Beruflich Dokumente

Kultur Dokumente

10.1007 - s10570 013 9972 9

Hochgeladen von

swambabuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

10.1007 - s10570 013 9972 9

Hochgeladen von

swambabuCopyright:

Verfügbare Formate

Author's personal copy

Cellulose

studied by QCM-D and application as a paper strength

additive. Cellulose 15(2):303314. doi:10.1007/s10570007-9167-3

Celzard A, Mareche JF, Payot F (2000) Simple method for

characterizing synthetic graphite powders. J Phys D Appl

Phys 33(12):1556

Celzard A, Fierro V, Pizzi A (2008) Flocculation of cellulose

fibre suspensions: the contribution of percolation and

effective-medium theories. Cellulose 15(6):803814. doi:

10.1007/s10570-008-9229-1

Celzard A, Fierro V, Kerekes R (2009) Flocculation of cellulose

fibres: new comparison of crowding factor with percolation

and effective-medium theories. Cellulose 16(6):983987.

doi:10.1007/s10570-009-9314-0

Czaja WK, Young DJ, Kawecki M, Brown RM (2006) The

future prospects of microbial cellulose in biomedical

applications. Biomacromolecules 8(1):112. doi:10.1021/

bm060620d

Dalpke B, Kerekes RJ (2005) The influence of fibre properties

on the apparent yield stress of flocculated pulp suspensions.

J Pulp Pap Sci 31(1):3943

Derakhshandeh B, Kerekes RJ, Hatzikiriakos SG, Bennington

CPJ (2011) Rheology of pulp fibre suspensions: a critical

review. Chem Eng Sci 66(15):34603470. doi:10.1016/

j.ces.2011.04.017

Dufresne A, Dupeyre D, Vignon MR (2000) Cellulose microfibrils from potato tuber cells: processing and characterization of starch-cellulose microfibril composites. J Appl

Polym Sci 76(14):20802092

Dzuy NQ, Boger DV (1985) Direct yield stress measurement

with the vane method. J Rheol 29(3):335347

Eichhorn S, Dufresne A, Aranguren M, Marcovich N, Capadona

J, Rowan S, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K,

Nogi M, Nakagaito A, Mangalam A, Simonsen J, Benight

A, Bismarck A, Berglund L, Peijs T (2010) Review: current

international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):133. doi:10.1007/s10853009-3874-0

Henriksson M, Berglund LA, Isaksson P, Lindstrom T, Nishino

T (2008) Cellulose nanopaper structures of high toughness.

Biomacromolecules 9(6):15791585. doi:10.1021/bm800

038n

Ishii D, Saito T, Isogai A (2011) Viscoelastic evaluation of

average length of cellulose nanofibers prepared by

TEMPO-mediated oxidation. Biomacromolecules 12(3):

548550. doi:10.1021/bm1013876

Jakob HF, Fengel D, Tschegg SE, Fratzl P (1995) The elementary cellulose fibril in picea abies: comparison of

transmission electron microscopy, small-angle X-ray

scattering, and wide-angle X-ray scattering results. Macromolecules 28(26):87828787. doi:10.1021/ma00130

a010

Janarthanan S, Sain M (2006) Isolation of cellulose microfibrils

an enzymathic approach. Bioresources 1(2):176188

Karppinen A, Vesterinen A-H, Saarinen T, Pietikainen P, Seppala J (2011) Effect of cationic polymethacrylates on the

rheology and flocculation of microfibrillated cellulose.

Cellulose 18(6):13811390. doi:10.1007/s10570-0119597-9

123

Kerekes RJ, Schell CJ (1992) Characterization of fibre flocculation regimes by a crowding factor. J Pulp Pap Sci 18(1):

J32J38

Kerekes RJ, Soszynski RM, Tam Doo PA (1985) The flocculation of pulp fibres. In: Proceedings of the 8th fundamental

research symposium, Oxford, England. Mechanical Engineering Publications, pp 265310

Kropholler HW, Sampson WW (2001) The effect of fibre length

distribution on suspension crowding. J Pulp Pap Sci

27(09):301305

Lasseuguette E, Roux D, Nishiyama Y (2008) Rheological

properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 15(3):425433

Liddel PV, Boger DV (1996) Yield stress measurements with

the vane. J Nonnewton Fluid Mech 63(23):235261. doi:

10.1016/0377-0257(95)01421-7

Malcolm Brown R Jr, Saxena IM, Kudlicka K (1996) Cellulose

biosynthesis in higher plants. Trends Plant Sci

1(5):149156. doi:10.1016/S1360-1385(96)80050-1

Martinez DM, Buckley K, Jivan S, Lindstrom A, Thiruvengadaswamy R, Olson JA, Ruth TJ, Kerekes RJ (2001)

Characterizing the mobility of papermaking fibres during

sedimentation. In: Baker CF (ed) The science of papermaking, transactions of the 12th fundamental research

symposium, Oxford. The Pulp and Paper Fundamental

Research Society, Bury, Lancaster, UK, pp 225254

Mosse WKJ, Boger DV, Garnier G (2012a) Avoiding slip in

pulp suspension rheometry. J Rheol 56(6):15171533

Mosse WKJ, Boger DV, Simon GP, Garnier G (2012b) Effect of

cationic polyacrylamides on the interactions between cellulose fibers. Langmuir 28(7):36413649. doi:10.1021/

la2049579

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically

transparent nanofiber paper. Adv Mater 21(16):

15951598. doi:10.1002/adma.200803174

Perkins EL, Batchelor WJ (2012) Water interaction in paper

cellulose fibres as investigated by NMR pulsed field gradient. Carbohydr Polym 87:361367. doi:10.1016/j.carbpol.

2011.07.065

Siro I, Plackett D (2010) Microfibrillated cellulose and new

nanocomposite materials: a review. Cellulose 17(3):

459494. doi:10.1007/s10570-010-9405-y

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47(3):291294. doi:

10.1002/(sici)1097-0126(199811)47:3\291:aid-pi11[3.0.

co;2-1

Varanasi S, Batchelor W (2013) Rapid preparation of cellulose

nanofibre sheet. Cellulose 20(1):211215. doi:10.1007/

s10570-012-9794-1

Varanasi S, Chiam HH, Batchelor WJ (2012) Application and

interpretation of zero and short-span testing on nanofibre

sheet materials. Nord Pulp Pap Res J 27(2):343352

Xu J, Chatterjee S, Koelling KW, Wang Y, Bechtel SE (2005)

Shear and extensional rheology of carbon nanofiber suspensions. Rheol Acta 44(6):537562. doi:10.1007/

s00397-005-0436-5

Zhang L, Batchelor W, Varanasi S, Tsuzuki T, Wang X (2012)

Effect of cellulose nanofiber dimensions on sheet forming

through filtration. Cellulose 19(2):561574. doi:10.1007/

s10570-011-9641-9

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- General Information and Format: For Submission of Project Proposals For Financial AssistanceDokument22 SeitenGeneral Information and Format: For Submission of Project Proposals For Financial AssistanceswambabuNoch keine Bewertungen

- Carbon SphereDokument11 SeitenCarbon SphereswambabuNoch keine Bewertungen

- Hydrogen Storage With Carbon FibresDokument35 SeitenHydrogen Storage With Carbon FibresswambabuNoch keine Bewertungen

- Uniflow Cyclone For Oil - Gas SeparationDokument315 SeitenUniflow Cyclone For Oil - Gas SeparationswambabuNoch keine Bewertungen

- Biodegradable PackagingDokument7 SeitenBiodegradable PackagingswambabuNoch keine Bewertungen

- Li-F - CNF Hydrogen StorageDokument9 SeitenLi-F - CNF Hydrogen Storageswambabu100% (1)

- Hydrogen Storage With Carbon FibresDokument35 SeitenHydrogen Storage With Carbon FibresswambabuNoch keine Bewertungen

- Synthesis and Study of Silver Nano ParticlesDokument4 SeitenSynthesis and Study of Silver Nano ParticlesOng Chin LengNoch keine Bewertungen

- Potential Applications of Nanocellulose-Containing Materials in The Biomedical FieldDokument31 SeitenPotential Applications of Nanocellulose-Containing Materials in The Biomedical FieldgoldennanukNoch keine Bewertungen

- Petroleum Engineering: 6 SemesterDokument6 SeitenPetroleum Engineering: 6 SemesterswambabuNoch keine Bewertungen

- Main Building, II Floor, AU College of Engineering (A) Andhra University, Visakhapatnam - 530 003Dokument27 SeitenMain Building, II Floor, AU College of Engineering (A) Andhra University, Visakhapatnam - 530 003swambabuNoch keine Bewertungen

- Petroleum Engineering: 6 SemesterDokument6 SeitenPetroleum Engineering: 6 SemesterswambabuNoch keine Bewertungen

- Potential Applications of Nanocellulose-Containing Materials in The Biomedical FieldDokument31 SeitenPotential Applications of Nanocellulose-Containing Materials in The Biomedical FieldgoldennanukNoch keine Bewertungen

- Petroleum Engineering: 6 SemesterDokument6 SeitenPetroleum Engineering: 6 SemesterswambabuNoch keine Bewertungen

- 10.1007 s10570 013 9972 9 PrintedDokument12 Seiten10.1007 s10570 013 9972 9 PrintedswambabuNoch keine Bewertungen

- Ammonia Paper Little TheoryDokument59 SeitenAmmonia Paper Little TheoryThabangNoch keine Bewertungen

- Position Description - FSI Research AssociateDokument3 SeitenPosition Description - FSI Research AssociateswambabuNoch keine Bewertungen

- Fluid: Catalytic Oxidation of Hydrogen Chloride Ina Bed ReactorDokument8 SeitenFluid: Catalytic Oxidation of Hydrogen Chloride Ina Bed ReactorswambabuNoch keine Bewertungen

- IRCTCs eDokument1 SeiteIRCTCs eswambabuNoch keine Bewertungen

- B - Environmental Engineering, LecturerDokument3 SeitenB - Environmental Engineering, LecturerswambabuNoch keine Bewertungen

- Derakhshandeh at AlDokument18 SeitenDerakhshandeh at AlswambabuNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Waste-To-Energy Plant Process Safety ChallengesDokument5 SeitenWaste-To-Energy Plant Process Safety Challengessomesh sharmaNoch keine Bewertungen

- Sikament 2002 NS: Superplasticizing AdmixtureDokument2 SeitenSikament 2002 NS: Superplasticizing AdmixtureHarshvardhan PathakNoch keine Bewertungen

- Bet MethodDokument16 SeitenBet MethodG Nivetha100% (1)

- Chocolate: Chocolate Is A Raw or Processed Food Produced From The Seed of The TropicalDokument7 SeitenChocolate: Chocolate Is A Raw or Processed Food Produced From The Seed of The TropicalNyimas Irina SilvaniNoch keine Bewertungen

- ECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BADokument152 SeitenECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BALuis RicaldiNoch keine Bewertungen

- (T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterDokument214 Seiten(T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterANTENOR JOSE ESCUDERO GÓMEZNoch keine Bewertungen

- Iso 14687 3 2014Dokument11 SeitenIso 14687 3 2014Tatiana Sainara Maia FernandesNoch keine Bewertungen

- Organic Chemistry PDFDokument181 SeitenOrganic Chemistry PDFShyam Yadav100% (1)

- IGNTU Econtent 674613883400 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 2Dokument136 SeitenIGNTU Econtent 674613883400 B.SC EnvironmentalSciences 2 PallaviDas EnvironmentalPollutionandHumanHealth 2Neeraj Raushan KanthNoch keine Bewertungen

- Table 1: Patient's Response On The Effectiveness of The Aratiles Leaves TeaDokument11 SeitenTable 1: Patient's Response On The Effectiveness of The Aratiles Leaves TeaAlice Del Rosario CabanaNoch keine Bewertungen

- Regents Homeostasis and EnzymesDokument5 SeitenRegents Homeostasis and Enzymesapi-3031203990% (1)

- Metaxil DANDokument1 SeiteMetaxil DANgurinder pal singhNoch keine Bewertungen

- Ohm's Law and Circuits: 2. Conductance, Insulators and ResistanceDokument29 SeitenOhm's Law and Circuits: 2. Conductance, Insulators and ResistanceDita PramidaNoch keine Bewertungen

- 4 Different Ways To Use Hair Oils Curly Hair Care The Wild CurlDokument1 Seite4 Different Ways To Use Hair Oils Curly Hair Care The Wild CurlMaria jose MondragonNoch keine Bewertungen

- (MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QDokument27 Seiten(MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QIsmaliza IshakNoch keine Bewertungen

- G10 - Handout - Organic - Makeup Handout - First WeekDokument4 SeitenG10 - Handout - Organic - Makeup Handout - First WeekSheela BatterywalaNoch keine Bewertungen

- (En GB) DBE 821 - 1.00Dokument7 Seiten(En GB) DBE 821 - 1.00Enio Miguel Cano LimaNoch keine Bewertungen

- List of Psychotropic Substances Under International ControlDokument25 SeitenList of Psychotropic Substances Under International ControlандрейNoch keine Bewertungen

- Nursing Care Plan PrenatalDokument5 SeitenNursing Care Plan PrenatalKim Galamgam100% (2)

- UNIT 4 Raman Spectroscopy 12309Dokument24 SeitenUNIT 4 Raman Spectroscopy 12309NathanianNoch keine Bewertungen

- Gravimetric Analysis Laboratory ReportDokument9 SeitenGravimetric Analysis Laboratory ReportShawn RizalNoch keine Bewertungen

- REPORTDokument31 SeitenREPORTUnique Boss50% (2)

- Microstructure Examination of SteelDokument8 SeitenMicrostructure Examination of SteelArunodha Hettiarachchi50% (6)

- Freecor LPC English 0Dokument7 SeitenFreecor LPC English 0mgamal1080Noch keine Bewertungen

- Biomechanical Properties of A New Fiber-Reinforced CompositesDokument10 SeitenBiomechanical Properties of A New Fiber-Reinforced Compositesazam ahmedNoch keine Bewertungen

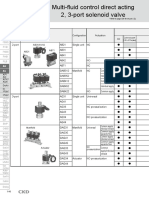

- General Purpose ValvesDokument46 SeitenGeneral Purpose ValvesbataNoch keine Bewertungen

- Materials and Design: Ehab A. El-Danaf, Magdy M. El-Rayes, Mahmoud S. SolimanDokument6 SeitenMaterials and Design: Ehab A. El-Danaf, Magdy M. El-Rayes, Mahmoud S. Solimankamal touilebNoch keine Bewertungen

- Application of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaDokument24 SeitenApplication of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaSJ ChuaNoch keine Bewertungen

- Industrial Materials: Instructed By: Dr. Sajid ZaidiDokument13 SeitenIndustrial Materials: Instructed By: Dr. Sajid ZaidiarulmuruguNoch keine Bewertungen

- Gen Bio W3-5Dokument9 SeitenGen Bio W3-5Alyson EscuderoNoch keine Bewertungen