Beruflich Dokumente

Kultur Dokumente

Interconnect: Interconnect and Wire Engineering

Hochgeladen von

jubincb2Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Interconnect: Interconnect and Wire Engineering

Hochgeladen von

jubincb2Copyright:

Verfügbare Formate

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Interconnect

Analysis of interconnect is becoming as important as transistors in modern processes.

Modern processes use 6-10 metal layers

Layer T (nm) W (nm) S (nm) AR

Layer stack for 180nm process

Pitch = w + s

Aspect Ratio = t / w

Newer processes have AR ~ 2

2

1

860

2.0

1600

800

800

2.0

540

540

2.0

320

320

2.2

320

320

2.2

250

250

1.9

1000

3

l

860

1000

5

Thicker wires as you move towards

upper metal layers

1720

1080

700

700

700

700

700

480

800

Substrate

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Wire Resistance

w

l

w

4 Rec tangular Bloc ks

R = R (2L/2W)

= R (L/W)

1 Rec tangular Bloc k

R = R (L/W)

= resistivity ( m )

l

R = --- ---- = R

tw

R

l

---w

sheet resistance

Count number of squares and multiply by sheet resistance to get R

2

Principles of VLSI Design

Interconnect and Wire Engineering

CMPE 413

Wire Resistance

Older processes used aluminum, today's processes use copper

Special barrier layer required to stop copper from diffusing into silicon and destroying

transistors

Typical sheet resistance values in 180nm process

Layer

Diffusion (silicided)

Sheet Resistance

3-10

Diffusion (unsilicided)

50-200

Polysilicon (silicided)

3-10

Polysilicon (unsilicided)

50-400

Metal1

0.08

Metal2

0.05

Metal3

0.05

Metal4

0.03

Metal5

0.02

Metal6

0.02

3

Principles of VLSI Design

Interconnect and Wire Engineering

CMPE 413

Contact Resistance

Contacts and vias also have about 2-20

of resistance.

Higher resistance than that of metal wires.

Use many contacts to get lower R

As current crowds at the periphery, many small contacts required rather than one huge

contact.

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Wire Capacitance

Wire have capacitance per unit length to neighboring layers and layers above and below

Ctotal = Cbottom + Ctop + 2Cadjacent

s

w

layer n+1

h2

Ctop

layer n

t

h1

Cbot

Cadj

layer n-1

Parallel plate capacitance equation C = A d

Wires are not truly parallel plate, but obey trends

Increasing area (W or t) increases capacitance

Increasing distance (s or h) decreases capacitance

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Wire Capacitance

Dielectric constant in the previous equation

= k 0

0 = 8.85 x 10-14F/cm and k = 3.9 for SiO2

Newer processes are starting to use low-k dielectric materials to reduce capacitance

400

350

300

M1, M3 planes

s = 320

s = 480

s=

200

s = 640

Isolated

s = 320

150

Typically wire have ~0.2fF/m

Gate capacitance ~2fF/m

s = 480

s = 640

100

s=

Ctotal (aF/m)

250

50

0

0

500

1000

1500

2000

w (nm)

Principles of VLSI Design

Interconnect and Wire Engineering

CMPE 413

Diffusion and Polysilicon Capacitance

Diffusion capacitance is very high (~2fF/m)

Comparable to gate capacitance

Diffusion also has high resistance

Avoid using diffusion runners for wires!!

Polysilicon has lower C but higher R

Use for transistor gates

Occasionally for very small wires between gates

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Wire Delay: Lumped Element Models

Wires are a distributed system

Approximated using lumped element models

N segments

R

R/N

R/N

C/N

C/N

R

C

L-model

C/2

R/N

R/N

C/N

C/N

R/2 R/2

C/2

-model

C

T-model

3 segment -model is accurate to within 3% in simulations

L-model would require about 100 segments to obtain the same accuracy

Use single segment -model for Elmore delay

8

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Wire Delay: Lumped Element Models

Example: Metal2 wire in 180nm process that is 5 mm long and 0.32 m wide

Construct a 3 segment -model

R = 0.05

R = 781 and C permicron = 0.2fF m C = 1pF

260

260

260

167 fF 167 fF

167 fF 167 fF

167 fF 167 fF

Estimate delay of 10x inverter driving a 2x inverter at the end of the above wire

R = 2.5k m for gates

Unit inverter: 0.36 m for NMOS, 0.72 m for PMOS

781

690

Driver

500 fF 500 fF

Wire

4 fF

tpd = 1.1 ns

Load

Principles of VLSI Design

Interconnect and Wire Engineering

CMPE 413

Crosstalk

A capacitor does not like to change its voltage instantaneously

A wire has high capacitance to its neighbor

When neighbor switches from 1-> 0 or 0 -> 1 the wire tends to switch too

Called capacitive coupling or crosstalk

Effects: Noise on non-switching wires and increased delay on switching wires

Assume wires above and below on average are quiet and therefor second terminal of capacitor can be ignored

Modeled as Cgnd = Ctop + Cbottom

A

Cgnd

B

Cadj

Cgnd

Effective Cadjacent depends on behavior of neighbors

Miller Effect (Miller Coupling Factor MCF)

B

DV

Ceff(A)

MCF

constant

VDD

Cgnd + Cadjacent

switching same direction as A

Cgnd

switching opposite direction as A

2VDD

Cgnd + 2Cadjacent

2

10

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Crosstalk

Crosstalk causes noise on non-switching wires

If the victim is floating

model as capacitive voltage divider

Aggressor

Vaggressor

Cadj

Victim

Cgnd-v

Vvictim

C adj

V victim = -------------------------------------- V aggressor

C

+ C adj

gnd v

11

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Crosstalk Noise: Victim

Usually victim is driven by a gate that fights noise

Noise depends on relative resistances

Victim driver is in linear region, aggressor in saturation

If sizes are same, Raggresor = 2-4 x Rvictim

Raggressor

Aggressor

Cgnd-a

Vaggressor

Cadj

Rvictim

Victim

Vvictim

Cgnd-v

C adj

1

V victim = --------------------------------------- ------------ V aggressor

C gnd v + C adj 1 + k

R aggressor ( C

+ C adj )

aggressor

gnd a

k = ------------------------- = ---------------------------------------------------------------------- victim

+ C adj )

R victim ( C

gnd v

12

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Crosstalk Coupling: Waveforms

Simulated coupling for Cadj = Cvictim

Aggressor

1.8

1.5

1.2

Victim (undriven): 50%

0.9

0.6

Victim (half size driver): 16%

Victim (equal size driver): 8%

0.3

Victim (double size driver): 4%

0

0

200

400

600

800

1000

1200

1400

1800

2000

t(ps)

13

Principles of VLSI Design

Interconnect and Wire Engineering

CMPE 413

Crosstalk noise

Noise implications:

If the noise is less than the noise margin nothing happens

Static CMOS logic will eventually settle to correct output even if disturbed by a large

noise spike

But these glitches cause extra delay

Also causes extra power from false transitions

Dynamic logic (discussed later) will never recover from noise

Memories and other sensitive circuits can also produce wrong answers

14

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Wire Engineering

Goal: Achieve delay, area and power specifications with acceptable noise

Degrees of freedom

Width, Spacing, Layer and Shielding

0.8

1.8

0.7

Coupling:2Cadj / (2C adj+Cgnd)

2.0

1.6

Delay (ns):RC/2

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0.6

WireSpacing

(nm)

320

480

640

0.5

0.4

0.3

0.2

0.1

0

500

1000

1500

Pitch (nm)

vdd a0

a1 gnd a2

a3 vdd

2000

500

1000

1500

2000

Pitch (nm)

vdd a0 gnd a1 vdd a2 gnd

a0

b0

a1

b1

a2

b2

15

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Repeaters

R and C are proportional to l

RC delay is proportional to l2

Unacceptably high for long wires

Break long wires into N shorter segments

Drive each segment with an inverter or buffer

Wire Length: l

Driver

Receiver

N Segments

Segment

l/N

Driver

l/N

Repeater

l/N

Repeater

Repeater

Receiver

16

Interconnect and Wire Engineering

Principles of VLSI Design

CMPE 413

Repeaters

How many repeaters should we use?

How large should each one be?

Equivalent circuit

Wire length l

Wire capacitance Cw * l, Resistance Rw * l

Inverter width W (NMOS = W, PMOS = 2W)

Gate capacitance C`* W, Resistance R / W

RwlN

R/W

Cwl/2N Cwl/2N

C'W

17

Principles of VLSI Design

Interconnect and Wire Engineering

CMPE 413

Repeaters

Write equation for Elmore Delay

Differentiate with respect to W and N

Set equal to 0 and solve

Best length of wire between repeaters, neglecting diffusion parasitics

l

---- =

N

2RC'

--------------Rw Cw

Delay per unit length of a properly repeated wire is

t pd

------- = ( 2 + 2 ) RC'R w C w

l

NMOS transistor width to achieve this delay

W =

RC w

-----------R w C'

18

Das könnte Ihnen auch gefallen

- Swimming Pool EstimatesDokument1 SeiteSwimming Pool EstimatesgreatgeniusNoch keine Bewertungen

- Aashto M288Dokument29 SeitenAashto M288jong_hao_su5167% (3)

- Solution Manual for 100 Genesys Design Examples: Second EditionVon EverandSolution Manual for 100 Genesys Design Examples: Second EditionNoch keine Bewertungen

- Astm D1287Dokument4 SeitenAstm D1287Eduardo CarlovichNoch keine Bewertungen

- Designing 400 KV Transmission LineDokument61 SeitenDesigning 400 KV Transmission LineMohammed K Hawa92% (12)

- RF and Microwave Systems IntroductionDokument38 SeitenRF and Microwave Systems IntroductionAbdul Hafiz AnuarNoch keine Bewertungen

- Designing Loop AntennasDokument18 SeitenDesigning Loop AntennasCesar AvilaNoch keine Bewertungen

- Class Presentation On CH 6 Interconnect: ECE 525 Digital Integrated Circuit Design-1 Presenter Zahed Reza KhurasaniDokument27 SeitenClass Presentation On CH 6 Interconnect: ECE 525 Digital Integrated Circuit Design-1 Presenter Zahed Reza KhurasaniGuru VelmathiNoch keine Bewertungen

- EE 447 VLSI Design Lecture 5: Wires and Interconnect RC DelayDokument36 SeitenEE 447 VLSI Design Lecture 5: Wires and Interconnect RC Delaylipun12ka4100% (1)

- Vlsi WiresDokument23 SeitenVlsi WiresTalha Syed NaqviNoch keine Bewertungen

- LectureDokument26 SeitenLectureKAMARUDHEEN KPNoch keine Bewertungen

- Transmission LineDokument55 SeitenTransmission LinePuja Setiawan20100% (1)

- Commutation ChokesDokument10 SeitenCommutation Chokestudor_x27Noch keine Bewertungen

- Ansoft Q3D TraningDokument24 SeitenAnsoft Q3D TraningleivajNoch keine Bewertungen

- 24 WiresDokument38 Seiten24 WiresGokul KuthatiNoch keine Bewertungen

- Logic Gates: Power and Other Logic FamilyDokument36 SeitenLogic Gates: Power and Other Logic FamilybhawnaNoch keine Bewertungen

- Voltage Drop and Short CircuitDokument39 SeitenVoltage Drop and Short CircuitMinerva Abanto100% (1)

- EE251 Note 2 - Sequence Impedance of Transmission LinesDokument96 SeitenEE251 Note 2 - Sequence Impedance of Transmission LinesRogzJrBernzNoch keine Bewertungen

- Compute RLC Parameters of Radial Copper Cables With Single Screen Based On Conductor and Insulator Characteristics - MATLABDokument8 SeitenCompute RLC Parameters of Radial Copper Cables With Single Screen Based On Conductor and Insulator Characteristics - MATLABHai NguyenNoch keine Bewertungen

- Net Delay Factors and ModelsDokument16 SeitenNet Delay Factors and ModelsPerumal NamasivayamNoch keine Bewertungen

- Broadband Electrical Modeling of Transitions and Interconnects Useful For PCB and Co-Fired Ceramic Packaging - ForPublicationDokument20 SeitenBroadband Electrical Modeling of Transitions and Interconnects Useful For PCB and Co-Fired Ceramic Packaging - ForPublicationrickNoch keine Bewertungen

- SL Electroplating 270 01Dokument20 SeitenSL Electroplating 270 01pmurphNoch keine Bewertungen

- Staggered Twisted-Bundle Interconnect for Crosstalk and Delay ReductionDokument30 SeitenStaggered Twisted-Bundle Interconnect for Crosstalk and Delay ReductionBeverly PamanNoch keine Bewertungen

- VLSI Interconnect OptimizationDokument46 SeitenVLSI Interconnect Optimizationparty0703Noch keine Bewertungen

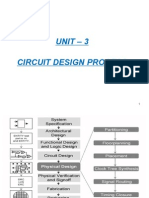

- Unit - 3 Circuit Design ProcessDokument30 SeitenUnit - 3 Circuit Design ProcessNagarjun RajputNoch keine Bewertungen

- Physical Design EssentialsDokument88 SeitenPhysical Design EssentialsentercodeNoch keine Bewertungen

- HT Cable Sizing Cal - For HT SWBD, Dist. Trafo. & HT Motor 27.07.10Dokument12 SeitenHT Cable Sizing Cal - For HT SWBD, Dist. Trafo. & HT Motor 27.07.10mahesh_sali2003Noch keine Bewertungen

- Saravanan Sia Lab 1Dokument18 SeitenSaravanan Sia Lab 1Raja PerumalNoch keine Bewertungen

- R. Ludwig and G. Bogdanov "RF Circuit Design: Theory and Applications" 2 Edition Figures For Chapter 1Dokument29 SeitenR. Ludwig and G. Bogdanov "RF Circuit Design: Theory and Applications" 2 Edition Figures For Chapter 1grsandhya6Noch keine Bewertungen

- 7SS522 CT RequirementDokument4 Seiten7SS522 CT RequirementAnonymous 9EV0OmkNoch keine Bewertungen

- CHP 2 - Mos Design and LayoutDokument104 SeitenCHP 2 - Mos Design and Layoutkkece41Noch keine Bewertungen

- Transmission Line BasicsDokument49 SeitenTransmission Line BasicsPooja SinhaNoch keine Bewertungen

- Cntfet Technology Based Precision Full-Wave Rectifier Using DDCCDokument8 SeitenCntfet Technology Based Precision Full-Wave Rectifier Using DDCCresearchinventyNoch keine Bewertungen

- Litz Design Calculations GuidelineDokument3 SeitenLitz Design Calculations GuidelineRodrigo CunhaNoch keine Bewertungen

- WWW - Stanford.edu Jbarral Downloads JoelleBarral CoilDesignDokument9 SeitenWWW - Stanford.edu Jbarral Downloads JoelleBarral CoilDesignSachin_AnchanNoch keine Bewertungen

- Docs EEEPSLNotes2013 PDFDokument46 SeitenDocs EEEPSLNotes2013 PDFHtet Mrak AungNoch keine Bewertungen

- Power System Analysis: Development of Transmission Line ModelsDokument40 SeitenPower System Analysis: Development of Transmission Line ModelsPotchinoParuntongNoch keine Bewertungen

- Unit-4 VLSIDokument21 SeitenUnit-4 VLSIAbdul Sami MohdNoch keine Bewertungen

- Sa2009-001608 en Rel670 CT Calculation ExampleDokument7 SeitenSa2009-001608 en Rel670 CT Calculation ExampleinsanazizNoch keine Bewertungen

- Peter H ChenDokument10 SeitenPeter H ChenYunping HuangNoch keine Bewertungen

- Transmission Line XDokument21 SeitenTransmission Line XKifaru Micro-electronicsNoch keine Bewertungen

- Modeling Power System ComponentsDokument30 SeitenModeling Power System ComponentsEngr Imtiaz Hussain GilaniNoch keine Bewertungen

- Power System 2Dokument46 SeitenPower System 2Prakash Chandran CNoch keine Bewertungen

- Power System Analysis: Development of Transmission Line Models Tom Overbye and Ross BaldickDokument29 SeitenPower System Analysis: Development of Transmission Line Models Tom Overbye and Ross BaldickSheik HussainNoch keine Bewertungen

- Power System Analysis: Development of Transmission Line Models Tom Overbye and Ross BaldickDokument29 SeitenPower System Analysis: Development of Transmission Line Models Tom Overbye and Ross Baldickصدام حسینNoch keine Bewertungen

- High Speed Layout AnalogDokument4 SeitenHigh Speed Layout AnalogMahendra SakreNoch keine Bewertungen

- Filter inductor and transformer design using the Kg methodDokument63 SeitenFilter inductor and transformer design using the Kg methodBahadır AkbalNoch keine Bewertungen

- 06 - Simple Method For Predicting A Cable Shielding Factor Based On Transfer Impedance 1000%Dokument5 Seiten06 - Simple Method For Predicting A Cable Shielding Factor Based On Transfer Impedance 1000%Caio SilvaNoch keine Bewertungen

- Chapter04 ExDokument6 SeitenChapter04 ExKarthikeya VemparalaNoch keine Bewertungen

- EE369 Power System Analysis Lecture 6 Development of Transmission Line ModelsDokument29 SeitenEE369 Power System Analysis Lecture 6 Development of Transmission Line ModelsEarly JobsNoch keine Bewertungen

- BSNL Paper On 20Th June, 2008 Visit Site For More InformationDokument11 SeitenBSNL Paper On 20Th June, 2008 Visit Site For More InformationReganNoch keine Bewertungen

- Planar Transmission Lines: SyllabusDokument30 SeitenPlanar Transmission Lines: SyllabusAdvait KumarNoch keine Bewertungen

- Voltage Drop Calculation Typical CasesDokument4 SeitenVoltage Drop Calculation Typical CasesKhaled ZayedNoch keine Bewertungen

- D-Band Frequency Tripler For Passive Imaging - Final 13th JulyDokument4 SeitenD-Band Frequency Tripler For Passive Imaging - Final 13th JulyTapas SarkarNoch keine Bewertungen

- Filter Design PDFDokument11 SeitenFilter Design PDFarunkr1Noch keine Bewertungen

- On AC ResistanceDokument4 SeitenOn AC ResistancesreedharNoch keine Bewertungen

- HV Cable SizingDokument11 SeitenHV Cable SizingPallab MukherjeeNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument65 SeitenNew Microsoft Office Word Documentsinghashish35Noch keine Bewertungen

- Pn-Junction: Excess Minority Carrier Charge Space ChargeDokument28 SeitenPn-Junction: Excess Minority Carrier Charge Space ChargePrashant Kumar SinghNoch keine Bewertungen

- MOS Integrated Circuit DesignVon EverandMOS Integrated Circuit DesignE. WolfendaleNoch keine Bewertungen

- High-Performance D/A-Converters: Application to Digital TransceiversVon EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNoch keine Bewertungen

- Datapath & Control SubsystemsDokument53 SeitenDatapath & Control Subsystemsjubincb2Noch keine Bewertungen

- InterconnectDokument83 SeitenInterconnectjubincb2Noch keine Bewertungen

- Crosstalk Noise and Delay Reduction in Vlsi InterconnectsDokument5 SeitenCrosstalk Noise and Delay Reduction in Vlsi Interconnectseditor_ijaterNoch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Analysis, Reduction and Avoidance of Crosstalk On VLSI ChipsDokument8 SeitenAnalysis, Reduction and Avoidance of Crosstalk On VLSI Chipsjubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Analysis, Reduction and Avoidance of Crosstalk On VLSI ChipsDokument8 SeitenAnalysis, Reduction and Avoidance of Crosstalk On VLSI Chipsjubincb2Noch keine Bewertungen

- Datapath & Control SubsystemsDokument53 SeitenDatapath & Control Subsystemsjubincb2Noch keine Bewertungen

- Analysis, Reduction and Avoidance of Crosstalk On VLSI ChipsDokument8 SeitenAnalysis, Reduction and Avoidance of Crosstalk On VLSI Chipsjubincb2Noch keine Bewertungen

- CadDokument8 SeitenCadjubincb2Noch keine Bewertungen

- Issues in IntereDokument6 SeitenIssues in Interejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Chap4 Lect13 WireDokument18 SeitenChap4 Lect13 Wirejubincb2Noch keine Bewertungen

- Keur 00824-401 201505Dokument4 SeitenKeur 00824-401 201505erik0007Noch keine Bewertungen

- Alcohols: Properties, Naming and ReactionsDokument15 SeitenAlcohols: Properties, Naming and ReactionsPedro Moreno de SouzaNoch keine Bewertungen

- China's First Ministry of Machine-Building Standard for Radiography of WeldsDokument133 SeitenChina's First Ministry of Machine-Building Standard for Radiography of Weldsmsiddique1Noch keine Bewertungen

- Indian Railways MIG Wire Technical RequirementsDokument17 SeitenIndian Railways MIG Wire Technical RequirementsJoherNoch keine Bewertungen

- Healthcare WasteDokument32 SeitenHealthcare WasteEddiemtongaNoch keine Bewertungen

- Weldment Deffect and Rejected by StationDokument28 SeitenWeldment Deffect and Rejected by StationHadi azfar channelNoch keine Bewertungen

- Design of Biogas DigestersDokument22 SeitenDesign of Biogas DigestersSharath Chandra100% (5)

- Safety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingDokument4 SeitenSafety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingqualityfreekNoch keine Bewertungen

- Tabele Saturacije PDFDokument20 SeitenTabele Saturacije PDFTrkulja GoranNoch keine Bewertungen

- DEGASSING AGENT AF 100 - Ind1 - AngDokument1 SeiteDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- Injection Molding Defects Causes RemediesDokument60 SeitenInjection Molding Defects Causes RemediesMada PopescuNoch keine Bewertungen

- IEC20091118133046Dokument5 SeitenIEC20091118133046SEANMNoch keine Bewertungen

- General ChemistryDokument44 SeitenGeneral ChemistrySUSANA, NIÑA FELIZ C.100% (1)

- Freeze Dryer Lyophilisation FishDokument4 SeitenFreeze Dryer Lyophilisation FishcouvrefeuNoch keine Bewertungen

- About Welding Process 47Dokument1 SeiteAbout Welding Process 47XerexNoch keine Bewertungen

- Applied Thermodynamics For Marine Systems Prof. P. K. Das Department of Mechanical Engineering Indian Institute of Technology, KharagpurDokument19 SeitenApplied Thermodynamics For Marine Systems Prof. P. K. Das Department of Mechanical Engineering Indian Institute of Technology, KharagpurTommyVercettiNoch keine Bewertungen

- 651 PDFDokument12 Seiten651 PDFjitendraNoch keine Bewertungen

- Neil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorDokument4 SeitenNeil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorMahusay Neil DominicNoch keine Bewertungen

- Introduction To Mass TransferDokument44 SeitenIntroduction To Mass TransferGhazanferAliNoch keine Bewertungen

- QBDokument18 SeitenQBMudrikaNoch keine Bewertungen

- 1 PDFDokument7 Seiten1 PDFJose Luis Martinez SaavedraNoch keine Bewertungen

- Welding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsDokument1 SeiteWelding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsLLNoch keine Bewertungen

- Road Project Steps and Interview QuestionsDokument54 SeitenRoad Project Steps and Interview QuestionsaamirNoch keine Bewertungen

- Presentación SHOTPEEN 2016Dokument48 SeitenPresentación SHOTPEEN 2016aeroericNoch keine Bewertungen

- BECHEM Special Lubricants For Open Gear Drives 2015 01Dokument11 SeitenBECHEM Special Lubricants For Open Gear Drives 2015 01satfas100% (1)

- Strut and Tie Model Analysis of Prestressed Deep BeamsDokument24 SeitenStrut and Tie Model Analysis of Prestressed Deep BeamsKannan Chandrabhanu100% (1)

- CSR July August 2014 DigitalDokument60 SeitenCSR July August 2014 Digitalolger huancara gasparaNoch keine Bewertungen