Beruflich Dokumente

Kultur Dokumente

Ciclo Combinado

Hochgeladen von

carzanteOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ciclo Combinado

Hochgeladen von

carzanteCopyright:

Verfügbare Formate

Ambient temperature

Ambient pressure

Pressure loss at compressor intake

Pressure loss after GTU

Compression ratio

Turbine inlet temperature

Average temperature of turbine blades

Gas constant for air

Gas turbine output

Fuel calorific value (gas natural)

Fuel calorific value (Fuel oil)

Blades cooling effectiveness

Expansion coefficient of cooling air

Electricity generator efficiency

Mechanical efficiency

1%P4

Specific heat air (Ta)

25 C

1.013 bar

0.0125 bar

bar

15.7

1100 C

850 C

8.314 J/molK

51 MW

44.3 MJ/kg

29.31 MJ/kg

0.42

0.35

0.98

0.98

1005.385825 J/kgK

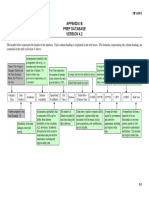

1) GAS-TURBINE THERMODYNAMICS ANALYSIS

1 ITERACIN

Compresor

gamma a

P1

T1

h1=f(T1,P1)

Specific heat ratio

Presin en primera etapa del compresor

P2

T2s

h2s=f(T2s,P2)

Cpm a

gamma a *

Compressor polytropic efficiency

Compressor efficiency

h2

T2=f(h2,P2)

Wk

Compressor specific work

1.4

1.0005 bar

25 C

8671.4 J/mol

15.70785 bar

381.667728 C

18758.1 J/mol

28.28038313

1.416399903

0.905

0.863510609

20352.43772 J/mol

414.68 C

11681.03772 J/mol

2 ITERACIN

Combustion chamber

mc

L0

relative air mass flow rate for blades cooling

Fuel ratio for combustion

0.027777778

15 kg air/kg fuel

mloss

relative air losses mass flow

combustion chamber efficiency

alphaG

excess air coefficient

h3=f(T3,alphaG)

L0

Qar

theretical air quantity

calorific value of fuel

0.005 kg air/kg air

0.94

3

44216.1 J/mol

25.23809524 kg/kg

88201620 J/kg

776174.256 J/mol

mf

relative fuel mass flow for gas turbine unit

PM gas natural

0.032976986 kg fuel/kg air

17.87 g/mol

alphaG*

1.955347931

P3

T3

hydraulic losses coefficient within the gas combustion chamber

0.02

15.393693 bar

Turbine inlet temperature

1373.15 K

3 ITERACIN

Expansion process solution

Pressure drop4Hydraulic

(turbine connected

resistance after

to heat

theexchanger

turbine or HRSG)

Pressure drop4 (exhaust gases are sent to stack)

0.025 bar

0.075 bar

P4

1.088 bar

gammaG

heat capacity ratio for product gases

1.4

gases expansion ratio

turbine polytropic efficiency

14.14861489

0.855

turbine isentropic efficiency

0.804198502

T4s

644.0840936 C

h4s

27731.6 J/mol

h4

30959.28979 J/mol

h4a

gases specific enthalpy at the end of expansion process

57472.91021

CpmG=f(T3,T4s,alphaG)

36.1568872

gammaG*

1.29860409

Wa

T4a

relative turbine work for product gases

185224.4573 J/kg

1460.79 C

Energy loss coefficient in gas turbine due to using -0.26274624

cooling system

cooling systen effectiveness

0.42

TCO

597.5144 C

hCO=f(TCO)?? enthalpy of cooling air before the expansion process 44353.9 J/mol

QCO

relative quantity of extraction heat in the cooling 666.7072854

system

J/kg

Wac

relative work of the expansion process for product185399.6322

gases in the gas

J/kgturbine taking into account the eff

Expansion ratio for cooling air within the turbine 9.196599678

hCO4=f(TCO)??enthalpy of cooling air after the expansion process

28333.3 J/mol

WCO

relative work of the cooling air expansion in the gas

445.0166667

turbine

J/kg

WT

total relative work of the gas turbine

185844.6488 J/kg

We

net gas turbine output

174163.6111 J/kg

NEGT

gas turbine unit output

51 MW

mK

air mass flow

304.9022322 kg/s

BGT

gas turbine fuel consumption

10.05475666 kg/s

mgas

mass flow rate of exhaust gases from the gas turbine

313.4324777

unit

h4

alphaG

be

58238.52668 J/mol

2.011503817

specific fuel consumption of the gas turbine unit 0.197152091 tonne/MWh

Gas turbine unit efficiency

0.114497205

Valores tpicos

Fuente

Rango 0,01:0,015

Rango 750-850C

Depende del tipo de combustible

Depende del tipo de combustible

Rango 0,9:0,91

Alrobaei, 1998

1048 Tomo 1048 mientras

Datos obtenidos de "Winpro"

A ESTIMAR

Datos a introducir

(1) Los datos obtenidos de Winpro deben conseguirse de tablas. Consegu

654.817728

PM

g/mol

H2

components (%)

H2

Fuel A

Fuel B

Fuel C

Fuel D

0.6

0.5

0.4

0.3

tipical 0,005 kg air/kg air

Rango 0,9:0,98

A ESTIMAR

Fuente: Optimization Calculation of Characteristic Parameters of Gas-steam

Fuente: Wikipedia

Rango 0,015:0,025

Dato inicial

Rango 0,02:0,03

Rango 0,005:0,01

0.79659269

A ESTIMAR

Rango 0,84:0,87

917.234094

P4s=P1; T4s--> Winpro con aire (Modificar)

Alrobaei, 1998

Aire en 3

Aire en 4

Elegir Qcv dependiendo del tipo de combustible

Winpro deben conseguirse de tablas. Conseguir esas tablas para no tener dependencia de un programa externo

CH4

CO

16

CH4

28

CO

0.3

0.35

0.3

0.4

0.1

0.15

0.3

0.3

Pmfuel (g/mol)

8.8

10.8

14

15.4

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Overhead Line DesignDokument37 SeitenOverhead Line DesignPramod B.Wankhade100% (4)

- Composite Materials and MechanicsDokument2 SeitenComposite Materials and MechanicsroscillaNoch keine Bewertungen

- Microsoft PowerPoint - Lect Soil Dynamics Wo MachineDokument275 SeitenMicrosoft PowerPoint - Lect Soil Dynamics Wo MachineFekadu WubNoch keine Bewertungen

- Manual Cost Analysis Tool V1.0Dokument54 SeitenManual Cost Analysis Tool V1.0carzanteNoch keine Bewertungen

- Maintenance and Overhaul of Steam TurbinesDokument46 SeitenMaintenance and Overhaul of Steam Turbinessubbusenthil78% (9)

- Solar400 AlgeriaDokument7 SeitenSolar400 AlgeriacarzanteNoch keine Bewertungen

- Tabla Disponibilidad (Alternativa OREDA)Dokument18 SeitenTabla Disponibilidad (Alternativa OREDA)carzanteNoch keine Bewertungen

- Tiempos de Arranque Segun Tipos de PlantasDokument17 SeitenTiempos de Arranque Segun Tipos de PlantascarzanteNoch keine Bewertungen

- H2 Storage - CostDokument26 SeitenH2 Storage - CostcarzanteNoch keine Bewertungen

- Costos ISCCDokument35 SeitenCostos ISCCcarzanteNoch keine Bewertungen

- Lahmeyer - Costes de O&MDokument225 SeitenLahmeyer - Costes de O&McarzanteNoch keine Bewertungen

- Fog Cooling Wet Compression and Droplet Dynamics in Gas Turbine PDFDokument247 SeitenFog Cooling Wet Compression and Droplet Dynamics in Gas Turbine PDFcarzanteNoch keine Bewertungen

- ET150 y Prototipo PSA PDFDokument5 SeitenET150 y Prototipo PSA PDFcarzanteNoch keine Bewertungen

- Vaccum Pump Vs Steam Ejector AdvantagesDokument6 SeitenVaccum Pump Vs Steam Ejector AdvantagescarzanteNoch keine Bewertungen

- Wittmann Some Aspects On Parabolic Trough Field Operation PDFDokument9 SeitenWittmann Some Aspects On Parabolic Trough Field Operation PDFcarzanteNoch keine Bewertungen

- Quality of Natural Gas Burnt in Combustion TurbinesDokument20 SeitenQuality of Natural Gas Burnt in Combustion TurbinescarzanteNoch keine Bewertungen

- Task 2 Final Report PDFDokument94 SeitenTask 2 Final Report PDFcarzanteNoch keine Bewertungen

- Cimentaciones CSP PDFDokument12 SeitenCimentaciones CSP PDFcarzanteNoch keine Bewertungen

- Simulation Test Loop PDFDokument8 SeitenSimulation Test Loop PDFcarzanteNoch keine Bewertungen

- Integrated Solar Power Plants (ISCC)Dokument13 SeitenIntegrated Solar Power Plants (ISCC)carzanteNoch keine Bewertungen

- Thermal and Optical Study of Parabolic Trough Collectors of Shiraz Solar Power PlantDokument6 SeitenThermal and Optical Study of Parabolic Trough Collectors of Shiraz Solar Power PlantmridupavanNoch keine Bewertungen

- Datos Satelite Vs Datos GroundDokument8 SeitenDatos Satelite Vs Datos GroundcarzanteNoch keine Bewertungen

- Compressor SpecificationDokument9 SeitenCompressor Specificationcarzante100% (1)

- Roos PresentationDokument86 SeitenRoos PresentationJignesh ChaudharyNoch keine Bewertungen

- Technical Description Steam EnginesDokument6 SeitenTechnical Description Steam Enginescarzante100% (1)

- Aerosols en SolarGISDokument4 SeitenAerosols en SolarGIScarzanteNoch keine Bewertungen

- Solar Radiation in AfricaDokument12 SeitenSolar Radiation in AfricacarzanteNoch keine Bewertungen

- Viabilidad CSP GreciaDokument15 SeitenViabilidad CSP GreciacarzanteNoch keine Bewertungen

- Little ChangesDokument1 SeiteLittle ChangescarzanteNoch keine Bewertungen

- HTF Venting System - MojaveDokument29 SeitenHTF Venting System - MojavecarzanteNoch keine Bewertungen

- Truncation of The Secondary Concentrator As Means To Cost Effective Beam-Down SystemDokument4 SeitenTruncation of The Secondary Concentrator As Means To Cost Effective Beam-Down SystemcarzanteNoch keine Bewertungen

- HTF Venting System - MojaveDokument29 SeitenHTF Venting System - MojavecarzanteNoch keine Bewertungen

- Heat and ThermodynamicsDokument15 SeitenHeat and ThermodynamicsYasir KhanNoch keine Bewertungen

- Ce1013 09Dokument42 SeitenCe1013 09Durga SharmaNoch keine Bewertungen

- EXP - 4 Chip MorphologyDokument2 SeitenEXP - 4 Chip MorphologyRaju SaiNoch keine Bewertungen

- Lame ConstantsDokument2 SeitenLame ConstantsAldi NurseptaNoch keine Bewertungen

- Cam Design Cam Design: Output FunctionDokument54 SeitenCam Design Cam Design: Output FunctionasritaipNoch keine Bewertungen

- Met 1Dokument46 SeitenMet 1Ahmed AbdelhamedNoch keine Bewertungen

- Spreading Dynamics of Polymer Nanodroplets: Sandia National Laboratories, Albuquerque, New Mexico 87185, USADokument10 SeitenSpreading Dynamics of Polymer Nanodroplets: Sandia National Laboratories, Albuquerque, New Mexico 87185, USAmh123456789Noch keine Bewertungen

- Richard Shoup and Thomas Etter - The RetroComm Experiment - Using Quantum Randomness To Send A Message Back in TimeDokument7 SeitenRichard Shoup and Thomas Etter - The RetroComm Experiment - Using Quantum Randomness To Send A Message Back in TimeCanola_OliveNoch keine Bewertungen

- (Chapter Iii) : Earthquake Records and Measuring InstrumentsDokument7 Seiten(Chapter Iii) : Earthquake Records and Measuring InstrumentsDominic FloresNoch keine Bewertungen

- Modular Compact Rheometers: MCR 72 MCR 92Dokument7 SeitenModular Compact Rheometers: MCR 72 MCR 92Tank TopNoch keine Bewertungen

- Recent Progress Toward A Three-Dimensional Unstructured Navier-Stokes Flow SolverDokument21 SeitenRecent Progress Toward A Three-Dimensional Unstructured Navier-Stokes Flow SolverDanielle HaysNoch keine Bewertungen

- Digital Power Clamp Meter HIOKI 3286Dokument4 SeitenDigital Power Clamp Meter HIOKI 3286industrialindiaNoch keine Bewertungen

- 6 Orthogonal and Oblique CuttingDokument12 Seiten6 Orthogonal and Oblique CuttingPRASAD326100% (6)

- Efficiency Analysis of Canards-Based Course Correction Fuze For A 155-mm Spin-Stabilized ProjectileDokument10 SeitenEfficiency Analysis of Canards-Based Course Correction Fuze For A 155-mm Spin-Stabilized Projectileali_raza117Noch keine Bewertungen

- NMR SplittingDokument36 SeitenNMR SplittingsabbysamuraNoch keine Bewertungen

- Inductor and Flyback Transformer DesignDokument20 SeitenInductor and Flyback Transformer Designbmmostefa100% (1)

- Chapter 5 Flexural MembersDokument40 SeitenChapter 5 Flexural MembersAriel Dela CruzNoch keine Bewertungen

- PDB - Single R32Dokument72 SeitenPDB - Single R32Duy ChuNoch keine Bewertungen

- ME2134 Review SlidesDokument60 SeitenME2134 Review SlidesowenwongsohyikNoch keine Bewertungen

- Emulsions Questions and AnswersDokument3 SeitenEmulsions Questions and AnswersAhmad FarhanNoch keine Bewertungen

- Radio Wave PropagationDokument12 SeitenRadio Wave Propagationمصطفى نوزادNoch keine Bewertungen

- Aerodynamic Implications of Parametric Changes in Flat and Wrap-Around Fins On A MissileDokument4 SeitenAerodynamic Implications of Parametric Changes in Flat and Wrap-Around Fins On A MissileRohan DharneNoch keine Bewertungen

- Phase DiagramDokument13 SeitenPhase DiagramJayzl Lastrella CastanedaNoch keine Bewertungen

- Design of A Reverberation ChamberDokument4 SeitenDesign of A Reverberation ChamberFacundo Ramon100% (1)

- Determination and Enlarging of The Acoustic Sweet-Spot in An AuditoriumDokument4 SeitenDetermination and Enlarging of The Acoustic Sweet-Spot in An AuditoriumInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- High-Density Polyethylene Foams. I. Poly PDFDokument9 SeitenHigh-Density Polyethylene Foams. I. Poly PDFamirsuryahidayahNoch keine Bewertungen

- 8 WORKSHEET Properties of SolidsDokument1 Seite8 WORKSHEET Properties of Solidskomal sheikhNoch keine Bewertungen