Beruflich Dokumente

Kultur Dokumente

JC Labyrinth ProTech

Hochgeladen von

MachineryengCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

JC Labyrinth ProTech

Hochgeladen von

MachineryengCopyright:

Verfügbare Formate

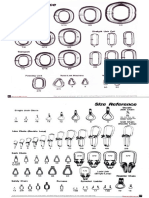

Bearing Isolators

A ProTech Rotor

B ProTech Stator

C Contaminant

Discharge Slot

D Oil Drain Slot

E O-Rings

TM

E

D

E

C

Product Description

Applications

The ProTech bearing isolators have been uniquely

designed to protect bearings by eliminating lubricant

leakage and excluding all contaminants from entering

the bearing housing. It is based on a simple, unitized,

two-piece design with just two o-rings.

Chemical Processing

Food and Beverage Processing

Mining

Oil and Gas Processing

ProTech bearing isolators are available in several

designs and material combinations to meet rotating

equipment application requirements.

Pharmaceuticals

Power Generation

Pulp and Paper

Steel and Aluminum Manufacturing

Utilities

Can be supplied split for ease of installation.

Can be supplied to operate on flooded, oil mist,

force-fed applications, and hermetically sealed

bearing housings.

Design Features

Non-contacting design

Manufactured in nonsparking and chemically

resistant PTFE.

Can accommodate a large amount of initial shaft

misalignment and eccentricity.

Requires no installation tools.

Can be used to retrofit lip seals in existing housings

without modifications.

ProTech is a registered trademark of JM Clipper

Patents: 5,316,317; 5,431,414; 5,552,601; 5,735,530, other patents pending.

ProTech

ProTech

TM

ProTech

ProTech

TM

Bearing Isolators

ProTech Typical Arrangement/Dimensional Data

L90**

L92

L90**

L92

L39

TM

LUBRICANT

SIDE

LUBRICANT

SIDE

X1

X1

D4*

D4*

D1

D1

Type LS Flange Design

Type LN Nonflange Design

L90**

D1

L92

L39

L39

L90**

L92

D4*

X1

LUBRICANT

SIDE

LUBRICANT SIDE

X1

D4*

D1

Type LX (Vertical Shaft Top Bearing)

L90

Type LD (Multipoint)

L92

L90**

L39

L39

L92

D4*

D4*

X1

X1

LUBRICANT

SIDE

LUBRICANT

SIDE

D1

D1

Type SS

(Severe Duty Applications)

*D4 = D1 + 2(X1)

Type Millennium

(High Speed and Temperature Applications)

**L90 = Nearest Obstruction

ProTech

TM

Bearing Isolators

ProTech Typical Arrangement/Dimensional Data

D4*

L90**

D1

X1

L92

LUBRICANT

SIDE

L92

D4*

X1

L90**

LUBRICANT

SIDE

L39

D1

Type FS*** Flange Design

Type FN*** Nonflange Design

(Vertical Shaft Bottom Bearing, Oil Mist, Force-Fed,

Flooded Applications and Hermetically Sealed

Bearing Housings)

(Vertical Shaft Bottom Bearing, Oil Mist, Force-Fed,

Flooded Applications and Hermetically Sealed

Bearing Housings)

LUBRICANT

SIDE

LUBRICANT

SIDE

Type LB

Type LM Electric Motors

(Designed to Suit Individual Bearing Plummer/Pillow Blocks)

(Designed to Suit Particular Applications)

L90**

L39

L92

X1

D4*

LUBRICANT

SIDE

D1

Type SL

(Split Applications)

* D4 = D1 + 2(X1)

** L90 = Nearest Obstruction

*** Types FS and FN can be installed on horizontal, vertical, and angled shafts.

ProTech

TM

Bearing Isolators

ProTech Dimensional Data (mm)

X1

Isolator Type

LS

LS

LS

LS

LS

LN

LN

LN

LX

LX

LX

LX

LX

LD

LD

LD

LD

LD

MILLENNIUM

MILLENNIUM

MILLENNIUM

FS

FS

FS

FN

FN

SS

SS

SS

SL

SL

SL

SL

SL

Isolator Size/D1

12.0 - 40.0

40.1 - 60.0

60.1 - 80.0

80.1 - 130.0

130.1 - 250.0

12.0 - 80.0

80.1 - 130.0

130.1 - 250.0

12.0 - 40.0

40.1 - 60.0

60.1 - 80.0

80.1 - 130.0

130.1 - 250.0

13.0 - 35.0

35.1 - 36.0

56.1 - 76.0

76.1 - 127.0

127.1 - 250.0

13.0 - 76.0

76.1 - 100.0

100.1 - 250.0

13.0 - 76.0

76.1 - 152.0

152.1 - 250.0

13.0 - 152.0

152.1 - 250.0

40.0 - 60.0

60.1 - 130.0

130.1 - 250.0

12.0 - 40.0

40.1 - 60.0

60.1 - 80.0

80.1 - 130.0

130.1 - 250.0

D4

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

L39

9.0

9.0

9.0

9.0

9.0

0.0

0.0

0.0

9.0

9.0

9.0

9.0

9.0

8.0

8.0

8.0

8.0

8.0

10.0

8.0

8.0

9.0

9.0

9.0

0.0

0.0

9.0

9.0

9.0

20.0

20.0

20.0

24.0

24.0

Min.

5.0

6.0

7.5

10.0

12.0

7.0

8.0

9.0

5.0

6.0

7.5

10.0

12.0

9.5

9.5

9.5

12.7

12.7

8.0

8.0

11.0

9.0

9.0

12.0

9.0

12.0

12.0

12.0

12.0

5.0

6.0

7.5

10.0

12.0

L39

0.375

0.375

0.375

0.377

0.000

0.000

0.375

0.375

0.377

0.088

0.151

0.151

0.151

0.186

0.375

0.375

0.375

0.375

0.375

0.377

0.000

0.000

0.375

0.375

0.377

0.800

0.900

1.000

Min.

0.313

0.313

0.437

0.437

0.357

0.437

0.375

0.437

0.437

0.375

0.375

0.375

0.500

0.500

0.312

0.312

0.375

0.375

0.375

0.438

0.375

0.437

0.500

0.500

0.500

0.312

0.312

0.437

Max.

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

L90

10.5

10.5

10.5

12.0

15.0

1.5

3.0

6.0

10.5

10.5

10.5

12.0

15.0

9.5

9.5

9.5

11.0

14.0

9.5

11.0

17.0

10.5

12.0

15.0

3.0

6.0

10.5

12.0

15.0

40.0

40.0

40.0

45.0

55.0

L92

7.0

8.0

9.0

9.0

11.0

10.0

12.0

15.0

7.0

8.0

9.0

9.0

11.0

8.0

10.0

11.0

11.0

11.0

8.0

11.0

11.0

8.0

9.0

11.0

14.0

15.0

8.0

9.0

11.0

7.0

8.0

9.0

9.0

11.0

*D4 = D1 + 2(X1) For other sizes, contact John Crane Engineering.

ProTech Dimensional Data (inches)

X1

Isolator Type

LS

LS

LS

LS

LN

LN

LX

LX

LX

LD

LD

LD

LD

LD

MILLENNIUM

MILLENNIUM

MILLENNIUM

FS

FS

FS

FN

FN

SS

SS

SS

SL

SL

SL

Isolator Size/D1

0.500 - 3.000

3.001 - 4.000

4.001 - 6.000

6.001 - 10.000

0.500 - 4.000

4.001 -10.000

0.500 - 3.000

3.001 - 6.000

6.001 - 10.000

0.500 - 1.375

1.376 - 2.200

2.201 - 3.000

3.001 - 5.000

5.001 - 10.000

0.500 - 3.000

3.001 - 4.000

4.001 - 10.000

0.500 - 3.000

3.001 - 6.000

6.001 - 10.000

0.500 - 6.000

6.001 - 10.000

0.750 - 3.000

3.001 - 6.000

6.001 - 10.000

0.500 - 3.000

3.001 - 6.000

6.001 - 10.000

D4

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*D4 = D1 + 2(X1) For other sizes, contact John Crane Engineering.

Max.

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

0.750

L90

0.435

0.500

0.500

0.625

0.060

0.250

0.435

0.500

0.625

0.150

0.210

0.210

0.275

0.435

0.435

0.500

0.625

0.435

0.500

0.625

0.500

0.625

0.435

0.500

0.625

1.625

1.750

2.500

L92

0.313

0.375

0.375

0.438

0.562

0.625

0.313

0.375

0.438

0.375

0.375

0.438

0.438

0.438

0.313

0.375

0.375

0.313

0.375

0.438

0.562

0.625

0.313

0.375

0.438

0.313

0.375

0.438

ProTech

TM

Bearing Isolators

Operating Parameters

ISOLATOR

TYPE

TEMPERATURE

C/F

PRESSURE

bar g/psig

SPEED

m/s / fpm (max.)

ALLOWABLE TIR

mm/inch (max.)

AXIAL MOVEMENT

mm/inch (max. initial)

LS

-40 to 120C -40 to 250F

0.0

0.0

25

5,000

0.50mm

0.020"

0.8mm

0.032"

LN

-40 to 120C -40 to 250F

0.0

0.0

25

5,000

0.50mm

0.020"

0.8mm

0.032"

LX

-40 to 120C -40 to 250F

0.0

0.0

25

5,000

0.50mm

0.020"

0.8mm

0.032"

LD

-40 to 120C -40 to 250F

0.0

0.0

25

5,000

0.50mm

0.020"

0.8mm

0.032"

MILLENNIUM -40 to 200C -40 to 400F

0.0

0.0

50

10,000

0.50mm

0.020"

0.8mm

0.032"

LM

-40 to 120C -40 to 250F

0.0

0.0

25

5,000

0.50mm

0.020"

0.8mm

0.032"

FS

-40 to 120C -40 to 250F

0.7

10.0

25

5,000

0.13mm

0.050"

0.5mm

0.020"

FN

-40 to 120C -40 to 250F

0.7

10.0

25

5,000

0.13mm

0.050"

0.5mm

0.020"

SL

-40 to 120C -40 to 250F

0.0

0.0

25

5,000

0.50mm

0.020"

0.4mm

0.015"

LB

-40 to 120C -40 to 250F

0.0

0.0

25

5,000

0.50mm

0.020"

0.8mm

0.032"

For applications outside these limits, contact John Crane Engineering.

Materials of Construction

ISOLATOR COMPONENTS

MATERIALS

Description

Standard

Options

Stator

Graphite-Filled PTFE

High-Temperature Graphite-Filled PTFE

Mineral-Filled PTFE*

Bronze

Rotor

Graphite-Filled PTFE

High-Temperature Graphite-Filled PTFE

Mineral-Filled PTFE*

Bronze

O-Rings

Fluoroelastomer

Silicon*

Other materials are available if required. Contact John Crane Engineering.

Types FS and FN have a stainless steel rotor as standard.

*Food and FDA approved materials.

International Specifications

ProTech bearing isolator meets and exceeds Severe Duty Electric Motor Specification IEEE 841 for IP 55 and IP 56.

ProTech bearing isolator complies with API 610 8th edition.

ProTech

TM

Bearing Isolators

Ordering Information

Measure shaft, bore, bore depth, and distance outside the housing.

Note any deviations from these dimensions outside the housing

(i.e., shaft step down or housing counter bore).

Provide dimensional descriptions and distance from the end of the housing.

DISTANCE TO NEAREST

OBSTRUCTION

DEPTH

BORE DIAM.

SHAFT DIAM.

DIAM. AT STEP

(IF ANY)

NORMAL OIL LEVEL

RADIUS AT STEP

DISTANCE

TO STEP

Europe

Slough, UK

Latin America

So Paulo, Brazil

Middle East, Africa, Asia

Dubai, United Arab Emirates

North America

Morton Grove, Illinois USA

Tel: 44-1753-224000

Fax: 44-1753-224224

Tel: 55-11-3371-2500

Fax: 55-11-3371-2599

Tel: 971-4-3438940

Fax: 971-4-3438970

1-800-SEALING

Tel: 1-847-967-2400

Fax: 1-847-967-3915

For your nearest John Crane facility, please contact one of the locations above.

If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior to their selection and use.

In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications without prior notice. It is dangerous to smoke while handling

products made from PTFE. Old and new PTFE products must not be incinerated.

2003 John Crane Inc. Print 1/01

www.johncrane.com

ISO 9001 and QS-9000 Certified

S-ProTech

Das könnte Ihnen auch gefallen

- Manual Best Management PortsDokument156 SeitenManual Best Management PortsAchraf DouiriNoch keine Bewertungen

- Seal Design GuideDokument119 SeitenSeal Design GuideaytepeNoch keine Bewertungen

- JC Gasket CranfoilDokument2 SeitenJC Gasket CranfoilMachineryengNoch keine Bewertungen

- ESA Best Available Techniques Issue 1Dokument4 SeitenESA Best Available Techniques Issue 1vprochockyNoch keine Bewertungen

- Api 617 CameronDokument31 SeitenApi 617 CameronMachineryengNoch keine Bewertungen

- Steam TurbinesDokument8 SeitenSteam Turbinesspalaniyandi100% (1)

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDokument25 SeitenHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- Lip Seal Installation PDFDokument11 SeitenLip Seal Installation PDFMachineryengNoch keine Bewertungen

- SOP Templates 03Dokument1 SeiteSOP Templates 03MachineryengNoch keine Bewertungen

- Seal Design For High Pressure Offshore-Morton & EvansDokument10 SeitenSeal Design For High Pressure Offshore-Morton & EvansMachineryengNoch keine Bewertungen

- Compressor MountingDokument41 SeitenCompressor MountingjmacarroNoch keine Bewertungen

- SOP Number Insert Number: Standard Operating ProcedureDokument2 SeitenSOP Number Insert Number: Standard Operating ProcedureLawNoch keine Bewertungen

- Norsok ST 2001Dokument131 SeitenNorsok ST 2001mamounsdNoch keine Bewertungen

- Hsg253 The Safe Isolation of Plant and EquipmentDokument81 SeitenHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayNoch keine Bewertungen

- Borsig BZM - 2016 - EngDokument84 SeitenBorsig BZM - 2016 - EngMachineryengNoch keine Bewertungen

- Creating A World That Doesnt BreakdownDokument23 SeitenCreating A World That Doesnt BreakdownmersiumNoch keine Bewertungen

- BORSIG ZM Compression - Innovative Solutions for Process Gas CompressionDokument16 SeitenBORSIG ZM Compression - Innovative Solutions for Process Gas CompressionMachineryengNoch keine Bewertungen

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDokument23 SeitenCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengNoch keine Bewertungen

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDokument25 SeitenHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- UtilityDokument8 SeitenUtilityAmit JainNoch keine Bewertungen

- Compressor Turbo-Air API a4-IRDokument12 SeitenCompressor Turbo-Air API a4-IRMachineryengNoch keine Bewertungen

- BORSIG Valve PresentationDokument18 SeitenBORSIG Valve PresentationMachineryengNoch keine Bewertungen

- Pit Ot Tube Pump TechnologyDokument12 SeitenPit Ot Tube Pump TechnologymariasofiarossiNoch keine Bewertungen

- Perf Improv To Aches Rev 0Dokument16 SeitenPerf Improv To Aches Rev 0Poncho RmzNoch keine Bewertungen

- Lifiting Chain Size Referance PDFDokument1 SeiteLifiting Chain Size Referance PDFMachineryengNoch keine Bewertungen

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDokument1 SeiteBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNoch keine Bewertungen

- Lifts and Hoists Maintenance Tasks PDFDokument19 SeitenLifts and Hoists Maintenance Tasks PDFMachineryengNoch keine Bewertungen

- Selection of Material Nace - H2S - Technical Paper PDFDokument21 SeitenSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009Noch keine Bewertungen

- SVS.435 Steam Turbine Control UpgradesDokument4 SeitenSVS.435 Steam Turbine Control UpgradesMachineryengNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Materi TOEFL ListeningDokument29 SeitenMateri TOEFL Listeningputra fajarNoch keine Bewertungen

- Algorithmic Composer: Openmusic and Chaos - Omchaos LibraryDokument11 SeitenAlgorithmic Composer: Openmusic and Chaos - Omchaos LibrarysophochaNoch keine Bewertungen

- Week February 15TH To 19THDokument18 SeitenWeek February 15TH To 19THQUETEVALGAMADRESNoch keine Bewertungen

- Ten Frames Subtraction Lesson PlanDokument4 SeitenTen Frames Subtraction Lesson Planapi-581503405Noch keine Bewertungen

- CV - Nguyen Trung KienDokument1 SeiteCV - Nguyen Trung KienNguyễn Trung KiênNoch keine Bewertungen

- 7 Basic Qualty Tools & Root Cause AnalysisDokument42 Seiten7 Basic Qualty Tools & Root Cause AnalysisRamonS.FernandezOrozco100% (1)

- Ds Esprimo c910 LDokument9 SeitenDs Esprimo c910 Lconmar5mNoch keine Bewertungen

- G5 - CLC 30Dokument5 SeitenG5 - CLC 30Phuong AnhNoch keine Bewertungen

- Egerton Genetics eLearning MaterialsDokument213 SeitenEgerton Genetics eLearning MaterialsAringo ArumNoch keine Bewertungen

- Chapter - 4 Ob Perception ReDokument23 SeitenChapter - 4 Ob Perception Rep bbNoch keine Bewertungen

- Thomas Calculus 13th Edition Thomas Test BankDokument33 SeitenThomas Calculus 13th Edition Thomas Test Banklovellgwynavo100% (24)

- This Study Resource Was: Ran - Shorrer@hks - Harvard.edu Eneida - Rosado@hks - Harvard.eduDokument5 SeitenThis Study Resource Was: Ran - Shorrer@hks - Harvard.edu Eneida - Rosado@hks - Harvard.eduTOM ZACHARIASNoch keine Bewertungen

- Barangay Clearance2014Dokument68 SeitenBarangay Clearance2014Barangay PangilNoch keine Bewertungen

- Registration Form: National Hospital Insurance FundDokument5 SeitenRegistration Form: National Hospital Insurance FundOgweno OgwenoNoch keine Bewertungen

- HCTS Fabricated Products Group Empowers High Tech MaterialsDokument12 SeitenHCTS Fabricated Products Group Empowers High Tech MaterialsYoami PerdomoNoch keine Bewertungen

- Xtract V 3 0 8Dokument72 SeitenXtract V 3 0 8Don Ing Marcos LeónNoch keine Bewertungen

- Ipc2012 90095Dokument11 SeitenIpc2012 90095Marcelo Varejão CasarinNoch keine Bewertungen

- Pipelining VerilogDokument26 SeitenPipelining VerilogThineshNoch keine Bewertungen

- 2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONDokument5 Seiten2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONkkumar_717405Noch keine Bewertungen

- 16.5.3 Optional Lab: Troubleshooting Access Security With Windows 7Dokument12 Seiten16.5.3 Optional Lab: Troubleshooting Access Security With Windows 7Jayme ReedNoch keine Bewertungen

- NetflixDokument10 SeitenNetflixJosue Yael De Los Santos DelgadoNoch keine Bewertungen

- Arun GangwarDokument7 SeitenArun GangwarArun GangwarNoch keine Bewertungen

- Genbio 2 Module 1 Genetic Engineering ProcessDokument26 SeitenGenbio 2 Module 1 Genetic Engineering Processeaishlil07Noch keine Bewertungen

- Classroom Management PlanDokument6 SeitenClassroom Management Planapi-607580556Noch keine Bewertungen

- Methodologies For Sign Language Recognition A SurveyDokument4 SeitenMethodologies For Sign Language Recognition A SurveyInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Reading Process Theories: Bottom-Up Model Interactive Model Top-Down ModelDokument2 SeitenReading Process Theories: Bottom-Up Model Interactive Model Top-Down ModelBeverly Panganiban CadacioNoch keine Bewertungen

- Arduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFDokument33 SeitenArduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFefrain100% (1)

- Bashar - Abundance IIIDokument3 SeitenBashar - Abundance IIIDraco XulNoch keine Bewertungen

- Analyze: ADDIE WorksheetDokument2 SeitenAnalyze: ADDIE WorksheetCatherine LaraNoch keine Bewertungen

- CASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDokument2 SeitenCASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDijin MaroliNoch keine Bewertungen