Beruflich Dokumente

Kultur Dokumente

Choosing A Sampling Plan With Given OCR

Hochgeladen von

aaro_oraal0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

57 Ansichten6 SeitenChoosing a Sampling Plan

Originaltitel

Choosing a Sampling Plan With Given OCR

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenChoosing a Sampling Plan

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

57 Ansichten6 SeitenChoosing A Sampling Plan With Given OCR

Hochgeladen von

aaro_oraalChoosing a Sampling Plan

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

1 of 6

6. Process or Product Monitoring and Control

6.2. Test Product for Acceptability: Lot Acceptance Sampling

6.2.3. How do you Choose a Single Sampling Plan?

Sample

OC

curve

We start by looking at a typical OC curve. The OC curve for a (52 ,3)

sampling plan is shown below.

Number of

defectives is

approximately

binomial

It is instructive to show how the points on this curve are

obtained, once we have a sampling plan (n,c) - later we will

demonstrate how a sampling plan (n,c) is obtained.

We assume that the lot size N is very large, as compared to

the sample size n, so that removing the sample doesn't

significantly change the remainder of the lot, no matter how

many defects are in the sample. Then the distribution of the

number of defectives, d, in a random sample of n items is

approximately binomial with parameters n and p, where p is

the fraction of defectives per lot.

The probability of observing exactly d defectives is given

by

2 of 6

The binomial

distribution

The probability of acceptance is the probability that d, the

number of defectives, is less than or equal to c, the accept

number. This means that

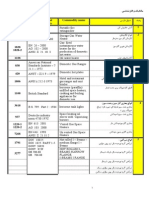

Sample table

for Pa, Pd

using the

binomial

distribution

Using this formula with n = 52 and c=3 and p = .01, .02,

...,.12 we find

Pa

Pd

.998

.980

.930

.845

.739

.620

.502

.394

.300

.223

.162

.115

.01

.02

.03

.04

.05

.06

.07

.08

.09

.10

.11

.12

Solving for (n,c)

Equations for

calculating a

sampling plan

with a given

OC curve

In order to design a sampling plan with a specified OC

curve one needs two designated points. Let us design a

sampling plan such that the probability of acceptance is 1for lots with fraction defective p1 and the probability of

acceptance is

for lots with fraction defective p2. Typical

choices for these points are: p1 is the AQL, p2 is the LTPD

and , are the Producer's Risk (Type I error) and

Consumer's Risk (Type II error), respectively.

If we are willing to assume that binomial sampling is valid,

then the sample size n, and the acceptance number c are the

solution to

3 of 6

These two simultaneous equations are nonlinear so there is

no simple, direct solution. There are however a number of

iterative techniques available that give approximate

solutions so that composition of a computer program poses

few problems.

Average Outgoing Quality (AOQ)

Calculating

AOQ's

We can also calculate the AOQ for a (n,c) sampling plan,

provided rejected lots are 100% inspected and defectives are

replaced with good parts.

Assume all lots come in with exactly a p0 proportion of

defectives. After screening a rejected lot, the final fraction

defectives will be zero for that lot. However, accepted lots

have fraction defectivep0. Therefore, the outgoing lots from

the inspection stations are a mixture of lots with fractions

defective p0 and 0. Assuming the lot size is N, we have.

For example, let N = 10000, n = 52, c = 3, and p, the quality

of incoming lots, = 0.03. Now at p = 0.03, we glean from

the OC curve table that pa = 0.930 and

AOQ = (.930)(.03)(10000-52) / 10000 = 0.02775.

Sample table

of AOQ

versus p

Setting p = .01, .02, ..., .12, we can generate the following

table

AOQ

.0010

.0196

.0278

.0338

.0369

p

.01

.02

.03

.04

.05

4 of 6

.0372

.0351

.0315

.0270

.0223

.0178

.0138

.06

.07

.08

.09

.10

.11

.12

Sample plot

of AOQ

versus p

A plot of the AOQ versus p is given below.

Interpretation

of AOQ plot

From examining this curve we observe that when the

incoming quality is very good (very small fraction of

defectives coming in), then the outgoing quality is also very

good (very small fraction of defectives going out). When

the incoming lot quality is very bad, most of the lots are

rejected and then inspected. The "duds" are eliminated or

replaced by good ones, so that the quality of the outgoing

lots, the AOQ, becomes very good. In between these

extremes, the AOQ rises, reaches a maximum, and then

drops.

The maximum ordinate on the AOQ curve represents the

worst possible quality that results from the rectifying

inspection program. It is called the average outgoing

quality limit, (AOQL ).

From the table we see that the AOQL = 0.0372 at p = .06 for

the above example.

One final remark: if N >> n, then the AOQ ~ pa p .

5 of 6

The Average Total Inspection (ATI)

Calculating

the Average

Total

Inspection

What is the total amount of inspection when rejected lots

are screened?

If all lots contain zero defectives, no lot will be rejected.

If all items are defective, all lots will be inspected, and the

amount to be inspected is N.

Finally, if the lot quality is 0 < p < 1, the average amount of

inspection per lot will vary between the sample size n, and

the lot size N.

Let the quality of the lot be p and the probability of lot

acceptance be pa, then the ATI per lot is

ATI = n + (1 - pa) (N - n)

For example, let N = 10000, n = 52, c = 3, and p = .03 We

know from the OC table that pa = 0.930. Then ATI = 52 +

(1-.930) (10000 - 52) = 753. (Note that while 0.930 was

rounded to three decimal places, 753 was obtained using

more decimal places.)

Sample table

of ATI versus

p

Setting p= .01, .02, ....14 generates the following table

ATI

P

70

.01

253

.02

753

.03

1584 .04

2655 .05

3836 .06

5007 .07

6083 .08

7012 .09

7779 .10

8388 .11

8854 .12

9201 .13

9453 .14

6 of 6

Plot of ATI

versus p

A plot of ATI versus p, the Incoming Lot Quality (ILQ) is

given below.

Das könnte Ihnen auch gefallen

- G T Deshpande - AbhinavaguptaDokument183 SeitenG T Deshpande - Abhinavaguptaaaro_oraal100% (3)

- The OC Curve of Attribute Acceptance PlansDokument7 SeitenThe OC Curve of Attribute Acceptance PlansOusmane CisseNoch keine Bewertungen

- Poisson Interval Distribution and Random Walks discussionDokument8 SeitenPoisson Interval Distribution and Random Walks discussionaaro_oraalNoch keine Bewertungen

- Marxs Economics For Anarchists Wayne Price ReadDokument86 SeitenMarxs Economics For Anarchists Wayne Price ReadAchilleKarangwaNoch keine Bewertungen

- A Semiotic Satan's Tango (On Semitotic Diads in Satantango)Dokument4 SeitenA Semiotic Satan's Tango (On Semitotic Diads in Satantango)aaro_oraalNoch keine Bewertungen

- Sterility 63601 Tetra Pak DocumentDokument16 SeitenSterility 63601 Tetra Pak Documentaaro_oraal100% (1)

- Poisson Interval Distribution and Random Walks discussionDokument8 SeitenPoisson Interval Distribution and Random Walks discussionaaro_oraalNoch keine Bewertungen

- Clash of GlobalisationsDokument336 SeitenClash of GlobalisationsAnamariaCioanca100% (5)

- QAM Sampling Recommendations for Low and High Acid ProductsDokument4 SeitenQAM Sampling Recommendations for Low and High Acid Productsaaro_oraalNoch keine Bewertungen

- Cultural Politics Peter SloterdijkDokument128 SeitenCultural Politics Peter Sloterdijknetdogstar6388100% (3)

- András Bálint Kovács - The World According To Béla TarrDokument11 SeitenAndrás Bálint Kovács - The World According To Béla Tarraaro_oraalNoch keine Bewertungen

- James Joll-The AnarchistsDokument193 SeitenJames Joll-The Anarchistsaaro_oraalNoch keine Bewertungen

- Jorge A. Pino - Volatile Components From Mango (Mangifera Indica L.) CultivarsDokument11 SeitenJorge A. Pino - Volatile Components From Mango (Mangifera Indica L.) Cultivarsaaro_oraalNoch keine Bewertungen

- Kafka - Blue Octavo NotebooksDokument80 SeitenKafka - Blue Octavo NotebooksTimothy LavenzNoch keine Bewertungen

- Social Impacts EmailDokument36 SeitenSocial Impacts Emailaaro_oraalNoch keine Bewertungen

- Falling Down, Walking, Destroying, Thinking - A Conversation With Béla TarrDokument8 SeitenFalling Down, Walking, Destroying, Thinking - A Conversation With Béla Tarraaro_oraalNoch keine Bewertungen

- RMM Product Matrix - Rapid Microbiology and Rapid Microbiological MethodsDokument14 SeitenRMM Product Matrix - Rapid Microbiology and Rapid Microbiological Methodsaaro_oraal100% (1)

- SHX9ER55UCDokument2 SeitenSHX9ER55UCaaro_oraalNoch keine Bewertungen

- TARCOG Mathematical Models for Calculating Thermal Performance of Glazing SystemsDokument56 SeitenTARCOG Mathematical Models for Calculating Thermal Performance of Glazing Systemsaaro_oraalNoch keine Bewertungen

- Essential Guide to Food Equipment CleaningDokument11 SeitenEssential Guide to Food Equipment Cleaningaaro_oraalNoch keine Bewertungen

- BEJS - Issue 1.1 Syed Anwr HusainDokument4 SeitenBEJS - Issue 1.1 Syed Anwr Husainaaro_oraalNoch keine Bewertungen

- Monitoring Spores and Spore-Forming Bacteria Populations in CommeDokument1 SeiteMonitoring Spores and Spore-Forming Bacteria Populations in Commeaaro_oraalNoch keine Bewertungen

- Interpreting The WorldDokument7 SeitenInterpreting The Worldaaro_oraalNoch keine Bewertungen

- ENSaderatDokument37 SeitenENSaderataaro_oraalNoch keine Bewertungen

- Eikhenbaum The Theory of The Formal MethodDokument4 SeitenEikhenbaum The Theory of The Formal Methodplume1978Noch keine Bewertungen

- A Semiotic Satan's Tango (On Semitotic Diads in Satantango)Dokument4 SeitenA Semiotic Satan's Tango (On Semitotic Diads in Satantango)aaro_oraalNoch keine Bewertungen

- Communitarianism and LiberalismDokument4 SeitenCommunitarianism and Liberalismaaro_oraalNoch keine Bewertungen

- Aesthetics and Homo MobilisDokument15 SeitenAesthetics and Homo Mobilisaaro_oraalNoch keine Bewertungen

- Sizing Shell and Tube Heat ExchangerDokument17 SeitenSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Monte Carlo SimulationDokument9 SeitenMonte Carlo SimulationDika DevintasariNoch keine Bewertungen

- (R. H. G. Jongman, C. J. F. Ter Braak, O. F. R. Va PDFDokument321 Seiten(R. H. G. Jongman, C. J. F. Ter Braak, O. F. R. Va PDFPabloDarlanNoch keine Bewertungen

- Midterm Quiz 1 - Attempt ReviewDokument4 SeitenMidterm Quiz 1 - Attempt ReviewSharila GaluteraNoch keine Bewertungen

- The Use and Misuse of SEMDokument30 SeitenThe Use and Misuse of SEMPPDTBM renNoch keine Bewertungen

- I2ml3e Chap19Dokument33 SeitenI2ml3e Chap19EMS Metalworking MachineryNoch keine Bewertungen

- Estimating The Economic Model of Crime With Panel Data: June 2019Dokument12 SeitenEstimating The Economic Model of Crime With Panel Data: June 2019aiNoch keine Bewertungen

- J. K. Sharma - Business Statistics-Pearson Education (2007)Dokument98 SeitenJ. K. Sharma - Business Statistics-Pearson Education (2007)Sujal SinghNoch keine Bewertungen

- Unit 6 IDokument33 SeitenUnit 6 Iankit mehtaNoch keine Bewertungen

- EconometricsDokument300 SeitenEconometricsmriley@gmail.com100% (4)

- FFM15, CH 08 (Risk), Chapter Model, 2-08-18Dokument16 SeitenFFM15, CH 08 (Risk), Chapter Model, 2-08-18ALFINA BUDI RAHMADANINoch keine Bewertungen

- Weighted Regression of Calibration CurveDokument2 SeitenWeighted Regression of Calibration CurveBaharnarenj11Noch keine Bewertungen

- Biostatistics and ExerciseDokument97 SeitenBiostatistics and ExerciseMINANI Theobald100% (4)

- 613 PDokument2 Seiten613 PAman ChhedaNoch keine Bewertungen

- Answers and Solutions To ExercisesDokument14 SeitenAnswers and Solutions To Exercisesmuhammad agungNoch keine Bewertungen

- Presentation 2Dokument27 SeitenPresentation 2Henok AsemahugnNoch keine Bewertungen

- Racaza CKL1 Laboratory3Dokument2 SeitenRacaza CKL1 Laboratory3Jevan Monte RacazaNoch keine Bewertungen

- Statistics 1Dokument149 SeitenStatistics 1Zaid AhmedNoch keine Bewertungen

- Chapter 19, Factor AnalysisDokument7 SeitenChapter 19, Factor AnalysisKANIKA GORAYANoch keine Bewertungen

- Stationarity and Unit Root TestingDokument21 SeitenStationarity and Unit Root TestingAwAtef LHNoch keine Bewertungen

- Community Project: Friedman TestDokument3 SeitenCommunity Project: Friedman TestLeah Mae AgustinNoch keine Bewertungen

- Final Project - Group 1Dokument6 SeitenFinal Project - Group 1Ana ChikovaniNoch keine Bewertungen

- Chapter 8Dokument30 SeitenChapter 8Yusuf Sa'ad MuhammadNoch keine Bewertungen

- Biostatistics Module-1 PDFDokument13 SeitenBiostatistics Module-1 PDFHenrique MartinsNoch keine Bewertungen

- Machine Learning and Data Mining: Prof. Alexander IhlerDokument51 SeitenMachine Learning and Data Mining: Prof. Alexander IhlerSuraj PatilNoch keine Bewertungen

- Chapter 4 - RevisionDokument3 SeitenChapter 4 - Revisionjeremias marticioNoch keine Bewertungen

- Midterm Exam - Probability and StatisticsDokument2 SeitenMidterm Exam - Probability and StatisticsManuel John SorianoNoch keine Bewertungen

- Correlation vs CausationDokument8 SeitenCorrelation vs CausationelegadoNoch keine Bewertungen

- ANSWER SCHEME TEST STA404 JULY 2021 LatestDokument3 SeitenANSWER SCHEME TEST STA404 JULY 2021 LatestNURUL AIN ABDULL MANANNoch keine Bewertungen

- Practice Exam FinalDokument11 SeitenPractice Exam FinalMagalyIpiñaNoch keine Bewertungen

- CH 10 RevisedDokument3 SeitenCH 10 RevisedRestu AnggrainiNoch keine Bewertungen