Beruflich Dokumente

Kultur Dokumente

A Thermodynamic Theory of Short-Term and Creep Rupture

Hochgeladen von

eid elsayedOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Thermodynamic Theory of Short-Term and Creep Rupture

Hochgeladen von

eid elsayedCopyright:

Verfügbare Formate

Materials Science and Engineering A 419 (2006) 168171

A thermodynamic theory of short-term and creep rupture

strength of materials

B. Goldenberg

Physics Department, New Jersey Institute of Technology, University Heights, Newark, NJ 07102,

USA

Received 17 August 2005; received in revised form 12 December 2005; accepted 12 December 2005

Abstract

The objective of the work is the investigation of the relationship between the mechanisms of the short-term tensile strength and the creep

rupture strength at testing temperatures more than 2/3 of the materials melting temperatures.

The fundamental equations relating the materials tensile strength to the creep rupture strength at different temperatures and structural factors

are obtained. These equations are derived by the use of the phenomenological and statistical thermodynamics of the crystalline lattice. The

derived theoretical equation is used to determine creep on the bases of experimental values of the short-term test. The agreement between

experimental and theoretical values of the creep is demonstrated. The presented results can be applied for prediction of the creep strength of

new materials, particularly materials with enhanced mechanical properties.

2006 Elsevier B.V. All rights reserved.

Keywords: Tensile strength; Creep rupture strength; Thermodynamic

1. Introduction

For most materials, the ultimate tensile strength decreases

regularly with the increase of the temperature. Creep is normally observed by placing a constant load on a specimen and

measuring its deformation in the course of time at a constant

elevated temperature. For most materials curves of the stress at

elevated temperature (above 0.75 of the absolute melting

temper- ature, Tm ) for lines of constant rupture life or constant

minimum creep rate are common and give a complete

description of the mechanical behavior over a wide

temperature range. At low tem- peratures, when creep is less

important, the engineering design is based on the result of

short-term tensile tests; at higher tem- peratures, when the

creep rupture strength curves are below the tensile test curves,

designs must be based on the creep rupture behavior.

In many applications, the life of a part far exceeds that of a

practical laboratory test. Thus, the experimental data acquired

in the course of laboratory study must be extrapolated. The

long- range creep deformation is often estimated as the

product of the minimum creep rate and the rate prior to the

materials destruc

Tel.: +1 973 596 5714; fax: +1 973 596

5794.

E-mail address: boris.goldenberg@njit.edu.

0921-5093/$ see front matter 2006 Elsevier B.V. All rights

reserved. doi:10.1016/j.msea.2005.12.022

tion. Minimum creep rates can be established with sufficient

accuracy using calculations based on the data acquired during

the tests running from 1000 to 10,000 h (i.e. between 42 days

and about 14 months). The results of these calculations can be

used to estimate the deformation that would result from

continuous running for 100,000 h (about 11.5 years) or more.

During the last 90 years, significant effort has been devoted

to the development of relations between stress, strain and time.

Basically, a variety of empirical laws have been suggested

for description of creep rupture. Attempts have been made to

describe creep rupture strength or lifetime and other behavior

at elevated temperatures of materials based on tensile strength

(also known as short-term tensile or short lifetime). In most

cases sep- arate techniques are used to describe material

deformation for short and long lifetime.

The goal of this work is to find a correlation between the

short and long lifetime tests of metal creep and to use this

correlation to predict long lifetime behavior using the results

of the short time testing.

2. Deformation and creep at an elevated temperature

Numerous investigations [13,7] showed that the tensile

strength of materials, subjected to short-term testing, decreases

B. Goldenberg / Materials Science and Engineering A 419 (2006) 168171

with the increase of testing temperature, particularly at the

tem- peratures exceeding 2/3Tm K. In a simplified manner this

change is represented by the empirically equation similar to

the Arrehenius equation:

= 0 exp(BT )

(1)

where is the tensile strength, T the test temperature, 0 is

the empirical constant representing the critical tensile strength

extrapolated to T = 0 K and B is an empirically constant independent from deformation and temperature. B is the apparent

activation energy correlating with the melting temperature.

The experimental information about tensile strength [11]

demon- strates that in most cases Eq. (1) accurately describes

metals behavior.

Notwithstanding, a considerable number of published

results on creep rupture strength [17], based on the theory of

thermo- dynamic fluctuations, can be given by Garofalo [1]

Hi (T, S)

Zi (, T, S)i (T, S) exp RT

(2)

where is creep rate, Zi depends on temperature (T) and

contains the normal frequency () for the flow unit, the entropy

change and a structure term (S) which correlates with grain

size,

tion in which they change in various irreversible processes. At

a constant temperature and deformation we have:

d =

dP

P

Substituting (4) into (3) and making the needed

transformations, we obtain:

(4)

dP

(5)

d

=

On the other hand, Frenkel [8] has shown that the difference

between thermodynamic potential and free energy does not

explicitly depend on temperature and is in fact the difference

equal to the potential energy (internal energy) of the

crystalline system:

F = U0

(6)

At the same time:

d = S dT

(7)

or, taking in account that S = F/T, we obtain

d =

F dT

T

precipitation dispersion phases, density, distribution and length

of dislocations. The stress function i may depend on

tempera-

Substituting (6) and (8) into (5), we have:

ture and structure because creep mechanisms are temperatureand structure-dependent. Hi in the exponential term is the

true

activation energy for ith process governing the creep rate and

is

temperature- and structure-dependent.

Many experimental results and also theoretical works

confirm this equation in different experimental forms and with

different degrees of accuracy.

Most experimental results of creep rupture strength are used

as bases for mathematical equations and to extrapolate long

lifetime for different materials. Unfortunately, most of these

experimental equations have been determined only in

qualitative manner, and such evidence does not add

sufficiently to the basic understanding of mechanism creep.

dP = (F/T ) dT

P

U0

3. Statistical thermodynamics analysis of the crystalline

lattice

Eqs. (3)(10) based on fundamental principles of statistics

physics are well described [8,9], and derivation was given here

for clear understanding of the logic of the theory to combine

the

short-term and creep rupture strength of the solid state.

Eq. (1) suggested by Zaikov [11] is taken as the basis for

the following derivation and based on the free energy of the

solid state, at an applied external force P, can be written in the

169

(8)

(9)

Free energy of the solid state can be presented in the form [9]:

ln(1 ehv / kT )

F = F0 + kT

(10)

In this case the summation is carried out over all oscillations

3N with an index . The constant F0 , the energy of interaction

of all atoms of the body in the state of equilibrium, i.e. in the

state of zero oscillations of frequency 0 , is added to the sum

of all oscillations. At any given volume it does not depend on

temperature. At high temperatures one can assume that

h

1 eh /kT

kT

(11)

and with sufficient degree of accuracy (as noted in [10]), free

energy of metals can be written in the form

F = 3RT

ln

0

(12)

form [8]:

F = P

P

(3)

where is the thermodynamic potential, a function of

tempera- ture, load and deformation. The free energy and

thermodynamic potential have an important property which

determine the direc-

with regard to time = 1/ , where is oscillation of the

atoms that lose their bond with each other. The derivative of

the free energy with respect to temperature sum time for all

atoms which lose their bond during falure has the form (13)

0

F = 3RT ln

(13)

where 0 is period oscillation atoms in solid state at low

tepera- ture close to 0 K and assumed value 1013 s. is the

total time of period of oscillation atoms that achieved the

amplitude to lost bonds of atoms and the fact failure of a solid

state.

170

B. Goldenberg / Materials Science and Engineering A 419 (2006) 168171

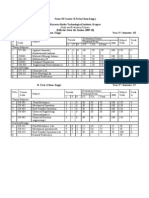

Table 1

Calculation of the tensile strength 0 and activation energy U0 of the elements of the periodic table at elevated temperature

No.

Chemical

element

Mode of

production

Melting

temperature (K)

Temperature

testing (K)

Type of crystalline

lattice

Tensile strength,

0 (MPa)

Activation energy,

U0 (kJ/mol)

Ref.

1

2

3

4

5

6

7

8

9

10

11

12

Pb

Al

Cu

Cu

Ni

Ni

Sn

V

Nb

Mo

Ta

W

NA

NA

NA

Forging

Casting

Forging

NA

NA

NA

NA

NA

NA

600

933

1357

1357

1728

1728

505

2183

2750

2896

3290

3695

423538

673913

8731273

810995

11731573

11441366

426500

10001500

11731573

18002300

21553090

22553033

fcc

fcc

fcc

fcc

fcc

fcc

bcc

bcc

bcc

bcc

bcc

bcc

313.8

941.3

3853.0

2990.0

5020.0

6520.0

402.0

1304.0

2598.2

2692.3

3392.4

4520.0

123.5

147.8

185.1

185.1

224.4

253.7

85.4

317.4

444.2

522.5

493.6

592.5

[12]

[12]

[12]

[12]

[12]

[12]

[12]

[13]

[13]

[13]

[13]

[13]

Substituting (13) into (9) and assuming that for a solid state

P = , where is the critical tensile strength, one can

rewrite:

d

3R ln(0 /) dT

=

U0

(14)

As the temperature increases from 0 up to T K, the strength

decreases from 0 to . So 0 could be interpreted as a stress

limit for solid states at temperature close to 0 K. Integrating

(14) with the corresponding limits, we obtain (15):

d= T 3R ln( /)

0

dT0

U0

or

3RT ln(0 /)

ln =

0

U0

(15)

Since 0 / < 1 and / 0 < 1, ln( 0 /) and ln(/ 0 ) are

negative and in the case under consideration it follows that

the tensile strength always decreases with the increase of

temperature. Tak- ing into account the negative sign one can

write:

= 0

exp

3RT ln(0 /)

U0

(16)

Comparing expressions (16) and (1) we see that

B=

3RT ln(0 /)

U0

(17)

that is, it depends on time of deformation and energy U0 .

From (16) it is easy to obtain the relation for the lifetime of

mate- rials depending on stress (), temperature (T) and

structure of materials ( 0 , 0 , U0 ):

U0 ln(/0 )

= 0

exp

3RT

(18)

In this case the dependence of on temperature has the

purely exponential character. At the same time with the

increase of the deformation rate in (19) the value of ln(0

)/ decreases, i.e.

increases, which is a good correlation with the data given by

Zaikov [3].

4. Experimental results and discussion

In order to estimate quantitatively the values of 0 , and U0

of (16), I used the results given by the mechanical tests [12,13]

and the standard procedure approximated by the trend line as

calculated by the program Excel.

The corresponding values of 0 and U0 for 12 pure elements

of the periodic table determined from computed coefficients

with

regard to the time of the mechanical tests, given in [12,13],

were processed according to (16) regarding 0 = 1013 s. The

results of the calculations are presented in Table 1. Fig. 1

shows

that dependence of U0 on Tm K is analogous to the wellknown

dependence of self-diffusion activation energy on Tm K [1].

The way 0 depends on Tm K is rather complex and is

different for

the crystalline lattices of the studied metals (Fig. 2). Following

Fig. 2 and taking into account (18) one can see that at higher

testing rates the fcc lattice metals are more advantageous,

since at the same melting temperature they have a higher value

of 0 .

In order to check (18), the calculation of creep rupture

strength of Al was carried out, using the computed values of

0 = 941.3 MPa and U0 = 147.8 kJ/mol (the value is close to

acti- vation energy of self-diffusion) (Table 1). The obtained

results

Expression (18) is written with regards to / 0 < 1 and, thus,

ln(/ 0 ) < 0.

Eq. (14) can be written with regards to the deformation rate

and = / as:

3RT ln(0 /)

= 0 exp

U0

(19)

Since the short-term tests, as a rule, are being carried out at

constant rates of loading, the value of the natural logarithm in

(16) can be considered to be approximately constant.

Fig. 1. Relation between activation energy and temperature melting of some

elements of periodic table in accordance with Table 1.

B. Goldenberg / Materials Science and Engineering A 419 (2006) 168171

2.

3.

4.

Fig. 2. Tensile strength of periodic table elements extrapolated to T

=0K

depends on temperature melting and structure of crystalline lattice.

5.

171

term lifetimes for temperature test at more than 2/3 of the

melting temperature which tell us about the one physical

mechanism for both short- and long-term lifetimes at this

temperature.

The empirical coefficient (B) from Eq. (1) is physical interpreted in the obtained Eq. (17).

The lifetime dependent on the structure of the crystalline

lattice is shown.

The lifetime should be better for fcc crystalline lattice at the

homological temperature.

The long-term lifetime of materials should be calculated

based on short-term test results of the same materials.

References

Fig. 3. Compare experimental lifetime pure Al with theoretical prediction in

accordance with Eq. (18).

for aluminum tested at 673 K in the strength range from 1.86

to

19.6 MPa are presented in Fig. 3, in comparison with the

exper- imental results from [3]. Fig. 3 shows that the

calculated value of the lifetime agrees with the experimental

results.

Thus, the tensile strength at high temperature tests of the

metals allows the calculation of the creep rupture strength in

this temperature range.

5. Conclusion

1. Based on statistical thermodynamics, Eqs. (18) and (19)

are received which can be used for both short- and long-

[1] F. Garofalo, Fundamentals of Creep Rupture in Metals, Macmillan, New

York, 1965, p. 258.

[2] M.E. Kassner, M.T. Perez-Prado, Five-Power-Law Creep in Single

Phase Metals and Alloys, Pergamon Press, Prog. Mater. Sci. 45

(2000)

102.

[3] M.A. Zaikov, Deformation Regimes and Forces under Hot Rolling, Metallurgizdat, Moscow, 1990, p. 223.

[4] V.R. Regel, A.I. Slutzker, E.E. Tomashevsky, The Kinetic of Solid Body

Strength, Nauka, Moscow, 1974, p. 560.

[5] F.J. Clauss, Engineers Guide to High-temperature Metals, AddisonWesley Publishing Company, 1969, p. 401.

[6] J.P. Poirier, Creep of Crystals High-Temperature Deformation Processes

in Metals Ceramics and Materials, Cambridge University Press,

1985, p. 260.

[7] V.A. Stepanov, V.V. Shpeizman, Failure of Metals, Physics

of Metals and Metal Science, University Press, Leningrad,

1973, pp. 533.

[8] Y.I. Frenkel, Statistical Physics, Academia Nauk, Leningrad, 1948, p.

760.

[9] L.D. Landau, E.M. Lifshits, Theoretical Physics, vol. 5, Nauka, Moscow,

1964, p. 567.

[10] Y.I. Frenkel, Introduction into the Theory of Metals, Nauka, Leningrad,

1948, p. 220.

[11] M.A. Zaikov, J. Theor. Phys. 19 (6) (1949) 684695.

[12] A.A. Presnyakov, Plasticity of Technical Alloys, AN KazSSR,

Alma- Ata, 1964, p. 220.

[13] A.T. Tumanov, K.I. Portnoy (Eds.), High Temperature

Materials for

Design Machine,

Handbook,

Mashinostroenie,

Moscow, 1967, p. 392.

Das könnte Ihnen auch gefallen

- Qpedia Oct14 Heat Transfer Calculations of ThermosyphonDokument5 SeitenQpedia Oct14 Heat Transfer Calculations of ThermosyphonHMMSPNoch keine Bewertungen

- Albany Profile (GT) RevDokument48 SeitenAlbany Profile (GT) RevHeri SetyantoNoch keine Bewertungen

- 5 IR Correction Program (CorrectIR)Dokument21 Seiten5 IR Correction Program (CorrectIR)barry nancoo100% (1)

- Handout PDFDokument51 SeitenHandout PDFSCE SOLAPURNoch keine Bewertungen

- Boiler Tubes Overheating Failures and Actions To Control ThemDokument2 SeitenBoiler Tubes Overheating Failures and Actions To Control ThemThanhluan NguyenNoch keine Bewertungen

- Steam Turbin Thermal EvaluationDokument22 SeitenSteam Turbin Thermal EvaluationRi Ko100% (1)

- A View On The General Practice in Engineering Failure AnalysisDokument8 SeitenA View On The General Practice in Engineering Failure Analysisandsateb_01Noch keine Bewertungen

- Certificate of Analysis: National Institute of Standards and TechnologyDokument5 SeitenCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosNoch keine Bewertungen

- Status of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229Dokument57 SeitenStatus of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229sarangss100% (1)

- High Temperature CorrosionDokument3 SeitenHigh Temperature CorrosiontechzonesNoch keine Bewertungen

- B&W IR-CFB: Operating Experience and New Development: Technical PaperDokument8 SeitenB&W IR-CFB: Operating Experience and New Development: Technical PaperS. P.Noch keine Bewertungen

- Nickel-Iron-Chromium Alloy Seamless Pipe and Tube: Standard Specification ForDokument8 SeitenNickel-Iron-Chromium Alloy Seamless Pipe and Tube: Standard Specification ForGreg YeeNoch keine Bewertungen

- 1584Dokument6 Seiten1584malsttarNoch keine Bewertungen

- Syn Converter NitridingDokument10 SeitenSyn Converter NitridingGaurav GuptaNoch keine Bewertungen

- Steam Boiler Inspections Using Remote Field Testing: by Mynor Celis, P.Eng, Russell NDE SystemsDokument11 SeitenSteam Boiler Inspections Using Remote Field Testing: by Mynor Celis, P.Eng, Russell NDE SystemsAnonymous lmCR3SkPrKNoch keine Bewertungen

- Fatigue Failure Resulting From Variable Loading 1-2Dokument24 SeitenFatigue Failure Resulting From Variable Loading 1-2Rahul SinghNoch keine Bewertungen

- Creep and Life Assessment of Engineering Components in Power Plants and Process IndustriesDokument30 SeitenCreep and Life Assessment of Engineering Components in Power Plants and Process IndustriesThomas TuckerNoch keine Bewertungen

- Shutdown System in PFBRDokument8 SeitenShutdown System in PFBRCuddalore J ShanthakumarNoch keine Bewertungen

- 226 Eddystone Station UnitDokument24 Seiten226 Eddystone Station UnitsbktceNoch keine Bewertungen

- 1 - Combustion Principle & Flue Gas Analysis - Muka 16-18 Sep 2015 - YP Rev0Dokument21 Seiten1 - Combustion Principle & Flue Gas Analysis - Muka 16-18 Sep 2015 - YP Rev0yuliantoNoch keine Bewertungen

- Metallographic Investigation On The Cladding FailureDokument18 SeitenMetallographic Investigation On The Cladding FailureAndres_Pastor1987Noch keine Bewertungen

- Coke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Dokument31 SeitenCoke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Piyush PrasadNoch keine Bewertungen

- Failure of PigtailsDokument32 SeitenFailure of Pigtailsbarry nancoo100% (1)

- Aiche-36-022Ammonia Converter-Ll Outlet LinesDokument16 SeitenAiche-36-022Ammonia Converter-Ll Outlet LinesHsein WangNoch keine Bewertungen

- Fatigue Analysis and Design of Different Compressor Rotor BladeDokument16 SeitenFatigue Analysis and Design of Different Compressor Rotor BladeAmbrish SinghNoch keine Bewertungen

- Steel AssignmentDokument31 SeitenSteel AssignmentAnonymous 7J96P4ANNoch keine Bewertungen

- In-Service Feed Water Heater Condition Assessment Using The Pulsed Eddy Current NDE Technology PDFDokument68 SeitenIn-Service Feed Water Heater Condition Assessment Using The Pulsed Eddy Current NDE Technology PDFhirenkumar patelNoch keine Bewertungen

- Steam Turbine Blade Erosion Protection Options: Donald R Leger and Paul Franklin EthosenergyDokument13 SeitenSteam Turbine Blade Erosion Protection Options: Donald R Leger and Paul Franklin EthosenergySh.nasirpurNoch keine Bewertungen

- Boiler Tube AssessmentDokument7 SeitenBoiler Tube AssessmentNorman IskandarNoch keine Bewertungen

- Boiler Corrosion MagnetiteDokument14 SeitenBoiler Corrosion MagnetiteJakeTheSnake69Noch keine Bewertungen

- Jte11725j DL.1415051 1 PDFDokument5 SeitenJte11725j DL.1415051 1 PDFpaolaNoch keine Bewertungen

- Zinc CoatingsDokument12 SeitenZinc CoatingsvvgdreamNoch keine Bewertungen

- BoilerDokument7 SeitenBoilerXie ShjNoch keine Bewertungen

- en 10213 2007 Steel Castings For Pressure Purposes PDFDokument29 Seitenen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNoch keine Bewertungen

- RLA in High Temp Zones of Power Plant ComponentsDokument7 SeitenRLA in High Temp Zones of Power Plant ComponentsEzhil Vendhan PalanisamyNoch keine Bewertungen

- Troubleshooting ST Path Damage MechanismsDokument40 SeitenTroubleshooting ST Path Damage Mechanismsjerezg25100% (1)

- Corrosion of Water Walls and Superheaters in Wte MSW PlantsDokument114 SeitenCorrosion of Water Walls and Superheaters in Wte MSW Plantsvijay_nani124Noch keine Bewertungen

- Nilai MK Post-Intermediate Listening 2017Dokument6 SeitenNilai MK Post-Intermediate Listening 2017Ledi Wakha WakhaNoch keine Bewertungen

- Creep - Iwshibli PDFDokument32 SeitenCreep - Iwshibli PDFIvanUribeNoch keine Bewertungen

- Measurements in A Pulsating FlowDokument13 SeitenMeasurements in A Pulsating Flowusebio64Noch keine Bewertungen

- Making O&M More EfficientDokument7 SeitenMaking O&M More EfficientNadia AlvaradoNoch keine Bewertungen

- Module 3. Pipe Scanning: 3.1. PrinciplesDokument8 SeitenModule 3. Pipe Scanning: 3.1. PrinciplesWillykateKairuNoch keine Bewertungen

- Superheater Corrosion in USC Power PlantDokument136 SeitenSuperheater Corrosion in USC Power PlantDanie-Els100% (1)

- Module 8 - Energy Performance Assessment of BoilersDokument24 SeitenModule 8 - Energy Performance Assessment of BoilersAnonymous a19X9GHZNoch keine Bewertungen

- ElectriSCAN Sample ReportDokument22 SeitenElectriSCAN Sample ReportAnonymous Wu6FDjbNoch keine Bewertungen

- TP Metals 09 01Dokument13 SeitenTP Metals 09 01carl2001Noch keine Bewertungen

- Guidelines For Enhancing The Functions of Critical Equipment Owners at Fossil Power PlantsDokument84 SeitenGuidelines For Enhancing The Functions of Critical Equipment Owners at Fossil Power PlantsDidin GhaziNoch keine Bewertungen

- OsidationDokument49 SeitenOsidationSadhasivam VeluNoch keine Bewertungen

- Weld Cracks in An Ammonia Converter: James D. CampbellDokument6 SeitenWeld Cracks in An Ammonia Converter: James D. Campbellvaratharajan g rNoch keine Bewertungen

- Module 7 - Flame Safeguard PrinciplesDokument18 SeitenModule 7 - Flame Safeguard PrinciplesAnonymous a19X9GHZNoch keine Bewertungen

- Edwards John Fuad HTADokument22 SeitenEdwards John Fuad HTAixoteeNoch keine Bewertungen

- Failure Avoidance Brief: Estimating Heater Tube Life: FeatureDokument3 SeitenFailure Avoidance Brief: Estimating Heater Tube Life: Featureriza9847Noch keine Bewertungen

- ASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceDokument5 SeitenASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceWagner Renato AraújoNoch keine Bewertungen

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationVon EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationNoch keine Bewertungen

- Handbook of Infrared Standards II: with Spectral Coverage betweenVon EverandHandbook of Infrared Standards II: with Spectral Coverage betweenNoch keine Bewertungen

- Thermal Shock Resistance Predictionms PDFDokument10 SeitenThermal Shock Resistance Predictionms PDFkonstantasNoch keine Bewertungen

- 2000 Creep Rupture of A GFRP Composite at Elevated Temperatures - Dutta - Hui - 2000Dokument9 Seiten2000 Creep Rupture of A GFRP Composite at Elevated Temperatures - Dutta - Hui - 2000Rodrigo LameirasNoch keine Bewertungen

- Celentano 2002Dokument13 SeitenCelentano 2002fernando_iteNoch keine Bewertungen

- Stress-Strain Constitutive Equations of Concrete Material at Elevated TemperaturesDokument18 SeitenStress-Strain Constitutive Equations of Concrete Material at Elevated TemperaturesMaurício Prado MartinsNoch keine Bewertungen

- Recovered PDF 3 PDFDokument7 SeitenRecovered PDF 3 PDFeid elsayedNoch keine Bewertungen

- Recovered PDF 3 PDFDokument7 SeitenRecovered PDF 3 PDFeid elsayedNoch keine Bewertungen

- Recovered PDF 7 PDFDokument6 SeitenRecovered PDF 7 PDFeid elsayedNoch keine Bewertungen

- Recovered PDF 10 PDFDokument9 SeitenRecovered PDF 10 PDFeid elsayedNoch keine Bewertungen

- Determination of The Elastic Properties of Au5Sn and AuSn PDFDokument7 SeitenDetermination of The Elastic Properties of Au5Sn and AuSn PDFeid elsayedNoch keine Bewertungen

- Ab-Initio Investigation of Electronic Properties and Magnetism of Half-Heusler Alloys XCrAl (X Fe, Co, Ni) PDFDokument7 SeitenAb-Initio Investigation of Electronic Properties and Magnetism of Half-Heusler Alloys XCrAl (X Fe, Co, Ni) PDFEidelsayedNoch keine Bewertungen

- Acta 2004 52 14 4121 PDFDokument11 SeitenActa 2004 52 14 4121 PDFeid elsayedNoch keine Bewertungen

- 1 s2.0 S0925838806011017 Main PDFDokument5 Seiten1 s2.0 S0925838806011017 Main PDFeid elsayedNoch keine Bewertungen

- 215-cbh 2011 PDFDokument9 Seiten215-cbh 2011 PDFeid elsayedNoch keine Bewertungen

- 163-Leejh Jap PDFDokument3 Seiten163-Leejh Jap PDFeid elsayedNoch keine Bewertungen

- Tensile, Creep, and ABI Tests On Sn5%Sb Solder PDFDokument8 SeitenTensile, Creep, and ABI Tests On Sn5%Sb Solder PDFeid elsayedNoch keine Bewertungen

- Study On The Properties of Sn-9Zn-Xcr Lead-Free Solder: Xi Chen, Anmin Hu, Ming Li, Dali MaoDokument7 SeitenStudy On The Properties of Sn-9Zn-Xcr Lead-Free Solder: Xi Chen, Anmin Hu, Ming Li, Dali Maoeid elsayedNoch keine Bewertungen

- Materials Science and Engineering BDokument7 SeitenMaterials Science and Engineering Beid elsayedNoch keine Bewertungen

- Materials Science & Engineering A: A.A. El-Daly, A. Fawzy, S.F. Mansour, M.J. YounisDokument10 SeitenMaterials Science & Engineering A: A.A. El-Daly, A. Fawzy, S.F. Mansour, M.J. Youniseid elsayedNoch keine Bewertungen

- Materials Science & Engineering A: Lu Shen, Zheng Yu Tan, Zhong ChenDokument7 SeitenMaterials Science & Engineering A: Lu Shen, Zheng Yu Tan, Zhong Cheneid elsayedNoch keine Bewertungen

- D (NG) (NV) DP - (NS) DT: 1. Gibbs Free EnergyDokument9 SeitenD (NG) (NV) DP - (NS) DT: 1. Gibbs Free EnergySheraz AliNoch keine Bewertungen

- Chemical Metallurgy Student PapersDokument3 SeitenChemical Metallurgy Student PapersParesh SaksenaNoch keine Bewertungen

- Intermolecular ForcesDokument62 SeitenIntermolecular ForcesSupasinee RNoch keine Bewertungen

- Crop Physiology Final PDFDokument113 SeitenCrop Physiology Final PDFPushp Lata100% (1)

- Practical Work Book: MY-201 Metallurgical Thermodynamics and KineticsDokument31 SeitenPractical Work Book: MY-201 Metallurgical Thermodynamics and Kineticsk_banhawyNoch keine Bewertungen

- The Concept of Exergy and Energy Quality - Truls GundersenDokument26 SeitenThe Concept of Exergy and Energy Quality - Truls Gundersenuser_account100% (1)

- Study ChemDokument13 SeitenStudy ChemJanthina Rose AusteroNoch keine Bewertungen

- Gaskell Solution ManualDokument211 SeitenGaskell Solution ManualJess Shih100% (1)

- ChE SyllabusDokument30 SeitenChE SyllabusSubodh DwivediNoch keine Bewertungen

- Summary Notes of Advanced ThermodynamicsDokument517 SeitenSummary Notes of Advanced Thermodynamicshassanmb0% (1)

- Ch12 Free Energy and ThermodynamicsDokument8 SeitenCh12 Free Energy and ThermodynamicsCitrus_EscapeNoch keine Bewertungen

- Cap 2Dokument22 SeitenCap 2MaggyBalcazarNoch keine Bewertungen

- Chemistry For Engineering PDFDokument474 SeitenChemistry For Engineering PDFzerocool86Noch keine Bewertungen

- Chapter-6 Thermodynamics Test Paper QuestionsDokument2 SeitenChapter-6 Thermodynamics Test Paper QuestionsNevin ShajiNoch keine Bewertungen

- Polymer Materials PDFDokument64 SeitenPolymer Materials PDFGajendran PandiNoch keine Bewertungen

- The Principles of Chemical Equilibrium - 1st Ed - DenbighDokument514 SeitenThe Principles of Chemical Equilibrium - 1st Ed - DenbighJoseNoch keine Bewertungen

- Electrode Potentials 2 PDFDokument93 SeitenElectrode Potentials 2 PDFDedi WahyudinNoch keine Bewertungen

- Surigao State College of Technology: Learning ModuleDokument34 SeitenSurigao State College of Technology: Learning ModuleJenemarNoch keine Bewertungen

- CH 5. Surface Chemistry (Chem +2)Dokument49 SeitenCH 5. Surface Chemistry (Chem +2)Sajag GargNoch keine Bewertungen

- Streitweiser Solvolytic Displacement ReactionsDokument182 SeitenStreitweiser Solvolytic Displacement ReactionsCharles BilleraNoch keine Bewertungen

- ChE SyllabusDokument30 SeitenChE SyllabusRavindra Kumar NiranjanNoch keine Bewertungen

- Thermochemistry: Chemical EnergyDokument24 SeitenThermochemistry: Chemical EnergygnpanagiotouNoch keine Bewertungen

- Lecture - Week 4 - Chemical Potential and Fugacity PDFDokument24 SeitenLecture - Week 4 - Chemical Potential and Fugacity PDFfNoch keine Bewertungen

- Change of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaDokument13 SeitenChange of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaEuphoria V KhosaNoch keine Bewertungen

- Simple Applications of Macroscopic ThermodynamicsDokument33 SeitenSimple Applications of Macroscopic ThermodynamicsreianreyNoch keine Bewertungen

- Home Exam in FYS2160 - Thermodynamics and Statistical PhysicsDokument3 SeitenHome Exam in FYS2160 - Thermodynamics and Statistical Physicspurity89Noch keine Bewertungen

- Lithium Ion BatteriesDokument140 SeitenLithium Ion BatteriesKosygin Leishangthem100% (1)

- Adv Eng Mater - 2008 - Zhang - Solid Solution Phase Formation Rules For Multi Component AlloysDokument5 SeitenAdv Eng Mater - 2008 - Zhang - Solid Solution Phase Formation Rules For Multi Component AlloysFábio MartinsNoch keine Bewertungen