Beruflich Dokumente

Kultur Dokumente

GEneral Welding System Requirements

Hochgeladen von

vominhthaiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GEneral Welding System Requirements

Hochgeladen von

vominhthaiCopyright:

Verfügbare Formate

CURRENT BEST APPROACH

P&G

General Welding System Requirements

Number:

Page:

Eff. Date:

Network Owner:

WE01

Page 1 of 6

11/05/2012

Welding

I. SCOPE

PURPOSE

This CBA provides guidelines for safe welded fabrication. These guidelines are in compliance with legally

required, as well as local and nationally recognized construction codes and P&G practices. This CBA also

provides welding management guidelines.

A written site welding system must be implemented for control of welding quality consistent with this and other

P&G Welding CBAs. Specific System requirements can be found in WE02.

NOTE requirements in this document also apply to brazing activities.

Project managers, site engineers, welding inspectors, purchasing managers, and the site welding system

owner need to use this CBA. This will help to ensure that welding related activities are done properly and cost

effectively. This includes design, fabrication, erection, examination, testing and inspection. Utilizing this CBA

will also help increase site reliability.

Welding is a skill that requires extensive training and experience. Continual use of welding skills is needed to

maintain the expertise in metal joining. A minimum number of welders should be qualified consistent with the

quantity and type of welding processes and joints to be done. For a qualified welder to maintain code

certification and quality requirements, a considerable number of hours should be devoted to welding. Workers

who only occasionally weld have difficulty meeting qualification requirements of legal construction codes and

increase the maintenance or construction costs to the site due to rework and repair.

Welding examination, testing and inspection is necessary to help ensure proper execution. It is required by

the construction codes and standards.

II. RESOURCES

P&G Corporate Welding & Fabrication Engineering (CWFE) is the owner of this CBA. Contact CWFE for

guidance and clarifications. For Welding Engineering Support go to

http://vcs.pg.com/ext/GEX/Weld/default.aspx

III. APPROACH

1.

COVERAGE

This Welding CBA assists with implementation of the company global policies of:

a. P&G insists on safe operation, and

b. P&G operates within the law.

Sites must have a written system to implement this Welding CBA. This CBA covers the following

welding topics for fabricated equipment, systems and structures in company installations: design,

fabrication, on-site construction, site maintenance (rework/repair), failure analysis, inspection and

testing.

Sites must comply with the requirements of all National, Federal, State, and local construction codes

and standards having jurisdiction.

The following paragraphs contained in this Welding CBA and other Welding CBAs assure compliance

in most locations.

Page 1 of 6

CURRENT BEST APPROACH

P&G

2.

General Welding System Requirements

Number:

Page:

Eff. Date:

Network Owner:

WE01

Page 2 of 6

11/05/2012

Welding

Terms and Definitions

Responsibility

Welding Inspectors

Welding Procedure and Welder Performance Qualification

Procurement of Fabricated Equipment

Construction Welding Quality Practice

Assist with Audits of Site Technical Safety Programs and Surveys of Construction Welding

Programs

TERMS & DEFINITIONS

The following terms and titles used in this company practice have the following meaning:

2.1

Site Welding System : A written system to be implemented for control of welding quality consistent

with this Welding CBA. The system should address operating standards, practices, CBAs, systems

and resources. See WE02, Site Welding System Requirements for welding management guidelines

which are in compliance with legally required, as well as local and nationally recognized construction

codes and P&G practices. Guidelines are based upon different levels of welding risk. This will help to

ensure that welding related activities are done properly. This includes design, fabrication, erection,

examination, testing and inspection. Utilizing this will also help site reliability.

2.2

Welding Engineer: A P&G Corporate Welding Engineer from Corporate Functions, Project

Technologies & Systems Department (PT&S), Construction & Welding Engineering Section.

2.3

Qualified Welder/Welding Operator: A person who has demonstrated the ability to deposit sound weld

metal by passing the requirements of a specific performance qualification test as prescribed the

requirements of any National, State, and local construction codes having jurisdiction. In cases where

this is not covered by law; the welding performance qualifications must meet the requirements of US,

Japanese or European Common Market standards. Refer to CBA WE04 Performance Qualification of

Welders.

2.4

Certification: confirmation that some fact or statement is true through the use of documentary

evidence.

2.5

Welding Inspector: A person who is certified, and has the ability to qualify welders and determine

welding quality in accordance with predefined specifications. Refer to CBA WE03, Welding Inspectors,

for responsibilities and certification requirements.

2.6

Welding System Owner: A P&G employee who is responsible for a Site's Welding System. Welding

System Owner training and certification is outlined in the HS&E webpage:

http://intraprod1.internal.pg.com/technet/tech_dev/Engineer/HSE/KnowledgeSystems/KS_WELD/WEL

D_INDEX.htm .

2.7

Site: manufacturing plants, corporate buildings, technical centers, and similar facilities.

3.

RESPONSIBILITY

3.1

Sites are responsible for:

a. Ensuring safe, legal, and code compliant use of welded fabrications in P&G facilities.

b. Allocation of resources necessary to implement and execute the Welding System and related

CBAs at the site level.

c.

Owning the process of selection, training and qualification of the site Welding System Owner and

all site Welding Inspectors (P&G and contractor).

Page 2 of 6

CURRENT BEST APPROACH

P&G

General Welding System Requirements

Number:

Page:

Eff. Date:

Network Owner:

WE01

Page 3 of 6

11/05/2012

Welding

d. Following legally required construction codes and standards in their country or region. Including a

Welding Section in the Construction Quality Management Plan to insure compliance with P&G

Welding CBAs.

e. Ensuring appropriate qualification of Project Welding Inspectors.

f.

3.2

Arranging for involvement of Welding Engineering for assistance in defining special welding

requirements on projects requiring their level of expertise.

Site and Technical Building Welding System Owner is responsible for:

a. Meeting the requirements of the HS&E Welding Systems Operation & Maintenance checklist.

b. Recognizes welding/brazing defects, corrosion, failure mechanisms, causes, and corrective

action.

c.

Trains people on site welding/brazing requirements, safe procedures, and hot work permits (as

required).

d. Ensures that welding/brazing on boilers and code vessels is done by code shops with appropriate

code stamps and certifications. This applies to some tanks and piping systems if required by local

codes.

e. States who the corporate welding resources are and when to contact them.

f.

Selects a qualified welding inspector when needed.

g. Monitors site welding system compliance with CBAs and code and legal requirements.

h. Works with Project Managers to select welding contractors and contract welding inspectors.

NOTES:

a. In some countries and/or regions, governmental agencies or a P&G regional resource may

have some of the responsibilities shown above.

b. The Welding System Owner may be a Welding Inspector (if qualified/certified as both).

3.3

Corporate Welding Engineering Global Responsibility:

a. Determine which countries require P&G Welding Engineering oversight for pressure vessels,

hazardous systems and/or building integrity versus utilizing Government provided

agencies/systems to insure code compliance.

b. For fabricated equipment requiring P&G Welding Engineering oversight*:

Specify training and qualification requirements for field welders and welding inspectors.

- Provide concurrence to the selection and approve the P&G certification of Welding Inspectors

(both P&G and contractor).

Development of P&G standard welding practices and concurrence to deviations by

businesses

* This equipment includes: tanks, PVs, piping and other components fabricated from materials

other than mild steel or 300 series stainless steel; equipment for hazardous service; field erected

tanks; sanitary fabrication; and equipment where reliability is unusually critical.

c.

Own the Corporate Welding CBAs

d. Define P&Gs Welding Procedure Specifications

Page 3 of 6

CURRENT BEST APPROACH

P&G

General Welding System Requirements

Number:

Page:

Eff. Date:

Network Owner:

WE01

Page 4 of 6

11/05/2012

Welding

e. Understand construction code requirements in countries where we have the majority of our

welding fabrication work performed. This includes code design, fabrication, testing, examination

and inspection requirements.

f.

Provide high-level technical expertise to businesses concerning welding fabrication, equipment

repair, non-destructive examination, and failure analysis and code requirements.

g. Evaluate and approve Company pre-qualified fabrication shops, and manage this information via

a pre-qualified vendors list.

h. Ensure a satisfactory remedy is applied when the Welding Engineer discovers the design or

quality of fabricated equipment may have an actual or potentially harmful effect on human safety,

or does not meet legal requirements (construction codes, standards).

i.

Ensure a satisfactory remedy is put in place if systemic welding related issues in critical areas

become apparent. Critical areas include, but are not limited to: P&G defined Class I chemical

systems, building integrity and code/standard compliance.

j.

Periodically review business incident databases to determine if systemic issues are developing in

countries.

k.

Provide P&Gs interpretation of matters relating to compliance of welding construction codes and

standards.

l.

Work to find new and more efficient ways P&G can leverage welding to improve TDC and save

capital expenditures.

m. Provide concurrence to the selection and approve the P&G certification of Welding System

Owners.

n. Facilitate a welding network to efficiently transfer and/or share welding knowledge within P&G.

3.4

When requested by GBU Project Managers or site personnel, the Corporate Welding Engineers can

(based on priority):

a. Conduct surveys of Construction Welding Plans.

b. Conduct surveys of site welding quality control practices as requested to supplement Technical

Safety Program audits.

c.

Provide review and approval of vendor and contractor welding procedures.

d. Specify the level and amount of inspection required for purchases of welded fabrications.

e. On complex welding projects: Provide a welding section for the Construction Quality Management

Plan for construction projects. Develop project specific welding performance criteria for fixed bid

packages. Provide review and approval of welding designs for fabricated equipment.

3.5

When does Welding & Fabrication Engineering need to be involved in projects? See Appendix A

4.

WELDING INSPECTORS

Page 4 of 6

CURRENT BEST APPROACH

P&G

General Welding System Requirements

Number:

Page:

Eff. Date:

Network Owner:

WE01

Page 5 of 6

11/05/2012

Welding

Verification of correct execution of welding activities must be performed by a properly qualified and

certified welding inspector on a frequency that assures construction code and company standards

compliance. Details of certification and responsibilities of the Welding Inspector are defined in CBA

WE03 Welding Inspectors.

5.

WELDING PROCEDURES

Practices for Welding Procedure Qualification and Use are located in CBA WE08.

6.

WELDER PERFORMANCE QUALIFICATIONS

Practices for qualification and re-qualification are located in CBA WE04 Performance Qualification of

Welders.

7.

PROCUREMENT OF FABRICATED EQUIPMENT

All fabrication inquiries and purchase orders must include weld quality acceptance criteria; normally

contained in nationally recognized construction codes and standards. WE05 Specification for

Purchase of Fabricated Equipment, Structures and Components, should be a part of the standards

provided.

8.

MAINTENANCE OF EQUIPMENT

When maintenance involving welding related processes is necessary to be performed on fabricated

equipment, it is defined as either rework or repair. Rework is defined as restoring the equipment to

the original condition and specification(s), while repair makes the equipment functional, but not to the

original condition and specification(s). Maintenance of equipment must follow the outline and guide(s)

shown in P&G Welding CBA WE07, Fabrication Guidelines for Maintenance of Equipment.

9.

SAFETY

There are hazards associated with welding, brazing and cutting. As a minimum, legally required, local

and nationally recognized safety standards/codes must be followed. Welding/Hot Work permits must

be used to make certain proper safety precautions are taken before and during welding operations.

One industrial standard used in the area of welding safety is the American Welding Society (AWS)

Standard, American National Standard ANSI/ASC Z49.1 "Safety in Welding and Cutting". This

standard covers aspects of safety and health in the welding environment, emphasizing oxygen gas

and arc welding processes. It contains information on protection of personnel and the general area,

ventilation, fire prevention and protection, and confined spaces. ANSI/ASC Z49.1 "Safety in Welding

and Cutting" is a voluntary consensus standard that has been developed in accordance with the rules

of the American National Standards Institute. Other welding safety standards may exist in regions

other than North America.

Page 5 of 6

CURRENT BEST APPROACH

P&G

General Welding System Requirements

Number:

Page:

Eff. Date:

Network Owner:

WE01

Page 6 of 6

11/05/2012

Welding

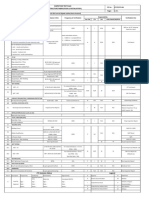

APPENDIX A - When Does P&G Welding & Fabrication Engineering Need to be Involved in a Project?

"Involvement" starts with a discussion to determine what and how, if anything, needs to be done by

P&G Welding Engineering. The "Project" may be a capital project, a maintenance project, or a

combination of both. There is significant opportunity to save capital and/or improve project results by

using this process.

CRITERIA: If "YES" to one or more, then contact Welding Engineer.

1. New technology at the site?

2. Not sure that the site has the skills or experience for the review

3. Need construction welding inspector (CWI or equivalent)

4. Project with a 10 or more contractor welders and/or more than $100M worth of vendor fabrication

5. Proprietary or special welded fabrication

6. New fabricators, not on P&G "pre-qualified" list

7. For tanks, pressure vessels, piping, machinery, etc.:

- materials other than carbon/mild steel or austenitic stainless steel

- Hazardous service (OSHA 1910.119, pressure > 300 psi, etc.)

- FDA (USA) or sanitary fabrication

- reliability of welded equipment is unusually critical

8. Field erected tanks

NOTE: When the project is a reapplication or direct repeat of something recently completed, the

need for or scope of involvement will be reduced or in some cases eliminated. However, a short

discussion about the need for involvement is still appropriate.

Page 6 of 6

Das könnte Ihnen auch gefallen

- Method of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Dokument17 SeitenMethod of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Sherief Abd El Baky83% (12)

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- Job Description - Pressure Vessel Design EngineerDokument3 SeitenJob Description - Pressure Vessel Design EngineerPankaj SinglaNoch keine Bewertungen

- Catalog Valve ToyoDokument28 SeitenCatalog Valve ToyoMustafa Kamal100% (1)

- Planned Parenthood Response To DHHDokument5 SeitenPlanned Parenthood Response To DHHKevin LittenNoch keine Bewertungen

- HaarslevDokument12 SeitenHaarslevjimdacalano1911Noch keine Bewertungen

- Cswip QuestionDokument3 SeitenCswip Questionfasith9534Noch keine Bewertungen

- Golden WeldsDokument5 SeitenGolden WeldsRe SinNoch keine Bewertungen

- Approved Weld Procedure SpecificationsDokument38 SeitenApproved Weld Procedure SpecificationsJohan0001Noch keine Bewertungen

- Stage 1 - Welding Inspection Prior To Welding WorkDokument7 SeitenStage 1 - Welding Inspection Prior To Welding WorkIrvansyah RazadinNoch keine Bewertungen

- AKP Storage TanksDokument51 SeitenAKP Storage Tankscris_2010Noch keine Bewertungen

- Ss Pipe WeldingDokument3 SeitenSs Pipe WeldingshridharbshenoyNoch keine Bewertungen

- Weld Repair ProcedureDokument51 SeitenWeld Repair Proceduremohd as shahiddin jafriNoch keine Bewertungen

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDokument3 SeitenSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNoch keine Bewertungen

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDokument26 SeitenNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNoch keine Bewertungen

- Lesson 14 WelderQuals - New2Dokument80 SeitenLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- General Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelsDokument14 SeitenGeneral Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelspawanNoch keine Bewertungen

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Dokument6 SeitenRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNoch keine Bewertungen

- The Welding Inspection Services Are Define in Three Stages As BelowDokument9 SeitenThe Welding Inspection Services Are Define in Three Stages As BelowdeliNoch keine Bewertungen

- Job Description NDTDokument4 SeitenJob Description NDTNDTInstructorNoch keine Bewertungen

- Weld Cleaning MethodsDokument7 SeitenWeld Cleaning MethodsTrần Thùy LinhNoch keine Bewertungen

- Auditing Oof Welding Under ASME Section IXDokument21 SeitenAuditing Oof Welding Under ASME Section IXsabahiraqNoch keine Bewertungen

- FactoryDokument72 SeitenFactorywhitebrosNoch keine Bewertungen

- PBI-WI 005 Dimensional Control Procedure Rev.0Dokument5 SeitenPBI-WI 005 Dimensional Control Procedure Rev.0Tadaya KasaharaNoch keine Bewertungen

- QAQC Questions & AnswersDokument5 SeitenQAQC Questions & Answersnafis2uNoch keine Bewertungen

- Hot Dip GalvanizingDokument3 SeitenHot Dip Galvanizingapply19842371Noch keine Bewertungen

- Quality Assurance Audit For Piping FabricationDokument3 SeitenQuality Assurance Audit For Piping Fabricationapply19842371Noch keine Bewertungen

- WELDINGDokument4 SeitenWELDINGArputharaj Maria LouisNoch keine Bewertungen

- Contents Dossier Painting of PipesDokument1 SeiteContents Dossier Painting of PipesDemetrio RodriguezNoch keine Bewertungen

- Welding Inspector Job and ResponsilbilitiesDokument5 SeitenWelding Inspector Job and ResponsilbilitiesFelix GomintongNoch keine Bewertungen

- Samples ITPDokument4 SeitenSamples ITPHassan SajidNoch keine Bewertungen

- Certificate of Welding InspectorDokument1 SeiteCertificate of Welding InspectortuatkNoch keine Bewertungen

- Preguntas Al Comite API 1104Dokument12 SeitenPreguntas Al Comite API 1104alefeli26Noch keine Bewertungen

- 2.1. Material Identification and Traceability - American Institute of Steel ConstructionDokument2 Seiten2.1. Material Identification and Traceability - American Institute of Steel ConstructionMuhammed Abo-FandoodNoch keine Bewertungen

- Sop Welding RevisiDokument12 SeitenSop Welding RevisifandyNoch keine Bewertungen

- WACEL Structural Steel Study GuideDokument11 SeitenWACEL Structural Steel Study GuideAnkur Patel100% (1)

- QC Sample Manual GenericDokument34 SeitenQC Sample Manual GenericIan Stewart PorterNoch keine Bewertungen

- Approved ITP 06012023 For WT6Dokument1 SeiteApproved ITP 06012023 For WT6mohamed irsath100% (1)

- Appendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Dokument24 SeitenAppendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Tahir AliNoch keine Bewertungen

- Submerged Arc Welding (Saw)Dokument5 SeitenSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNoch keine Bewertungen

- AB-518b Quality Manual and Audit ChecklistDokument24 SeitenAB-518b Quality Manual and Audit ChecklistStan Lee PaulsonNoch keine Bewertungen

- NDT As Per B31.3Dokument2 SeitenNDT As Per B31.3invilink87Noch keine Bewertungen

- Resume Sample PDFDokument4 SeitenResume Sample PDFamitrdttecNoch keine Bewertungen

- Metal Core WireDokument30 SeitenMetal Core WireHuỳnh TrươngNoch keine Bewertungen

- Procedure For Erection of Pipings and StructuresDokument10 SeitenProcedure For Erection of Pipings and StructuresraviNoch keine Bewertungen

- Prequalification - Pipe Welding JobDokument43 SeitenPrequalification - Pipe Welding JobPothi RaajaNoch keine Bewertungen

- Welding Quality ControlDokument7 SeitenWelding Quality ControlPRAMOD KUMAR SETHI S100% (1)

- Fabrication - Assembly & ErectionDokument83 SeitenFabrication - Assembly & ErectionRengga Andryastama100% (2)

- WPQR Sample FormDokument1 SeiteWPQR Sample FormshwayeNoch keine Bewertungen

- Weld Matrix Format 1Dokument7 SeitenWeld Matrix Format 1Arslan WaheedNoch keine Bewertungen

- Spec - WeldingDokument6 SeitenSpec - Weldingprasad_kcpNoch keine Bewertungen

- Pipework Pretest Checklist (Empty)Dokument1 SeitePipework Pretest Checklist (Empty)Jorge GarciaNoch keine Bewertungen

- QC Engineer (Mechanical) - 2Dokument5 SeitenQC Engineer (Mechanical) - 2Rajkumar ANoch keine Bewertungen

- Suggested Specifications For Hot-Dip GalvanizingDokument11 SeitenSuggested Specifications For Hot-Dip GalvanizingSreedhar Patnaik.M100% (1)

- Technical Manual - 2000 USG Horizontal Lined Acid TankDokument20 SeitenTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyNoch keine Bewertungen

- The Welding Procedure and Its QualificationDokument51 SeitenThe Welding Procedure and Its QualificationYousef Adel HassanenNoch keine Bewertungen

- PreheatDokument2 SeitenPreheatScott TrainorNoch keine Bewertungen

- Dutyies of Welding InspectorDokument30 SeitenDutyies of Welding InspectorMorg Actus100% (1)

- Saep 324Dokument13 SeitenSaep 324Hansel Francis100% (4)

- Saep 324Dokument8 SeitenSaep 324brecht1980100% (3)

- Aplicacion de TorqueDokument11 SeitenAplicacion de TorqueJose Javier Sierra ArrietaNoch keine Bewertungen

- A Quick Guide to Welding and Weld InspectionVon EverandA Quick Guide to Welding and Weld InspectionBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Nasa STD 5005dDokument76 SeitenNasa STD 5005dvominhthaiNoch keine Bewertungen

- Project Standards and Specifications Fan and Blower Systems Rev01Dokument12 SeitenProject Standards and Specifications Fan and Blower Systems Rev01vominhthaiNoch keine Bewertungen

- DG FoundationDokument40 SeitenDG Foundationjk.dasguptaNoch keine Bewertungen

- Equipment Fabrication SpecificationsDokument1 SeiteEquipment Fabrication SpecificationsvominhthaiNoch keine Bewertungen

- (9 10) Transient Heat ConductionDokument28 Seiten(9 10) Transient Heat ConductionSalam AlbaradieNoch keine Bewertungen

- Grund F O S: W HIT E Pap ERDokument9 SeitenGrund F O S: W HIT E Pap ERvominhthaiNoch keine Bewertungen

- FOUNDATIONS FOR INDUSTRIAL MACHINES AND EARTHQUAKE EFFECTS - K.G. Bhatia - ISET Journal of Earthquake Technology, Paper No. 495, Vol. 45, No. 1-2, March-June 2008, Pp. 13-29Dokument17 SeitenFOUNDATIONS FOR INDUSTRIAL MACHINES AND EARTHQUAKE EFFECTS - K.G. Bhatia - ISET Journal of Earthquake Technology, Paper No. 495, Vol. 45, No. 1-2, March-June 2008, Pp. 13-29R Mani MuruganNoch keine Bewertungen

- Clean Design Standard For Utility ModulesDokument2 SeitenClean Design Standard For Utility ModulesvominhthaiNoch keine Bewertungen

- Buterfly ValveDokument16 SeitenButerfly ValvevominhthaiNoch keine Bewertungen

- Ventialtion Calculation SampleDokument21 SeitenVentialtion Calculation SampleNico EchavarriaNoch keine Bewertungen

- Specification-Insulation Construction STDDokument4 SeitenSpecification-Insulation Construction STDvominhthaiNoch keine Bewertungen

- Do ThiDokument1 SeiteDo ThivominhthaiNoch keine Bewertungen

- How We Can Become A Piping Designer ?Dokument1 SeiteHow We Can Become A Piping Designer ?vominhthaiNoch keine Bewertungen

- Flange Size TableDokument1 SeiteFlange Size TableBharat TailorNoch keine Bewertungen

- Autocad Mechanical - PGS. TS Nguyen Huu LocDokument192 SeitenAutocad Mechanical - PGS. TS Nguyen Huu LocvominhthaiNoch keine Bewertungen

- Sample Duct 1Dokument20 SeitenSample Duct 1vominhthaiNoch keine Bewertungen

- Design ManualDokument3 SeitenDesign ManualvominhthaiNoch keine Bewertungen

- 19XRDDokument24 Seiten19XRDvominhthaiNoch keine Bewertungen

- Best Practice Manual-Fluid PipingDokument43 SeitenBest Practice Manual-Fluid Pipingapi-3869476100% (1)

- 1 Beam DeflectionDokument5 Seiten1 Beam DeflectionqazilaNoch keine Bewertungen

- 19XRDDokument24 Seiten19XRDvominhthaiNoch keine Bewertungen

- Alcohol Abuse-Related Severe Acute Pancreatitis With Rhabdomyolysis ComplicationsDokument4 SeitenAlcohol Abuse-Related Severe Acute Pancreatitis With Rhabdomyolysis ComplicationsMihai SebastianNoch keine Bewertungen

- Brain Savior - LabelDokument1 SeiteBrain Savior - LabelRonnie BercasionNoch keine Bewertungen

- Dosis Ranitidin cw1Dokument5 SeitenDosis Ranitidin cw1Cristine Indria Pieter IINoch keine Bewertungen

- Intussusception: DR Phillipo Leo ChalyaDokument19 SeitenIntussusception: DR Phillipo Leo ChalyaSibabaong'ombe MasakaNoch keine Bewertungen

- Injuries Diseases & Disorders of The Muscular SystemDokument22 SeitenInjuries Diseases & Disorders of The Muscular SystemAngeli LozanoNoch keine Bewertungen

- Stress MGMT in Call CentersDokument70 SeitenStress MGMT in Call CentersJayesh Kambli100% (1)

- Nqs NQSDokument270 SeitenNqs NQSManpreet KaurNoch keine Bewertungen

- Wiri 08 - Zambia Trip Application FormDokument11 SeitenWiri 08 - Zambia Trip Application Forminfo@zcfcanada.orgNoch keine Bewertungen

- MPKAY v1003Dokument39 SeitenMPKAY v1003Pranil MestryNoch keine Bewertungen

- FAQ Mid Day MealsDokument7 SeitenFAQ Mid Day Mealsvikramhegde87Noch keine Bewertungen

- SOP For Cleaning of Ultrasound Probes in Trust Imaging Departments PDFDokument2 SeitenSOP For Cleaning of Ultrasound Probes in Trust Imaging Departments PDFShinta Vivoy21Noch keine Bewertungen

- Historical Developments of Community Health Nursing in The WorldDokument75 SeitenHistorical Developments of Community Health Nursing in The Worldsoniya naik0% (1)

- Aldinga Bay's Coastal Views April 2014Dokument48 SeitenAldinga Bay's Coastal Views April 2014Aldinga BayNoch keine Bewertungen

- Heart BNHADokument13 SeitenHeart BNHAX OloGyNoch keine Bewertungen

- Senile Cataract (Age-Related Cataract) : Practice Essentials, Background, PathophysiologyDokument6 SeitenSenile Cataract (Age-Related Cataract) : Practice Essentials, Background, PathophysiologyadliahghaisaniNoch keine Bewertungen

- PoemDokument8 SeitenPoemJeevitraNoch keine Bewertungen

- (ThichTiengAnh - Com) de Theo Cau Truc Moi Nam 2017 de 1 Khong Dap AnDokument101 Seiten(ThichTiengAnh - Com) de Theo Cau Truc Moi Nam 2017 de 1 Khong Dap AnRoland VietnamNoch keine Bewertungen

- 2011 Sewarage SystemDokument29 Seiten2011 Sewarage Systemceafalld CE AF100% (1)

- Post Test 30 Items OBDokument5 SeitenPost Test 30 Items OBJohnasse Sebastian NavalNoch keine Bewertungen

- Presented To The Faculty of Bula National School of Fisheries General Santos CityDokument8 SeitenPresented To The Faculty of Bula National School of Fisheries General Santos CityUnknown NameNoch keine Bewertungen

- MAPEH Study NotesDokument5 SeitenMAPEH Study NotesBithao DaisyNoch keine Bewertungen

- HDR 2015 Statistical AnnexDokument73 SeitenHDR 2015 Statistical AnnexsssshekharNoch keine Bewertungen

- Bài tập tiếng anhDokument8 SeitenBài tập tiếng anhLinh KhánhNoch keine Bewertungen

- Washington D.C. Afro-American Newspaper, July 24, 2010Dokument20 SeitenWashington D.C. Afro-American Newspaper, July 24, 2010The AFRO-American NewspapersNoch keine Bewertungen

- Division of Blood Transfusion Services: Ministry of Health and Family WelfareDokument40 SeitenDivision of Blood Transfusion Services: Ministry of Health and Family WelfareKirandragonNoch keine Bewertungen

- Giáo viên: NGUYỆT CA: Khóa học Luyện thi PEN-I: Môn Tiếng Anh (Cô Nguyệt Ca)Dokument8 SeitenGiáo viên: NGUYỆT CA: Khóa học Luyện thi PEN-I: Môn Tiếng Anh (Cô Nguyệt Ca)Thu Phương0% (1)

- The ConsulDokument4 SeitenThe ConsulPrince Adesina HaastrupNoch keine Bewertungen

- First - Aid Common Emergencies and Safety Practices in Outdoor ActivitiesDokument14 SeitenFirst - Aid Common Emergencies and Safety Practices in Outdoor ActivitiesJhon Keneth NamiasNoch keine Bewertungen