Beruflich Dokumente

Kultur Dokumente

Sharp Blade Choices For Smooth Cuts

Hochgeladen von

ottomansearchCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sharp Blade Choices For Smooth Cuts

Hochgeladen von

ottomansearchCopyright:

Verfügbare Formate

equip your shop

Sharp Blade

Choices For

Smooth Cuts

Our blade-buying advice

cuts to the bottom line.

ot that many years ago, circular

saw blades were simply steel

discs with teeth ground around

the rim. But todays blades feature tough carbide teeth that stay sharp

much longer, and the body of the blade

often has laser-cut slots that combat friction, noise, and heat-induced distortion.

Special coatings are another frictionfighting feature.

Saw blade tech

All of the technological innovations

made the blades body more stable so that

manufacturers could slim down the thickness of the blade, ushering in the era of

thin-kerf blades. (The kerf is the blades

width of cut.)

Although a slightly thinner cutline

may not initially seem like a big deal,

it generates an entire cascade of benefits. These include conserving stock and

reducing dust, but perhaps the biggest

benefit is boosting apparent cutting power

at the same horsepower. Without modern

blades, the present generation of cordless

circular saws would probably still be a

glimmer in a toolmakers eye.

CIRCULAR SAW BLADES

Bi-metal advances

Just as circular blades combine carbide

teeth with a steel body, straight blades

in reciprocating saws and jigsaws also

employ a bi-metal technology. In these

cases, though, teeth made from hard (but

brittle) tool steel team up with a flexible

backing though electron- or laser-welding.

The resulting blades are far better than

ones made from a single material. In fact,

bi-metal blades typically outlast conventional ones by three to one. So you spend

your time cutting material instead of

fiddling with blade changes.

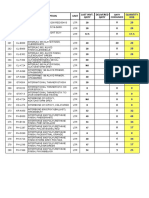

Just the facts, man

18 tpi

40 tpi

24 tpi

92

Blade production is a technical field, and

it would be easy to get bogged down in

the details. To keep things simple, here

are our recommendations for blades

throughout your shop.

Obtaining the results you want is a

matter of balancing the need for speed

against the quality of the cut. Fewer teeth

generally mean more aggressive cutting at

the sacrifice of a smooth surface. A high

tooth count often means a smooth cut

when the blade is sharp; but when allowed

to dull, you soon see burned edges.

CIRCULAR SAW BLADES Equipped

with the right blade, a portable circular

saw can cut tough jobs down to size in a

hurry. For rough cutting and framing jobs

with a 7" corded saw, choose a carbideBest-Ever Home Shop Ideas

2006

tipped blade with 18 to 24 teeth. Those

same tooth counts are also valid for the 5"

and 6" blades used on cordless saws.

For demolition jobs where you may

encounter embedded fasteners, select a

blade rated for nail-cutting. When youre

building a deck with pressure-treated

lumber thats still wet, reach for a special

blade that resists bogging down. For finish cuts in both solid wood and plywood,

reach for a 36-tooth blade. Steel blades

may be in the rearview mirror of technology, but theyre still useful for rough

carpentry work.

JIGSAW BLADES

14-tpi metal

24-tpi metal

6-tpi wood

TABLESAW BLADES If you work pri-

marily in veneered plywood, a good

crosscut blade will serve you well. In

the 10" size, the blade will have 80 teeth.

Switch to a 40-tooth combination blade

for solid stock.

If you work in both solid woods and

sheet goods, making rips (with the grain)

and crosscuts, buy two identical 40-tooth

combination blades instead. Install one

in your tablesaw, and set the other aside.

At the first sign of dulling (burned edges

and/or increased feed resistance), switch

to the second blade and get the first blade

cleaned and sharpened. That way, youll

always have a fresh blade ready for action.

For brick and landscaping block, a

diamond blade is a better investment than

the inexpensive abrasive blades, which

dull quickly.

RECIPROCATING SAW BLADES This

tough saw can be a remodelers best buddy,

rapidly chewing through demanding

20-tpi scrolling in wood

10-tpi wood

demolition tasks. A 6" blade shown below with 6 tpi (teeth per inch) is a good

choice for most jobs because it combines

ample capacity with fast cutting and ample rigidity. For demolition jobs, it pays

to buy good-quality blades that will slice

through nails without complaint.

Some now use a progressive tooth

spacing, where teeth are close together

near the tang for think stock and wide

near the end for thick stock.

For jobs where youre attacking thicker

material, move to a longer blade such as

the 10" blade (not shown). Like the shorter

version, this blade also has 6 tpi.

RECIPROCATING SAW BLADES

6" 6 tpi

A 10-tpi blade will yield a smoother

surface, but youll rarely use a reciprocating saw for finished cuts.

For metal cutting, select a blade thats

engineered to handle the job. Choose a

blade with 18 to 24 tpi depending on the

thickness of the metalthe thinner the

stock, the more teeth.

JIGSAW BLADES Recommendations for

jigsaw blades (shown above) closely follow the advice for the reciprocating saw:

6 tpi for rough cuts and 10 tpi for smoother cuts. For cutting a tight radius, choose

a blade that has a narrower bodythis is

typically called a scrolling blade.

If your jigsaw has a provision for

switching from reciprocating to orbital

action, youll gain further control over

your cut. A reciprocating (straight up and

down) motion yields a smoother surface

but requires more time. Orbital action

gives a faster but rougher cut.

Switch to a new blade

9" 6 tpi

6" 10 tpi

6" metal tpi

woodmagazine.com

Trying to coax additional cuts out of a dull

blade is false economy. It wastes your time,

wears out your arms, stresses your motors

bearings, and overheats your patience. In

addition, a burned surface is nearly worthless from a gluing standpoint. Switch to

a new blade as soon you sense that a cut

requires additional effort.

Written by: Robert J. Settich

93

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- UntitledDokument3 SeitenUntitledVince GomezNoch keine Bewertungen

- Regal Cutting ToolsDokument279 SeitenRegal Cutting Toolsbenj bandalNoch keine Bewertungen

- Textile Process FlowchartDokument10 SeitenTextile Process FlowchartAnik RajbongshiNoch keine Bewertungen

- Creo Parametric Milling PDFDokument364 SeitenCreo Parametric Milling PDFJ Vignesh50% (2)

- Workshop Hammer ReportDokument10 SeitenWorkshop Hammer ReportRido Orid OdirNoch keine Bewertungen

- Desert PillowDokument3 SeitenDesert PillowsnejiNoch keine Bewertungen

- Final Sheet (Rolled Size) - 24122019Dokument17 SeitenFinal Sheet (Rolled Size) - 24122019sourajpatelNoch keine Bewertungen

- Seer SuckeringDokument24 SeitenSeer SuckeringAbdul kader100% (1)

- Daily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateDokument1 SeiteDaily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateGokul KgsNoch keine Bewertungen

- Pak0202 006462MDokument3 SeitenPak0202 006462MNacada DacanNoch keine Bewertungen

- R PT Instruction PlanDokument6 SeitenR PT Instruction PlanVipin KumarNoch keine Bewertungen

- Cross Bookmark Crochet PatternDokument2 SeitenCross Bookmark Crochet Patternbibirebel0% (1)

- Gtu SyllabusDokument5 SeitenGtu SyllabussanjayNoch keine Bewertungen

- Process Drilling Metso NP1213MDokument31 SeitenProcess Drilling Metso NP1213Mharsha p100% (1)

- Smile CrochetDokument2 SeitenSmile CrochetRenataNoch keine Bewertungen

- How To Make A Roller Bender - Mistry MakeToolDokument10 SeitenHow To Make A Roller Bender - Mistry MakeToolaaron mathewsNoch keine Bewertungen

- Bearer of The Tradition of Folk CraftDokument3 SeitenBearer of The Tradition of Folk Craftdona.alburiNoch keine Bewertungen

- StitchDokument14 SeitenStitchTatiana D'hanisNoch keine Bewertungen

- ShopNotes #17 (Vol. 03) - Easy To Build Sawhorse - Text-4Dokument1 SeiteShopNotes #17 (Vol. 03) - Easy To Build Sawhorse - Text-4adanNoch keine Bewertungen

- Tle Handicraft Quarter 1 Module 1Dokument32 SeitenTle Handicraft Quarter 1 Module 1Roxanne Jessa CatibogNoch keine Bewertungen

- Machine Guarding StandardDokument68 SeitenMachine Guarding StandardDave CNoch keine Bewertungen

- Safety Engineering For M.E.: Bandsaw MachineDokument6 SeitenSafety Engineering For M.E.: Bandsaw MachineRogelioB.AlobII100% (1)

- PAINTS INVENTORY Apr.14 2016Dokument1 SeitePAINTS INVENTORY Apr.14 2016Pavel ViktorNoch keine Bewertungen

- Nas6703 NationalaerospacestandardDokument8 SeitenNas6703 NationalaerospacestandardSAPTONoch keine Bewertungen

- Floral Vine Lariat Scarf - My PatternDokument3 SeitenFloral Vine Lariat Scarf - My Patternonyxnox100% (1)

- English Baler in ADokument12 SeitenEnglish Baler in AMurielle Gillet-Moreau100% (1)

- French MacaroonDokument6 SeitenFrench MacaroonLilia BarriosNoch keine Bewertungen

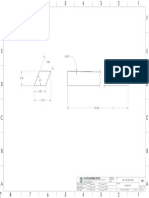

- Lathe GibDokument1 SeiteLathe Gibmohdshakir bahariNoch keine Bewertungen

- Furniture & Cabinetmaking 279 - Jan 2019 PDFDokument84 SeitenFurniture & Cabinetmaking 279 - Jan 2019 PDFcrm102bNoch keine Bewertungen

- Design of FixturesDokument19 SeitenDesign of FixturesSwaminathanNoch keine Bewertungen