 103778-San Ignacio Elementary School: Department of Education Region 02 (Cagayan Valley)Dokument1 Seite103778-San Ignacio Elementary School: Department of Education Region 02 (Cagayan Valley)efraem reyesNoch keine Bewertungen

- 21st Century Literature DLLDokument3 Seiten21st Century Literature DLLJanella NuquiNoch keine Bewertungen

- Research Methods in ArchitectureDokument4 SeitenResearch Methods in ArchitecturedellcyberNoch keine Bewertungen

- Custodio Castro Elementary School: School Heads Monthly Instructional / Supervisory PlanDokument7 SeitenCustodio Castro Elementary School: School Heads Monthly Instructional / Supervisory PlanRodnel MonceraNoch keine Bewertungen

- BarneyDokument96 SeitenBarneyLiyanage AroshaniNoch keine Bewertungen

- Building Technology 05 (BT5 L/L) : Learner'S GuideDokument10 SeitenBuilding Technology 05 (BT5 L/L) : Learner'S GuideAna ArcangelNoch keine Bewertungen

- When Older Students Cant ReadDokument5 SeitenWhen Older Students Cant ReadcikckmanisNoch keine Bewertungen

- Medical Camp Sponsoship Proposal 2017Dokument5 SeitenMedical Camp Sponsoship Proposal 2017Joan MaryNoch keine Bewertungen

- 5054 s15 Ms 42Dokument3 Seiten5054 s15 Ms 42usama masood23Noch keine Bewertungen

- Lesson Plan Template UCLADokument7 SeitenLesson Plan Template UCLARobert DeAbreuNoch keine Bewertungen

- Agriculture Journal An Assessment of The Socio-Economic Impact of Maiganga Resettlement Scheme, Akko LGA, Gombe State, NigeriaDokument9 SeitenAgriculture Journal An Assessment of The Socio-Economic Impact of Maiganga Resettlement Scheme, Akko LGA, Gombe State, NigeriaAgriculture JournalNoch keine Bewertungen

- Wtia Iiw Iwe V3 - 0 PDFDokument2 SeitenWtia Iiw Iwe V3 - 0 PDFRizwan NazirNoch keine Bewertungen

- Cover LetterDokument2 SeitenCover Letterapi-319238480Noch keine Bewertungen

- Lesson 32 My BackpackDokument7 SeitenLesson 32 My BackpackDORA ELIANA TOBONNoch keine Bewertungen

- Checklist For Students at University College/university/vocational School and in Upper Secondary EducationDokument4 SeitenChecklist For Students at University College/university/vocational School and in Upper Secondary EducationNODARINoch keine Bewertungen

- Operational Plan Template. Assess 2 Part 2Dokument4 SeitenOperational Plan Template. Assess 2 Part 2Milena Maria Sarmiento Perez100% (3)

- Course Guide English 321Dokument4 SeitenCourse Guide English 321jackelinev51Noch keine Bewertungen

- Anthony Nnamdi Nwabuisi CV inDokument10 SeitenAnthony Nnamdi Nwabuisi CV inNwabuisiNoch keine Bewertungen

- Assessment of Learning Final Exam BacunawaDokument7 SeitenAssessment of Learning Final Exam BacunawaMeldrid BacunawaNoch keine Bewertungen

- AC315 Auditing & Assurance Principles-RPT-OBE-sem17 Theory HalfDokument15 SeitenAC315 Auditing & Assurance Principles-RPT-OBE-sem17 Theory HalfLalaine De JesusNoch keine Bewertungen

- Ha ResumeDokument2 SeitenHa Resumevr2114Noch keine Bewertungen