Beruflich Dokumente

Kultur Dokumente

Fire Pump Start Up PDF

Hochgeladen von

walitedisonOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fire Pump Start Up PDF

Hochgeladen von

walitedisonCopyright:

Verfügbare Formate

B- Series Diesel Fire Pump Start-up Check Off List

1

Battery 1

Battery 2

1

Date/Alarms 2

Pressure

O

Volts

4 .

3 .

6 : 3

Current

Mode

2 5

9 . 5

b u l

5 0

0 . 5

f l o

1 2 - 0 7

1 3 : 2

5

I : 2 5

P : 0

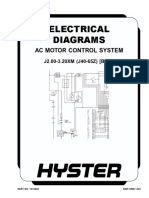

This is the Standard Display found on the Door of the

Fire Pump Controller. Alarms will flash on Line 3 in place

of the Date when trouble is detected.

Pressure: O = Cut Out (upper setting of pressure control)

I = Cut In (lower setting of pressure control)

For Discussion Purposes - Phase 1 has bell mounted on Door and Buttons below LED Display

P = Actual System Pressure

Phase 2 has bell mounted on Trim above Door.

Phase 3 has bell mounted on Door and Buttons on Left of LED Display.

Job Information:

k

a t

2 : 3 6

0 0 p s i

Controller Information:

Job Name:

Job Location:

Pump Mfg:

Pump Rep:

Sprinkler Co:

Sprinkler Rep:

Fire Dept Rep:

Insurance Rep:

Bulletin Number:

Catalog Number:

Serial Number:

Diesel MFG:

Battery Volts:

AC Voltage:

Date of Test:

Technician Name:

Engine Related Check Off Items :

1

2

3

4

5

6

7

8

These are the responsibility of others, but we should at least check to confirm they have been done.

Yes

No

Fill Cooling System with Antifreeze Solution

Fill Engine Crank Case with Lubricating Oil.

Fill Fuel Supply Tank with Fuel Oil ( at least enough to

run Diesel for required Test time

Connect The Batteries to the Engine

Fill Batteries with Electrolyte

Connect Wires between Engine and Controller

1-6,8-11 for most engines, 2-6,8-12 for Caterpillar

Connect Crank Case Heater to 120V (some 240V)

Connect Water Solenoid to terminals 1 and 11

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

The Pump Representative is our customer. The Electrical Contractor is either a sub to the Sprinkler Contractor or the General.

Either way, it is the electrical contractor's responsibility to complete the wiring connections.

B-Series Diesel Phase 3 Field Test Procedure

Controller Rep Responsibility to check

Yes

1

2

3

4

5

List :

6

7

8

9

10

11

Is Selector Switch in "Off" Position?

Does wiring agree with Connection Drawing?

Do Wire Sizes agree, especially 6, 8, and 11?

Are All Connections Tight?

What Alarms are connected?

No

______

______

______

______

______

______

______

______

______

______

Before Power is applied, all construction debris

______

and tools must be removed.

Locate CB3 and CB4 and turn on or confirm on.

______

Phase 2 units will be already on unless tripped.

Does voltage for batteries appear OK? See Display

______

If batteries are connected, Located CB1 and CB2

______

and turn "ON". Wait 5 seconds, Did "no ans" disappear?

Confirm Charging Currents are OK? No user adj.

______

Check for Jumper at Remote Start Input

______

______

Terminals:

______ Phase 1 CB's are located inside Top Left

Phase 2 CB's are not switchable

______

______ Both CB's are located in lower middle of

controller near AC Input Terminals

______

______ Phase 1 - Terminals 21 - 13

Phase 2 - Terminals 17 - 13

Phase 3 - Terminals J18-1 and J18-2

12

Check for Jumper at Deluge Valve Input

______ ______ Phase 1 - Terminals 23 - 25

Phase 2 - Terminals 23 - 42

Phase 3 - Terminals J19 or J4-25 and C

13

14

Check for Low Fuel Level Switch in Fuel Tank

Confirm landing of wires on proper Terminals

______ ______ Phase 1 - Terminals 23 - 24

Check for Jumper in place of High Fuel Level Sw

______ ______

Phase 2 - Terminals 23 - 43

Phase 3 - Terminals J4-24 and C

Phase 1 - Terminals 23 - 29

Phase 2 - Terminals 23 - 38

Phase 3 - Terminals J20 or J4-29 and C

15

Check Pressure Sensing Line to pressure Switch/Trans ______ ______

Be sure it is connected to system side of Check Valve.

FT-B10710-3001

Page 2

B-Series Diesel Phase 3 Field Test Procedure

Starting of the Pump

The following functions are only to be performed after the approval of the Pump Representative.

Yes

No

1

Place the Selector Switch in the Manual Position and Observe

_______ _______

that the Water Solenoid operated and cooling water is flowing.

2

Press the #1 Start Button and observe engine starting.

_______ _______

3

Move the Selector Switch to OFF to stop Engine

_______ _______

4

Press the #2 Start Button and observe engine starting.

_______ _______

5

Move the Selector Switch to OFF to stop Engine

_______ _______

6

Observe that the water solenoid closes off the cooling water flow.

_______ _______

7

Move the Selector Switch to AUTO

8

Relieve some water from the sensing line to drop the pressure

_______ _______

below the lower setpoint ( I = 25 psi). The pump should start.

9

Observe the Engine Running Light on the front of the Controller

_______ _______

confirm the engine speed switch closes at 15% of rated speed.

10

With Pressure above upper setting, press Red Stop button.

_______ _______

Engine should Stop and remain stopped unless pressure is low.

11

Move the Selector Switch to "OFF"

He must give the OK to proceed.

Phase 1&3 - Crank #1, Phase 2 Start #1

Phase 1&3 - Crank #2, Phase 2 Start #2

Phase 1&3 - Door Mounted, Phase 2 - Trim

Adjusting the Pressure Settings

Open the Door and look at the left edge of the Electronic Control Module.

You will find two DIP switch groupings. The upper switch group is S5 and should have all 4 switches "OFF"

The Second Group is S10 and controls several functions of the Fire Pump Controller.

#8, the top switch is for Factory Adjustment, Leave in OFF position

#7 and #6 should both be OFF to give a pressure reading interval of 5 PSI

#5 in the OFF position allows the controller to operate in PSI

#4 and #3 select the Delay Start timer setting, Both OFF give 0 Seconds delay.

#2 when OFF selects Manual Stop. Moving #2 to ON selects Automatic Stop set for 30 Min

#1 should be OFF for normal operation, Moving #1 to ON allows Pressure settings to be adjustable

Note: Alarm Display on Front of controller shows " DIP Switch Misset" while #1 is on to remind

you to Switch it OFF when pressures are set to prevent changes.

Move #1 to the ON position. Then observe front Display.

Press Cut Out until Desired Upper Pressure setting is reached. Push and hold will advance faster.

Value goes up until transducer limit is reached, the cycles back to 0 and up again.

Press Cut IN until Desired Starting Pressure setting is reached. Push and hold will advance faster.

Value goes up until CutOut limit is reached, the cycles back to 0 and up again.

Move #1 to the OFF position and unit has been set.

FT-B10710-3001

Page 3

B-Series Diesel Phase 3 Field Test Procedure

Engine Monitor Functions

1

With Engine Running from Auto Start position, Short Terminals

on Engine Temperature Switch. Observe light on Front of Control

2

With Engine Running from Auto Start position, Short Terminals

on Low Oil Pressure Switch. Hold for 10 seconds. Observe light

on Front of Controller.

3

Test Engine overspeed switch by using test switch on front of

engine panel or jumpering terminals on Speed Switch Relay.

Observe Engine Stop and proper light on front of controller.

4

Reset Engine Speed Switch, Turn Selector Switch to OFF to

Reset Controller.

5

Remove Battery Cable, Positive Terminal on Battery #1

Observe Battery 1 Failure and Red Light on Front of Controller

Re-install Battery Cable on Battery #1

6

Remove Battery Cable, Positive Terminal on Battery #2

Observe Battery 2 Failure and Red Light on Front of Controller

Re-install Battery Cable on Battery #2

7

Turn off CB1 inside controller. Observe AC Failure Light on

front of Controller. Note AC Failure in Display - Top Row.

Turn on CB1 inside controller.

8

Turn off CB1 inside controller. Observe AC Failure Light on

front of Controller. Note AC Failure in Display - Top Row.

Turn on CB1 inside controller.

Yes

_______

No

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

Testing the Controller Starting

Bat Set 1

1

Turn the Selector Switch to Manual and using one of the

Manual Start Buttons, start the engine. When the

_______

engine speed stabilizes, Move the Selector Switch to OFF.

Manual

Let the engine come to a full stop and wait for Turbo charger

to stop rotating as well, then move Selector back to Manual.

2

Place a mark on the line above for the Battery Set used

During this start. Then use the other Manual Start Button

to perform the next Manual Start. Alternate Starts until

you have 3 starts on each battery set.

3

Now move the Selector Switch to the AUTO position.

_______

Using the hand valve on the sensing line just outside the

Automatic

controller, drain some pressure from the sensing line until

the pump starts. Observe the Pump Running LED and when engine

speed stabilizes, Push STOP Button on controller. Wait for engine

to stop as before and then drop pressure again. 3 times on each battery set.

FT-B10710-3001

Bat Set 2

_______

Manual

_______

Automatic

Page 4

B-Series Diesel Phase 3 Field Test Procedure

SetClock / Weekly Test Setup / Change

Hold "Print Events" Button for 6 Seconds

Display Changes to

T u

A u g

1 5 ,

0 6

1 3 : 4 1

W e e k l y

T e s t

: N

W e

1 4 : 2 2

1 4 : 2 3

E X I T

S t a r t

S t o p

S A V E

Set Clock Display

Choose Weekly Test: Y or N

Set Day, Start Time and Stop Time, Exit without changing

Save Changes

Use "Print Events" Button to move around display

Press "Engine Test" Button to Change an item.

When all changes are complete, Use "Print Events" button to get back to SAVE.

Then press "Engine Test" Button to SAVE the changes

Timer Setup, Sequence Start, RPT, AC Failure Start

Hold "Print Events" Button for 6 Seconds, Display Changes to Weekly Test Setup above

While still Holding "Print Events" Button, Press "Engine Test" three (3) times

Display Changes to

S e q u e n t .

T i m e : 1 5

S e c

Set Sequence Start timer here 0 - 99 Sec in 1 sec increments

R u n

P e r .

T i m e : 3 0

M i n

Set RPT here 1-60 Minutes in 1 minute increments

A C

F a i l

S t a r t

: N O

M

Set AC Fail Start Time Delay, 0 - 255 Minutes in 1 minute increments

S A V E

E X I T

Save Changes or Exit without saving

Pressure Transducer Calibration (Requires 2 Screens)

(Transducer Calibration only needed when replacing Transducers.)

Hold "Print Events" Button for 6 Seconds, Display Changes to Weekly Test Setup above

While still Holding "Print Events" Button, Press "Engine Test" four (4) times

Display Changes to

C U R

P R E S S U R E

0 P S I

Read Signal Pressure from Sensing Line Gauge, just outside the controller.

P R E S S 1

0 0 0 0

R E A D

Drop Signal pressure to near Zero- Enter Here, move to Read, Press Eng. Test

Increase Signal pressure to Maximum, Enter here, move to Read Press Eng. Test

P R E S S 2

0 5 0 0

R E A D

N E X T

E X I T

Exit if you do not wish to continue Calibration, otherwise, Choose Next

Pressing NEXT will get you to

O L D

N E W

G A I N

1 6 9 4 1

1 6 9 4 1

These are the calibration numbers that have been calculated based on the

O F F S E T

0 3 6 7

0 3 6 7

readings taken above. If you wish to save them choose Save, or

S A V E

E X I T

Exit without saving new calibration values.

FT-B10710-3001

Page 5

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Boiler and Piping ToolsDokument4 SeitenBoiler and Piping ToolswalitedisonNoch keine Bewertungen

- Senior Welding InspectorDokument1 SeiteSenior Welding InspectorwalitedisonNoch keine Bewertungen

- Hydrostatic Test Procedure PDFDokument2 SeitenHydrostatic Test Procedure PDFLuis Pullas86% (44)

- Valve List Test LimitDokument37 SeitenValve List Test LimitwalitedisonNoch keine Bewertungen

- Gag For Pressure Safety Valve JimCaseyDokument1 SeiteGag For Pressure Safety Valve JimCaseywalitedisonNoch keine Bewertungen

- Tripper GalleryDokument14 SeitenTripper GallerywalitedisonNoch keine Bewertungen

- Yuhan Welder List - Nov.22017 PDFDokument2 SeitenYuhan Welder List - Nov.22017 PDFwalitedisonNoch keine Bewertungen

- T0rque Value of A193 B7Dokument2 SeitenT0rque Value of A193 B7walitedisonNoch keine Bewertungen

- Final Alignment Monitoring: IR Number Equipment Name Date of Inspection Inspection Conducted Inspection Comments RemarksDokument2 SeitenFinal Alignment Monitoring: IR Number Equipment Name Date of Inspection Inspection Conducted Inspection Comments RemarkswalitedisonNoch keine Bewertungen

- List of Inspection Report For Turnover Package For WWTDokument1 SeiteList of Inspection Report For Turnover Package For WWTwalitedisonNoch keine Bewertungen

- Final Alignment Monitoring: IR Number Equipment Name Date of Inspection Inspection Conducted Inspection Comments RemarksDokument2 SeitenFinal Alignment Monitoring: IR Number Equipment Name Date of Inspection Inspection Conducted Inspection Comments RemarkswalitedisonNoch keine Bewertungen

- Re PR 40-1018 For Steel Material. Please Advise Thickness of The Angle and Channel Bars Requested Below. ThanksDokument1 SeiteRe PR 40-1018 For Steel Material. Please Advise Thickness of The Angle and Channel Bars Requested Below. ThankswalitedisonNoch keine Bewertungen

- T0rque Value of A193 B7Dokument2 SeitenT0rque Value of A193 B7walitedisonNoch keine Bewertungen

- Yuhan Welder List - Nov.22017Dokument1 SeiteYuhan Welder List - Nov.22017walitedisonNoch keine Bewertungen

- Welding Properties and Chemical Composition SelectionDokument84 SeitenWelding Properties and Chemical Composition SelectionwalitedisonNoch keine Bewertungen

- Yuhan Welder List - Nov.22017Dokument2 SeitenYuhan Welder List - Nov.22017walitedisonNoch keine Bewertungen

- AGP Welder List - Nov.032017Dokument7 SeitenAGP Welder List - Nov.032017walitedisonNoch keine Bewertungen

- NDT TrainingDokument1 SeiteNDT TrainingwalitedisonNoch keine Bewertungen

- Tension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMDokument4 SeitenTension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMwalitedisonNoch keine Bewertungen

- Woolim Welder List - Oct.302017Dokument1 SeiteWoolim Welder List - Oct.302017walitedisonNoch keine Bewertungen

- Xwell StickerDokument1 SeiteXwell StickerwalitedisonNoch keine Bewertungen

- Xwell StickerDokument1 SeiteXwell StickerwalitedisonNoch keine Bewertungen

- Correct Welding of Main Steam LineDokument2 SeitenCorrect Welding of Main Steam LinewalitedisonNoch keine Bewertungen

- Yuhan Welder List - Oct.312017Dokument3 SeitenYuhan Welder List - Oct.312017walitedisonNoch keine Bewertungen

- Ut Formate1Dokument187 SeitenUt Formate1walitedisonNoch keine Bewertungen

- B31.1 Nde RequirementsDokument1 SeiteB31.1 Nde RequirementswalitedisonNoch keine Bewertungen

- Review of Radiographic Examination ReportDokument1 SeiteReview of Radiographic Examination ReportwalitedisonNoch keine Bewertungen

- NDT Advantage and DisadvantageDokument4 SeitenNDT Advantage and DisadvantagewalitedisonNoch keine Bewertungen

- Tuvr Equipment Inventory - 2Dokument16 SeitenTuvr Equipment Inventory - 2walitedisonNoch keine Bewertungen

- Review of Radiographic Examination ReportDokument1 SeiteReview of Radiographic Examination ReportwalitedisonNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cmci Cmci: Cemtec 200Dokument2 SeitenCmci Cmci: Cemtec 200pravi3434Noch keine Bewertungen

- Divya Tandon and Nivedita SharmaDokument13 SeitenDivya Tandon and Nivedita SharmaDianaElenaNoch keine Bewertungen

- 22 Welding Equipment Ebook PDFDokument65 Seiten22 Welding Equipment Ebook PDFNida Ahmad MusyafaNoch keine Bewertungen

- Electrical Diagrams: Ac Motor Control SystemDokument34 SeitenElectrical Diagrams: Ac Motor Control SystemIonut GrozaNoch keine Bewertungen

- MSC Thesis Final 21jan09Dokument132 SeitenMSC Thesis Final 21jan09David Cruz ZamoraNoch keine Bewertungen

- TB016 Operators Manual TakeuchiDokument214 SeitenTB016 Operators Manual TakeuchiDaniel William Hill100% (3)

- Saes B 055Dokument33 SeitenSaes B 055Tarek Mustafa100% (1)

- Basic Coal InformationDokument23 SeitenBasic Coal InformationHazem DiabNoch keine Bewertungen

- Poly Transfer Operation ManualDokument12 SeitenPoly Transfer Operation Manualab5951Noch keine Bewertungen

- Basic BlastingDokument79 SeitenBasic BlastingSunilNoch keine Bewertungen

- Inlet Ex SystemDokument5 SeitenInlet Ex SystembejoythomasNoch keine Bewertungen

- NSTSE Class 8 Solved Paper 2011Dokument20 SeitenNSTSE Class 8 Solved Paper 2011Sweta SharanNoch keine Bewertungen

- sp-2800 ManualDokument6 Seitensp-2800 Manualmailme_viju0% (2)

- E813 04-2009 90 Hyster XMsDokument630 SeitenE813 04-2009 90 Hyster XMsManutenção Base AnápolisNoch keine Bewertungen

- Instrument and Control Designer Rev01Dokument5 SeitenInstrument and Control Designer Rev01masilamaniNoch keine Bewertungen

- Product Brochure T 236Dokument24 SeitenProduct Brochure T 236Rómulo Zevallos GutiérrezNoch keine Bewertungen

- 99the Material For The 2nd Public and Private Joint Forum PDFDokument287 Seiten99the Material For The 2nd Public and Private Joint Forum PDFZaf MeerzaNoch keine Bewertungen

- Tanker Time and Delay Sheet: National Iranian Oil Company Iranian Oil Terminals CompanyDokument1 SeiteTanker Time and Delay Sheet: National Iranian Oil Company Iranian Oil Terminals CompanyReza ZahediNoch keine Bewertungen

- 2116W Parts Manual 514018 R0Dokument434 Seiten2116W Parts Manual 514018 R0lrodr_guez_1100% (1)

- AeromodellingDokument29 SeitenAeromodellingPreshit SamNoch keine Bewertungen

- Project Guide M25C Propulsion - 04.2012Dokument120 SeitenProject Guide M25C Propulsion - 04.2012Khairudin NawawiNoch keine Bewertungen

- User Manual: HGM9200/9300/9400 SeriesDokument65 SeitenUser Manual: HGM9200/9300/9400 Seriesnhocti007Noch keine Bewertungen

- Synthesis Gas Production 4Dokument34 SeitenSynthesis Gas Production 4Aravind KumarNoch keine Bewertungen

- 16620s01 Standby Generators PDFDokument6 Seiten16620s01 Standby Generators PDFVICTOR JOSE VILORIANoch keine Bewertungen

- PC78US-8 Troubleshooting of Engine (S-Mode)Dokument24 SeitenPC78US-8 Troubleshooting of Engine (S-Mode)Hai Van100% (2)

- T-SB-0163-08 Fuel TankDokument7 SeitenT-SB-0163-08 Fuel TankdonotbugNoch keine Bewertungen

- Handbook Co2 SystemDokument21 SeitenHandbook Co2 SystemJunifer Macauba100% (2)

- Unit KG (LB) Model SK200 - 8 SK210LC - 8 Item: 2. SpecificationsDokument20 SeitenUnit KG (LB) Model SK200 - 8 SK210LC - 8 Item: 2. SpecificationsShop ManualNoch keine Bewertungen

- Higgins 78ft Operating Manual PT71-94Dokument19 SeitenHiggins 78ft Operating Manual PT71-94Sean CampbellNoch keine Bewertungen

- Bhasin, S. K. - Sharma, Vijay - Essentials of Engineering Chemistry-Himalaya Pub. House (2010) PDFDokument386 SeitenBhasin, S. K. - Sharma, Vijay - Essentials of Engineering Chemistry-Himalaya Pub. House (2010) PDFkehinde ogunleyeNoch keine Bewertungen