Beruflich Dokumente

Kultur Dokumente

Conveyor Tension and Trajectory Calculation

Hochgeladen von

Gregory Nick Toledo VelizOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Conveyor Tension and Trajectory Calculation

Hochgeladen von

Gregory Nick Toledo VelizCopyright:

Verfügbare Formate

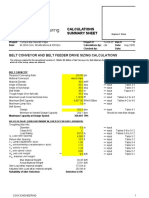

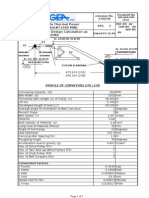

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.

03

Specifier Sheet and Recommendation Summary

01/07/15

Date

Telephone

Telefax

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Copyright - Rulmeca Corp.

Project Name

Conveyor Reference

Standard Loading Conditions:

Conveyor Length (ft)

Tonnage Rate (tons/hour)

Belt Speed (fpm)

Material Lift Height (ft)

Ambient temperature (F) Min

Ambient temperature (F) Max

Initial Velocity of Material (fpm)

Number of Belt Cleaners

Number of Return Belt Scrapers

Length of Skirt Zone (ft)

Depth of Mat'l in skirt zone (in)

Number of Non-driven Pulleys

Elev. Above Sea Level (ft)

Mat'l, friction coeff

1000

800

300

-10

100

1

12

3

4

3300 ft

Coal, bitum. mined,

Bulk Density (pcf)

Size Consist

0.075

Coal, lignite, 45 pcf

REQUIRED POWER:

BELT PULL SUMMARY:

Standard Loading Belt Pull

Extra pull for Hopper (if any)

Extra pull for Slider Bed (if any)

Extra pull for Diverter or Tripper (if any)

TOTAL Required Belt Pull (Te):

44.9 HP

Force (lbs)

4,714

4,714

RECOMMENDED OPTIONS:

SPECIAL NOTES:

Minimum allowable belt width for lump size is 12 in

Minimum Acceptable Diameter is 14 in. *

Avg is 50% Max Lump Size

Max. Lump Size (in)

*A smaller pulley diameter may cause belt carcass or fastener damage.

RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY:

Material Surcharge Angle

Belt Width

25 deg.

Models Available:

Fabric

Power:

Belt Speed:

50HP

Belt Carcass Type

300 FPM

630

Idler Roll diameter

5 in

Face Width:

43.31 in.

42 in

CEMA Type

Troughing Idler Spacing

Angle of Wrap**

4 ft

180 degrees

Type of Take-up

Type of Belt

Drive Location

RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Partial (2/3)

Automatic

Power:

Belt Speed:

25 HP/each

300 FPM

2 ply, 225 piw

Head

Face Width:

43.31 in.

Type of Lagging

Elevating or Horizontal

Material Flow

well maintained

Condition of Idlers & Pulleys

Type of Dual Drive, if any

none

** This parameter is for either single or dual drive arrangement.

Models Available:

500

Power savings - 1 shift and 3 shift per day:

(Motorized Pulley compared to exposed motor, gearbox, V-belt conveyor drives)

Save: 9135 Kw-Hrs/Yr, 1 shift/day or 27404 Kw-Hrs/Yr, 3 shifts/day

Save: $731 /Yr, 1 shift/day or $2192 /Yr, 3 shifts/day @ $0.08/Kw-Hr

Special Loading Conditions:

1. For hopper feeder specify opening dimensions below.

2. For slider bed, specify bed length & type of bed mat'l below.

3. If belt is driven on return run, specify drive pulley location.

4. If belt has cleats and/or sidewalls show dimensions below.

5. If conveyor has a tripper, define tripper below.

6. If conveyor has diverter(s), define below.

1. Hopper Feeder Design Parameters

Hopper opening width (in)

Hopper opening length (in)

5. Tripper Design Parameters

Tripper length (ft)

Material lift height on tripper (ft)

No. of belt cleaners on tripper

Length of tripper skirt zone (ft)

2. Slider Bed Design Parameters

Slider Bed Length (ft)

Type of Slider Bed Material

Slider Bed Frictional Coefficient

4. Sidewall & Cleated Belt Parameters:

Sidewall & cleat height (in)

Thickness of sidewall (in)

Distance between cleats (in)

Thickness of cleats (in)

Extra Sidewall & Cleat Wt (incl above)

None

3. Drive Pulley Location ("return run" drive only)

Conveyor Length, tail to drive snub (ft)

Height, top of tail to bottom of drive (ft)

\\vboxsrv\conversion_tmp\scratch_2\256611390.xls.ms_office, Specifier, Page 1 of 8

Depth of material in skirt zone (in)

No. of non-driven pulleys on tripper

Estimated belt tension, Te (lbs)

Estimated factor, Ky

0.03

6. Material Diverter (Belt Plow)

No. of diverters that work simultaneously

1/7/2015 12:42 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Model Selector

01/07/15

Date

Telephone

Telefax

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Project Name

Conveyor Reference

Copyright - Rulmeca Corp.

REQUIRED POWER:

BELT PULL SUMMARY:

Standard Loading Belt Pull

Extra pull for Hopper (if any)

Extra pull for Slider Bed (if any)

Extra pull for Diverter or Tripper (if any)

TOTAL Required Belt Pull (Te):

44.9 HP

Force (lbs)

4,714

4,714

Select Model

320H

Check Radial Load (to prevent

internal damage to pulley)

Maximum Allowable Radial Load

Estimated Maximum Radial Load**

Error: Selected model is incorrect.

Force (lbs)

7,868

10,466

Choose stronger or larger model to handle estimated radial load.

RECOMMENDED OPTIONS (if any):

SPECIAL NOTES (if any):

Minimum allowable belt width for lump size is 12 in

Minimum Acceptable Diameter is 14 in. *

*A smaller pulley diameter may cause belt carcass or fastener damage.

Check Pulley Diameter

(to prevent belt damage.)

Minimum Acceptable Diameter is 14 in.

Selected Diameter is 12.64 in

Error: selected diameter is incorrect.

Choose larger diameter to prevent belt or fastener damage.

Check Maximum Belt Tension

prevent belt damage)

Maximum Belt Tension (T1)

Allowable Fabric Belt Tension

(to

Force (lbs)

7,590

9,450

RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY:

Power:

Belt Speed:

Face Width:

Models Available:

50HP

300 FPM

43.31 in.

630

Belt Tension Calculation Summary

Te, effective belt tension

T2, to prevent belt/pulley slippage

T2, to limit belt sag to 2 %

T1, maximum belt tension

Force (lbs)

4,714

2,876

2,808

7,590

**Measured at Drive A in Dual Drive, if applicable.

Calculation for "Dual Drive on Carry Side" is under construction.

RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Power:

Belt Speed:

Face Width:

Models Available:

25 HP/each

300 FPM

43.31 in.

500

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Bulk Handling Trajectory Calculator and Plotter

(based on CEMA 5th Edition)

1/7/15

Date

Phone

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Fax

Copyright - Rulmeca Corp.

Project Name

Conveyor Ref.

System Design Parameters:

Belt Width

Material Trajectory:

42 in

Small Pulley (scale: inches)

Troughing Idler Angle

35

Diameter Pulley (in)

13.26 in

Lagging Thickness (in)

0.31 in

Belt Speed

300 fpm

Surcharge Angle

25 deg.

Tonnage Rate (TPH)

Material Density (pcf)

Belt Thickness (in)

Distance to Chute Plate (in)

800

45

0.75

24

Angle of Conv. Inclination (deg)

350

39

36

33

30

27

24

21

18

15

12

9

6

3

0

-3

-6

-9

-12

-15

-18

-21

-24

-27

Alternate Belt Speed (fpm)

18

15

12

9

6

3

0

-3

-6

-9

-12

-15

-18

-21

-24

Design Trajectory - red line; Alternate speed - blue.

WARNING: Material cross section exceeds CEMA allowable maximum.

Calculated Results:

Calc'd mat'l height at centerline

9 in

Calc'd actual height of C.O.G.*

4 in

Calc'd actual mat'l cross section

CEMA Max Allow. height at center

CEMA Max Height of C.O.G.*

CEMA Max Allow. cross section

271.1 sq ft

Mat'l Cross Section at Pulley Face:

Small Pulley (scale: inches)

9

8 in

3 in

211.8 sq ft

3

0

Note:

18

15

12

-3

-6

-9

-12

-15

top of belt (based on actual cross section) to plot

-3

-18

This program uses actual C.O.G.* height above

trajectory. Height of C.O.G. for CEMA

max. allow. cross section is given for ref. only.

Design Cross Section - red line; CEMA max allow. - black line.

*C.O.G. = center of gravity of material, shown as and

\\vboxsrv\conversion_tmp\scratch_2\256611390.xls.ms_office, trajectory, Page 3 of 8

1/7/2015 12:42 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Material Cross Section Plotter

1/7/15

Date

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Fax

Phone

Copyright - Rulmeca Corp.

Reference Name

Conveyor Number

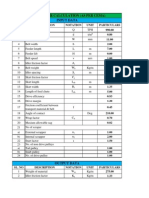

Cross Section at Troughing Idler:

Narrow Belt (scale: inches)

System Design Parameters:

Tonnage Rate (tph)

Belt Speed (fpm)

Bulk Density (lbs/cu ft)

Material Surcharge Angle

800

300

45

15

25 degrees

Belt Width

42 in.

Idler Angle

35 degrees

12

9

6

3

Material Geometry in Troughing Idler:

CEMA Max. Allow. Cross Section

Calculated Cross Section

-3

15

12

-3

-6

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Warning: Specified Material Cross Section Exceeds CEMA Max. Allowable.

Material Geometry at Pulley Discharge:

Calculated Cross Section

Material Height at Centerline

Height of Center of Gravity (A1)

Assumed Edge Distance

Calculated Surcharge Angle

CEMA Max. Allow height at center

CEMA Max Height of C.O.G.

CEMA Standard Edge Distance

-9

-12

131%

3.2 in

0.8 in

11 in

-15

Calc'd Xsec/CEMA Xsec

CEMA Standard Edge Distance

Calculated Edge Distance

Calc'd Material Height at Centerline

1.5 sq ft

1.9 sq ft

2 sq ft

#DIV/0!

#DIV/0!

0.41 in

0 deg

7.8 in.

3.1 in.

1.61 in

9

6

SSX

3.1

3

0.00

0

-3

18

15

12

-3

-6

-9

-12

-15

-18

Note:

This program calculates height of actual C.O.G.*

by assuming that actual edge distance at pulley

face equals 1/2 of actual edge distance in troughed

section. Height of C.O.G.* for CEMA maximum

allowable cross section pulley face is given for

reference only.

Cross Section at Pulley Face:

Narrow Belt (scale: inches)

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

* C.O.G. = center of gravity of material

\\vboxsrv\conversion_tmp\scratch_2\256611390.xls.ms_office, Page 4 of 8

1/7/2015 12:42 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Material Cross Section Plotter

1/7/15

Date

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Fax

Phone

Copyright - Rulmeca Corp.

Reference Name

Conveyor Number

System Design Parameters:

Tonnage Rate (tph)

Belt Speed (fpm)

Bulk Density (lbs/cu ft)

Material Surcharge Angle

800

300

45

25 degrees

Belt Width

42 in.

Idler Angle

35 degrees

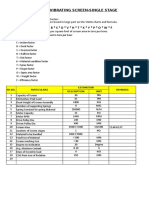

Cross Section at Troughing Idler:

Wide Belt (scale: inches)

42

36

30

24

18

12

Material Geometry in Troughing Idler:

CEMA Max. Allow. Cross Section

Calculated Cross Section

-6

42

36

30

24

18

12

Cross Section at Pulley Face:

Wide Belt (scale: inches)

18

12

6

3.1

0.00

-6

48

42

36

30

24

18

12

-6

-12

-18

-24

-30

-36

-42

-48

Note:

This program calculates height of actual C.O.G.*

by assuming that actual edge distance at pulley

face equals 1/2 of actual edge distance in troughed

section. Height of C.O.G.* for CEMA maximum

allowable cross section pulley face is given for

reference only.

-6

2 sq ft

#DIV/0!

#DIV/0!

0.41 in

0 deg

7.8 in.

3.1 in.

1.61 in

-12

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Warning: Specified Material Cross Section Exceeds CEMA Max. Allowable.

Material Geometry at Pulley Discharge:

Calculated Cross Section

Material Height at Centerline

Height of Center of Gravity (A1)

Assumed Edge Distance

Calculated Surcharge Angle

CEMA Max. Allow height at center

CEMA Max Height of C.O.G.

CEMA Standard Edge Distance

-18

-24

-30

131%

3.2 in

0.8 in

11 in

-36

-42

Calc'd Xsec/CEMA Xsec

CEMA Standard Edge Distance

Calculated Edge Distance

Calc'd Material Height at Centerline

1.5 sq ft

1.9 sq ft

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

* C.O.G. = center of gravity of material

\\vboxsrv\conversion_tmp\scratch_2\256611390.xls.ms_office, Page 5 of 8

1/7/2015 12:42 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Design Parameter Summary

01/07/15

Date

Telephone

Telefax

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Copyright - Rulmeca Corp.

Project Name

Conveyor Reference

Power Calculation Summary

Calculated power to drive conveyor belt:

Drive pulley bearing friction:

Power at motor:

Gear loss in motorized pulley:

Calculated power

Derate for high elevation

Derate for high temperature

Required Power for motorized pulley:

Symbol

Value

Te

ang

Cw

T2

4714 lbs

180 degrees

0.61

2876 lbs.

T1

T1 + T2

T_L

Tatype

Beltype

w

str

pstr

btr

Ai

Cs

H

Kt

Kx

7590 lbs

10466 lbs

Partial (2/3)

Automatic

2 ply, 225 piw

42 in.

9450 lbs.

80 %

3/16 to 7/16 in.

1.8 lbs

0.0754

0 ft

1.59

0.52 lbs/ft

Ky

L

Q

Si

Tac

Tam

Tb

Tbc

Te

Tm

Tp

0.03

1000 ft

800 tph

4 ft

290 lbs

69 lbs

0 lbs

210 lbs

4714 lbs

0 lbs

160 lbs

Tpl

Tsb

Ttr

Tx

Tyb

Tyc

Tym

Tyr

V

Wb

Wm

Sag

Ls

Hd

0 lbs

80 lbs

0 lbs

824 lbs

831 lbs

545 lbs

2541 lbs

286 lbs

300 fpm

12 lbs/ft

89 lbs/ft

2.0%

42.9

0.6

43.5

1.4

44.9

HP

HP

HP

HP

HP

HP

HP

44.9 HP

Definition of Terms

Te = effective belt tension at drive.

ang = angle of belt wrap around drive pulley(s).

Cw = "wrap factor", to determine slack side tension to prevent belt slippage on drive pulley.

T2 = estimated slack-side tension required to either keep belt from slipping on pulley surface

or maintain trough at allowable sag percentage, whichever is greater.

T1 = Te + T2

T1 + T2 = Sum of belt forces on drive pulley. NOTE: This is not a vector sum.

T_L = type of lagging specified for drive pulley(s).

Tatype = type of take-up specified to apply "slack-side tension".

Beltype = type of belt carsass specified.

w = belt width

str = tensile strength of specified belt.

pstr = percentage of available belt tensile strength used.

btr = thickness range of specified belt

Ai = belt tension required to overcome frictional resistance and rotate idlers.

Cs = skirtboard friction factor.

H = vertical distance that material is lifted or lowered.

Kt = ambient temperature correction factor.

Kx = factor to calculate frictional resistance of the idlers and the sliding resistance between

belt and idler rolls.

Ky = factor to calculate resistance of belt and resistance of load to flexure as they move over idlers.

L = length of conveyor.

Q = tons per hour conveyed.

Si = troughing idler spacing.

Tac = total of the tensions from conveyor accessories.

Tam = tension required to accelerate the material continuously as it is fed onto belt.

Tb = tension required to lift or lower the belt.

Tbc = tension required to overcome belt cleaner drag.

Te = effective belt tension at drive.

Tm = tension required to lift or lower conveyed material.

Tp = tension required to overcome resistance of belt to flexure around pulleys and resistance

of pulleys to rotate on their bearings.

Tpl = tension required to overcome belt plow drag.

Tsb = tension required to overcome skirtboard drag.

Ttr = tension required to overcome special loading condition(s.)

Tx = tension required to overcome carrying and return idler friction.

Tyb = total of tensions due to resistance of belt to flexure as it rides over carrying and return idlers.

Tyc = tension due to resistance of belt to flexure as it rides over carrying idlers.

Tym = tension due to resistance of material to flexure as it rides over carrying idlers.

Tyr = tension due to resistance of belt to flexure as it rides over return idlers.

V = design belt speed.

Wb = weight of belt per unit of length of conveyor.

Wm = weight of material per unit of length of conveyor.

Sag = recommended maximum sag percentage to avoid spillage in troughed section of belt.

Ls = Length of conveyor from tail pulley to Drive snub (for return run drive only)

Hd = Height of conveyor from top of tail pulley to bottom of drive pulley (for return run drive only)

\\vboxsrv\conversion_tmp\scratch_2\256611390.xls.ms_office, Design Parameters, Page 6 of 8

1/7/2015 12:42 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Bulk Handling Belt Conveyor Terminology

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Copyright - Rulmeca Corp.

Conveyor Profile

Initial Velocity of Material

Conveyor Cross Section in Skirt Zone

Belt Conveyor with Tripper

Hopper Feeder Conveyor

Cleated Belt with Sidewalls

Belt Conveyor with Two Diverter(s)

"CEMA" Idler Type Definitions

(Based on Conveyor Equipment Manufacturers Association Manual)

Belt Width

Idler Type >

Idler (deg) >

18

24

30

36

42

48

54

60

72

84

96

20

300

300

300

275

-

A

35

300

300

280

256

-

45

300

289

270

248

-

20

410

410

410

410

390

380

-

B

35

410

410

410

410

363

353

-

Idler Load Ratings* (lbs)

C

45

20

35

45

20

410 900 900 900

410 900 900 900 1200

410 900 900 900 1200

396 900 837 810 1200

351 850 791 765 1200

342 800 744 720 1200

750 698 675 1200

700 650 630 1150

1050

-

D

35

1200

1200

1200

1200

1200

1116

1070

977

-

45

1200

1200

1200

1200

1200

1080

1035

945

-

20

1800

1800

1800

1800

1800

1800

1800

1800

1800

1750

E

35

1800

1800

1800

1800

1800

1800

1800

1800

1674

1628

45

1800

1800

1800

1800

1800

1800

1800

1800

1620

1575

*These ratings are for three-equal-roll idlers and are based on a 30,000 hour minimum

BU bearing life at 500 RPM. BU bearing life represents the statistical point in hours where

a minimum of 90% of the bearings will still be functional with no increase in torque or noise.

Material Surcharge Angle Guide

(Based on Conveyor Equipment Manufacurters Association Manual)

Surcharge

Angle

Angle of

Repose

Description of Material

0 to 19

Uniform size, very small rounded particles, either very wet or very dry; such as dry

silica sand, cement, and wet concrete.

10

20 to 29

Rounded, dry polished particles, of medium weight, such as whole grain and beans.

20

30 to 34

Irregular, granular or lumpy materials of medium weight, such as anthracite coal,

cottonseed meal, and clay.

25

35 to 39

Typical common materials such as bituminous coal, stone, and most ores.

40+

Irregular, stringy, fibrous, interlocking material, such as wood chips, bagasse, and

tempered foundry sand.

30

\\vboxsrv\conversion_tmp\scratch_2\256611390.xls.ms_office, Terminology, Page 7 of 8

1/7/2015 12:42 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Conveyor Height Calculator

Inclined conveyor length (ft)

Angle of inclination (degrees)

Material lift height (ft)

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Copyright - Rulmeca Corp.

\\vboxsrv\conversion_tmp\scratch_2\256611390.xls.ms_office, Lift Height, Page 8 of 8

1/7/2015 12:42 PM

Das könnte Ihnen auch gefallen

- Apron Weigh FeederDokument4 SeitenApron Weigh FeederRaji SuriNoch keine Bewertungen

- Design of ConveyorsDokument15 SeitenDesign of ConveyorsRamachandran VenkateshNoch keine Bewertungen

- CEMA8 5pgDokument5 SeitenCEMA8 5pgkmats100% (2)

- Gr5.Science Teachers Guide JPDokument108 SeitenGr5.Science Teachers Guide JPCyril jay BedrijoNoch keine Bewertungen

- Belt Conveyor CalcsDokument3 SeitenBelt Conveyor Calcspandu_chemengNoch keine Bewertungen

- Conveyor Design DraftDokument47 SeitenConveyor Design DraftSandi Apriandi100% (1)

- Apron FeederDokument2 SeitenApron FeederRaji Suri100% (1)

- DAT Belt ConveyorDokument8 SeitenDAT Belt ConveyorEDUARDONoch keine Bewertungen

- Chain Pull and Power Calculation - WC 2125 KGMDokument2 SeitenChain Pull and Power Calculation - WC 2125 KGMdeddy ariyanto100% (1)

- Belt Conveyors With Shaft SizingDokument5 SeitenBelt Conveyors With Shaft SizingRakhi Mor100% (2)

- Chain Conveyor ExampleDokument4 SeitenChain Conveyor ExampledeeptidhaNoch keine Bewertungen

- Screw ConveyorDokument5 SeitenScrew ConveyorEDUARDO100% (3)

- Belt Conveyor CalculationDokument8 SeitenBelt Conveyor CalculationFarrahxviiiNoch keine Bewertungen

- Design (Imperial) 7.23Dokument9 SeitenDesign (Imperial) 7.23Salih HasNoch keine Bewertungen

- Belt Feeder Calculation CEMADokument7 SeitenBelt Feeder Calculation CEMANAITIK100% (4)

- Hoist DesignDokument16 SeitenHoist DesignluisparedesNoch keine Bewertungen

- Bucket Elevator Calculation: Yellow Cell To Be FilledDokument2 SeitenBucket Elevator Calculation: Yellow Cell To Be Filledm_verma21100% (2)

- Screw ConveyorDokument4 SeitenScrew ConveyorRaji SuriNoch keine Bewertungen

- Belt Conveyor: Designer's ChoiceDokument4 SeitenBelt Conveyor: Designer's ChoiceAmeu CostaNoch keine Bewertungen

- Belt Selection CalculationDokument29 SeitenBelt Selection CalculationElwathig BakhietNoch keine Bewertungen

- Conveyor CalculationDokument56 SeitenConveyor CalculationsigisyahNoch keine Bewertungen

- Belt Conveyor Take Up DesignDokument4 SeitenBelt Conveyor Take Up DesignKroya HunNoch keine Bewertungen

- Conveyor Chains TsubakiDokument184 SeitenConveyor Chains Tsubakitepu msosaNoch keine Bewertungen

- M 275 ContentDokument40 SeitenM 275 ContentAnonymous DQ4wYUmNoch keine Bewertungen

- Chute Calculation ExampleDokument1 SeiteChute Calculation ExampleBimal DeyNoch keine Bewertungen

- Belt Feeder Calc. Pns Line 1Dokument4 SeitenBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- SCC500EDokument32 SeitenSCC500Eardane100% (1)

- Huang 2014 Slope Stability Analysis by The Limit Equilibrium MethodDokument378 SeitenHuang 2014 Slope Stability Analysis by The Limit Equilibrium MethodpamelaNoch keine Bewertungen

- Screw Conveyor CalculationDokument2 SeitenScrew Conveyor CalculationJK71% (7)

- Screw Conveyor Calculation SheetDokument36 SeitenScrew Conveyor Calculation SheetMugurelVasilescuNoch keine Bewertungen

- Feeder Breaker Chain (Renold Chain) Double Pitch Sprocket DesignDokument1 SeiteFeeder Breaker Chain (Renold Chain) Double Pitch Sprocket DesignWaris La Joi Wakatobi0% (1)

- Design (Metric) 6.25Dokument8 SeitenDesign (Metric) 6.25Salih Has100% (2)

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDokument10 SeitenAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiNoch keine Bewertungen

- Belt Conveyor CalcsDokument3 SeitenBelt Conveyor Calcsjnmanivannan100% (4)

- Conveyor Design Summary ReportDokument53 SeitenConveyor Design Summary ReportTotok ChemScoutNoch keine Bewertungen

- Screw Conveyor CalculationDokument1 SeiteScrew Conveyor CalculationRavindra RautNoch keine Bewertungen

- Conveyor CalculationDokument46 SeitenConveyor CalculationBuditama Chandranegara100% (1)

- Travelling Tripper CalculationDokument5 SeitenTravelling Tripper CalculationHarshGupta100% (2)

- Conveyor Design-DraftDokument42 SeitenConveyor Design-Draftmkchy1295% (21)

- Screw Conveyor Calculation - Rev. 1Dokument19 SeitenScrew Conveyor Calculation - Rev. 1octatheweelNoch keine Bewertungen

- Mod 4 Perform Mensuration & CalculationDokument41 SeitenMod 4 Perform Mensuration & CalculationDaneNoch keine Bewertungen

- Vibrating ScreensDokument3 SeitenVibrating ScreensvinodsnNoch keine Bewertungen

- Conveyor CalculationsDokument3 SeitenConveyor Calculationsmishra_1982Noch keine Bewertungen

- Screw ConveyorsDokument4 SeitenScrew ConveyorsAshish SharmaNoch keine Bewertungen

- BELT FEEDER Preliminary Dimension IngDokument29 SeitenBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- CONVEYOR CALCULATION SHEET DraftDokument24 SeitenCONVEYOR CALCULATION SHEET DraftRaghava0% (1)

- Mechanical Conveyors: 29 Materials HandlingDokument2 SeitenMechanical Conveyors: 29 Materials HandlingSMNCI Cadet EngineersNoch keine Bewertungen

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADokument7 SeitenProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- Konveyör Hesabı 7.24Dokument9 SeitenKonveyör Hesabı 7.24Salih HasNoch keine Bewertungen

- Screw Conveyor DesignDokument9 SeitenScrew Conveyor DesignAJAY1381Noch keine Bewertungen

- Conveyor Design CalcDokument6 SeitenConveyor Design CalcGregory Nick Toledo VelizNoch keine Bewertungen

- Belt Conveyors With Shaft SizingDokument5 SeitenBelt Conveyors With Shaft SizingArun Chopra100% (1)

- Conveyor CalculationDokument32 SeitenConveyor CalculationsutanuprojectsNoch keine Bewertungen

- Screw Conveyor DesignDokument8 SeitenScrew Conveyor DesignPavan Kumar100% (1)

- Design Aspects of A Motorised Travelling TripperDokument5 SeitenDesign Aspects of A Motorised Travelling Trippercar5lyle100% (1)

- Bucket ElevatorDokument2 SeitenBucket ElevatorAndrés Lagos Méndez100% (5)

- Belt Conveyor Capacity - CalculatorDokument6 SeitenBelt Conveyor Capacity - CalculatorRolando Daclan67% (3)

- Screw Conveyor CalculationDokument14 SeitenScrew Conveyor Calculationvvijaybhan100% (2)

- BELT CONVEYOR - Discharge TrajectoryDokument3 SeitenBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNoch keine Bewertungen

- TS of Travelling TripperDokument10 SeitenTS of Travelling TripperShashank HegdeNoch keine Bewertungen

- Air Slide Data SheetDokument2 SeitenAir Slide Data SheetTECHCONS Consulting and Engineering Pvt LtdNoch keine Bewertungen

- Design (Imperial) 7.23Dokument9 SeitenDesign (Imperial) 7.23ozgurturunc4Noch keine Bewertungen

- RCS3-CT8C/CTZ5C: ROBO Cylinder High-Speed TypeDokument8 SeitenRCS3-CT8C/CTZ5C: ROBO Cylinder High-Speed TypeElectromateNoch keine Bewertungen

- Quantum Mechanics, Haldane, and Leibniz PDFDokument5 SeitenQuantum Mechanics, Haldane, and Leibniz PDFDren HotiNoch keine Bewertungen

- 3 A) PDS - E - JER - v4.1Dokument4 Seiten3 A) PDS - E - JER - v4.1Anish KarthikeyanNoch keine Bewertungen

- Wa0010.Dokument6 SeitenWa0010.Ali SalmanNoch keine Bewertungen

- BS 1041 - 7-Temperature MeasureDokument19 SeitenBS 1041 - 7-Temperature MeasuregadNoch keine Bewertungen

- Lab 1 - Truss AnalysisDokument44 SeitenLab 1 - Truss AnalysisPULLNoch keine Bewertungen

- A Few Basics of ElectrochemistryDokument7 SeitenA Few Basics of ElectrochemistryAbdulbar kelilNoch keine Bewertungen

- Jee Advance 1 Paper 2Dokument11 SeitenJee Advance 1 Paper 2iLearn MathNoch keine Bewertungen

- Localize (Phase Ambiguity)Dokument54 SeitenLocalize (Phase Ambiguity)Mirko ZambelliNoch keine Bewertungen

- Bolted Flanged Joint Creep/Relaxation Results at High TemperaturesDokument7 SeitenBolted Flanged Joint Creep/Relaxation Results at High TemperaturesjlbarretoaNoch keine Bewertungen

- SHS General Physics 1 1Dokument37 SeitenSHS General Physics 1 1nicole b100% (3)

- Ec8701 Antennas and Microwaveengineering 548086392 Antenna NotesDokument608 SeitenEc8701 Antennas and Microwaveengineering 548086392 Antenna NotesGeetha SupriyaNoch keine Bewertungen

- Sa Node Action PotentialDokument2 SeitenSa Node Action PotentialAljon AniesNoch keine Bewertungen

- Memoria de Calculo SismicoDokument2 SeitenMemoria de Calculo SismicoRodrigoNoch keine Bewertungen

- Lecture 3 - Laplace Transform-Part1Dokument12 SeitenLecture 3 - Laplace Transform-Part1John AlvarezNoch keine Bewertungen

- Tubular Heat Exchanger in Phosphoric AcidDokument18 SeitenTubular Heat Exchanger in Phosphoric Acidleo nineNoch keine Bewertungen

- GGN DD 013Dokument143 SeitenGGN DD 013Akshit KhuranaNoch keine Bewertungen

- Bma63/Uma63 - Complex Analysis - Ii: Gßó Öuõh SS J (Suø ÷/õvupDokument6 SeitenBma63/Uma63 - Complex Analysis - Ii: Gßó Öuõh SS J (Suø ÷/õvupJohnsonNoch keine Bewertungen

- Format Usulan SSH, ASB Dan SBUDokument2 SeitenFormat Usulan SSH, ASB Dan SBUAndini AnugrahNoch keine Bewertungen

- F 414 - 96 Rjqxnc1sruqDokument5 SeitenF 414 - 96 Rjqxnc1sruqmonica andrea suarezNoch keine Bewertungen

- Radioactivity and Half LifeDokument5 SeitenRadioactivity and Half LifeMaria Sol LambertNoch keine Bewertungen

- History and Philosophy of Science and TechnologyDokument6 SeitenHistory and Philosophy of Science and TechnologyPhilip LaraNoch keine Bewertungen

- MEC331-Chapter-03 - Rivets & BearingsDokument52 SeitenMEC331-Chapter-03 - Rivets & BearingsMuhammad Muadz Amirul AzamNoch keine Bewertungen

- Physical Properties of Toluene: 1. Common DataDokument11 SeitenPhysical Properties of Toluene: 1. Common DataPhượng NguyễnNoch keine Bewertungen

- Non Circular GearsDokument10 SeitenNon Circular GearsihaNoch keine Bewertungen

- Rotor Particulars D275R14 Generator: Drawn Rev Ecn/Description Approved 00 KMC Original Issue CLDokument1 SeiteRotor Particulars D275R14 Generator: Drawn Rev Ecn/Description Approved 00 KMC Original Issue CLpwmvsiNoch keine Bewertungen

- CWI-Module 4 - Weld Joint Geometry & Welding Symbols (Compatibility Mode)Dokument80 SeitenCWI-Module 4 - Weld Joint Geometry & Welding Symbols (Compatibility Mode)thanhtung156Noch keine Bewertungen

- Murmurs From The Vascular Members: A Generalized Theoretical OutlookDokument13 SeitenMurmurs From The Vascular Members: A Generalized Theoretical OutlookAsian Journal of Basic Science & ResearchNoch keine Bewertungen