Beruflich Dokumente

Kultur Dokumente

002 Hot Well Make Up

Hochgeladen von

Santoshkumar GuptaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

002 Hot Well Make Up

Hochgeladen von

Santoshkumar GuptaCopyright:

Verfügbare Formate

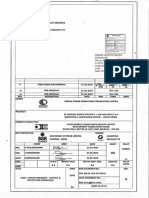

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 1 of 8

1. PURPOSE

: MAINTENANCE OF HWM

2. SCOPE

: HWM

3. REFERENCE

: JITPL/SMP/Mech/002

Prepared By:

Checked By:

Reviewed By:

Approved By:

NAME:

NAME:

NAME:

NAME:

DESIGNATION:

DESIGNATION:

DESIGNATION:

DESIGNATION:

SIGNATURE:

SIGNATURE:

SIGNATURE:

SIGNATURE:

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 2 of 8

AMENDMENT HISTORY

Sl

no.

1

Amendment Description

a. Inclusion of new hazard controls

b. Version change

Current Ver.

No.

00

Current

Rev.No

00

Issue Date

17.10.2014

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 3 of 8

GENERAL SPECIFICATION OF HOT WELL

MAKE UP PUMP:

Make

FLOWMORE

Model number

F5625-100x65

Type

Horizontal End casing

No of HWM pumps

3

Duty of pump

Continuous

Liquid handled

DM water

Stage

Single

Construction features

Type of impeller

Mixed flow in enclosed type

Seal

Mechanical seal

Type of coupling

Flexible

Prime mover

3 phase induction motor

Type of Bearing

Anti Friction

Speed

1460

Capacity

70 M3/hr

Total Head

35 Mtr

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 4 of 8

1. DEFINITION: Applicable for Hot well Make up PTW-permit to work

2. WORK INSTRUCTIONS

(NROU-3.1, 3.2)

Isolate the power supply of motor.

Close the suction & discharge valve.

Disconnect all oil & water line.

Open the coupling bolt & Decouple the motor & pump

Check the coupling & coupling bush condition.

Shift the motor form desired location.

Remove the coupling from pump shaft.

Open the bearing housing cover & check bearing condition.

Remove the mechanical seal from it position.

Check the mechanical seal outer surface condition.

Remove the casing bolt.

Check casing condition.

Check the casing neck ring condition.

Check the impeller check nut tightness condition.

Loosen the impeller check nut & remove the impeller from its

position.

Check the shaft straightness condition.

Again start assembling procedure. Sequence of assembly is

reverse of dismantling.

Check the alignment of motor & pump.

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 5 of 8

3. QUALITY CHECKS:

All the parameters, activities are maintained within limit

4. CHECKS BEFORE RELEASE OF PERMIT:

All Tools & materials and manpower are removed.

Clean the maintenance area properly.

Ensure safety protection cover / guards are fitted in its position.

4. RE-COMMISSIONING PROCEDURE:

Return PTW.

Normalize isolations after release of PTW

1.0 RESPONSIBILITY

Mechanical Engineers

2.0 MAN POWER REQUIRED: 2 Technicians,3 Helper,2 Rigger,

3.0 DURATION: 8 hrs.

4.0 OTHER DEPARTMENT TO BE INTIMATED: (Main Plant Operation

/Mech.)

5.0 DETAILS OF HAZARD INVOLVE

1. Fall/ Slip due to oily surface.

2. Fire.

3. Failure of lifting tools & tackles.

4. Exposure to high noise.

5. Contact with hot surface.

6. Exposure to process liquid.

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 6 of 8

6.0 SAFETY PRECAUTION REQUIRED:

Keep the fire extinguishers ready within reachable limit for any exigency.

Ceramic hand gloves to be used while handling thrust collar Ensure use of

periodically tested proper lifting tools & tackles.

Use of earplug is mandatory along with other general PPEs.

Ensure good housekeeping of maintenance bay

Put barricade tapes around the equipment under maintenance.

7.0 PERMIT TYPE: Permit To Work Order.

8.0 PERMIT APPROVING AUTHORITY: Shift- In-Charge (Main Control

Room)

9.0 TOOLS REQUIRED:SL. NO.

TYPE OF THE TOOL

SPECIFICATION

QUANTITY

Hammering Spanner

41 mm

4 Nos

Hammer

4lb

2 Nos

Screw driver

2 Nos

Chisel

2 Nos

Gasket Cutter

--

1 Nos

Retch Spanner

19~21

1 Nos

Retch Spanner

21~23

1 Nos

Ring ID

--

--

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 7 of 8

9

Chain Block

2T

2 Nos

10.0 MATERIALS REQUIRED:-

SL. NO.

TYPE OF THE MATERIAL

QUANTITY

Tri-pod

1 Nos

Bucket

--

Plastic bin

2 Nos

Hose pipe-1

30mtr

Scaffolding plate

8nos

Water gasket

2 Nos

10

RTV- Red Compound

04tubes

11

Embay paper-400

8 Nos

12

WP-40

2 Nos

13

Diesel

2litter

14

Wire bush

1 Nos

15

Jub clamp

1 16nos

16

Hand globes

08nos

17

Cotton west

2kg

JINDAL INDIA THERMAL POWER LIMITED

INTEGRATED MANAGEMENT SYSTEM

DEPARTMENT: MECHANICAL MAINTENANCE

WORK INSTRUCTION TITLE: MAINTENANCE OF HOT WELL MAKE UP PUMP

REV.NO : 00

JITPL/SMP/Mech/002

DATE:1.10.2014

Page 8 of 8

11.0 FREQUENCY OF MAINTENANCE: Annual Outage / In case of failures /

when required.

12.0 CHECKS BEFORE RELEASE OF PERMIT:

All Tools & materials and manpower are removed.

Clean the maintenance area properly.

Ensure safety protection cover / guards are fitted in its position.

13.0 RE-COMMISSIONING PROCEDURE:

Return PTW.

Normalize isolations after release of PTW

Das könnte Ihnen auch gefallen

- 4.3L GM Gas Engine Parts Manual PN 0D3749Dokument28 Seiten4.3L GM Gas Engine Parts Manual PN 0D3749Da GuruNoch keine Bewertungen

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsVon Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsBewertung: 1 von 5 Sternen1/5 (1)

- 3512B Engine-Maintenance Intervals PDFDokument50 Seiten3512B Engine-Maintenance Intervals PDFEdwin Morales80% (5)

- Major Process Equipment Maintenance and RepairVon EverandMajor Process Equipment Maintenance and RepairBewertung: 4 von 5 Sternen4/5 (4)

- BPM TDS Maintenance ManualDokument45 SeitenBPM TDS Maintenance ManualAnonymous MxwCc467% (3)

- Booster PumpDokument3 SeitenBooster PumpKarthi KeyanNoch keine Bewertungen

- JLG 3394RT 4394RT Service Manual PDFDokument234 SeitenJLG 3394RT 4394RT Service Manual PDFnelsonyNoch keine Bewertungen

- Henrob MaintenanceDokument10 SeitenHenrob Maintenancecesar palomoNoch keine Bewertungen

- Perforadora MD6240 - 6290+OMM - C+ (412450) Mantenimiento PDFDokument228 SeitenPerforadora MD6240 - 6290+OMM - C+ (412450) Mantenimiento PDFRonald Bustios Sanchez100% (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineVon EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineBewertung: 5 von 5 Sternen5/5 (1)

- Turbine Oil Flushing ProcedureDokument25 SeitenTurbine Oil Flushing Proceduresrigirisetty208Noch keine Bewertungen

- CarePlus Service Manual PDFDokument232 SeitenCarePlus Service Manual PDFManuel Vivero DiéguezNoch keine Bewertungen

- CDU II Operating ManualDokument562 SeitenCDU II Operating ManualRajeshwar Telang91% (11)

- 005 Scanner Air FanDokument9 Seiten005 Scanner Air FanSantoshkumar GuptaNoch keine Bewertungen

- Preliminary Erection Manual DDokument266 SeitenPreliminary Erection Manual Dganesan 0011Noch keine Bewertungen

- Boiler Drum Standard Operating ProcedureDokument10 SeitenBoiler Drum Standard Operating ProcedureAnonymous iZqHwJEIm100% (1)

- CAT MD6240 - 6290 - Manual InglésDokument228 SeitenCAT MD6240 - 6290 - Manual InglésJORGE C. CHAO R.100% (3)

- Grease Spray System User ManualDokument78 SeitenGrease Spray System User ManualDIAGNENoch keine Bewertungen

- TRANE IOM Air Cooled Scroll - Cgap CgahDokument31 SeitenTRANE IOM Air Cooled Scroll - Cgap Cgahari_arista100% (2)

- Master Drawing List-TRYDokument276 SeitenMaster Drawing List-TRYSantoshkumar GuptaNoch keine Bewertungen

- DH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0Dokument6 SeitenDH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0hungNoch keine Bewertungen

- Builders List For Website DisplayDokument2 SeitenBuilders List For Website DisplayjkahamedNoch keine Bewertungen

- BFP Test ProceduresDokument22 SeitenBFP Test ProceduresParthiban KarunaNoch keine Bewertungen

- CCB - Rev 04Dokument102 SeitenCCB - Rev 04Alok SinghNoch keine Bewertungen

- Jindal India Thermal Power Limited Integrated Management SystemDokument8 SeitenJindal India Thermal Power Limited Integrated Management SystemSantoshkumar GuptaNoch keine Bewertungen

- Jindal India Thermal Power Limited Integrated Management SystemDokument9 SeitenJindal India Thermal Power Limited Integrated Management SystemSantoshkumar GuptaNoch keine Bewertungen

- 004 HFO Forwarding PumpDokument7 Seiten004 HFO Forwarding PumpSantoshkumar GuptaNoch keine Bewertungen

- 06027electric House ManualDokument21 Seiten06027electric House ManualHayLenLeeNoch keine Bewertungen

- Rotary Kiln Hydraulic Oil Station User ManualDokument44 SeitenRotary Kiln Hydraulic Oil Station User ManualDIAGNE100% (1)

- User Manual: SMC-450 Extrusion Kerb Slipforming MachineDokument14 SeitenUser Manual: SMC-450 Extrusion Kerb Slipforming Machineshan ooiNoch keine Bewertungen

- CCB PDFDokument101 SeitenCCB PDFbruce lian100% (1)

- Oil Gun Cleaning1 PDFDokument2 SeitenOil Gun Cleaning1 PDFDevendra Singh DhakreyNoch keine Bewertungen

- Work Instruction VCBDokument3 SeitenWork Instruction VCBTAHIR HUSAINNoch keine Bewertungen

- stc12017q0002 - Post Provided Generator Checklist PDFDokument13 Seitenstc12017q0002 - Post Provided Generator Checklist PDFAnand KrishnanNoch keine Bewertungen

- TDS-Maintenance ManualDokument51 SeitenTDS-Maintenance ManualAlejandro Hernadez100% (2)

- Axial Split Volute Case PumpsDokument21 SeitenAxial Split Volute Case Pumpshardik sakariya100% (1)

- Maintenance LevelsDokument25 SeitenMaintenance Levelsmuhi salehNoch keine Bewertungen

- NUMBER: 4-10-13 S.M. REF.: Listed in Table ENGINE: EPA07 Series 60 DATE: April 2013Dokument12 SeitenNUMBER: 4-10-13 S.M. REF.: Listed in Table ENGINE: EPA07 Series 60 DATE: April 2013Walter A Gómez de la CruzNoch keine Bewertungen

- Chapter 2 Machine Maintenance.: General Workshop ProceduresDokument22 SeitenChapter 2 Machine Maintenance.: General Workshop ProcedureswillifenlonNoch keine Bewertungen

- Daihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 General Information PDFDokument9 SeitenDaihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 General Information PDFMozes SimataaNoch keine Bewertungen

- Operating & Maintenance Manual: Magnum Coolant UnitDokument28 SeitenOperating & Maintenance Manual: Magnum Coolant UnitLuis VargasNoch keine Bewertungen

- BMed Manual Manifold HTM ISO Instruction Book EN 2006230 03Dokument24 SeitenBMed Manual Manifold HTM ISO Instruction Book EN 2006230 03sai kumar GoduguNoch keine Bewertungen

- FAW CA4GA5 Engine Maintenance ManualDokument135 SeitenFAW CA4GA5 Engine Maintenance ManualjamesNoch keine Bewertungen

- Maintenance of Stenter & SteamerDokument17 SeitenMaintenance of Stenter & SteamerImtiaz Ahmed0% (2)

- Operation Manual: & Parts ListDokument62 SeitenOperation Manual: & Parts ListanggieNoch keine Bewertungen

- Maintenance Manual 90 Degree Bend WO 11244Dokument16 SeitenMaintenance Manual 90 Degree Bend WO 11244swttuningNoch keine Bewertungen

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Dokument255 SeitenD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- MJR For 30M Maintenance Check of Check ValvesDokument9 SeitenMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Diesel Motor Use and MaintenanceDokument46 SeitenDiesel Motor Use and MaintenanceMario StrašniNoch keine Bewertungen

- DENAIR Oil Free Scroll Compressor Operation ManualDokument23 SeitenDENAIR Oil Free Scroll Compressor Operation ManualGrumetcomNoch keine Bewertungen

- 81W173047 (P13069) PDFDokument435 Seiten81W173047 (P13069) PDFharounNoch keine Bewertungen

- Skgd2000 CeDokument98 SeitenSkgd2000 CeRafael GiraldoNoch keine Bewertungen

- IOM DUrcoDokument28 SeitenIOM DUrcoAlex RodriguezNoch keine Bewertungen

- Gi PDFDokument34 SeitenGi PDFdunesNoch keine Bewertungen

- Maintenance InstructionsDokument27 SeitenMaintenance InstructionsDaniel TostaNoch keine Bewertungen

- DVC O&M Manual Axial FanDokument291 SeitenDVC O&M Manual Axial FanAmitava PalNoch keine Bewertungen

- Cogen Maintenance ManualDokument31 SeitenCogen Maintenance ManualircasinagaNoch keine Bewertungen

- JLG 400S 460SJ Service and Maintenance Manual Boom Lift 3120895Dokument460 SeitenJLG 400S 460SJ Service and Maintenance Manual Boom Lift 3120895LarryNoch keine Bewertungen

- Service and Maintenance Instructions: 48TC D Nominal 15 To 25 Tons With Puron® (R - 410A) RefrigerantDokument103 SeitenService and Maintenance Instructions: 48TC D Nominal 15 To 25 Tons With Puron® (R - 410A) RefrigerantdjtruquitosNoch keine Bewertungen

- 178 - Manual Advantage Lab AL02-02 & AL02-06 & AL02-08 Rev 00Dokument51 Seiten178 - Manual Advantage Lab AL02-02 & AL02-06 & AL02-08 Rev 00ermanno100% (1)

- General Information OverviewDokument9 SeitenGeneral Information OverviewandriNoch keine Bewertungen

- PM 11.04.2016Dokument3 SeitenPM 11.04.2016Santoshkumar GuptaNoch keine Bewertungen

- Latest Battery ChecklistDokument4 SeitenLatest Battery ChecklistSantoshkumar GuptaNoch keine Bewertungen

- Ep 3 GN 107 006 Typical SLD of LTSWGRDokument10 SeitenEp 3 GN 107 006 Typical SLD of LTSWGRSantoshkumar GuptaNoch keine Bewertungen

- 3200 Amps Temparature Rise TestDokument10 Seiten3200 Amps Temparature Rise TestSantoshkumar GuptaNoch keine Bewertungen

- Method Statement Earthing Rev03 Signed Cover SheetDokument1 SeiteMethod Statement Earthing Rev03 Signed Cover SheetSantoshkumar GuptaNoch keine Bewertungen

- Switchyard Tower Structure Installation - RV 01Dokument15 SeitenSwitchyard Tower Structure Installation - RV 01Santoshkumar GuptaNoch keine Bewertungen

- EPD-391-506-E001 Rev00Dokument5 SeitenEPD-391-506-E001 Rev00Santoshkumar GuptaNoch keine Bewertungen

- Comments Reply SheetDokument3 SeitenComments Reply SheetSantoshkumar GuptaNoch keine Bewertungen

- 630 Amps Short Circuit TestDokument21 Seiten630 Amps Short Circuit TestSantoshkumar GuptaNoch keine Bewertungen

- BGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Dokument4 SeitenBGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Santoshkumar GuptaNoch keine Bewertungen

- BGR PPD 0208 El MQP 0494 r2 Mitp 400kv Swyd STR Cat 1Dokument4 SeitenBGR PPD 0208 El MQP 0494 r2 Mitp 400kv Swyd STR Cat 1Santoshkumar GuptaNoch keine Bewertungen

- OPGC Comments On Method Statement For 400 KV Switch Yard Structural InstallationDokument2 SeitenOPGC Comments On Method Statement For 400 KV Switch Yard Structural InstallationSantoshkumar GuptaNoch keine Bewertungen

- 415V PMCC/MCC, 415V Ac & 220V DC DB/SVB/FB, 220V DC Starter: 2X660Mw Ib Valley Tps Data Sheet LV SwitchgearDokument14 Seiten415V PMCC/MCC, 415V Ac & 220V DC DB/SVB/FB, 220V DC Starter: 2X660Mw Ib Valley Tps Data Sheet LV SwitchgearSantoshkumar GuptaNoch keine Bewertungen

- Skeleton GrammarDokument19 SeitenSkeleton GrammardiemnganNoch keine Bewertungen

- Ep 3 GN 107 001R1Dokument14 SeitenEp 3 GN 107 001R1Santoshkumar GuptaNoch keine Bewertungen

- GID 208 ME GAF DS 50322 Raw Water Motor Datasheet R2 Cat 2Dokument6 SeitenGID 208 ME GAF DS 50322 Raw Water Motor Datasheet R2 Cat 2Santoshkumar GuptaNoch keine Bewertungen

- Kohet e Foljes - 1Dokument21 SeitenKohet e Foljes - 1Shqipni etnike 1912Noch keine Bewertungen

- 01660570011C203 - R1 (Approved) - 07.11.14Dokument1 Seite01660570011C203 - R1 (Approved) - 07.11.14Santoshkumar GuptaNoch keine Bewertungen

- HE-10821-16605-D - R0 (Commented) - 09.06.14Dokument2 SeitenHE-10821-16605-D - R0 (Commented) - 09.06.14Santoshkumar GuptaNoch keine Bewertungen

- HE-10821-16605-D - R1 (Approved) - 07.11.14Dokument5 SeitenHE-10821-16605-D - R1 (Approved) - 07.11.14Santoshkumar GuptaNoch keine Bewertungen

- GID 208 ME GAF DS 50323 Characteristic Curves R2 Cat 1Dokument6 SeitenGID 208 ME GAF DS 50323 Characteristic Curves R2 Cat 1Santoshkumar GuptaNoch keine Bewertungen

- IB Thermal Power Station Units 3 & 4 Odisha Power GenerationDokument1 SeiteIB Thermal Power Station Units 3 & 4 Odisha Power GenerationSantoshkumar GuptaNoch keine Bewertungen

- Exciter Outline - 01450001115 - EOL - REV01 - 09.12.2014 - Action 5Dokument1 SeiteExciter Outline - 01450001115 - EOL - REV01 - 09.12.2014 - Action 5Santoshkumar GuptaNoch keine Bewertungen

- 01660570008C203 - R0 (Commented) - 09.06.14Dokument1 Seite01660570008C203 - R0 (Commented) - 09.06.14Santoshkumar GuptaNoch keine Bewertungen

- Booster Pump Motor Technical Data Sheet ReviewedDokument7 SeitenBooster Pump Motor Technical Data Sheet ReviewedSantoshkumar GuptaNoch keine Bewertungen

- Gid 208 Me Sga Ds 52347 r0 Perf. Curves Booster Cat 1Dokument5 SeitenGid 208 Me Sga Ds 52347 r0 Perf. Curves Booster Cat 1Santoshkumar GuptaNoch keine Bewertungen

- IB Thermal Power Station Units 3 & 4 Odisha Power GenerationDokument1 SeiteIB Thermal Power Station Units 3 & 4 Odisha Power GenerationSantoshkumar GuptaNoch keine Bewertungen

- Gid 208 El Aca XK 58353 r0 420kv CKT BKR CTRL Cat 6Dokument13 SeitenGid 208 El Aca XK 58353 r0 420kv CKT BKR CTRL Cat 6Santoshkumar GuptaNoch keine Bewertungen