Beruflich Dokumente

Kultur Dokumente

Iso Max Spec

Hochgeladen von

onspsnonsOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Iso Max Spec

Hochgeladen von

onspsnonsCopyright:

Verfügbare Formate

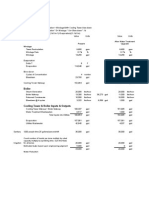

IsoMax Sound Isolation Clip Specifications

Part 1 General

1.01 Work Included

A. Furnish all labor, materials, tools, and equipment to install sound isolated walls and/or

ceilings. Construct walls and/or ceilings using the sound isolation clip where shown on

contract drawings.

1.02 System Description

A. Gypsum board shall be attached to resiliently supported furring channel to sound isolate

the material from the wall or ceiling structure. This resilient attachment substantially

reduces sound transmission through the wall or ceiling.

1.03 Quality Assurance

A. The resilient sound isolation clips shall be designed and fabricated at the facilities of a

manufacturer having a minimum of five years experience in furnishing similar sound

control products.

1.04 Submittals

A. Submit product data

1. Catalog cut sheet.

2. Sound Transmission Loss Test Report per ASTM E90-99 documenting a minimum

STC 57 wall assembly for a 2 in. x 4 in. wood stud wall with one layer of 5/8 in.

gypsum board on each side. Also submit same report for a 2 in. x 4 in. wall assembly

with two layers of 5/8 in. gypsum board on each side achieving a minimum STC 64.

3. Sound test reports must be from an independent laboratory accredited by the National

Institute of Standards and Technology (NIST) under the National Voluntary Laboratory

Accreditation Program (NVLAP).

Iso-Max Sound Isolation Clip Specifications

Page 2

Part 2.00 Product

2.01 Materials

A. Sound isolation clips specified shall be designed and manufactured by Kinetics Noise

Control, Dublin, Ohio. Product shall be Model Iso-Max Sound Isolation Clips.

B. Vertical Load capacity. Clips shall have sufficient capacity to support wall or ceiling

weights as constructed. In a vertical load test comparible to a ceiling installation, the clip

shall have a minimum design load capacity of 36 lbs. using 25 gauge furring channel.

The minimum design load capacity when using 22 gauge furring channel shall be 48 lbs.

Design Load capacity shall be based on a safety factor where the load to failure, defined

as pullout of the channel from the clip, is a minimum 2.5 times the allowable maximum

Design Load. Anchors for attachment of the clips to the substructure shall be selected to

support wall and/or ceiling weights at each clip.

C. The isolation clips shall consist of a rubber element into which a standard galvanized

steel furring channel, 7/8 in. x minimum 25 gauge, is captured. The channel legs snap fit

into the rubber element without any metal-to-metal or other rigid contact with building

elements.

D. The isolation clip is attached to the wall/ceiling framing or other structural substrate

through galvanized steel brackets on each side of the rubber isolation element. The

brackets shall be of sufficient strength to carry the wall or ceiling weight without bending

or failure.

Part 3.00 Execution

3.01 Installation

A. General Install work in accordance with the manufacturers approved product

installation procedures.

B. Spacing and location of sound isolation clips shall be determined by the manufacturer

based on wall or ceiling type. Installation drawing details shall be provided by the

manufacturer to assure optimum sound control and structural integrity of the system.

3/20/03

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Pipe Wall Thickness (ASME B31.3)Dokument12 SeitenPipe Wall Thickness (ASME B31.3)Rachmad HidayatNoch keine Bewertungen

- SPEC For Chilled Water Pipework and FittingsDokument4 SeitenSPEC For Chilled Water Pipework and FittingsonspsnonsNoch keine Bewertungen

- Basics of Refrigeration CycleDokument2 SeitenBasics of Refrigeration CyclePradeep SukumaranNoch keine Bewertungen

- 0014-Cpr-001 Concept Phase Report 170409bDokument15 Seiten0014-Cpr-001 Concept Phase Report 170409bonspsnonsNoch keine Bewertungen

- Ahu 01 (STD)Dokument5 SeitenAhu 01 (STD)onspsnonsNoch keine Bewertungen

- Ashraed2830120060711Dokument6 SeitenAshraed2830120060711kabardeyNoch keine Bewertungen

- 00 BLANK - Hot and Cold Water LU Calculation SheetDokument17 Seiten00 BLANK - Hot and Cold Water LU Calculation SheetmaxmorekNoch keine Bewertungen

- Vibration in Pumps PDFDokument5 SeitenVibration in Pumps PDFonspsnonsNoch keine Bewertungen

- Cib HDokument1 SeiteCib HonspsnonsNoch keine Bewertungen

- PDO SMO Buildings - Site Visit ReportDokument9 SeitenPDO SMO Buildings - Site Visit ReportonspsnonsNoch keine Bewertungen

- Fire Damper Installation DetailsDokument1 SeiteFire Damper Installation DetailsonspsnonsNoch keine Bewertungen

- WaStop SS - PVC - PE International Version 2014Dokument2 SeitenWaStop SS - PVC - PE International Version 2014onspsnonsNoch keine Bewertungen

- Air Distribution Basics and Duct DesignDokument46 SeitenAir Distribution Basics and Duct DesignVali GheorghisorNoch keine Bewertungen

- Balancing and Vibration LimitsDokument3 SeitenBalancing and Vibration Limitsramamoorthy_sNoch keine Bewertungen

- A O Smith Residential Water Heater CatalogDokument24 SeitenA O Smith Residential Water Heater CatalogonspsnonsNoch keine Bewertungen

- Cooling Tower ArticleDokument7 SeitenCooling Tower ArticleAudrey Patrick KallaNoch keine Bewertungen

- CalculationsDokument2 SeitenCalculationsAliAliNoch keine Bewertungen

- Drainge&Waste WaterDokument43 SeitenDrainge&Waste WatermohdnazirNoch keine Bewertungen

- 3/5/8 (Soft/standard/hard Membrane) : To Be Updated With The Requirement of The Installation/purposeDokument1 Seite3/5/8 (Soft/standard/hard Membrane) : To Be Updated With The Requirement of The Installation/purposeonspsnonsNoch keine Bewertungen

- Icc SpecDokument2 SeitenIcc SpeconspsnonsNoch keine Bewertungen

- FDS B 4 - CoilDokument1 SeiteFDS B 4 - CoilonspsnonsNoch keine Bewertungen

- ECO V - CatalogueDokument5 SeitenECO V - CatalogueonspsnonsNoch keine Bewertungen

- Icw SpecDokument3 SeitenIcw SpeconspsnonsNoch keine Bewertungen

- High TonesDokument2 SeitenHigh TonesonspsnonsNoch keine Bewertungen

- High Impact Hard SideDokument2 SeitenHigh Impact Hard SideonspsnonsNoch keine Bewertungen

- Commercial STL HTL Panels SpecificationDokument4 SeitenCommercial STL HTL Panels SpecificationonspsnonsNoch keine Bewertungen

- FLM SpecificationsDokument2 SeitenFLM SpecificationsonspsnonsNoch keine Bewertungen

- Chiller Barrier Wall SpecificationDokument2 SeitenChiller Barrier Wall SpecificationonspsnonsNoch keine Bewertungen

- Barrier Wall SystemsDokument2 SeitenBarrier Wall SystemsonspsnonsNoch keine Bewertungen

- Hard Side Cloud SystemDokument2 SeitenHard Side Cloud SystemonspsnonsNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Sika Chapdur - Floor HardenerDokument2 SeitenSika Chapdur - Floor HardenerVirah Sammy Chandra100% (1)

- Coconut Fatty Acid Diethanolamide - CDE 85Dokument6 SeitenCoconut Fatty Acid Diethanolamide - CDE 85Iqbal batchaNoch keine Bewertungen

- ME Con-1 Mock-1Dokument15 SeitenME Con-1 Mock-1vidya chakitwarNoch keine Bewertungen

- Eisen: 618B / 818B Series Precision Surface GrindersDokument2 SeitenEisen: 618B / 818B Series Precision Surface GrindersRam ViswanathanNoch keine Bewertungen

- Online Notice of School Assignment PDFDokument2 SeitenOnline Notice of School Assignment PDFRalph JaramilloNoch keine Bewertungen

- Game Maker Book 1 - New EditionDokument299 SeitenGame Maker Book 1 - New EditionBen Tyers100% (2)

- Some Observations and Experience With Pile Integrity Testing at Various Projects For EssarDokument5 SeitenSome Observations and Experience With Pile Integrity Testing at Various Projects For EssarKausik DewanNoch keine Bewertungen

- Using Mapping Tools in MATLABDokument22 SeitenUsing Mapping Tools in MATLABوجدي بلخيريةNoch keine Bewertungen

- Uganda Electricity Connections Policy (2018 - 2027)Dokument35 SeitenUganda Electricity Connections Policy (2018 - 2027)African Centre for Media Excellence80% (5)

- Lauda E200Dokument63 SeitenLauda E200Sepehr SaNoch keine Bewertungen

- Sieve Analysis Data Sheet: ASTM D422-63 (2007)Dokument1 SeiteSieve Analysis Data Sheet: ASTM D422-63 (2007)Bart LuceñaNoch keine Bewertungen

- Canon Ir2200 Ir2800 Ir3300 User ManualDokument362 SeitenCanon Ir2200 Ir2800 Ir3300 User ManualMohamed Kabsha50% (2)

- IQ FMEA TrainingDokument7 SeitenIQ FMEA TrainingKawadasanNoch keine Bewertungen

- BT-2500 Table Saw Revised PLDokument3 SeitenBT-2500 Table Saw Revised PLHYDRO-LECNoch keine Bewertungen

- Assam Power Distribution Company LTDDokument7 SeitenAssam Power Distribution Company LTDkabuldasNoch keine Bewertungen

- Gervasoni - PratoDokument98 SeitenGervasoni - PratoMiguel García FernándezNoch keine Bewertungen

- Cooling Water Treatment PDFDokument2 SeitenCooling Water Treatment PDFvjNoch keine Bewertungen

- Members List 08.04.2017 Updated. No Pseudo MbrsDokument165 SeitenMembers List 08.04.2017 Updated. No Pseudo Mbrsaroravikas100% (2)

- SP17316 Smartphones RF Front-End Module Sample System Plus ConsultingDokument23 SeitenSP17316 Smartphones RF Front-End Module Sample System Plus ConsultingVasikaran PrabaharanNoch keine Bewertungen

- As 60947.4.1-2004 Low-Voltage Switchgear and Controlgear Contactors and Motor-Starters - Electromechanical CoDokument12 SeitenAs 60947.4.1-2004 Low-Voltage Switchgear and Controlgear Contactors and Motor-Starters - Electromechanical CoSAI Global - APACNoch keine Bewertungen

- School Lawig National High School Grade Level Grade 9 Teacher Vangie P. Manuelo Learning Area T.L.E. - (ICT) Teaching Days and Time Quarter 1stDokument3 SeitenSchool Lawig National High School Grade Level Grade 9 Teacher Vangie P. Manuelo Learning Area T.L.E. - (ICT) Teaching Days and Time Quarter 1stManuelo Vangie100% (1)

- Calibracion TransCAT - Fluke754Dokument2 SeitenCalibracion TransCAT - Fluke754Rodrigo CalderonNoch keine Bewertungen

- Business Process Reengineering: M. Parthiban Dept of Mech EngineeringDokument60 SeitenBusiness Process Reengineering: M. Parthiban Dept of Mech Engineeringgiri123aeroNoch keine Bewertungen

- Photometer AL400 & AL410: Modern, Mobile Photometers For Rapid, Reliable Water TestingDokument4 SeitenPhotometer AL400 & AL410: Modern, Mobile Photometers For Rapid, Reliable Water TestingTan NguyenNoch keine Bewertungen

- Andhra Pradesh Public Service CommissionDokument3 SeitenAndhra Pradesh Public Service Commissionb.veenasriNoch keine Bewertungen

- What Is The Shopify Partner ProgramDokument17 SeitenWhat Is The Shopify Partner ProgramAvada CommerceNoch keine Bewertungen

- Warner Emails The Pirate Bay Re: Billy CorganDokument4 SeitenWarner Emails The Pirate Bay Re: Billy Corganmary engNoch keine Bewertungen

- 004 - Hadoop Daemons (HDFS Only)Dokument3 Seiten004 - Hadoop Daemons (HDFS Only)Srinivas ReddyNoch keine Bewertungen

- Catalogue Nacelle Tooling A320neoDokument31 SeitenCatalogue Nacelle Tooling A320neoPablo RestrepoNoch keine Bewertungen

- Fujitsu Lifebook A530 Notebook: DatasheetDokument6 SeitenFujitsu Lifebook A530 Notebook: DatasheetnirwalamitNoch keine Bewertungen