Beruflich Dokumente

Kultur Dokumente

Optimization of Temperature-Programmed Gas Chromatographic

Hochgeladen von

Anonymous atBeojaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Optimization of Temperature-Programmed Gas Chromatographic

Hochgeladen von

Anonymous atBeojaCopyright:

Verfügbare Formate

JOURNAL OF

CHROMATOGRAPHYA

ELSEVIER

Journal of Chromatography A, 756 (1996) 175-183

Optimization of temperature-programmed gas chromatographic

separations

II. Off-line Simplex optimization and column selection

Henri Snijders*, Hans-Gerd Janssen, Carel Cramers

Laboratota' ~f bzstrumental Analysis, Department ~[' Chemical Engineering, Eindhoven University of Technology, P.O. Box 513, 5600

MB Eindhoven, Netherlands

Received 3 May 1996: revised 9 July 1996; accepted 15 July 1996

Abstract

In this work a method is described which allows off-line optimization of temperature-programmed GC separations. The

method is based on a new numerical method that allows the off-line prediction of retention times and peak widths of a

mixture containing components with known identities in capillary GC. In the present work we apply this method for off-line

optimization of single- and multi-ramp temperature-programmed GC separations. First, it will be shown how the numerical

methods are incorporated in a Simplex optimization method. Next, it is described how the method can be used to determine

the optimal temperature program for the separation of a mixture containing components of different functionalities. Finally,

it is shown that the optimization strategy followed here allows selection of the capillary column most suited for the

separation problem under study from a given set of capillary columns containing the same stationary phase and varying inner

diameters and film thicknesses. The process can be performed without any experimental effort. The results indicate that fully

off-line simulation and optimization of single- and multi-ramp temperature-programmed GC separations as well as column

selection is possible.

Kevwords: Simplex optimization; Temperature-programming; Optimization; Column selection; Capillary columns; Chemo-

metrics

1. Introduction

In a previous article [1] we described a numerical

method to predict (truly off-line) linear temperatureprogrammed retention times and peak widths for

mixtures containing components with known identities in capillary GC. The procedure is based on

Corresponding author.

extracting thermodynamic values (entropy and enthalpy terms) from published Kovfits retention indices. A numerical method was developed, that uses

these thermodynamic values to calculate linear (single or multi-ramp) temperature-programmed retention times and peak widths on any capillary GC

column containing the same stationary phase but

with a different phase ratio and/or length. In short,

the numerical approach models the solute's chromatographic process into very small segments of

equal time. For every time interval the various

0021-9673/96/$15.00

1996 Elsevier Science B.V. All rights reserved

P l l S0021-9673(96)00626-7

176

H. Snijders et al, / J. Chromatogr. A 756 (1996) 175-183

chromatographic parameters are calculated, based on

a model developed from sound chromatographic

theory. Retention times are calculated from local

retention factors and the pressure and temperature

corrected local velocity in every time interval. Analogously, peak widths are calculated from local plate

heights (derived from the well-known Golay equation) in every segment. During the calculations

physical models and approximations are used to

obtain viscosity and diffusion data.

Apart from the thermodynamic quantities and the

solutes molecular formula, the only additional input

parameters needed for the predictions are the column characteristics (dimensions and coating efficiency), the carrier gas type and several instrumental parameters such as the temperature program and the column dead time or inlet pressure.

In the temperature-programmed mode a wide temperature range is allowed and isothermal plateaus

can be included in the program. An attractive

feature of the approach is that, once the thermodynamic values of the solutes of interest are

known, they can be stored in a database and future

predictions can be performed without the need to

perform new experimental input runs.

In the present work we apply this new numerical

method to off-line optimization of temperature-programmed GC separations, where we define the term

optimization as achieving baseline resolution in the

shortest possible analysis time. The ultimate goal of

the work is to develop an optimization strategy that

does not require any experimental input run. In other

words, a method that enables truly off-line optimization. First, it will be shown how the numerical

methods for retention time and peak width prediction

previously developed are incorporated in a Simplex

optimization method. Next, it is described how the

method can be used to determine off-line the optimal

(either single- or multi-ramp) temperature program

for the separation of a mixture containing components of different functionalities. Finally, it is

shown that the optimization strategy followed here

allows selection of the capillary column most suited

for the separation problem under study, from a given

set of capillary columns containing the same stationary phase but with varying phase ratios and/or

lengths.

2.

Theory

2.1. Chromatographic response function

Successful application of an optimization process

is preceded by careful selection of the quantity

(response factor) to be optimized. For chromatographic separations the main problem lies in proper

conversion of the retention times and peak widths of

all relevant chromatographic peaks into a single

number which accurately reflects the optimization

criterium. Several authors have recognized and discussed this problem [2-4] and many chromatographic response functions (CRF) have been suggested. In

this work we adopted the CRF used by Dose [5]. For

a given chromatogram the CRF value can be calculated from:

CRF

+ ~e

tR,crit

e~,~.r,

(1)

i~i

where tR,,, is the retention time of the last-eluting

peak, tR,~r~, is a user-selected time-cost weighting or

compromise factor and R~.cr~, is a user-selected

resolution target value. R~,,j is the resolution between

peak i and j which is defined as:

AtR.~i

R~,~ - 2(~ + %)

(2)

where AtR,~j is the retention time difference (expressed positive) between peak i and j. ~ and ~ are

the standard deviations of peak i and peak j, respectively.

From Eq. (1) it can be seen that both analysis time

and resolution are incorporated in the CRF. Moreover, all possible peak-to-peak interactions are included. The occurrence of overlapping peaks is

strongly discouraged. Additionally, it emphasizes the

least resolved peak pairs without totally ignoring the

other peak pairs. Further merits of the CRF used here

are extensively discussed by Dose [5].

2.2. Optimization algorithm

The optimization procedure used in this work is

the Modified Simplex Method (MSM) as described

H. Snijders et al. / J. Chromatogr. A 7.56 (1996) 175-183

by Nelder and Mead [6]. Successful application of

the Simplex method for the optimization of GC

separation problems was demonstrated by several

authors, e.g. [5,7]. In this section it will be shown

how the numerical methods previously derived for

the calculation of retention times and peak widths in

temperature-programmed GC separations [1] are

incorporated in an MSM for the purpose of off-line

optimization of temperature-programmed GC separations. Moreover, it will be shown how the strategy

followed here allows selection of the capillary

column most suited for a given separation problem

from a set of available columns. The discussion of

the various important aspects of the optimization

process is guided by the overall optimization algorithm, presented in Fig. 1.

Prior to starting the optimization, it must be

decided which parameters are to be optimized.

Normally only those factors are included which

exhibit the largest impact on the CRF (the quantity

to be optimized). For the majority of GC separations

the temperature-programming rate is the decisive

parameter in order to attain the ultimate separation

goal. Apart from the programming rate, also other

important parameters such as e.g. the initial oven

temperature, can be included in the optimization.

With the present algorithm the number of dimensions

to be optimized can be fully user-selected. This

means that the optimization can be performed for

single- and/or multi-ramp temperature-programmed

separations either with or without the incorporation

of isothermal plateaus. In fact, all variables which

describe a GC temperature program can be included

as optimization parameters. Parameters which are not

included in the optimization are held constant.

As already mentioned in the introduction, the

primary goal of the work presented here is to attain

truly off-line optimizations. During the optimization

calculations the mean linear velocity at the initial

oven temperature was kept constant. Hence, the

numerical methods applied here require a representative value for the mean linear velocity. This value

was estimated for a given combination of column

inner diameter and carrier gas type using Table 1.

This table is compiled by using the computer program described in [8]. With the value from the table

and given the initial oven temperature (determined

177

Input data

1) Column list

- column(s) dimensions

- stationary phase type

- carrier gas

- coating efficiency

2) Component list

- enthalpy/entropy-term

- molecular formula

Read column data

Read mean linear velocity

(Table I)

Select simplex

- parameters

- boundaries

- read & set fixed values

Create simplex

Read component data

Calculate t a & ~

no

aloulateC

Optimum

I

no

yes

, ~

More columns

Select best column

<

F i g . 1. O v e r a l l

algorithm

end

of the optimization

procedure.

by the vertex data), the corresponding column dead

time and required inlet pressure can be calculated

using the approach described in part I of this work

[1]. This means that during the execution of the

optimization no experimental data have to be ac-

H. Snijders et al. / J. Chromatogr. A 756 (1996) 175-183

178

Table 1

Estimated mean linear velocities [8] as a function of column

diameter and carrier gas type

Column inner diameter (~m)

Mean linear velocity (cm s ')

Carrier gas type

150 320

321-550

H2

He

N2

55-45

45-28

40-33

33-25

17 12

12- 7

The values for the mean linear velocities are retrieved from the

table by linear interpolation between the indicated column diameters.

quired, which satisfies our goal of truly off-line

optimization.

An other important aspect to be addressed are the

constraints which have to be put on the variables to

be optimized. Often, those boundaries are dictated by

the chromatographic equipment used. As an example, contemporary gas chromatographs have limited

maximum programming rates. Moreover, the maximum and minimum allowable operating temperatures

of the separation column are limited. Also parameter

values that would lead to highly undesirable results

such as too low a programming rate or too low an

initial oven temperature can be excluded from the

factor space. By taking those limitations into account, the factor space can thus be adapted to

practical and/or experimental considerations. The

simplex is held within the boundaries by assigning

unfavourable (very high) CRF values to vertices

which fall outside the factor space.

The location of the initial simplex should be

carefully chosen. The classical problem associated

with Simplex optimizations is that the final optimum

may not be the global optimum but a local optimum

with a less desirable response (in this case a less

desirable CRF value). For GC optimizations convergence to a local optimum can easily occur when e.g.

peak orders change under temperature-programmed

conditions. To locate the optimum which yields the

shortest possible analysis time (while maintaining

baseline resolution), the initial simplex is selected

near the upper or lower boundaries of the factor

space. In case of a three-factor optimization this

could mean that the initial simplex is located close to

the maximum allowable programming rate and initial

temperature and close to the minimum allowable

time for an isothermal plateau.

Once the initial simplex is determined, the optimization procedure proceeds as follows. Given the

conditions specified by the factors of each vertex of

the initial simplex, the retention times and peak

widths for each component are calculated by using

the numerical procedures. For this purpose the

entropy and enthalpy term and the molecular formula

for each component must be known. The calculated

peak data are than used to calculate the CRF for each

vertex. The optimization continues by rejecting the

vertex with the least desirable response followed by

determination of the next simplex, guided by the

Modified Simplex algorithm (note that a high CRF

value indicates a low response!). The process is

ended when the step size of each factor to be

optimized is less than a preselected maximum allowable difference. This value is usually given by the

accuracy of the instrumentation for each individual

factor.

The process described above is restarted when the

optimal chromatogram should be predicted for

another column, with a different phase ratio and/or

length, until all column data are processed. Finally,

comparison of the results yields the column exhibiting the lowest analysis time (indicated by the

retention time of the last-eluting component) for the

given separation problem. Here it should be realized

that in practical situations the final selection of the

column most suited for the separation problem under

study can also be guided by additional practical

considerations such as e.g. the oven cooling down

time.

3. Experimental

3.1. Instrumentation

GC was performed on an HP 5890 gas chromatograph equipped with a split-splitless injector and a

flame ionization detection (FID) system (HewlettPackard, Wilmington, DE, USA). The columns used

in this study are indicated in Table 2. Columns A, B

and D are coated with 100% methyl silicone, HP-1

(Hewlett-Packard). Column C is coated with 100%

methyl silicone, CP-Sil 5 CB (Chrompack, Middel-

H. Snijders et al. / J. Chromatogr. A 756 (1996) 175-183

Table 2

Dimensions of the columns used in this study

Symbol

L (m)

d (~xm)

d~ (~m)

/3

A

B

C

D

25

25

25

25

320

320

250

200

0.52

0.17

0.25

0.33

153

470

250

264

L - c o l u m n length; de=column diameter; d, = stationary phase

film thickness; /3 column phase ratio. All columns are coated

with 100% methyl silicone.

burg, The Netherlands). Injections were performed in

the split mode (split ratio 1:100) to minimize injection band broadening. The instrument was operated in the constant pressure mode. In experimental

verifications of predicted optimal chromatograms,

the optimal column dead time, reported after the

optimization, was set on the instrument by adjusting

the carrier gas (helium) pressure to the corresponding

value via methane injections. Both injector and

detector temperature were held constant at 300C

during the experimental work. The detector make-up

gas flow-rate (nitrogen) was maintained at 30 ml

rain t. An Omega data system (Perkin-Elmer, Norwalk, CT, USA) was used for data acquisition and

processing.

3.2. Calculations

During the simulations no correction for the

column coating efficiency was applied. For the

calculations it was assumed that the column outlet

pressure equals 100 kPa (abs.). The stepwidth At was

1000 ms [1]. The maximum allowable difference for

the factors is IC for temperatures and 0.1 C rain 1

for temperature programming rates. For CRF calculations, R~,~ri~ and tR,crit are set to 1.5 and 20 rain

respectively. All computations were carried out on a

486-DX2/66 MHz personal computer. Software was

written in Turbo Pascal 6.0 (Borland, USA). A

complete optimization for one column takes about 15

rain. Data entry is arranged through filed input.

3.3. Test mixture

To determine the applicability of the optimization

approach presented above, a test mixture was corn-

179

piled, containing sixteen components of different

functionality, p-Chlorotoluene, sec.-butylbenzene,

diphenyl ether, anthracene, pyrene and hexadecene

were purchased from Janssen Chimica (Geel, Belgium). Methyl esters of myristic acid, palmitic acid

and oleic acid were obtained from Polyscience

Corporation (IL, USA). n-Undecane, n-undecene, ntridecane and n-tetradecane were purchased from

Merck (Darmstadt, Germany). 1-Chlorotetradecane

was obtained from Humphrey Wilkinson (CT, USA)

and naphthalene and quinoline from Aldrich (Bornem, Belgium). The purity of all analytes was at

least 98%. The solvent used to prepare the mixture

was analytical grade n-hexane (Merck).

The entropy and enthalpy terms of the test components were obtained from Ref. [1]. For test

components for which no data were available the

entropy and enthalpy terms were experimentally

established.

4. Results and discussion

To demonstrate the applicability of the novel

optimization approach, optimizations of the test

mixture were performed for all columns. Ideally, the

optimum located by the Simplex procedure should be

the global optimum. To check whether the predicted

optimum equals the global optimum, detailed knowledge of the response surface should be available. For

a two-factor optimization the response surface can be

graphically represented by e.g. a contour plot. In Fig.

2. the calculated response surfaces for the separation

of the test mixture on all columns are presented. The

two factors plotted are the initial column temperature

and the oven programming rate. The CRF values

were calculated off-line by using the numerical

methods. In the contour plots the iso-response (isoCRF) points are connected by lines. From the figure

it can be seen that in all plots several local optima

can be observed. This occurs e.g. when peak orders

change during temperature programming. Closely

located optima are observed when the gain in

analysis time by starting the temperature program at

a higher initial temperature is partially offset by a

decrease in the programming rate. This leads to only

minor differences in the chromatographic separation

180

H. Snijders et al. / J. Chromatogr. A 756 (1996) 175-183

Column A

Column B

25

25

2o

2o

' i 15

lO

5

50

7'5

150

125

Initial temperature(C)

150

5 50

75

Column C

100

15

Initialtemperature(C)

150

Column D

25

,=

'~. 20

J

"i 15

1o

5 50

7~5

100

125

Initialtemperature(C)

150

5'o

7'5

t60

Initialtemperature(C)

l~5

t~o

Fig. 2. Iso-responseplots of the separationof the test mixtureon all four the columns.Parameters includedin the optimizationare the initial

oven temperature and the programmingrate. The optima found by the correspondingSimplex optimizationare indicated by the cross. The

temperature programs located by the optimizationare for column A: 100C ~ 13.0C rain ~ ---)300C; column B: 108C ~ 10.3C min

---+300C; column C: 97C ~ 20.4C min ~ -4 300C; column D: 108C --) 13.7C min ~ --~ 300C.

and/or analysis time. The corresponding CRF values

are nearly equal.

In parallel, the corresponding two-factor Simplex

optimization was performed for the test components

for all columns. The parameters plotted in the

contour plots were now optimized by using the novel

optimization approach. No initial hold time was

used. The final optima, located by the optimization,

are indicated in the contour plots of Fig. 2 as well.

From the figure it can be seen that the optima located

in all cases equal the global optima.

To verify the resemblance between predicted and

experimental optimal chromatograms, the test mix-

ture was analyzed under the conditions determined

by the values of the optimum for each column. The

results of these measurements are presented in Fig. 3.

The figure clearly shows that for all columns the

experimental and predicted chromatograms are very

similar. In the chromatograms several critical peak

pairs can be distinguished. The experimental data

corresponding to the optimization on column C and

D reveal partial peak overlap for the second critical

peak pair. Due to the smaller inner diameter of these

columns, compared to columns A and B, injection

band broadening becomes more critical and is probably responsible for the partial peak overlap observed.

H. Snijders et al. / J. Chromatogr. A 756 (1996) 175-183

Column A

!,1 ILIL

,~

Column B

t'2

(5

o.oo

Jl 11, I 11

230

Time (rain)

7.~o

(2

(5

0.00

2.50

5.00

7.50

Time (min)

Column C

Column D

10

0.00

2.50

12150

10.00

12.50

5.bo

7.~o

,1lOlOOI112150

Time (rain)

Time (rain)

10'.00

Time (min)

L,I

5.bo

Time (min)

181

1o

Time (rain)

o.oo

2.~o

5.bo

7.50

ioloo 12'.5o

Time (rain)

Fig. 3. Comparison of predicted (upper trace) and experimental (lower trace) chromatograms for single-ramp temperature-programmed

optimizations of the separation of the test mixture for all four the columns. Conditions see Fig. 2.

The chromatographic data further indicate that the

column most suited for single-ramp analysis of the

mixture would be column B. This column yields the

shortest analysis time while all critical peak pairs are

baseline separated.

Optimization of the separation of the test mixture

was also performed for a two-step multi-ramp temperature program. Parameters optimized now are the

initial and mid-point column temperature and the

corresponding two programming rates. In total four

parameters are optimized simultaneously. Again, the

predicted and experimental chromatograms are presented in Fig. 4. From the figure it can be concluded

that for all four columns the experimental and

predicted chromatograms are very similar. The experimental data corresponding to the optimizations

H. Sn(iders et al. I J. Chromatogr. A 756 (1996) 175;-183

182

Column A

0.00

2.50

Column B

Jll iI, Ill

5.00

7.50

10.00

12,50

0.00

1.50

2.30

5.00

7.50

3.00

4.50

10:00

12:50

0.00

1.50

3.00

4.50

Time (rain)

Time (rain)

Column C

Column D

Ill Jit, l Jl_

4

6

Time (rain)

6.00

7.50

6.00

7.50

Time (min)

Time (min)

0.00

1i itJ, l I

10

0.00

2.50

tll l,J

5.00

7.50

10.00

12.50

Time (min)

]L

8

i'0

0.00

2.'50

5.00

7.50

lo'.oo

12'.5o

Time (rain)

Time(min)

Fig. 4. Comparison of predicted (upper trace) and experimental (lower trace) chromatograms for multi-ramp temperature-programmed

optimizations of the separation of the test mixture for all four the columns. The temperature programs located by the optimization are for

column A: 105C ---) 13.8C rain ~ ---) 242C ~ 23.6C min ~ --~ 300C; column B: 91C ~ 24.8C min ~ --~ 245C ~ 21.4C rain ~ --~

300C; column C: 99C ~ 19.3C rain ~ --) 243C ~ 19.9C min ~ ~ 300C: column D: 105C --~ [3.8C min ~ ---) 266C ---) 15.0C

min ~ --~ 300C.

on c o l u m n

A , C a n d D a g a i n r e v e a l partial p e a k

o v e r l a p for the s e c o n d critical p e a k pair. A g a i n ,

a d d i t i o n a l p e a k b r o a d e n i n g d u e to i n j e c t i o n is the

m o s t p r o b a b l e c a u s e for t h e s e o b s e r v a t i o n s . T h e data

further i n d i c a t e that for separation o f the test m i x t u r e

column

should

be

temperature-programmed

used

under

the

multi-ramp

c o n d i t i o n s i n d i c a t e d in Fig.

4.

It s h o u l d be n o t e d that, in principal, m o r e varia b l e s c o u l d be a d d e d to the o p t i m i z a t i o n for further

H. Snijders et al. / J. Chromatogr. A 756 (1996) 175-I83

optimization of the separation. Moreover, the optimization could be extended to include other column

lengths a n d / o r phase ratios.

5. Conclusions

With the optimization approach presented here it

is possible to simulate and optimize both single- and

multi-ramp temperature-programmed GC separations. Moreover, the approach allows selection of the

capillary column most suited for the separation

problem under study. The most attractive feature of

the work presented here is that the optimizations can

be performed without any experimental effort. This

assures truly off-line optimizations and column

selections

183

References

[1] H. Snijders, H.-G. Janssen and C. Cramers, J. Chromatogr.

A, 718 (1995) 339.

[2] W. Wegscheider. E.R Lankmayr and M. Otto, Anal. Chim.

Acta, 150 (1983) 87.

[3] H.J.G. Debets, B.L. Bajema and D.A. Doornbos, Anal.

Chim. Acta, 151 (1983) 131.

[4] P.J. Schoenmakers(Editor), Optimizationof Chromatographic Selectivity,Elsevier, Amsterdam, 1986, Ch. 4.

[5] E. Dose, Anal. Chem., 59 (1987) 2420.

[6] J.A. Nelder and R. Mead, Computer J., 7 (1965) 308.

[7] S.L. Morgan and S.N. Deming, J. Chromatogr., 112 (1975)

267.

[8] RA. Leclercq and C.A. Cramers, J. High Resolut. Chromatogr. Chromatogr. Commun., 8 (1985) 764.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Dissolved OxygenDokument2 SeitenDissolved OxygenAnonymous atBeojaNoch keine Bewertungen

- Ansys Fensap-Ice in Ansys Workbench Users Guide 18.2Dokument64 SeitenAnsys Fensap-Ice in Ansys Workbench Users Guide 18.2Panda HeroNoch keine Bewertungen

- NHAI Under ImplementationDokument24 SeitenNHAI Under ImplementationFelix SandersNoch keine Bewertungen

- Technical Manual Index: Component Maintenance Manuals August 1, 2019Dokument91 SeitenTechnical Manual Index: Component Maintenance Manuals August 1, 2019chandradeo100% (1)

- Testsdumps: Latest Test Dumps For It Exam CertificationDokument7 SeitenTestsdumps: Latest Test Dumps For It Exam CertificationSekharNoch keine Bewertungen

- Pantone Color SwatchbookDokument10 SeitenPantone Color Swatchbookdongu100% (1)

- Company Post Anchor LetterDokument1 SeiteCompany Post Anchor LetterAnonymous atBeojaNoch keine Bewertungen

- Aims300v DC - 41201Dokument24 SeitenAims300v DC - 41201Anonymous atBeojaNoch keine Bewertungen

- Freight CalculatorDokument2 SeitenFreight CalculatorAnonymous atBeojaNoch keine Bewertungen

- List of Mobile Phone Makers by Country - WikipediaDokument7 SeitenList of Mobile Phone Makers by Country - WikipediaAnonymous atBeojaNoch keine Bewertungen

- Inserting Section And/or Page Breaks: ProcessDokument1 SeiteInserting Section And/or Page Breaks: ProcessAnonymous atBeojaNoch keine Bewertungen

- Enveronmental Polutution Control and EngineerDokument19 SeitenEnveronmental Polutution Control and EngineerAnonymous atBeojaNoch keine Bewertungen

- Plug-In How-To Guide: Adobe Acrobat XIDokument9 SeitenPlug-In How-To Guide: Adobe Acrobat XIAnonymous atBeojaNoch keine Bewertungen

- Withdraw RTP 45 145 Web 2Dokument1 SeiteWithdraw RTP 45 145 Web 2Anonymous atBeojaNoch keine Bewertungen

- Voice STV 145 425 Extn Aug2015 WebDokument1 SeiteVoice STV 145 425 Extn Aug2015 WebAnonymous atBeojaNoch keine Bewertungen

- End of Cauvery PV-72: Bharat Sanchar Nigam Limited Karnataka Telecom CircleDokument1 SeiteEnd of Cauvery PV-72: Bharat Sanchar Nigam Limited Karnataka Telecom CircleAnonymous atBeojaNoch keine Bewertungen

- Bharat Sanchar Nigam Limited Karnataka Telecom Circle: Introduction ofDokument2 SeitenBharat Sanchar Nigam Limited Karnataka Telecom Circle: Introduction ofAnonymous atBeojaNoch keine Bewertungen

- Expt 4-Estimation of CopperDokument4 SeitenExpt 4-Estimation of CopperAnonymous atBeojaNoch keine Bewertungen

- Result For STSA Trainees Kaiga SiteDokument9 SeitenResult For STSA Trainees Kaiga SiteAnonymous atBeojaNoch keine Bewertungen

- Grasim ABCIL MergerDokument5 SeitenGrasim ABCIL MergerAnonymous atBeojaNoch keine Bewertungen

- Exp10 PDFDokument17 SeitenExp10 PDFAnurag BajpaiNoch keine Bewertungen

- 8 Column and Thlrhayer Liquid Chromatography: (A) Bulk Property DetectorsDokument1 Seite8 Column and Thlrhayer Liquid Chromatography: (A) Bulk Property DetectorsAnonymous atBeojaNoch keine Bewertungen

- Vogel's Textbook of QuantitaDokument5 SeitenVogel's Textbook of QuantitaAnonymous atBeojaNoch keine Bewertungen

- Iron by 1,10 Phenanthroline Assay StudentDokument2 SeitenIron by 1,10 Phenanthroline Assay StudentAnonymous atBeojaNoch keine Bewertungen

- 344 - Vaagdevi College of Engineering - WGLDokument2 Seiten344 - Vaagdevi College of Engineering - WGLvishnavi vishuNoch keine Bewertungen

- Recruting Office HQ Chennai Online Cee Agniveer Cat 2023-24Dokument28 SeitenRecruting Office HQ Chennai Online Cee Agniveer Cat 2023-24KaisgNoch keine Bewertungen

- JLHBMS & JLHBMS-CPS High Bay Linear Series Spec SheetDokument3 SeitenJLHBMS & JLHBMS-CPS High Bay Linear Series Spec SheetAbner AguileraNoch keine Bewertungen

- Blended Learning Lesson PlanDokument5 SeitenBlended Learning Lesson Planapi-710577606Noch keine Bewertungen

- Addmrpt 1 36557 36558Dokument5 SeitenAddmrpt 1 36557 36558Anonymous ZGcs7MwsLNoch keine Bewertungen

- Manual ING SHJ 7005Dokument59 SeitenManual ING SHJ 7005ricardo assaf marchetiNoch keine Bewertungen

- Cylinder Cycle Time - CheckDokument3 SeitenCylinder Cycle Time - CheckNasrul arulNoch keine Bewertungen

- Hill CH 5Dokument158 SeitenHill CH 5Shahriar AhmedNoch keine Bewertungen

- A 1-D Theoretical Receiving Model For CMUT: November 2008Dokument7 SeitenA 1-D Theoretical Receiving Model For CMUT: November 2008Hehe JeansNoch keine Bewertungen

- Intuit IOPDokument16 SeitenIntuit IOPSanthosh PNoch keine Bewertungen

- When Intrusion Detection Meets Blockchain Technology A ReviewDokument10 SeitenWhen Intrusion Detection Meets Blockchain Technology A ReviewKaram Bou ChaayaNoch keine Bewertungen

- Smart Agricultural Crop Prediction Using Machine LearningDokument9 SeitenSmart Agricultural Crop Prediction Using Machine Learning19-512 Ratnala AshwiniNoch keine Bewertungen

- Type of Fixture Maximum Allowable Flow RateDokument3 SeitenType of Fixture Maximum Allowable Flow RateChinadevudu GandiNoch keine Bewertungen

- Irrevocable Corporate Purchase Order (Aluminum Ingot A7) : (Bauxited Smelted)Dokument2 SeitenIrrevocable Corporate Purchase Order (Aluminum Ingot A7) : (Bauxited Smelted)Kalo MbauhNoch keine Bewertungen

- GDC 800H Handset Eng User GuideDokument35 SeitenGDC 800H Handset Eng User Guideadyta_roNoch keine Bewertungen

- 09007dcc8030bc1cDokument5 Seiten09007dcc8030bc1cVenkatesh PeruthambiNoch keine Bewertungen

- 3 Series: Centrifugal Pumps Construction 50HzDokument2 Seiten3 Series: Centrifugal Pumps Construction 50HzocnogueiraNoch keine Bewertungen

- Assignment No. 3 - Eng Maj 11Dokument4 SeitenAssignment No. 3 - Eng Maj 11Mark GutierrezNoch keine Bewertungen

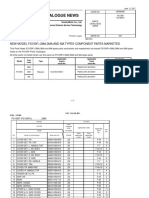

- Parts Catalogue News: New Model Fs150F - 2MA, 3MA and Ma Types Component Parts-MarketedDokument17 SeitenParts Catalogue News: New Model Fs150F - 2MA, 3MA and Ma Types Component Parts-MarketedJimanx Haziman100% (1)

- Enhancement of Time-Based One-Time Password For 2-Factor AuthenticationDokument6 SeitenEnhancement of Time-Based One-Time Password For 2-Factor AuthenticationInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Index: S.No Program List Page NoDokument26 SeitenIndex: S.No Program List Page NoVinay PadhiyarNoch keine Bewertungen

- Jiangsu Shuangdeng Group Co.,Ltd: ChinashotoDokument2 SeitenJiangsu Shuangdeng Group Co.,Ltd: ChinashotoBonjour Kyaw ZinNoch keine Bewertungen

- POM Class Note 07-Facility Layout Line BalancingDokument55 SeitenPOM Class Note 07-Facility Layout Line BalancingSADY MOHAMMEDNoch keine Bewertungen

- S3 Electronic Devices Vocabulary Conversation M3Dokument1 SeiteS3 Electronic Devices Vocabulary Conversation M3Juice CyyNoch keine Bewertungen

- 02 Handout 1Dokument8 Seiten02 Handout 1domcasintoNoch keine Bewertungen

- Schedule-40 Velocity Head Loss Steel Pipe (Fl/sec) (fl/1 O0 FL)Dokument5 SeitenSchedule-40 Velocity Head Loss Steel Pipe (Fl/sec) (fl/1 O0 FL)Ahmed ZidaneNoch keine Bewertungen