Beruflich Dokumente

Kultur Dokumente

UT Procedure OTC

Hochgeladen von

amin110110Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

UT Procedure OTC

Hochgeladen von

amin110110Copyright:

Verfügbare Formate

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 1 of 34

NATIONAL IRANIAN GAS COMPANY

IGAT V Booster Gas Compressor Station

DOCUMENT TITLE:

UT PROCEDURE

SPY-3-0000-CM-PR-212

A. M.

P. K.

A. M.

AUTHOR

CHECK

QA

M. A. T.

5GCS

AUTHORIZED

24 Aug '06

EP

MC

APPROVED

DATE OF

ISSUE

D00

REV.

For Information

PURPOSE OF

ISSUE

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

Page 2 of 34

REV

00

TABULAITON OF REVISED PAGES

PAGE

Rev.0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Rev.1

Rev.2

Rev.3

Rev.4

PAGE

Rev.0

Rev.1

Rev.2

Rev.3

Rev.4

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

CONTENTS

Page

1

Scope

Reference

Responsibility

Qualification of personnel

General requirement

Equipment and accessories

Calibration blocks and reference specimens

12

Distance calibration

16

Distance amplitude correction

16

10

Primary reference level and scanning sensitivity

17

11

Transfer value correction

17

12

Application UT examination

18

13

Parent metal evaluation

18

14

Inspection of welds

18

15

Discontinuity localization and size evaluation

21

16

Post cleaning

22

17

Acceptance standards

22

18

Defect marking and examination of repair

22

19

Reporting

23

20

Appendices

23

Page 3 of 34

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 4 of 34

1. Scope

1.1. This procedure covers requirements for ultrasonic examination for fabrication &

erection of piping and steel structure full penetration welds in ferrite materials,

usually minimum thickness of 5/16 inch (8mm) to be fabricated for IGAT V Booster

Gas Compressor Stations, contract No. 180502.

1.2. The purpose of ultrasonic examination is to determine and evaluate the severity of

internal discontinuities in welds and base metal. This procedure describes the

general requirements for ultrasonic testing of full penetration welds in ferrite

materials, usually minimum thickness of 5/16 inch (8mm).

2. References

2.1. ASME Sec. V : Nondestructive Examination

2.2. ASME E164, A578, Nondestructive Examination (vol.03-03, 01-03)

2.3. ASME B31.3 : Process Piping

2.4. AWS D1.1 : Structural Welding Code

2.5. ASNT SNT-TC-1A : Recommended practice for NDT personnel qualification and

certification

2.6. Project Specification : 602-000-PI-SP-010, 602-000-ST-SP-001

3. Responsibility

3.1. The QC engineer shall be responsible for cooperate with sub-contractor for NDE

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 5 of 34

work.

3.2. The sub-contractor shall be responsible for managing of general NDE work.

3.3. The QA/QC Manager or his designee of Subcontractor shall be responsible for

control of NDE sub-contractor and documents related to the NDE.

4. Qualification of Personnel

4.1. Personnel performing examination to this procedure shall be qualified as level II or

III in accordance with ASNT SNT-TC-1A Recommended practice for NDT

personnel qualification and certification or equivalent in PCN / CSWIP certification

systems.

4.2. Only Level II or Level III personnel shall interpret and evaluation test results to

determine acceptability.

5. General requirements

5.1. Surface preparation

5.1.1. The area adjacent to the weld to be examined shall be free of all weld

spatters, loose particles, non-adhering mill scale or any other foreign matter

that would interface with the free movement of search unit or with the

transmission of ultrasound into the test part.

5.1.2. Preparation of welds for examination will be identified in the specific

ultrasonic operating technique sheet.

5.1.3. Painted, primed or coated surfaces cannot be scanned.

5.2. Examination Coverage

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 6 of 34

5.2.1. Welds shall be examined by moving the search unit over the examination

surface so as to scan the entire volume.

5.2.2. The search unit will be moved laterally in zigzag pattern ensuring that the

forward movement is perpendicular to the weld axis and overlap by at least

10%.

5.3. The rate of search unit movement for examination shall not exceed 152mm/sec1

unless calibration is verified at scanning speed.

5.4. Recording of indication level shall be made in respect to the reference level.

5.5. Information furnished to the NDE Subcontractor shall clearly identify the drawing

No., materials category, thickness, weld No., welder(s), location and length of

welds to be examined. A copy of the weld procedure applicable to each specific

joint being examined shall be made available for the operators review, prior to

commencement of the examination.

6. Equipment and accessories

The following equipment and accessories will be considered as a minimum to fulfill the

requirements of this procedure and will be available to all technicians. The calibration

certificate for the UT equipment, and the certificate of conformity for UT probes,

calibration blocks are to be available on site for verification by certifying authority. and

company.

6.1. The examination shall be conducted with a pulse-echo ultrasonic instrument,

capable of generating, receiving and presenting the relevant pulses on a screen in

the frequency range from 1 to 6 MHz. (e.g. Krautkramer USK6, USK7, USN 50 and

Refer to ASME Sec. V, Art V

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 7 of 34

USN 52or equivalent). Instruments operating at other frequencies may be used if

equal or better sensitivity can be demonstrated and documented.

6.1.1. Equipment qualification and calibration

The operator shall carry out the following checks for calibration:

6.1.2. Any of the above checks found to be out of tolerance should be cause for

system repair followed by full re-calibration of affected points.

Checks

Frequency

Ref. Documents

Amplitude control

At least once a

ASME Sec.V, Para

linearity

month

T533

Screen height

At least once a

ASME Sec.V, Para

linearity

month

T533

Horizontal linearity

At least once a

ASME E 164

month

Internal reflection

At least once a

ASME E 164

week

Resolution

At least once a

ASME E 164

week

6.1.3. The result of such calibration should be signed by contractor and certifying

authority and should be maintained for reference in the NDT department and

available for Company inspection as required.

6.2. Transducers

The following transducer or equivalent shall be used.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 8 of 34

6.2.1. Longitudinal wave search units

Type

Angle

Frequency

Crystal size

Make of Probe

Single crystal

4 MHz

10 mm dia

Kraut Kramer

Twin crystal

4 MHz

3.5 x 10 mm

Kraut Kramer

Single crystal

2 MHz

10 mm dia

Kraut Kramer

Twin crystal

2 MHz

3.5 x 10mm

Kraut Kramer

6.2.2. Shear wave search units

Type

Angle

Frequency

Crystal size

Make of Probe

Single crystal

45

2 MHz

10 mm dia

Kraut Kramer

Single crystal

60

2 MHz

10 mm dia

Kraut Kramer

Single crystal

70

2 MHz

10 mm dia

Kraut Kramer

Single crystal

45

4 MHz

10 mm dia

Kraut Kramer

Single crystal

60

4 MHz

8 x 9 mm

Kraut Kramer

Single crystal

70

4 MHz

10 mm dia

Kraut Kramer

6.3. Calibration and reference blocks

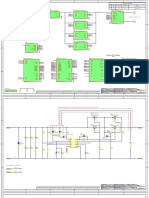

6.3.1. STB-A1, IIW Type 1 (Fig. 1) or IIW Type 2 block (Fig. 2)

6.3.2. IIW miniature block (Fig. 3) or STB-A3 (Fig. 4)

6.3.3. ASME basic calibration block (Fig. 5, 7)

6.3.4. IOW as calibration block

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

Fig. 1 STB-A1, IIW Type 1 Block

Fig. 2 STB-A2, IIW Type 2 Block

SEQ

212

REV

00

Page 9 of 34

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

Fig. 3 IIW Miniature Block

SEQ

212

REV

00

Page 10 of 34

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 11 of 34

Fig. 4 STB-A3 Block

6.3.5. A suitable couplant such as water based paste of cellulose gum, wall paper

adhesive or coupling paste having good wetting characteristics should be used

between the transducer and examination surface. The same couplant shall be

used for calibration and examination.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 12 of 34

7. Calibration blocks and reference specimens

7.1. Material

7.1.1. Material from which respective calibration blocks and reference specimens

are fabricated will be of the same product form and material specification or

equivalent. The calibration block material will be completely examined with a

straight beam search unit to ensure freedom from reflectors that exceed the

back wall echo.

7.1.2. For the examination for weldments which have been subjected to post weld

heat treatment the material from which the calibration block is fabricated will

have received a similar PWHT process, and also a post weld heat treatment of

at least 2 hr, if the calibration block contains weld prior to machine the

reflectors.

7.1.3. When calibration block have not received heat treatment, transfer method

shall be used to correlate the responses from the basic calibration block and

component. Transfer is accomplished by noting the difference between

responses received from the same reference reflector in the basic calibration

block and in the component and correcting for the difference.

7.2. The surface finish of the calibration blocks will be as representative of the surface

finish of the components as far as possible with suitable surface preparation or

treatment, as practical, to simulate testing conditions.

7.3. Reference specimens for testing the welds (ASME Basic Calibration Blocks)

7.3.1. For examination in materials where examination surface diameter is greater

than 20 inches, a flat basic calibration block, complying with the requirements

indicated on figure 5 will be used. Reflectors will have side-drilled holes and

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 13 of 34

surface notches oriented parallel to the longitudinal axis of annuals reference

specimen.

7.3.2. For examination in material where the examination surface is 20 inches or

less, curved annuals basic reference specimen will be used. The size and

location of the surface notches and diameter of range covered by each blocks

will be as shown in fig. 6 and 7.

7.3.3. A single reference specimen may be used to calibrate for examination on

component surfaces in the ranges of curvature from 0.9 to 1.5 times the basic

reference specimen diameter. Basic reference specimen thickness ranges will

be as stipulated in figure 5. These specimens could be a section pipe of the

same nominal size as one of the components being tested i.e. as off cut pipe

being used in fabrication.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 14 of 34

Hole Diameter

1 in or less

Basic Calibration

Block Thickness

3/4in. or t

Over 1in. through 2in.

1 1/2in. or t

1/8in.

Width=1/8in. to 1/4in.

Over 2in. through 4in.

3in. or t

3/16in.

Depth= 2%T or 0.04in.

Over 4in. through 6in.

5in. or t

1/4in.

Whichever is greater, into

Over 6in. through 8in.

7in. or t

5/16in.

the base metal.

Over 8in. through 10in.

9in. or t

3/8in.

Length= 2in. min.

Over 10in.

t1in.

[See note 6]

Weld Thickness

Notch Size

3/32in.

Notes:

a) Holes shall be drilled and reamed a minimum of 1-1/2in. deep, essentially parallel to the examination

surface.

b) Curved surfaces: for curved surface, two curved blocks, one for each representative curvature or two

sets of calibration reflectors orientated 90 deg. from each other shall be used.

c) Notches may be provided as required. The tolerance for hole diameter shall be 1/32in. The tolerance

on notch depth shall be +10% and -20%. The tolerance on hole location through the thickness shall be

1/8in.

d) For each increase in thickness on 2in. or fraction thereof over 10in., the hole diameter shall increase

1/16in.

Fig. 5 ASME Basic Calibration Block

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Fig. 6 Ratio limits for curved surfaces

Fig. 7 Angel beam calibration block dimension (Pipe welds)

Page 15 of 34

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 16 of 34

8. Distance calibration

The CRT will be calibrated for range using the international institute of welding STB-A1,

type 1, 2 and STB-A3 calibration blocks, in the relationship of time versus distance

(beam path length).

9. Distance amplitude correction (DAC curve)

9.1. For sensitivity calibration during all weld examination (Straight or Angle beam),

DAC curves will be constructed for every search unit to be utilized at each

particular range. Block used for DAC construction will be selected as appropriate

from those as specified in para. 7.3.

9.2. DAC curves will be constructed as follow.

9.2.1. Place the probe on the calibration block to obtain a reflection from the hole

that produces the greatest response.

9.2.2. Maximize the indication by manipulation and adjust to approx. 80% screen

height using the calibration gain control. Make a mark on the CRT at the peak

of the indication using an indelible fine tipped felt marker.

9.2.3. Points representing 20 % and 50 % of the primary gain are also to be

constructed. Repeat b) and c) using reflections from every reflector that can be

obtained within the beam length of the test range to be used, including those

reflections obtained from skip, if the sound path is more than probes specific

near field range.

9.2.4. Connect all points marked (minimum 3 points) with a smooth curving line,

this line will be referenced to as the DAC curve the respective probe used and

will apply for that particular material and configuration (or part geometry) only.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 17 of 34

9.2.5. DAC curves will be directly marked as the CRT time base screen cover with

an indelible ink marker or superimposed using clear plastic, polyester or

Perspex overlap. The DAC curve fail to search a level of at least 23 % of full

screen height at the limit of its range, as represented on the time base,

sufficient supplementary gain should be added to attain this level and the DAC

adjusted accordingly.

10. Primary reference level and scanning sensitivity

10.1. The primary reference level will be that gain setting whereby reflectors in the

applicable basic calibration block or reference specimen as described in para. 7.3

above, coincide with DAC curve constructed as described in para. 9.0 above. The

primary reference level will be corrected for differences in surface character and

attenuation between the basic reference block and the actual item under

examination by method, as described in para. 11 herein.

10.2. Sensitivity settings for parent material examination with 0 compression wave will

be that dB value where by the first back wall echo of the material reaches 80 % of

full screen height, DAC curves will not apply for evaluation during this application.

Scanning will be carried out at the same setting according to ASTM A578.

11. Transfer value correction

11.1. Transfer value will be determined and used for all shear wave examination to

compensate for differences in surface contour, finish, coating, and acoustical

attenuation characteristics. This exercise will be performed for each nominal angle

of refraction to be utilized for examination. To ensure that accurate transfer value

correction factors are obtained, signal comparison will only be made in the far

field area of the ultrasonic beam.

11.2. Transfer correction will be measured with the following way;

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 18 of 34

11.2.1. Construct the DAC as per para. 9.0.

11.2.2. Using the primary search unit as the transmitter and a similar search unit as

a receiver, position both on the basic calibration block facing each other, in a

pitch and catches arrangement with the instrument in the dual transducer

mode.

11.2.3. Maximize the indication and adjust the gain to allow the indication to peak

at the DAC curve. Note the gain value.

11.2.4. Repeat steps a), b) and c) above on the component to be examined. The

difference in gain values is the transfer value. This value may be positive or

negative and adjustments will be made to the sensitivity settings accordingly

and should be recorded in all the reports.

12. Application of UT Examination

12.1. The applicable specification are 602-000-PI-SP-010 and 602-000-ST-SP-001

12.2. When RT is required and is not practicable UT plus MT may be considered as an

alternative subject to COMPANY approval.

12.3. UT may be substituted for RT where it is impractical to obtain an interpretable

radiograph, subject to COMPANY review and approval.

13. Parent metal evaluation

13.1. Thickness measurement

13.1.1. Any member from which scanning is to be conducted shall first be scanned

with a 0 compression probe to establish the thickness. These results will be

recorded.

13.1.2. Any areas of significant thickness variation, which could possibly affect

calculation, will be highlighted, recorded and reported.

13.2. Parent metal examination

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 19 of 34

13.2.1. The scanning of the adjacent base metal shall be performed to detect

reflectors that might affect interpretation of angle beam results, and is not to be

used as an acceptance-rejection examination. Locations and areas of such

reflectors shall be recorded.

13.2.2. Ultrasonic examination within pipe end and shall be carried out according to

ASTM A578. Any discontinuity (e.g. lamination) causing a reflection echo

exceeding 50 % and accompanied by a 50 % loss of back reflection shall be

considered as reject when the discontinuity area exceeds 100 mm.

14. Inspection of welds

14.1. General

14.1.1. A minimum of two different probe angles should always be applied (see

table 2) this is in addition to the straight beam probe required as per para. 12.

14.1.2. For butt joint welds, the examination shall be made from both sides of the

weld axis from the accessible surface, wherever possible.

14.1.3. Upon discovering suspect indications both orbital and rotational scan will be

carried out to evaluate the characteristics of the reflector.

14.1.4. Time base ranges as specified may be suitably readjusted by the operator in

localized areas to highlight suspect deflections and subsequently assist in echo

evaluation.

14.1.5. The normal scanning is carried out with at least 6 dB increased gain level,

and that all defects sizes will be evaluated at a non-increased level.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 20 of 34

14.2. Longitudinal scanning

14.2.1. Scanning for longitudinal discontinuities in the weld body will be carried out

with the angle beam at approximately right angles to the weld axis, from two

directions whenever possible. Nominal angles of reflection to achieve this are

stated in table 2.

14.3. Transverse scanning

14.3.1. Scanning for discontinuities oriented transverse to the weld will be carried

out with the angle beam directed essentially parallel to the weld. For scanning

of transverse defects, it should be considered to scan on the weld cap itself,

which if necessary, must be ground flat. The search unit will be manipulated so

that the angle beam energy passes through the required volumes of weld and

adjacent base metal.

14.3.2. A transverse scan will be carried out on all welds scheduled for ultrasonic

examination.

14.3.3. Nominal angles of reflection to achieve this are stated in table 2. The

exception of the above will be when the search unit is scanning essentially as

tangent over curved surfaces of 20 diameter or less.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 21 of 34

Table 2

45

60

70

0

8 - 25.4 mm

25.4 - 50.8 mm

50.8 - 65 mm

HSD

N/A

A(36 72)

A(72 92)

FSD

N/A

A(72 144)

A(144 184)

HSD

N/A

A(51 102)

A(102 130)

FSD

A(32 102)

A(102 203)

N/A

HSD

N/A

A(74 148)

A(148 190)

FSD

A(47 148)

N/A

N/A

HSD

N/A

N/A

FSD

Note) HSD: Half sonic distance / FSD: Full sonic distance, A: Applicable / N/A: Not applicable

15. Discontinuity localization and size evaluation

15.1. Discontinuities will be confirmed and located within the weld cross section by

means of a probe manipulation to maximize the response obtained and to measure

beam path lengths and distance from established reference points. Location

reflectors may be aided by the use of trigonometry, electronic calculators and

ultrasonic plotting slides. The use of these additional tools will not be mandatory.

15.2. Evaluation

15.2.1. The corrected primary gain (primary reference level + transfer correction) is

to be increased by 6 dB for defect detection.

15.2.2. All discontinuities that produce reflectors at or grater than 20 % of DAC

when searching at the increased gain level as above, are to be subject to

defect size evaluation at non-increased gain level (i.e. with 6dB decrease).

These imperfections shall be investigated to determine the shape, identity, and

location.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 22 of 34

15.2.3. Dimensional evaluation of indication is made using either the 20 dB drop

method or the half value drop method.

15.2.4. Also each indication producing an echo, which exceeds 50 % of the

reference curve, is to be reported and its evaluated size as above checked for

acceptability.

16. Post cleaning

upon the completion of the examination, the surfaces shall be thoroughly cleaned by

wiping with a suitable one as required to remove all traces of couplant.

17. Acceptance standards

Acceptance criteria for piping welding shall be as per ASME B31.1 para. 344.6.2 and

for steel structure welding shall be as per AWS D1.1 section 6 part C.

18. Defect marking and examination of repair

18.1. All areas deemed to be rejectable that require repairing, will be clearly and

unambiguously marked up on the surface of the weld and the adjacent parent

material with indelible metal markers.

18.2. The extent of examination will guarantee the satisfactory inspection of the entire

cross sectional volume of weld and HAZ regardless of the extent of repair. The

whole length of repair will be examined plus 50 mm from the repair weld deposit at

the both ends where possible.

18.3. During repair examination, taking into consideration the nature, position and

extent of the original defect and the position of new fusion faces created by the

repair.

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

19. Reporting

19.1. The report attached here after shall be reviewed and signed by TPA.

19.2. QC engineer shall maintain UT reports

20. Appendices

20.1. Appendix 1: Specific UT technique sheets

20.2. Appendix 2: Calibration report of Ultrasonic instrument

20.3. Appendix 3: Examination report

20.4. Appendix 4 Detail of Ultrasonic Examination Report

Page 23 of 34

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 24 of 34

Appendix 1: Specific UT technique sheets

Technique 1

1. Joint Type: Butt Joint

2. Thickness (T): T 8~25.4mm similar thickness, plate and pipe (dia. > 20inch)

3. Probe

a. 0

4MHz

b. 60

4MHz

c. 70

4MHz

4. Range

a. 0~50mm

b. 0~100mm scanning with 0-1 skip

c. 0~100mm scanning with 0-1/2 skip

5. Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c Echo off 2.4mm dia. Side drilled hole set to DAC + additional 6db +

additional 2db transfer correction

Note) Additional 6db to be removed for evaluation purpose

6. Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7. Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 25 of 34

Technique 2

1 Joint Type: Butt Joint

2 Thickness (T): T 25.4~50.8mm similar thickness, plate and pipe (dia. > 20inch)

3 Probe

a. 0

4MHz

b. 45

4MHz

c. 60

4MHz

d. 70

2MHz

4 Range

a. 0~50mm

b. 0~150mm scanning with 0-1 skip

c. 0~100mm scanning with 0-1 skip

d. 0~150mm scanning with 0-1/2 skip

5 Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c, d Echo off 3.2mm dia. Side drilled hole set to DAC + additional 6db +

additional transfer correction

Note) Additional 6db to be removed for evaluation purpose

6 Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7 Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 26 of 34

Technique 3

1 Joint Type: Butt Joint

2 Thickness (T): 50.8mm ~ 65mm

3 Probe

a. 0

2MHz

b. 45

2MHz

c. 60

2MHz

d. 70

2MHz

4 Range

a. 0~50mm

b. 0~200mm scanning with 0-1 skip

c. 0~150mm scanning with 0-1 skip

d. 0~200mm scanning with 0-1/2 skip

5 Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c, d Echo off 4.8mm dia. Side drilled hole set to DAC + additional 6db +

additional transfer correction

Note) Additional 6db to be removed for evaluation purpose

6 Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7 Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 27 of 34

Technique 4

1 Joint Type: Tee or Branch Joint

2 Thickness (T): T 8~25.4mm similar thickness, plate and pipe (dia. > 20inch)

3 Probe

a. 0

4MHz

b. 60

4MHz

c. 70

4MHz

4 Range

a. 0~50mm

b. 0~100mm scanning with 0-1 skip

c. 0~100mm scanning with 0-1/2 skip

5 Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c Echo off 2.4mm dia. Side drilled hole set to DAC + additional 6db +

additional 2db transfer correction

Note) Additional 6db to be removed for evaluation purpose

6 Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7 Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 28 of 34

Technique 5

1 Joint Type: Tee or Branch Joint

2 Thickness (T): 25.4mm ~ 50.8mm

3 Probe

a. 0

4MHz

b. 45

4MHz

c. 60

4MHz

d. 70

2MHz

4 Range

a. 0~50mm

b. 0~150mm scanning with 0-1 skip

c. 0~100mm scanning with 0-1 skip

d. 0~150mm scanning with 0-1/2 skip

5 Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c, d Echo off 3.2mm dia. Side drilled hole set to DAC + additional 6db +

additional transfer correction

Note) Additional 6db to be removed for evaluation purpose

6 Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7 Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 29 of 34

Technique 6

1 Joint Type: Tee or Branch Joint

2 Thickness (T): 50.8mm ~ 65mm

3 Probe

a. 0

2MHz

b. 45

2MHz

c. 60

2MHz

d. 70

2MHz

4 Range

a. 0~50mm

b. 0~200mm scanning with 0-1 skip

c. 0~150mm scanning with 0-1 skip

d. 0~200mm scanning with 0-1/2 skip

5 Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c, d Echo off 4.8mm dia. Side drilled hole set to DAC + additional 6db +

additional transfer correction

Note) Additional 6db to be removed for evaluation purpose

6 Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7 Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 30 of 34

Technique 8

1 Joint Type: Butt Joint

2 Thickness (T): T 8~25.4mm similar thickness, plate and pipe (dia. 20inch)

3 Probe

a. 0

4MHz

b. 60

4MHz

c. 70

4MHz

4 Range

a. 0~50mm

b. 0~100mm scanning with 0-1 skip

c. 0~100mm scanning with 0-1/2 skip

5 Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c Echo off 2.4mm dia. Side drilled hole set to DAC + additional 6db +

additional 2db transfer correction

Note) Additional 6db to be removed for evaluation purpose

6 Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7 Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 31 of 34

Technique 8

1 Joint Type: Butt Joint

2 Thickness (T): T 44.45mm similar thickness, plate and pipe (dia. = 20inch)

3 Probe

a. 0

4MHz

b. 45

4MHz

c. 60

4MHz

d. 70

2MHz

4 Range

a. 0~50mm

b. 0~150mm scanning with 0-1 skip

c. 0~100mm scanning with 0-1 skip

d. 0~150mm scanning with 0-1/2 skip

5 Scanning Sensitivity

a. Echo off first back reflection adjusted to 80% full screen height

b. , c, d Echo off 3.2mm dia. Side drilled hole set to DAC + additional 6db +

additional transfer correction

Note) Additional 6db to be removed for evaluation purpose

6 Sizing Method: Length #6db amplitude drop, depth and height (width) #20db drop

7 Scanning Patterns

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

PHASE

SPY

UT Procedure

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

Page 32 of 34

REV

00

Appendix 2 Calibration report of ULTRASONIC instrument

INSTRUMENT TYPE:

CALIBRATION RECORD UNIT

I. D. No.

Sr. No.

Type

Marker

Frequency

Size

TRANSDUCER

Sr. No.

2. SCREEN HEIGHT LINEARITY

100%FSH ---------------%FSH

90%FSH ---------------%FSH

80%FSH ---------------%FSH

70%FSH ---------------%FSH

60%FSH ---------------%FSH

Screen

Height

Linearity

50%FSH ---------------%FSH

40%FSH ---------------%FSH

30%FSH ---------------%FSH

20%FSH ---------------%FSH

3. AMPLITUDE CONTROL LINEARITY

80%FSH-6dB ----------------------%FSH (32-48)

80%FSH-12dB ----------------------%FSH (16-24)

40%FSH-6dB ----------------------%FSH (64-96)

20%FSH-12dB ----------------------%FSH (64-95)

Amplitude

Control

Linearity

4. HORIZONTAL LINERARITY

1) Range-100mm

Liner scale

Echo position

(a)25

(a)

(b)50

(b)

(c)75

(c)

(d)100

(d)

(a)25

(a)

(b)50

(b)

(c)75

(c)

(d)100

(d)

2) Range-200mm

Liner scale

Echo position

Examined by

Level

Date

Approved by

(e)125

(e)

(f)150

(f)

Level

(g)175

(g)

(h)200

(h)

Date

FORM CM-PR-212-01 Rev. 00

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

Page 33 of 34

REV

00

Appendix 3 Ultrasonic Examination Report

ITP NO.

FIELD INSPECTION REPORT

REPORT NO. :

DATE

INSPECTION TYPE:

WORK NO.:

ITEM NO.

ULTRASONIC EXAMINATION

LOCATION :

SIGNATURE1

INSPECTION NOTICE NO.

COMPANY'S INSPECTOR

CONTRACTOR INSPECTOR

COMPANY

/

CONTRACTOR

SUBCONTR.

SUBCONTRACTOR'S INSPECTOR :

PROCEDURE METHOD

ACCEPTANCE CRITERIA

:

:

MATERIAL

THICKNESS:

METHOD

PROBE SIZE:

MEDIUM

ANGLE:

FREQUENCY:

MAKER & TYPE OF MACHINE:

DWG N0.

JOINT NO.

WELDER NO.

RESULT

ACC

REP

C-O

ABBREVIATIONS

ACC

: ACCEPT

EP

: EXCESS PENETRATION

REP

: REPAIR

IP

: INCOMPLETED PENETRATION

C-O

: CUT-OUT

LF

: LACK OF FUSION

: CRACK

: POROSITY

ND

: SLAG INCLUSION

: NO DEFECT

* SEE ATTACHED SHEET (DETAILED ULTRASONIC EXAMINATION RECORD)

1- To be signed if Accepted by all parties

LEGEND:

ACC.: ACCEPT

REJ.: REJECT

N/A: Not Applicable

FORM:QA-QA-51-06

1/2

Rev. 01

National Iranian Gas Company

IGAT V Booster Gas Compressor Stations

OTC

Document Title

UT Procedure

PHASE

SPY

AREA

3

TRAIN/UNIT

0000

Document No.

DIS

CM

DOC

PR

SEQ

212

REV

00

Page 34 of 34

Appendix 4 Detail of Ultrasonic Examination Report

ITP NO.

FIELD INSPECTION REPORT

REPORT NO. :

DATE

DETAILED ULTRASONIC EXAMINATION REPORT

DWG NO.

JOINT

NO

DISTANCE

LENGTH OF

INDICATION

COMMENTS2

2- Reason of Rejection and to be Signed by Refuser

LEGEND: ACC.: ACCEPT

REJ.: REJECT

N/A: Not Applicable

FORM:QA-QA-51-06

2/2

Rev. 01

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- AWS Procedure - Rev 2Dokument40 SeitenAWS Procedure - Rev 2Mario Perez100% (1)

- JIMAH East PAUT Procedure - Rev.0 - 14062017 PDFDokument62 SeitenJIMAH East PAUT Procedure - Rev.0 - 14062017 PDFRoslan Ali100% (2)

- UTDokument17 SeitenUTArputharaj Maria Louis100% (2)

- JIMAH East PAUT Procedure Rev 0 14062017 PDFDokument62 SeitenJIMAH East PAUT Procedure Rev 0 14062017 PDFRiccoNoch keine Bewertungen

- UT PROCEDURE RevDokument24 SeitenUT PROCEDURE RevMN AliNoch keine Bewertungen

- DN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowerDokument23 SeitenDN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowermaheshNoch keine Bewertungen

- D-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingDokument40 SeitenD-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingThinh NguyenNoch keine Bewertungen

- RT Procedure 10.09.16Dokument9 SeitenRT Procedure 10.09.16mukeshsingh6Noch keine Bewertungen

- UT Shear Wave Skip Distances and Search For Indications LabDokument4 SeitenUT Shear Wave Skip Distances and Search For Indications Lab1248a9a9a1q3we71Noch keine Bewertungen

- NDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Dokument6 SeitenNDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Mark BrailsfordNoch keine Bewertungen

- Calibration Sheet Ultrasonic Test EquipmentDokument1 SeiteCalibration Sheet Ultrasonic Test EquipmentjohnNoch keine Bewertungen

- Form PAUTDokument1 SeiteForm PAUTLuong Ho VuNoch keine Bewertungen

- Ultrasonic Testing of Tube To Tube SheetDokument6 SeitenUltrasonic Testing of Tube To Tube SheetDARSHIL RAJPURANoch keine Bewertungen

- UT ProcedureDokument6 SeitenUT ProcedureMurali YNoch keine Bewertungen

- Saferad ProcedureDokument19 SeitenSaferad ProcedureExsan OthmanNoch keine Bewertungen

- NDT SetupBuilder - OverviewDokument32 SeitenNDT SetupBuilder - OverviewgueridiNoch keine Bewertungen

- 193602csqrop034 00 Manual Ut ProcedureDokument24 Seiten193602csqrop034 00 Manual Ut Procedureyehia100% (2)

- ASME BPVC-Section V: Key Changes 2019 EditionDokument7 SeitenASME BPVC-Section V: Key Changes 2019 EditionArjun RawatNoch keine Bewertungen

- Phased Array Ut Procedure For WeldsDokument12 SeitenPhased Array Ut Procedure For WeldsMohd Salleh Zainal100% (7)

- PAUT Ultrasonic Testing Procedure ASME - SVDN Rev 01EDokument29 SeitenPAUT Ultrasonic Testing Procedure ASME - SVDN Rev 01ETrung Tinh Ho100% (2)

- DMTA 20102 01EN - Rev - 2 OmniScan - X3 User PDFDokument90 SeitenDMTA 20102 01EN - Rev - 2 OmniScan - X3 User PDFpjhollowNoch keine Bewertungen

- PCN Level III BrochureDokument5 SeitenPCN Level III Brochuremayav1100% (1)

- Report 1 Paut Sts 409Dokument12 SeitenReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Itp AsntDokument33 SeitenItp AsntSYED FADZIL SYED MOHAMED100% (1)

- Ut 2Dokument7 SeitenUt 2Akhilesh KumarNoch keine Bewertungen

- Ultrasonic Testing ProcedureDokument12 SeitenUltrasonic Testing ProcedureRohit Kumar Mishra100% (1)

- Mock Up Test ProcedureRev 0Dokument7 SeitenMock Up Test ProcedureRev 0Trung Tinh HoNoch keine Bewertungen

- NDE Written Procedure Where We Shall StartDokument21 SeitenNDE Written Procedure Where We Shall StartuaiphonNoch keine Bewertungen

- PAUT of ''CRA WELDSDokument7 SeitenPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- Digital Radiography ReportDokument7 SeitenDigital Radiography ReportadityaromasNoch keine Bewertungen

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDokument10 SeitenProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNoch keine Bewertungen

- Paut Paper PDFDokument7 SeitenPaut Paper PDFAyesha GeNoch keine Bewertungen

- Ultrasonic ExaminationDokument14 SeitenUltrasonic ExaminationLiliNoch keine Bewertungen

- Referance Block PDFDokument45 SeitenReferance Block PDFDağhan GrdNoch keine Bewertungen

- Evaluation For Paut ASME 8 DIV 2Dokument3 SeitenEvaluation For Paut ASME 8 DIV 2Woodrow FoxNoch keine Bewertungen

- AWSD1.1 Procedure UtDokument19 SeitenAWSD1.1 Procedure Utkevin desai50% (2)

- HT - Paut-Asme-01: Hi-Tech NDT Inspections Services (S) Pte. LTDDokument25 SeitenHT - Paut-Asme-01: Hi-Tech NDT Inspections Services (S) Pte. LTDphanthanhhungNoch keine Bewertungen

- MT ProcedureDokument8 SeitenMT Procedureshabbir626100% (1)

- PAUT Procedure ED - AMSYCO 500-8-2 Rev 00 PDFDokument34 SeitenPAUT Procedure ED - AMSYCO 500-8-2 Rev 00 PDFkbldam100% (3)

- VT Procedure 1Dokument1 SeiteVT Procedure 1Mahmoud Alwasif50% (2)

- Ultrasonic Testing ProcedureDokument19 SeitenUltrasonic Testing ProcedureHASBIL HASSANNoch keine Bewertungen

- Ut ProcedureDokument7 SeitenUt Procedurearavindan100% (1)

- Phased Array Ultrasonic Testing ProcedureDokument21 SeitenPhased Array Ultrasonic Testing ProcedureKarrar TalibNoch keine Bewertungen

- Silverwing RMS2 01Dokument4 SeitenSilverwing RMS2 01rubiodegoNoch keine Bewertungen

- MT Work InstructionDokument3 SeitenMT Work Instructionpandab bkNoch keine Bewertungen

- Phased Array UT Versus RT Report TruncatedDokument20 SeitenPhased Array UT Versus RT Report TruncatedSungsoo HanNoch keine Bewertungen

- Aws Application of Phased Array UltrasonicDokument7 SeitenAws Application of Phased Array UltrasonicDileep KumarNoch keine Bewertungen

- Paut Checklist AuditDokument1 SeitePaut Checklist Auditaakash0% (1)

- 05 Ultrasonic Test Procedure 500405Dokument11 Seiten05 Ultrasonic Test Procedure 500405Sefa KasapogluNoch keine Bewertungen

- PTDokument28 SeitenPTglazetm100% (1)

- Ut Proceduregeneral 141118232235 Conversion Gate02Dokument24 SeitenUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasNoch keine Bewertungen

- Ut PDFDokument88 SeitenUt PDFphillipskincaidNoch keine Bewertungen

- Guidelines For The Preparation and Grading of NDTDokument4 SeitenGuidelines For The Preparation and Grading of NDTL...nNoch keine Bewertungen

- Super Duplex Con PADokument8 SeitenSuper Duplex Con PAanon_447449056Noch keine Bewertungen

- PA Caracterization BlockDokument2 SeitenPA Caracterization BlockMuallim MursyidNoch keine Bewertungen

- Aws d1.1-UT Procedure For Back Strip T or Corner Joint PDFDokument6 SeitenAws d1.1-UT Procedure For Back Strip T or Corner Joint PDFnathgsurendraNoch keine Bewertungen

- Asme U Comparison QaDokument21 SeitenAsme U Comparison QajksankarNoch keine Bewertungen

- TOFD Procedure For VesselDokument12 SeitenTOFD Procedure For Vesselmohanraj67% (3)

- Temperature Prediction in Hot Tapping Process For High Pressure PipelineDokument8 SeitenTemperature Prediction in Hot Tapping Process For High Pressure Pipelineamin110110Noch keine Bewertungen

- Watari 2012 What Is The Small Parameter in The Chapman-Enskog Expansion of The Lattice Boltzmann MethodDokument7 SeitenWatari 2012 What Is The Small Parameter in The Chapman-Enskog Expansion of The Lattice Boltzmann Methodamin110110Noch keine Bewertungen

- Aman2017 PDFDokument13 SeitenAman2017 PDFamin110110Noch keine Bewertungen

- Mei1999 An Accurate Curved Boundary Treatment in The Lattice Boltzmann MethodDokument24 SeitenMei1999 An Accurate Curved Boundary Treatment in The Lattice Boltzmann Methodamin110110Noch keine Bewertungen

- Ansi Fci70 PDFDokument9 SeitenAnsi Fci70 PDFBingsu PowderNoch keine Bewertungen

- Nazari2015 Lattice Boltzmann Simulation of Natural Convection in Open End Cavity With Inclined Hot WallDokument18 SeitenNazari2015 Lattice Boltzmann Simulation of Natural Convection in Open End Cavity With Inclined Hot Wallamin110110Noch keine Bewertungen

- Ansys Workbench Training ManualDokument3 SeitenAnsys Workbench Training Manualamin110110Noch keine Bewertungen

- On Pressure and Velocity Boundary Conditions For The Lattice Boltzmann BGK ModelDokument9 SeitenOn Pressure and Velocity Boundary Conditions For The Lattice Boltzmann BGK Modelamin110110Noch keine Bewertungen

- Ansi Fci70 PDFDokument9 SeitenAnsi Fci70 PDFBingsu PowderNoch keine Bewertungen

- Wolf Glad Row 1995Dokument10 SeitenWolf Glad Row 1995amin110110Noch keine Bewertungen

- Schram 60 QuantumDokument11 SeitenSchram 60 Quantumamin110110Noch keine Bewertungen

- NeedleValves Dec2010Dokument1 SeiteNeedleValves Dec2010amin110110Noch keine Bewertungen

- Investigating The Function of The Expansion Valve of The Heat PumpDokument6 SeitenInvestigating The Function of The Expansion Valve of The Heat Pumpamin110110Noch keine Bewertungen

- DNV RP F101Dokument1 SeiteDNV RP F101amin110110100% (1)

- GRS CV Template 21 03 16 Secure1 PDFDokument3 SeitenGRS CV Template 21 03 16 Secure1 PDFamin110110Noch keine Bewertungen

- Stalker Pumps Pump Size and Type 50 X 32 - 200: 182mm 228mmDokument1 SeiteStalker Pumps Pump Size and Type 50 X 32 - 200: 182mm 228mmamin110110Noch keine Bewertungen

- CFD Simulation of A Stratified Gas-Liquid Flow With and Without The Effect of Gravity Kamel. Sidi-Ali and Renée. GatignolDokument2 SeitenCFD Simulation of A Stratified Gas-Liquid Flow With and Without The Effect of Gravity Kamel. Sidi-Ali and Renée. Gatignolamin110110Noch keine Bewertungen

- API-581 3rd Thinning Example 2Dokument42 SeitenAPI-581 3rd Thinning Example 2Javier Iglesias75% (4)

- API 581 Example, 2nd EditionDokument32 SeitenAPI 581 Example, 2nd Editionamr sNoch keine Bewertungen

- Listening Sample Task - Form CompletionDokument4 SeitenListening Sample Task - Form CompletionTrần Đăng Khoa100% (1)

- Cfans Asset 125224Dokument170 SeitenCfans Asset 125224amin110110Noch keine Bewertungen

- Edition Purch Guidelines R1 20120429Dokument1 SeiteEdition Purch Guidelines R1 20120429amin110110Noch keine Bewertungen

- Effective Implementation of Risk Based Inspection (Rbi) Approach in Asset Integrity Management of Oil and Gas FacilitiesDokument6 SeitenEffective Implementation of Risk Based Inspection (Rbi) Approach in Asset Integrity Management of Oil and Gas Facilitiesamin110110Noch keine Bewertungen

- Sample Pages Academic Reading EbookDokument4 SeitenSample Pages Academic Reading Ebookamin110110Noch keine Bewertungen

- 6A 20thhjgfgR1 20120429 PDFDokument1 Seite6A 20thhjgfgR1 20120429 PDFamin110110Noch keine Bewertungen

- 6A 20thhjgfgR1 20120429 PDFDokument1 Seite6A 20thhjgfgR1 20120429 PDFamin110110Noch keine Bewertungen

- API 6A ValveDokument12 SeitenAPI 6A Valveedo_tapia_ur100% (1)

- CAT 4110 NV NeedleValves Dec2010Dokument56 SeitenCAT 4110 NV NeedleValves Dec2010amin110110Noch keine Bewertungen

- Assessment of CorrosionDokument30 SeitenAssessment of Corrosionamin110110Noch keine Bewertungen

- Org ChartDokument1 SeiteOrg Chart2021-101781Noch keine Bewertungen

- Mix Cases UploadDokument4 SeitenMix Cases UploadLu CasNoch keine Bewertungen

- Bondoc Vs PinedaDokument3 SeitenBondoc Vs PinedaMa Gabriellen Quijada-TabuñagNoch keine Bewertungen

- Safety Inspection Checklist Project: Location: Inspector: DateDokument2 SeitenSafety Inspection Checklist Project: Location: Inspector: Dateyono DaryonoNoch keine Bewertungen

- Developments in Prepress Technology (PDFDrive)Dokument62 SeitenDevelopments in Prepress Technology (PDFDrive)Sur VelanNoch keine Bewertungen

- I.V. FluidDokument4 SeitenI.V. FluidOdunlamiNoch keine Bewertungen

- Scheme Bidirectional DC-DC ConverterDokument16 SeitenScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaNoch keine Bewertungen

- Coursework For ResumeDokument7 SeitenCoursework For Resumeafjwdxrctmsmwf100% (2)

- Community-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDokument28 SeitenCommunity-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDiane Rose LacenaNoch keine Bewertungen

- Introduction To Radar Warning ReceiverDokument23 SeitenIntroduction To Radar Warning ReceiverPobitra Chele100% (1)

- Reading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1Dokument27 SeitenReading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1shehla khanNoch keine Bewertungen

- Freqinv 3g3fv Ds 01oct2000Dokument20 SeitenFreqinv 3g3fv Ds 01oct2000Mohd Abu AjajNoch keine Bewertungen

- MPPWD 2014 SOR CH 1 To 5 in ExcelDokument66 SeitenMPPWD 2014 SOR CH 1 To 5 in ExcelElvis GrayNoch keine Bewertungen

- MOL Breaker 20 TonDokument1 SeiteMOL Breaker 20 Tonaprel jakNoch keine Bewertungen

- D6a - D8a PDFDokument168 SeitenD6a - D8a PDFduongpn63% (8)

- Occupational Therapy in Mental HealthDokument16 SeitenOccupational Therapy in Mental HealthjethasNoch keine Bewertungen

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Dokument101 SeitenInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqNoch keine Bewertungen

- Rundown Rakernas & Seminar PABMI - Final-1Dokument6 SeitenRundown Rakernas & Seminar PABMI - Final-1MarthinNoch keine Bewertungen

- IBMC Competition Booklet 2013Dokument40 SeitenIBMC Competition Booklet 2013Rollins Center at BYUNoch keine Bewertungen

- SPIE Oil & Gas Services: Pressure VesselsDokument56 SeitenSPIE Oil & Gas Services: Pressure VesselsSadashiw PatilNoch keine Bewertungen

- Computer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingDokument228 SeitenComputer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingWilfredo MolinaNoch keine Bewertungen

- NCR Minimum WageDokument2 SeitenNCR Minimum WageJohnBataraNoch keine Bewertungen

- Installation Manual EnUS 2691840011Dokument4 SeitenInstallation Manual EnUS 2691840011Patts MarcNoch keine Bewertungen

- Emco - Unimat 3 - Unimat 4 LathesDokument23 SeitenEmco - Unimat 3 - Unimat 4 LathesEnrique LueraNoch keine Bewertungen

- Frito Lay AssignmentDokument14 SeitenFrito Lay AssignmentSamarth Anand100% (1)

- Applications of MathematicsDokument35 SeitenApplications of MathematicsRamdas Sonawane100% (1)

- 8524Dokument8 Seiten8524Ghulam MurtazaNoch keine Bewertungen

- Mayor Breanna Lungo-Koehn StatementDokument2 SeitenMayor Breanna Lungo-Koehn StatementNell CoakleyNoch keine Bewertungen

- Gogte Institute of Technology: Karnatak Law Society'SDokument33 SeitenGogte Institute of Technology: Karnatak Law Society'SjagaenatorNoch keine Bewertungen

- Step-7 Sample ProgramDokument6 SeitenStep-7 Sample ProgramAmitabhaNoch keine Bewertungen

- The Perspective Drawing Guide: Simple Techniques for Mastering Every AngleVon EverandThe Perspective Drawing Guide: Simple Techniques for Mastering Every AngleBewertung: 4 von 5 Sternen4/5 (1)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsVon EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Beginner's Guide to Watercolor: Master Essential Skills and Techniques through Guided Exercises and ProjectsVon EverandThe Beginner's Guide to Watercolor: Master Essential Skills and Techniques through Guided Exercises and ProjectsNoch keine Bewertungen

- Creative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingVon EverandCreative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingNoch keine Bewertungen

- Celtic Line Drawing - Simplified InstructionsVon EverandCeltic Line Drawing - Simplified InstructionsBewertung: 5 von 5 Sternen5/5 (4)

- Drawing and Sketching Portraits: How to Draw Realistic Faces for BeginnersVon EverandDrawing and Sketching Portraits: How to Draw Realistic Faces for BeginnersBewertung: 5 von 5 Sternen5/5 (5)

- Art Models AnaRebecca009: Figure Drawing Pose ReferenceVon EverandArt Models AnaRebecca009: Figure Drawing Pose ReferenceBewertung: 4 von 5 Sternen4/5 (5)

- Art Models KatarinaK034: Figure Drawing Pose ReferenceVon EverandArt Models KatarinaK034: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (2)

- Acrylic Painting: Learn How to Paint Easy Techniques with Acrylic Paint (with photos)Von EverandAcrylic Painting: Learn How to Paint Easy Techniques with Acrylic Paint (with photos)Bewertung: 4 von 5 Sternen4/5 (4)

- Watercolor For The Soul: Simple painting projects for beginners, to calm, soothe and inspireVon EverandWatercolor For The Soul: Simple painting projects for beginners, to calm, soothe and inspireBewertung: 5 von 5 Sternen5/5 (6)

- Painting Perspective, Depth & Distance in WatercolourVon EverandPainting Perspective, Depth & Distance in WatercolourBewertung: 4.5 von 5 Sternen4.5/5 (2)

- 15-Minute Watercolor Masterpieces: Create Frame-Worthy Art in Just a Few Simple StepsVon Everand15-Minute Watercolor Masterpieces: Create Frame-Worthy Art in Just a Few Simple StepsBewertung: 4.5 von 5 Sternen4.5/5 (7)

- Art Models 10: Photos for Figure Drawing, Painting, and SculptingVon EverandArt Models 10: Photos for Figure Drawing, Painting, and SculptingBewertung: 2.5 von 5 Sternen2.5/5 (6)

- Beginner's Guide To Procreate: Characters: How to create characters on an iPad ®Von EverandBeginner's Guide To Procreate: Characters: How to create characters on an iPad ®3dtotal PublishingBewertung: 4 von 5 Sternen4/5 (1)

- Art Models Adrina032: Figure Drawing Pose ReferenceVon EverandArt Models Adrina032: Figure Drawing Pose ReferenceBewertung: 5 von 5 Sternen5/5 (2)

- Draw Every Little Thing: Learn to Draw More Than 100 Everyday Items, From Food to FashionVon EverandDraw Every Little Thing: Learn to Draw More Than 100 Everyday Items, From Food to FashionBewertung: 4.5 von 5 Sternen4.5/5 (4)

- How To Draw Chibi: Learn Drawing Supercute Chibi Characters for Kids and Beginners - Easy Step-By-Step TutorialsVon EverandHow To Draw Chibi: Learn Drawing Supercute Chibi Characters for Kids and Beginners - Easy Step-By-Step TutorialsBewertung: 4 von 5 Sternen4/5 (4)

- The Fundamentals of Watercolour Landscapes: Paintings for all seasonsVon EverandThe Fundamentals of Watercolour Landscapes: Paintings for all seasonsBewertung: 4 von 5 Sternen4/5 (1)

- Art Models AnaIv309: Figure Drawing Pose ReferenceVon EverandArt Models AnaIv309: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (2)

- Art Models Sam074: Figure Drawing Pose ReferenceVon EverandArt Models Sam074: Figure Drawing Pose ReferenceBewertung: 4 von 5 Sternen4/5 (1)

- Art Models Becca425: Figure Drawing Pose ReferenceVon EverandArt Models Becca425: Figure Drawing Pose ReferenceBewertung: 3.5 von 5 Sternen3.5/5 (3)

- David Bellamy's Seas & Shorelines in WatercolourVon EverandDavid Bellamy's Seas & Shorelines in WatercolourBewertung: 4 von 5 Sternen4/5 (1)

- Living Color: Painting, Writing, and the Bones of SeeingVon EverandLiving Color: Painting, Writing, and the Bones of SeeingBewertung: 4 von 5 Sternen4/5 (4)

- Art Models Felicia016: Figure Drawing Pose ReferenceVon EverandArt Models Felicia016: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (2)

- Watercolor Botanical Garden: A Modern Approach to Painting Bold Flowers, Plants, and CactiVon EverandWatercolor Botanical Garden: A Modern Approach to Painting Bold Flowers, Plants, and CactiBewertung: 5 von 5 Sternen5/5 (2)