Beruflich Dokumente

Kultur Dokumente

Alkalinity

Hochgeladen von

Shahadat HossainCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alkalinity

Hochgeladen von

Shahadat HossainCopyright:

Verfügbare Formate

DRILLING FLUID TEST PROCEDURE

ALKALINITY

Acidity is one measure of alkalinity that is indicated by pH. However, the nature and amount of other

ions such as carbonate or bicarbonate can also affect mud filtrates alkalinity. For fresh water mud

systems these ions can be indicative of the rheological stability of such mud systems. Concentrations

of either ion can result in high, low shear rate viscosity (yield point) and high, progressive gel

strengths. Three methods can be employed for the determination of carbonate and bicarbonate

concentration. The very common Pf/Mf method is restricted to mud systems having a low organic

content whereas the P1/P2 method or the Garrett Gas Train may be used for better, more quantitative

analysis, especially in the systems with high organic content.

Pf/Mf Method

Equipment

Product Code

1.

2.

3.

4.

5.

6.

7.

8.

EY1120

EY1010

EY1060

EY1220

E10173

E10339

EN5900

E83102

Phenolphthalein

Bromocresol green indicator

Distilled water

Sulfuric acid N/50

Titration dish

Stirring rod

Pipette (1 ml)

Pipette safety bulb

Test Procedures

1.

Using a 1 ml pipette, measure 1 ml of filtrate into a titration dish.

2.

Add 2 to 3 drops of phenolphthalein indicator.

if no colour change occurs, then Pf = 0.0, continue to step 4

if a pink or red colour develops, Pf > 0.0, continue to step 3

3.

Using a pipette, add N/50 sulfuric acid continuously while swirling or stirring until the

sample changes from red to colourless, (or original filtrate tint). the number of ml of N/50

sulfuric acid required to reach this point is recorded as the Pf value.

4.

To the sample, which has been titrated to the Pf end point, add 2-3 drops of bromocresol

indicator to obtain a light blue colour. Continue titrating with swirling (or stirring) until the

colour changes from light blue to apple green, (pH = 4.0-4.5). This end point, which

includes the number of ml required to obtain the Pf end point is recorded as the Mf end

point.

DRILLING FLUID TEST PROCEDURE

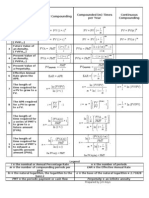

Calculations

Use the following table to estimate the carbonate, (CO3), bicarbonate, (HCO3), or hydroxyl, (OH),

present in the mud filtrate.

ALKALINITY

Pf/Mf Relation

Bicarbonate

(mg/l HCO3)

Carbonate

(mg/l CO3)

Hydroxyl

(mg/l OH)

Pf = 0

1220 x Mf

Pf = Mf

340 x Mf

2Pf = Mf

1200 x Pf

2Pf > Mf

1200(Mf - Pf)

340(2Pf - Mf)

2Pf < Mf

1220(Mf - 2Pf)

1200 x Pf

DRILLING FLUID TEST PROCEDURE

P1/P2 Method

Inorganic ions such as borate, silicate, sulfide, and phosphate ions can have a real effect on drilling

mud alkalinity. Additionally, organic compounds (e.g., anionic organic thinners, fluid loss additives, or

other polymers) and their degradation by-products may also affect the determination of the relative

amounts of carbonate, bicarbonate, or hydroxyl ions in solution. The P1/P2 method eliminates these

effects.

Equipment

Product Code

1.

2.

3.

4.

5.

6.

7.

8.

9.

EY1170

EY1000

EY1120

EY1220

E10173

E10339

EY1060

EN5900

E83102

Sodium hydroxide (0.2N)

Barium chloride

Phenolphthalein

Sulfuric acid (N/50)

Titration dish

Stirring rod

Distilled water

Pipette (1 ml)

Pipette safety bulb

Test Procedure

1.

Determine the Pf end point as outlined in step 1-3 of the Pf/Mf method. If the Pf = 0.0

there are no carbonates present.

2.

Place 1 ml of filtrate in a white titration dish and add 24 ml of distilled water.

3.

Add a measured 2 ml of 0.1N sodium hydroxide solution to convert all bicarbonates to

carbonates. Check the pH, if it is less than 11.5, continue to add 0.1N sodium hydroxide

in 1-2 ml increments until the pH exceeds 11.5. Make a record of the total amount of

sodium hydroxide added in this step.

4.

Add a measured amount of barium chloride to precipitate all the possible carbonates. Add

2-4 drops of phenolphthalein solution with stirring.

5.

Using a 1 ml pipette, titrate immediately to the end point with N/50 sulfuric acid. Record

the number of ml's of N/50 sulfuric acid added as the P1 end point.

6.

Place exactly the same amounts of 0.1N sodium hydroxide, barium chloride, and indicator

into 25 ml of distilled water and titrate to the end point using N/50 sulfuric acid and record

this as the P2 end point.

ALKALINITY

DRILLING FLUID TEST PROCEDURE

Calculations

Pf = 0.0, there are no carbonates present.

P1 > P2:

mg/l HCO3 = 0.0

mg/l CO3 = 1200 [Pf - (P1-P2)]

mg/l OH = 340 (P1 - P2)

P2 > P1:

mg/l OH = 0.0

mg/l CO3 = 1200 x Pf

mg/l HCO3 = l220(P2-P1)

WARNING: The reagents may be hazardous to the health and safety of the user if

inappropriately handled.

ALKALINITY

DRILLING FLUID TEST PROCEDURE

Garrett Gas Train Method

Either of the methods above is still subject to some error and certain situations may require yet

another method. The Garrett Gas Train separates gas from liquid, thereby preventing contamination

of the CO2 detecting Drger tube by the liquid phase. The CO2 Drger tube responds to the CO 2

passing through it by progressively staining (purple) along its length as the hydrazine chemical and

the CO2 react causing a methyl violet indicator to turn purple. The stain length is dependent on the

amount of CO2 present and the total gas volume that passed through the tube. Consequently, for

accurate results, the gas exiting the train must first be captured in a one-litre gasbag to allow the CO2

to mix uniformly with the carrier gas. Then the contents of the bag are drawn through the tube using

10 strokes of the Drger hand pump. This will draw exactly one (1) litre of gas through the tube.

Test Procedure

1.

Be sure the gas train is clean, dry and on a level surface.

2.

With the regulator T-handle backed off, install and puncture a N2 gas cartridge.

3.

Add 20 ml distilled water to chamber No. 1. (The chambers are numbered beginning at

the regulator).

4.

Add 5 drops of octanol defoamer to chamber No. 1.

5.

Install the top on the gas train and evenly hand tighten to seal all O-rings.

6.

Attach the flexible tubing from the regulator onto the dispersion tube of chamber No. 1.

7.

Inject with syringe, an accurately measured sample of filtrate into chamber No. 1. See

table below.

ALKALINITY

DRILLING FLUID TEST PROCEDURE

Drger Tube Identification

Carbonate

Range mg/l

Sample

Volume cm3

Drger Tube

Identification

Tube

Factor

25 - 750

1.0

CO2 100/a

2.5*

50 - 1500

5.0

250 - 7500

2.5

60 - 1020

10.0

CO2 0.2% o/a

0.12*

120 - 2040

240 - 4080

*Tube factor applies to new tubes, CO2 100/a with scale 100 to 3000. Old tubes use

tube factor 25,000.

8.

Flow carrier gas through the gas train for one minute to purge the system of air. Stop gas

flow.

9.

Install one end of a piece of flexible tubing onto the stopcock, which is fitted directly into

the gasbag. Have the gasbag fully collapsed. Fit the other end of the tubing onto the

outlet tube of chamber No. 3.

10.

Slowly inject 10 ml sulfuric acid solution into chamber No.1 through the septum using the

syringe and needle. Gently shake gas train to mix acid with sample in chamber No. 1.

11.

Open the stopcock on the gasbag. Restart nitrogen flow gently and allow the gasbag to

fill. When the bag is full, (DO NOT burst it) shut off and close the stopcock. Immediately

proceed to the next step.

12.

Remove the tubing from chamber No.3 outlet tube and re-install it onto upstream end of

the CO2 0.01%/A Drger tube. (Observe that the arrow indicates gas flow direction)

Attach Drger hand pump to other end of Drger tube.

13.

Open stopcock on bag. With a steady hand pressure fully depress the hand pump, then

release so that the gas flows out of the bag and through the Drger tube. Operate pump

ten times. This should essentially empty the bag.

14.

Observe a purple stain on the Drger tube if CO2 is present. Record the stain length in the

units marked on the Drger tube.

ALKALINITY

DRILLING FLUID TEST PROCEDURE

Calculations

mg/l CO3 = 25,000 x Tube stain length / ml sample volume

Care and Cleaning

To clean the gas train, remove the flexible tubing and gas train top. Wash out the chambers using a

brush with warm water and mild detergent. Use a pipe cleaner to clean the passages between the

chambers. Wash, rinse and then blow out the dispersion tube with air or nitrogen gas. Rinse the unit

with distilled water and allow to drain dry.

ALKALINITY

Das könnte Ihnen auch gefallen

- Ground WaterDokument29 SeitenGround WaterShahadat Hossain100% (2)

- Chapter 2: Literature ReviewDokument14 SeitenChapter 2: Literature ReviewShahadat HossainNoch keine Bewertungen

- TVM Formulas (I, N)Dokument2 SeitenTVM Formulas (I, N)basco23Noch keine Bewertungen

- Identify An Ore BodyDokument1 SeiteIdentify An Ore BodyShahadat HossainNoch keine Bewertungen

- Thesis ProposalDokument7 SeitenThesis ProposalShahadat HossainNoch keine Bewertungen

- AmbigramDokument13 SeitenAmbigramGayretli Münafık100% (2)

- Identify An Ore BodyDokument1 SeiteIdentify An Ore BodyShahadat HossainNoch keine Bewertungen

- CBM Book IntroDokument1 SeiteCBM Book IntroRihamNoch keine Bewertungen

- Preliminary Hazard AnalysisDokument26 SeitenPreliminary Hazard AnalysisShahadat HossainNoch keine Bewertungen

- Demonstration # 2Dokument11 SeitenDemonstration # 2Shahadat HossainNoch keine Bewertungen

- Report CBMDokument8 SeitenReport CBMShahadat HossainNoch keine Bewertungen

- Demonstration # 3Dokument5 SeitenDemonstration # 3Shahadat HossainNoch keine Bewertungen

- Dec - 14 Monthly Photo Ebook - AB Photography ClubDokument32 SeitenDec - 14 Monthly Photo Ebook - AB Photography ClubShahadat HossainNoch keine Bewertungen

- Demonstration # 2Dokument11 SeitenDemonstration # 2Shahadat HossainNoch keine Bewertungen

- Demonstration # 1Dokument18 SeitenDemonstration # 1Shahadat HossainNoch keine Bewertungen

- Bangladesh Fact Sheet PDFDokument4 SeitenBangladesh Fact Sheet PDFShahadat HossainNoch keine Bewertungen

- Demonstration # 1Dokument18 SeitenDemonstration # 1Shahadat HossainNoch keine Bewertungen

- Bangladesh Fact Sheet PDFDokument4 SeitenBangladesh Fact Sheet PDFShahadat HossainNoch keine Bewertungen

- ICC CWC 2015 Full FixturesDokument1 SeiteICC CWC 2015 Full FixtureszakirnagarNoch keine Bewertungen

- Well Logging TechDokument30 SeitenWell Logging TechfeliciaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- EDTA Titrations: Metal Chelate ComplexesDokument35 SeitenEDTA Titrations: Metal Chelate ComplexesJenny LlanesNoch keine Bewertungen

- Assertion and ReasonDokument12 SeitenAssertion and ReasonSamarpreetNoch keine Bewertungen

- MCQ WORKSHEET CH3 Metals Nonmetals AK converted-a92Z4eYUWwREEDokument3 SeitenMCQ WORKSHEET CH3 Metals Nonmetals AK converted-a92Z4eYUWwREEMohita RastogiNoch keine Bewertungen

- CSEC Chemistry January 2012 P032Dokument7 SeitenCSEC Chemistry January 2012 P032AshleyNoch keine Bewertungen

- 2016 Book NewApproachesToBuildingPatholo PDFDokument214 Seiten2016 Book NewApproachesToBuildingPatholo PDFCarlos Augusto Sanchez RondonNoch keine Bewertungen

- Group IV Chemistry-1Dokument18 SeitenGroup IV Chemistry-1SEBAGGALA YUNUSNoch keine Bewertungen

- 2Dokument5 Seiten2Egy RakhmasariNoch keine Bewertungen

- ZJC Form 1-2 Chemistry NotesDokument29 SeitenZJC Form 1-2 Chemistry NotesSalome Mupambirei100% (2)

- Ziprasidone CapsulesDokument4 SeitenZiprasidone CapsulesKasidit SornchaiNoch keine Bewertungen

- Edexcel AS Chemistry (Hodder) Data FilesDokument20 SeitenEdexcel AS Chemistry (Hodder) Data Filesdiscordsammy2Noch keine Bewertungen

- US4922043 Methyl ChlorideDokument7 SeitenUS4922043 Methyl ChlorideRizal EffendiNoch keine Bewertungen

- Chapter 18.3 Kognity PDFDokument21 SeitenChapter 18.3 Kognity PDFshiroi BPxTWNoch keine Bewertungen

- Iron Oxidation States ExperimentDokument2 SeitenIron Oxidation States ExperimentBarney slayNoch keine Bewertungen

- Cambridge IGCSE: Chemistry 0620/42Dokument15 SeitenCambridge IGCSE: Chemistry 0620/428d6b7pgyssNoch keine Bewertungen

- 1.B.2 Typical Reactions of AcidsDokument22 Seiten1.B.2 Typical Reactions of Acidsal katerjiNoch keine Bewertungen

- BS en Iso 6326-3-1998Dokument14 SeitenBS en Iso 6326-3-1998Rasool Fakhraei100% (1)

- Answer Key - Chemistry (KISA)Dokument8 SeitenAnswer Key - Chemistry (KISA)SwasthikNoch keine Bewertungen

- Experiment 9: Titration of AspirinDokument8 SeitenExperiment 9: Titration of AspirinSana CashmiriNoch keine Bewertungen

- CCE14 - Testing Salts For Anions and Student Handout PDFDokument3 SeitenCCE14 - Testing Salts For Anions and Student Handout PDFvNoch keine Bewertungen

- SolobilityDokument8 SeitenSolobilitygursinNoch keine Bewertungen

- THE COMPLETE General Science Notes (Chemistry) For Railway ExamsDokument54 SeitenTHE COMPLETE General Science Notes (Chemistry) For Railway ExamsChinmay JenaNoch keine Bewertungen

- Corrosion TheoryDokument42 SeitenCorrosion Theorygonvic7411Noch keine Bewertungen

- YslhalfdhaldhaoldhoaDokument30 SeitenYslhalfdhaldhaoldhoaG M Ali KawsarNoch keine Bewertungen

- CH 10 and 11 Acid-Base QuestionsDokument8 SeitenCH 10 and 11 Acid-Base QuestionsNap DoNoch keine Bewertungen

- Chemistry Project To Study Effect of Metal Coupling On CorrosionDokument3 SeitenChemistry Project To Study Effect of Metal Coupling On CorrosionSreeja SatheeshNoch keine Bewertungen

- PolycarbonateDokument13 SeitenPolycarbonateAdriana Lucia NavarroNoch keine Bewertungen

- Molecular Cell Biology Lodish 7th Edition Solutions ManualDokument7 SeitenMolecular Cell Biology Lodish 7th Edition Solutions ManualHeather Jamili100% (37)

- Testing reactions of the hydrogen sulfide groupDokument23 SeitenTesting reactions of the hydrogen sulfide groupsampong mga dalere100% (1)

- Chemical Compound Formula - Formula ChartDokument69 SeitenChemical Compound Formula - Formula Chartdev sutharNoch keine Bewertungen

- Objectives of HydrometallurgyDokument14 SeitenObjectives of HydrometallurgyAnubhav ChandilNoch keine Bewertungen